CVD Silicon Carbide (SiC) Mhete dzinopihwa neSemicera zvinhu zvakakosha musemiconductor etching, nhanho yakakosha mukugadzira semiconductor mudziyo. Kuumbwa kweiyi CVD Silicon Carbide (SiC) Mhete inovimbisa yakagadzika uye yakasimba chimiro chinogona kumirisana neyakaomarara mamiriro eiyo etching maitiro. Kemikari vapor deposition inobatsira kuumba yakakwirira-kuchena, yunifomu uye dense SiC layer, ichipa zvindori zvakanakisa simba remuchina, kugadzikana kwekupisa uye kusagadzikana kwekuora.

Sechinhu chakakosha mukugadzira semiconductor, CVD Silicon Carbide (SiC) Mhete inoshanda sechidziviriro chekudzivirira kuchengetedza kutendeseka kwesemiconductor machipisi. Iyo chaiyo dhizaini inovimbisa yunifomu uye inodzorwa etching, iyo inobatsira mukugadzira yakanyanya kuomarara semiconductor zvishandiso, ichipa yakawedzera kuita uye kuvimbika.

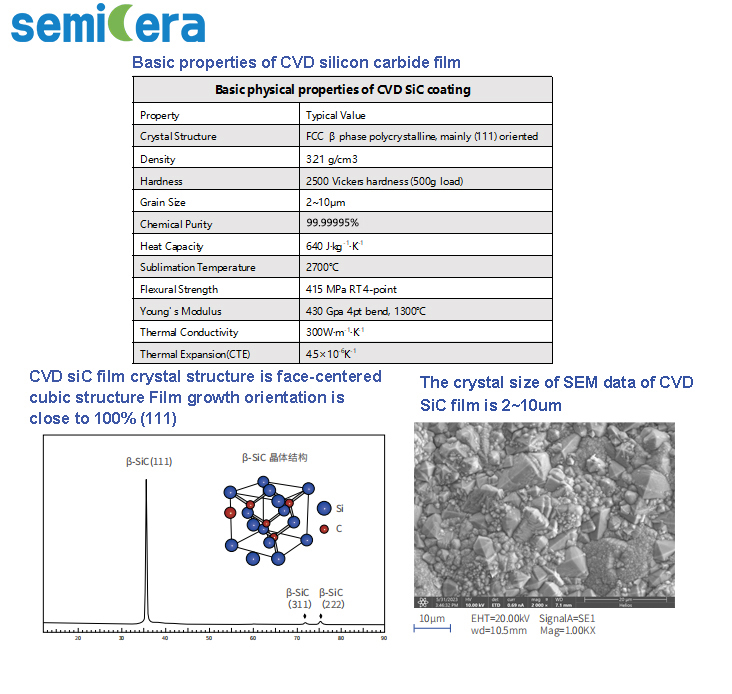

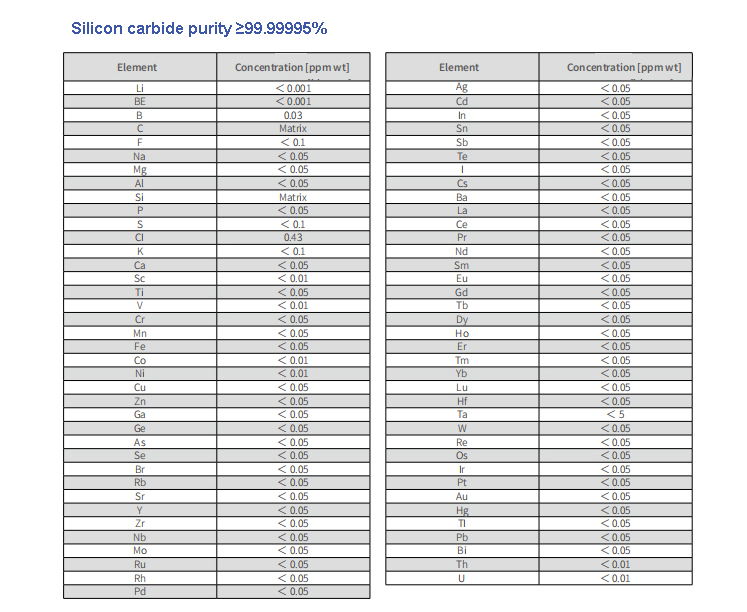

Kushandiswa kweCVD SiC zvinhu mukuvaka zvindori kunoratidza kuzvipira kuhutano uye kushanda mukugadzira semiconductor. Ichi chinyorwa chine zvimiro zvakasarudzika, zvinosanganisira yakakwira yekupisa yekupisa, yakanakisa makemikari inertness, uye kupfeka uye kusagadzikana kuramba, ichiita CVD Silicon Carbide (SiC) Mhete chinhu chakakosha mukutsvaga kwekunyatso uye kushanda zvakanaka mumasemiconductor etching maitiro.

Semicera's CVD Silicon Carbide (SiC) Mhete inomiririra mhinduro yepamberi mumunda wekugadzira semiconductor, ichishandisa yakasarudzika zvimiro zvemakemikari mhute yakaiswa silicon carbide kuita yakavimbika uye yepamusoro-inoshanda etching maitiro, kusimudzira kuenderera mberi kweiyo semiconductor tekinoroji. Isu takazvipira kupa vatengi zvigadzirwa zvakanakisa uye nehunyanzvi tekinoroji rutsigiro kusangana neiyo semiconductor indasitiri yekuda kwemhando yepamusoro uye inoshanda etching mhinduro.

