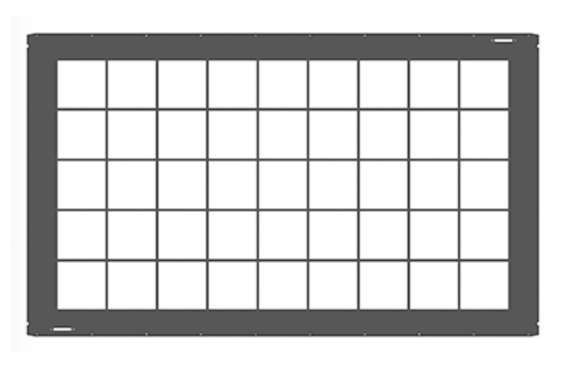

SiC Wafer Boat

Silicon carbide wafer boatchinhu chinotakura mutoro wewafers, chinonyanya kushandiswa muzuva uye semiconductor diffusion process. Iine hunhu hwakadai sekuramba kupfeka, corrosion resistance, high-temperature impact resistance, kuramba plasma bombardment, high tembiricha inotakura simba, high thermal conductivity, high heat dissipation, uye kushandiswa kwenguva refu kusiri nyore kukotama nekuremara. Kambani yedu inoshandisa yakakwira-kuchena silicon carbide zvinhu kuti ive nechokwadi chehupenyu hwesevhisi uye inopa akagadziridzwa magadzirirwo, kusanganisira. siyana yakatwasuka uye yakachinjikachikepe chewafer.

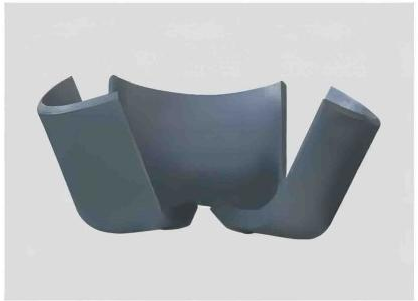

SiC Paddle

Thesilicon carbide cantilever paddleinonyanya kushandiswa mu (diffusion) coating yesilicon wafers, iyo inoita basa rakakosha mukurodha uye kutakura kwesilicon wafers pakupisa kwakanyanya. Icho chinhu chakakosha chesemiconductor waferekurodha masisitimu uye ane anotevera makuru maitiro:

1. Haina kukanganisa munzvimbo dzekushisa kwepamusoro uye ine simba guru rekutakura pazvimedu;

2. Inopikisa kutonhora kwakanyanya uye nekukurumidza kupisa, uye ine hupenyu hurefu hwebasa;

3. Thermal yekuwedzera coefficient idiki, inowedzera zvakanyanya kuchengetedza uye kuchenesa kutenderera, uye zvakanyanya kuderedza zvinosvibisa.

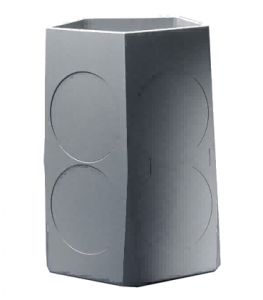

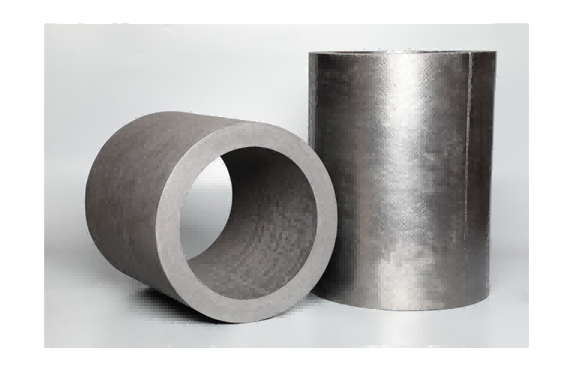

SiC Furnace Tube

Silicon carbide process chubhu, yakagadzirwa ne-high-purity SiC isina tsvina yesimbi, haisvibise chifukidziro, uye inokodzera maitiro akadai semiconductor uye photovoltaic diffusion, annealing uye oxidation process.

