Silicon carbide (SiC) single crystal material ine bhendi hombe gap upamhi (~Si 3 nguva), high thermal conductivity (~Si 3.3 nguva kana GaAs ka10), high electron saturation migration rate (~Si 2.5 times), high breakdown magetsi munda (~ Si 10 nguva kana GaAs 5 nguva) uye mamwe maitiro akatanhamara.

Yechitatu chizvarwa semiconductor zvinhu zvinonyanya kusanganisira SiC, GaN, diamond, nezvimwewo, nekuti bhendi gap upamhi (Eg) rakakura kupfuura kana kuenzana ne2.3 electron volts (eV), inozivikanwawo seyakafara bhendi gap semiconductor zvinhu. Zvichienzaniswa neyekutanga neyechipiri chizvarwa semiconductor zvinhu, chizvarwa chechitatu semiconductor zvinhu zvine zvakanakira high thermal conductivity, high breakdown electric field, high saturated electron migration rate uye high bonding simba, izvo zvinogona kuzadzisa zvinodiwa zvitsva zvemazuva ano zvemagetsi tekinoroji. tembiricha, simba guru, high pressure, high frequency uye radiation resistance nemamwe mamiriro akaomarara. Iyo ine zvakakosha zvekushandisa tarisiro muminda yekudzivirira yenyika, ndege, ndege, kuongorora mafuta, kuchengetwa kwemaziso, nezvimwewo, uye inogona kuderedza kurasikirwa kwesimba neanopfuura 50% mumaindasitiri mazhinji ane hunyanzvi senge Broadband kutaurirana, simba rezuva, kugadzira mota, semiconductor lighting, uye smart grid, uye inogona kuderedza vhoriyamu yemidziyo neinopfuura 75%, inova yakakosha mukusimudzira sainzi uye tekinoroji.

