Silicon carbide (SiC) epitaxy

Iyo epitaxial tray, inobata SiC substrate yekukura iyo SiC epitaxial slice, yakaiswa mukamuri yekupindura uye inobata zvakananga wafer.

Iyo yekumusoro hafu-mwedzi chikamu chinotakura chezvimwe zvishongedzo zvekamuri yekupindura yeSic epitaxy midziyo, nepo yepasi hafu-mwedzi chikamu chakabatana nequartz chubhu, ichiunza gasi kutyaira susceptor base kutenderera. iwo anodzora tembiricha uye akaiswa mukamuri rekuita pasina kusangana zvakananga newafer.

Si epitaxy

Iyo tray, inobata Si substrate yekukura Si epitaxial slice, inoiswa mukamuri yekupindura uye yakanangana newafer.

Mhete yepreheating iri pane yekunze mhete yeSi epitaxial substrate tray uye inoshandiswa pakugadzirisa uye kupisa. Inoiswa mukamuri yekupindura uye haibatanidzi zvakananga newafer.

An epitaxial susceptor, inobata Si substrate yekukura Si epitaxial slice, yakaiswa mukamuri yekupindura uye inobata zvakananga iyo wafer.

Epitaxial barrel chinhu chakakosha chinoshandiswa mumhando dzakasiyana-siyana dzekugadzira semiconductor, inowanzo shandiswa muMOCVD michina, ine yakanakisa kugadzikana kwemafuta, makemikari kuramba uye kusapfeka, yakakodzera kwazvo kushandiswa mukupisa kwakanyanya. Inobata mawafers.

| Zvenyama zvimiro zveRecrystallized Silicon Carbide | |

| Property | Typical Value |

| Tembiricha yekushanda (°C) | 1600°C (neokisijeni), 1700°C (inoderedza nharaunda) |

