Silicon carbide (SiC) single crystal material ine bhendi hombe gap upamhi (~Si 3 nguva), high thermal conductivity (~Si 3.3 nguva kana GaAs ka10), high electron saturation migration rate (~Si 2.5 times), high breakdown magetsi munda (~ Si 10 nguva kana GaAs 5 nguva) uye mamwe maitiro akatanhamara.

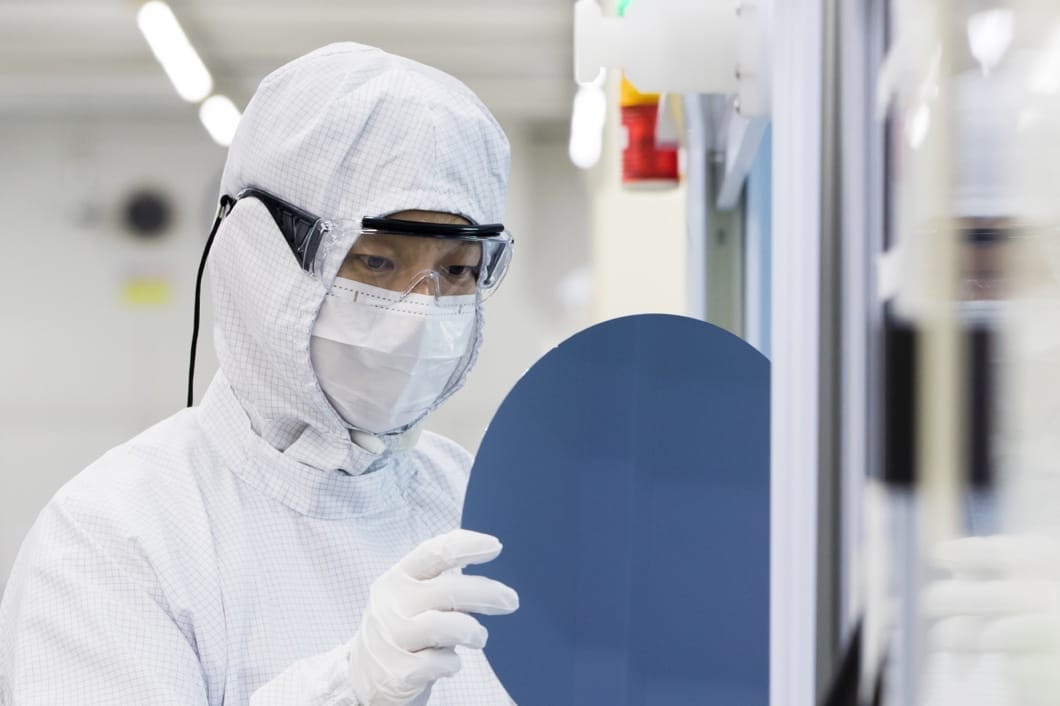

Semicera simba rinogona kupa vatengi nemhando yepamusoro Conductive (Conductive), Semi-insulating (Semi-insulating), HPSI (High Purity semi-insulating) silicon carbide substrate; Mukuwedzera, tinogona kupa vatengi vane homogeneous uye heterogeneous silicon carbide epitaxial sheets; Isu tinogona zvakare kugadzirisa iyo epitaxial pepa zvinoenderana nezvinodiwa chaizvo nevatengi, uye hapana hushoma hwekurongeka huwandu.

| Items | Kugadzirwa | Tsvakurudzo | Dummy |

| Crystal Parameters | |||

| Polytype | 4H | ||

| Kutadza kwekutarisa pamusoro | <11-20 >4±0.15° | ||

| Electrical Parameters | |||

| Dopant | n-mhando Nitrogen | ||

| Resistivity | 0.015-0.025ohm·cm | ||

| Mechanical Parameters | |||

| Diameter | 99.5 - 100mm | ||

| Ukobvu | 350±25 μm | ||

| Primary flat orientation | [1-100]±5° | ||

| Primary flat urefu | 32.5±1.5mm | ||

| Secondary flat position | 90° CW kubva kupuraimari flat ±5°. silicon yakatarisana kumusoro | ||

| Secondary flat urefu | 18±1.5mm | ||

| TTV | ≤5 μm | ≤10 μm | ≤20 μm |

| LTV | ≤2 μm(5mm*5mm) | ≤5 μm(5mm*5mm) | NA |

| Bow | -15μm ~ 15μm | -35μm ~ 35μm | -45μm ~ 45μm |

| Warp | ≤20 μm | ≤45 μm | ≤50 μm |

| Mberi(Si-face) roughness(AFM) | Ra≤0.2nm (5μm*5μm) | ||

| Chimiro | |||

| Micropipe density | ≤1 ea/cm2 | ≤5 ea/cm2 | ≤10 ea/cm2 |

| Metal tsvina | ≤5E10atomu/cm2 | NA | |

| BPD | ≤1500 ea/cm2 | ≤3000 ea/cm2 | NA |

| TSD | ≤500 ea/cm2 | ≤1000 ea/cm2 | NA |

| Mberi Hunhu | |||

| Mberi | Si | ||

| Surface finish | Si-face CMP | ||

| Zvimedu | ≤60ea/wafer (saizi≥0.3μm) | NA | |

| Makwara | ≤2ea/mm. Kureba kwekuwedzera ≤Diameter | Cumulative kureba≤2*Diameter | NA |

| Orenji svuura/makomba/mavara/mitsetse/pakatsemuka/kusvibiswa | Hapana | NA | |

| Edge chips/indents/fracture/hex plates | Hapana | NA | |

| Polytype nzvimbo | Hapana | Cumulative area≤20% | Cumulative area≤30% |

| Front laser marking | Hapana | ||

| Back Quality | |||

| Back finish | C-chiso CMP | ||

| Makwara | ≤5ea/mm,Cumulative kureba≤2*Diameter | NA | |

| Kuremara kumashure (kumucheto machipisi / indents) | Hapana | ||

| Back roughness | Ra≤0.2nm (5μm*5μm) | ||

| Back laser marking | 1 mm (kubva kumusoro kumucheto) | ||

| Edge | |||

| Edge | Chamfer | ||

| Packaging | |||

| Packaging | Bag remukati rinozadzwa nenitrogen uye bhegi rekunze rinobviswa vacuum. Multi-wafer cassette, epi-yakagadzirira. | ||

| * Notes: "NA" zvinoreva kuti hapana chikumbiro Zvinhu zvisina kutaurwa zvinogona kureva SEMI-STD. | |||

-

Zvishandiso Zvinonyanya Kutengesa Refractory-Yepamusoro Temperat...

-

Yakanaka Yakanaka Wafer Sucker Alumina Semiconductor...

-

Kudzikisira kukuru Chigadzirwa Chitsva Ceramic Beam Silico...

-

China Chigadzirwa Chitsva Silicon Carbide Radiation Sis...

-

2019 Yepamusoro mhando Sic Oxide Silicon Carbide Cer...

-

OEM/ODM Factory Silicon Carbide/Sic Mechanical ...