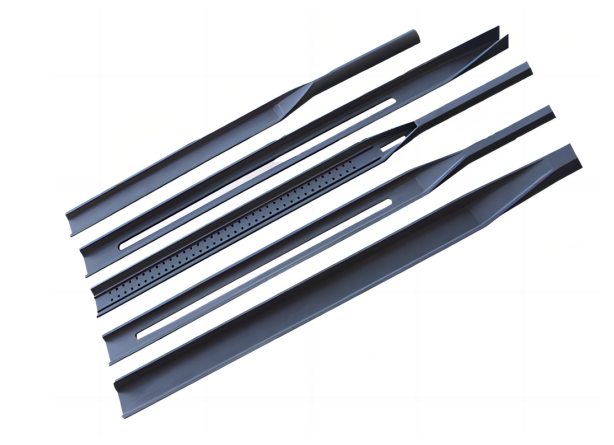

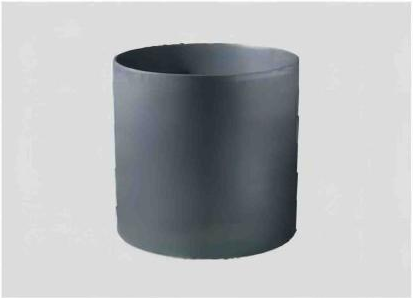

SiC Robot Arm

SiC robhoti ruoko, inozivikanwawo sewafer transfer end effector, irobhoti ruoko rinoshandiswa kutakura semiconductor wafers uye rinoshandiswa zvakanyanya mu semiconductor, optoelectronic, uye solar simba maindasitiri. Kushandisa yakakwirira-kuchena silicon carbide, nekuoma kwakanyanya, kupfeka kuramba, seismic kuramba, kushandiswa kwenguva refu pasina deformation, hupenyu hurefu hwebasa, nezvimwe, zvinogona kupa masevhisi akajairwa.

Graphite yekukura kwekristaro

Graphite heat shield

Graphite electrode chubhu

Graphite deflector

Graphite chuck

Ese maitiro anoshandiswa pakukura semiconductor crvstals anoshanda munzvimbo dzepamusoro-tembiricha uye dzinoora. Iyo inopisa nzvimbo yekristaro yekukura kwevira inowanzo eguinned nekupisa-inodzivirira uye corrosion-inodzivirira kuchena kwepamusoro. magirafu zvikamu, senge graphite heaters, crucibles, silinda, deflector, chucks, machubhu, mhete, zvibatiso, nzungu, etcl Chigadzirwa chedu chakapedzwa chinogona kuwana madota ari pasi pe5ppm.

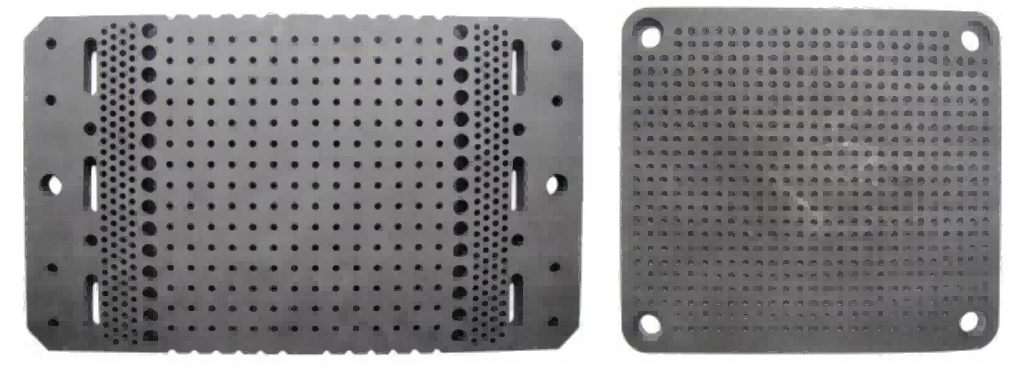

Graphite yeSemidonductor Epitaxy

MOCVD Graphite Zvikamu

Semiconductor Graphite Fixture

Epitaxial process inoreva kukura kwechinhu chimwe chekristaro pane imwe kristaro substrate ine imwechete lattice kurongeka se substrate. Inoda akawanda ekupedzisira-akakwirira kuchena graphite zvikamu uye graphite base ine SIC coating. Iyo yakanyanya kuchena graphite inoshandiswa semiconductor epitaxy ine huwandu hwakawanda hwekushandisa, iyo inogona kuenderana inowanzoshandiswa midziyo muindasitiri, Panguva imwecheteyo, ine yakanyanya kukwirira. kuchena, kupfekedza yunifomu, hupenyu hwesevhisi hwakanakisa, uye yakanyanya kukwirisa makemikari kuramba uye kugadzikana kwekupisa.

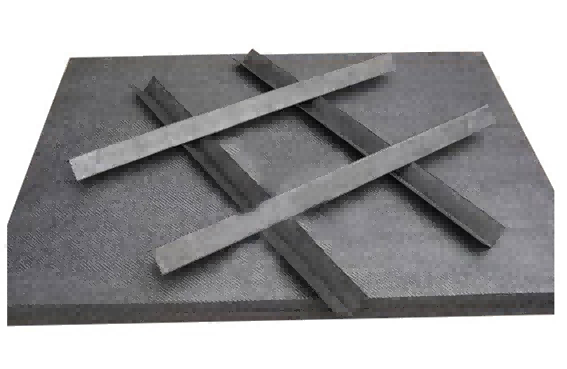

Insulation Material uye zvimwe

Thermal insulation materials inoshandiswa mukugadzira semiconductor graphite hard feel, soft feel, graphite foil, carbon composite materials, etc. Zvinhu zvedu zvakasvibirira zvinotengeswa kunze kwenyika magirafu zvinhu, zvinogona kutemwa maererano nezvinodiwa nevatengi, uye zvinogonawo kutengeswa se yakazara. Carbon composite zvinhu zvinowanzo shandiswa semutakuri we solar monocrystal uye polysilicon cell kugadzira process.