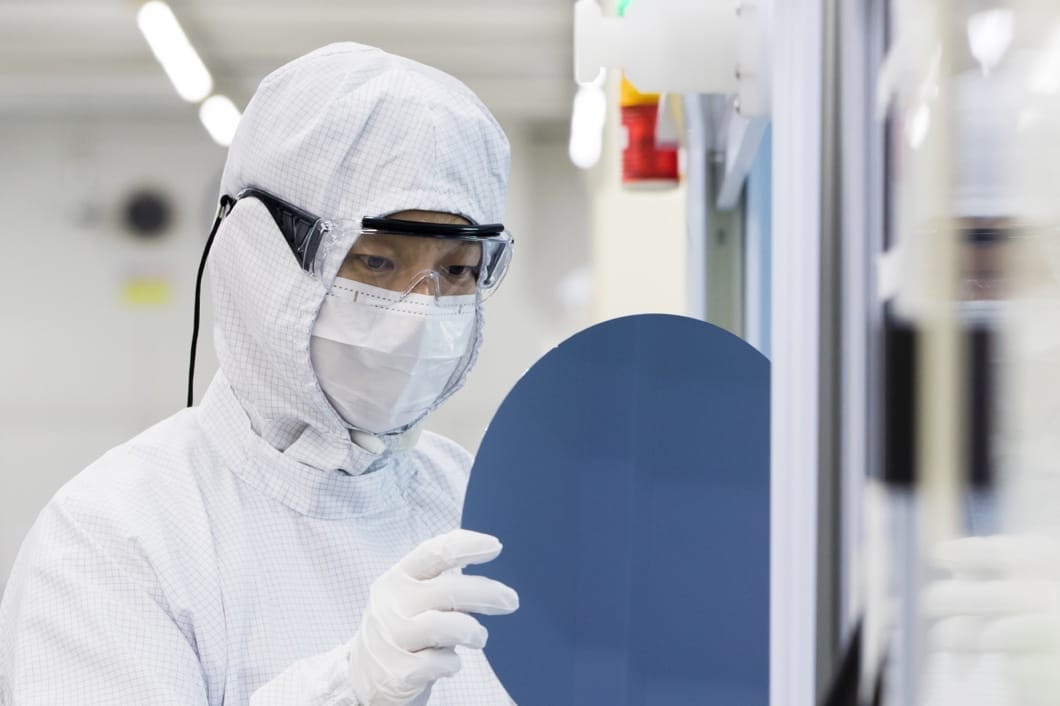

Semicera simba rinogona kupa vatengi nemhando yepamusoro Conductive (Conductive), Semi-insulating (Semi-insulating), HPSI (High Purity semi-insulating) silicon carbide substrate; Mukuwedzera, tinogona kupa vatengi vane homogeneous uye heterogeneous silicon carbide epitaxial sheets; Isu tinogona zvakare kugadzirisa iyo epitaxial pepa zvinoenderana nezvinodiwa chaizvo nevatengi, uye hapana hushoma hwekurongeka huwandu.

| Items | Kugadzirwa | Tsvakurudzo | Dummy |

| Crystal Parameters | |||

| Polytype | 4H | ||

| Kutadza kwekutarisa pamusoro | <11-20 >4±0.15° | ||

| Electrical Parameters | |||

| Dopant | n-mhando Nitrogen | ||

| Resistivity | 0.015-0.025ohm·cm | ||

| Mechanical Parameters | |||

| Diameter | 150.0±0.2mm | ||

| Ukobvu | 350±25 μm | ||

| Primary flat orientation | [1-100]±5° | ||

| Primary flat urefu | 47.5±1.5mm | ||

| Secondary flat | Hapana | ||

| TTV | ≤5 μm | ≤10 μm | ≤15 μm |

| LTV | ≤3 μm(5mm*5mm) | ≤5 μm(5mm*5mm) | ≤10 μm(5mm*5mm) |

| Bow | -15μm ~ 15μm | -35μm ~ 35μm | -45μm ~ 45μm |

| Warp | ≤35 μm | ≤45 μm | ≤55 μm |

| Mberi(Si-face) roughness(AFM) | Ra≤0.2nm (5μm*5μm) | ||

| Chimiro | |||

| Micropipe density | <1 pa/cm2 | <10 ea/cm2 | <15 ea/cm2 |

| Metal tsvina | ≤5E10atomu/cm2 | NA | |

| BPD | ≤1500 ea/cm2 | ≤3000 ea/cm2 | NA |

| TSD | ≤500 ea/cm2 | ≤1000 ea/cm2 | NA |

| Mberi Hunhu | |||

| Mberi | Si | ||

| Surface finish | Si-face CMP | ||

| Zvimedu | ≤60ea/wafer (saizi≥0.3μm) | NA | |

| Makwara | ≤5ea/mm. Kureba kwekuwedzera ≤Diameter | Cumulative kureba≤2*Diameter | NA |

| Orenji svuura/makomba/mavara/mitsetse/pakatsemuka/kusvibiswa | Hapana | NA | |

| Edge chips/indents/fracture/hex plates | Hapana | ||

| Polytype nzvimbo | Hapana | Cumulative area≤20% | Cumulative area≤30% |

| Front laser marking | Hapana | ||

| Back Quality | |||

| Back finish | C-chiso CMP | ||

| Makwara | ≤5ea/mm,Cumulative kureba≤2*Diameter | NA | |

| Kuremara kumashure (kumucheto machipisi / indents) | Hapana | ||

| Back roughness | Ra≤0.2nm (5μm*5μm) | ||

| Back laser marking | 1 mm (kubva kumusoro kumucheto) | ||

| Edge | |||

| Edge | Chamfer | ||

| Packaging | |||

| Packaging | Epi-yakagadzirira ine vacuum packaging Multi-wafer kaseti kurongedza | ||

| * Notes: "NA" zvinoreva kuti hapana chikumbiro Zvinhu zvisina kutaurwa zvinogona kureva SEMI-STD. | |||