| SiC content | > 99.96% |

| Free Si content | <0.1% |

| Bulk density | 2.60-2.70 g/cm3 |

| Inooneka porosity | <16% |

| Kumanikidza simba | > 600 MPa |

| Kutonhora kukotama simba | 80-90 MPa (20°C) |

| Simba rekukotama rinopisa | 90-100 MPa (1400°C) |

| Kuwedzera kupisa @1500°C | 4.70 10-6/°C |

| Thermal conductivity @1200°C | 23 W/m•K |

| Elastic modulus | 240 GPA |

| Thermal shock resistance | Kunyanya kunaka |

| Zvenyama zvimiro zveSintered Silicon Carbide | |

| Property | Typical Value |

| Kuumbwa Kwemakemikari | SiC>95%, Si<5% |

| Bulk Density | >3.07 g/cm³ |

| Inooneka porosity | <0.1% |

| Modulus yekuputika pa20 ℃ | 270 MPa |

| Modulus yekuputika pa1200 ℃ | 290 MPa |

| Kuoma pa20 ℃ | 2400 Kg/mm² |

| Kuputsika kusimba pa20% | 3.3 MPa · m1/2 |

| Thermal Conductivity pa1200 ℃ | 45 w/m .K |

| Thermal kuwedzera pa20-1200 ℃ | 4.5 1 ×10 -6/℃ |

| Max.kushanda tembiricha | 1400 ℃ |

| Thermal shock resistance pa1200 ℃ | Kugona |

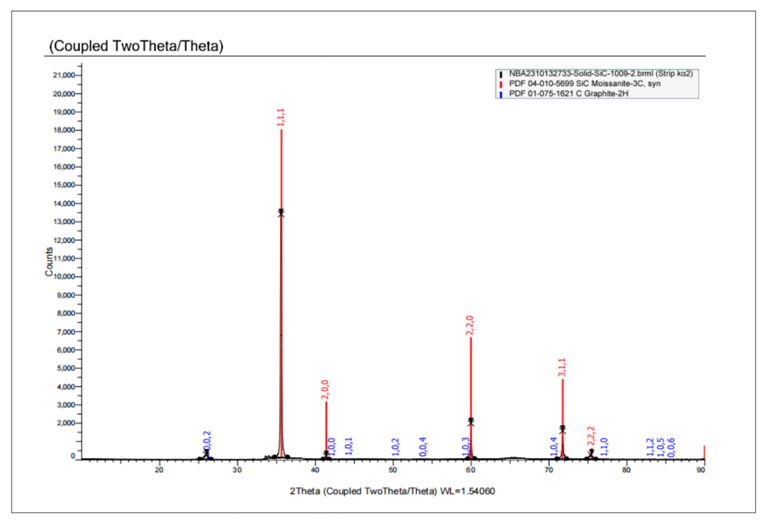

| Basic zvemuviri zvimiro zveCVD SiC mafirimu | |

| Property | Typical Value |

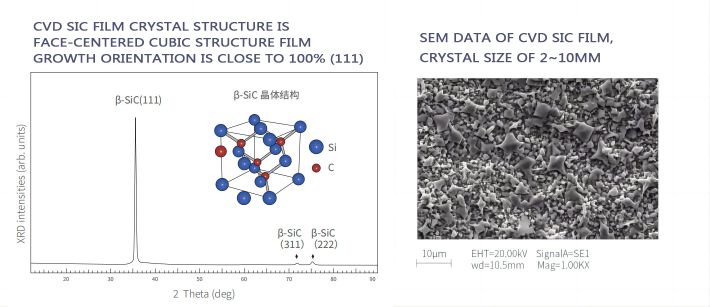

| Crystal Structure | FCC β phase polycrystalline, kunyanya (111) yakatarisana |

| Density | 3.21 g/cm³ |

| Kuoma 2500 | (500g mutoro) |

| Saizi yezviyo | 2~10μm |

| Chemical Purity | 99.99995% |

| Heat Capacity | 640 J·kg-1·K-1 |

| Sublimation Temperature | 2700 ℃ |

| Flexural Strength | 415 MPa RT 4-poindi |

| Young's Modulus | 430 Gpa 4pt bend, 1300 ℃ |

| Thermal Conductivity | 300Wm-1·K-1 |

| Kuwedzera kweThermal (CTE) | 4.5 × 10-6 K -1 |

Main features

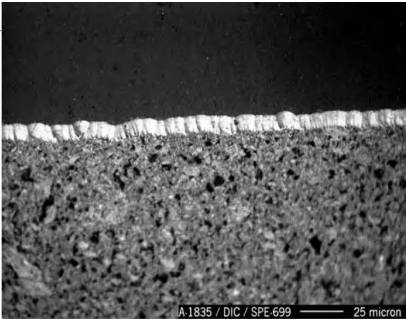

Nzvimbo yacho yakakora uye haina pores.

Kuchena kwepamusoro, kusvibiswa kwakakwana kwemukati <20ppm, kunaka kwemhepo.

Kunyanya kupisa tembiricha, simba rinowedzera nekuwedzera tembiricha yekushandisa, ichisvika pamutengo wepamusoro pa2750 ℃, sublimation pa3600 ℃.

Yakaderera elastic modulus, yakakwira yekupisa conductivity, yakaderera thermal yekuwedzera coefficient, uye yakanakisa kupisa kutyisa kuramba.

Kugadzikana kwekemikari yakanaka, inoshingirira kune acid, alkali, munyu, uye organic reagents, uye haina mhedzisiro pasimbi dzakanyungudutswa, slag, uye zvimwe zvinoparadza media. Haina oxidize zvakanyanya mumhepo iri pasi pe400 C, uye mwero weoxidation unowedzera zvakanyanya pa800 ℃.

Pasina kuburitsa chero gasi patembiricha yakakwira, inogona kuchengetedza vacuum ye10-7mmHg pakutenderedza 1800°C.

Product application

Melting crucible yekubuda mumhepo mune semiconductor indasitiri.

High power electronic tube gedhi.

Brush inobata voltage regulator.

Graphite monochromator yeX-ray uye neutron.

Yakasiyana maumbirwo egraphite substrates uye atomic absorption chubhu coating.

Pyrolytic carbon coating effect pasi pe500X microscope, ine yakasimba uye yakavharwa pamusoro.

TaC coating ndiyo chizvarwa chitsva chepamusoro tembiricha inodzivirira zvinhu, ine nani yakakwira tembiricha kugadzikana pane SiC. Sekupotera kusingadziviriki, anti-oxidation coating uye kupfeka-resistant coating, inogona kushandiswa munzvimbo iri pamusoro pe2000C, inoshandiswa zvakanyanya muaerospace yekupedzisira-yepamusoro tembiricha inopisa yekupedzisira zvikamu, yechitatu chizvarwa semiconductor single crystal kukura minda.

| Zvenyama zvimiro zveTaC coating | |

| Density | 14.3 (g/cm3) |

| Specific emssivity | 0.3 |

| Thermal kuwedzera coefficient | 6.3 10/K |

| Kuoma (HK) | 2000 HK |

| Resistance | 1x10-5 Ohm* masendimita |

| Thermal kugadzikana | <2500℃ |

| Graphite saizi inoshanduka | -10 ~ -20um |

| Coating ukobvu | ≥220um yakajairika kukosha (35um±10um) |

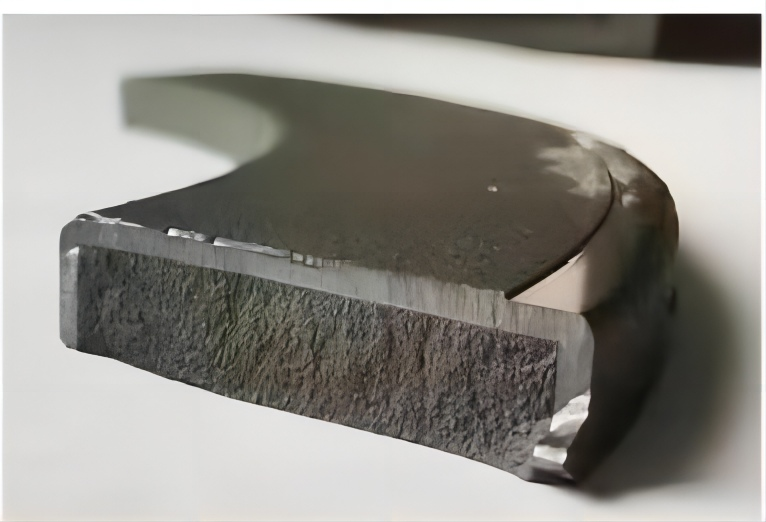

Solid CVD SILICON CARBIDE zvikamu zvinozivikanwa seyekutanga sarudzo yeRTP/EPI mhete nemabhesi uye plasma etch cavity zvikamu zvinoshanda panzvimbo yakakwirira inodiwa tembiricha yekushanda (> 1500 ° C), zvinodiwa pakuchena zvakanyanya kukwirira (> 99.9995%) uye mashandiro acho akanyanya kunaka kana iyo resistance tol makemikari yakanyanya kukwirira. Zvishandiso izvi hazvina zvikamu zvechipiri pamucheto wezviyo, saka zvikamu zveiyo zvinogadzira mashoma pane zvimwe zvinhu. Pamusoro pezvo, izvi zvikamu zvinogona kucheneswa uchishandisa inopisa HF/HCI nekushatisa kushoma, zvichikonzera mashoma mashoma uye hupenyu hurefu hwebasa.