✓Yepamusoro-mhando mumusika weChina

✓Sevhisi yakanaka nguva dzose kwauri, 7*24 maawa

✓Nguva pfupi yekutumira

✓Idiki MOQ inogamuchirwa uye inogamuchirwa

✓Masevhisi echivanhu

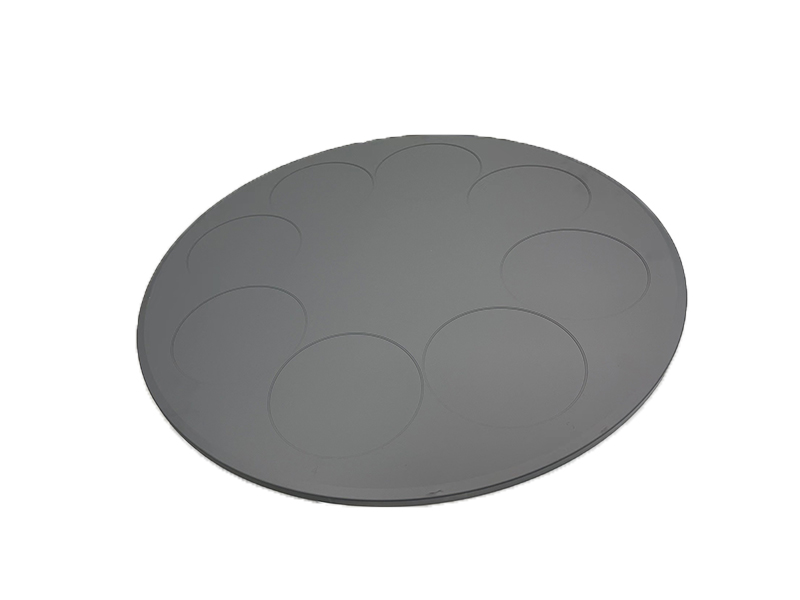

Epitaxy Kukura Susceptor

Silicon / silicon carbide wafers inoda kupfuura nematanho akawanda kuti ashandiswe mumidziyo yemagetsi. Nzira yakakosha ndeyesilicon/sic epitaxy, umo silicon/sic wafers inotakurwa pachigadziko chegraphite. Yakakosha mabhenefiti eSemicera's silicon carbide-yakavharwa graphite base inosanganisira yakanyanya kuchena kuchena, yunifomu yekupfeka, uye yakanyanyisa hupenyu hwesevhisi. Vanewo kukwirira kwemakemikari uye kugadzikana kwekupisa.

LED Chip Kugadzirwa

Munguva yekuputira kwakakura kweMOCVD reactor, chigadziko chepuraneti kana mutakuri anofambisa substrate wafer. Kuitwa kwechigadziko chinhu chine simba guru pahutano hwekuputira, izvo zvinokanganisa chiyero chezvimedu zvechip. Semicera's silicon carbide-coated base inowedzera kugona kwekugadzira kwemhando yepamusoro LED wafers uye inoderedza wavelength kutsauka. Isu tinopawo mamwe magirafu zvikamu kune ese MOCVD reactor ari kushandiswa parizvino. Tinogona kupfeka chero chinhu chine silicon carbide coating, kunyangwe iyo chikamu dhayamita inosvika 1.5M, isu tinogona kuramba takapfeka nesilicon carbide.

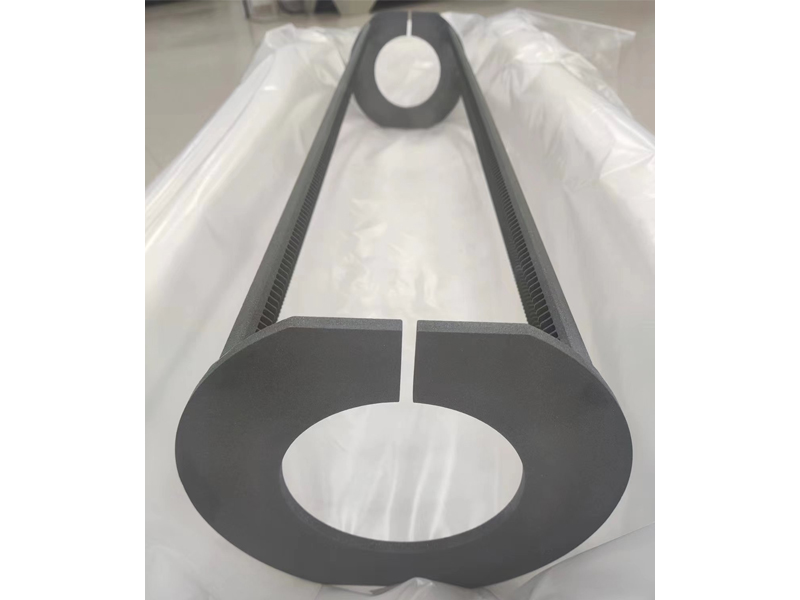

Semiconductor Munda, Oxidation Diffusion process, Etc.

Mukuita semiconductor, iyo oxidation yekuwedzera maitiro inoda yakakwira chigadzirwa kuchena, uye paSemicera tinopa tsika uye CVD yekupfekedza masevhisi kune mazhinji esilicon carbide zvikamu.

Mufananidzo unotevera unoratidza rough-yakagadziriswa silicon carbide slurry yeSemicea uye iyo silicon carbide furnace chubhu inocheneswa mu100.0-levelisina guruvaroom. Vashandi vedu vari kushanda vasati vapfeka. Kuchena kwesilicon carbide yedu kunogona kusvika 99.99%, uye kuchena kwe sic coating yakakura kupfuura 99.99995%.

Raw Silicon Carbide Paddle uye SiC Process Tube muKuchenesa

Silicon Carbide Wafer Boat CVD SiC Coated