Nzira dzekupfeka dzephotoresist dzinowanzo kupatsanurwa kuita spin coating, dip coating uye roll coating, pakati peiyo spin coating ndiyo inonyanya kushandiswa. Nekusonera coating, photoresist inodonhedzwa pane substrate, uye iyo substrate inogona kutenderedzwa nekumhanya kukuru kuti iwane photoresist firimu. Mushure meizvi, firimu yakasimba inogona kuwanikwa nekuipisa pahote inopisa. Spin coating inokodzera kupfekedzwa kubva kune ekupedzisira-mutete mafirimu (angangoita 20nm) kune akakora mafirimu anosvika zana. Hunhu hwayo hwakafanana hwakafanana, yunifomu yefirimu ukobvu pakati pezvimedu, mashoma akaremara, nezvimwewo, uye firimu rine yakakwira coating performance inogona kuwanikwa.

Spin coating process

Munguva yekupotera, iyo huru yekutenderera kumhanya kweiyo substrate inosarudza iyo firimu ukobvu hwephotoresist. Hukama pakati pekumhanya kwekutenderera uye ukobvu hwefirimu hwakaita seizvi:

Spin=kTn

Mune fomula, Spin ndiyo yekumhanyisa kutenderera; T ndiko kukora kwefirimu; k uye n zvimisodzi.

Zvinhu zvinokanganisa spin coating process

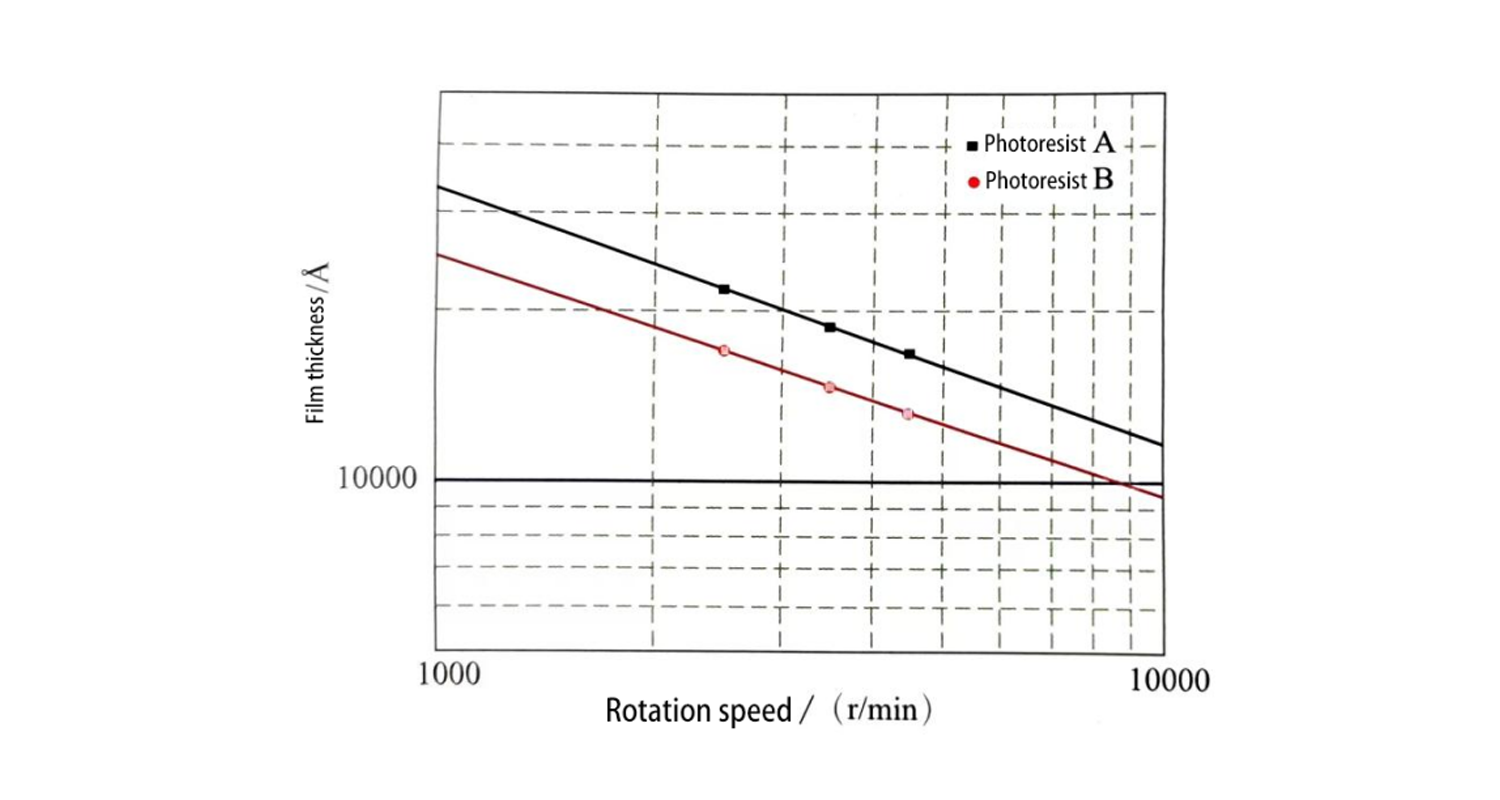

Kunyangwe iyo firimu ukobvu kunotemerwa neiyo huru yekutenderera kumhanya, zvakare ine chekuita nekamuri tembiricha, humidity, photoresist viscosity uye photoresist mhando. Kuenzanisa kwemhando dzakasiyana dze photoresist yekuputira curves inoratidzwa muMufananidzo 1.

Mufananidzo 1: Kuenzanisa kwemhando dzakasiyana dze photoresist coating curves

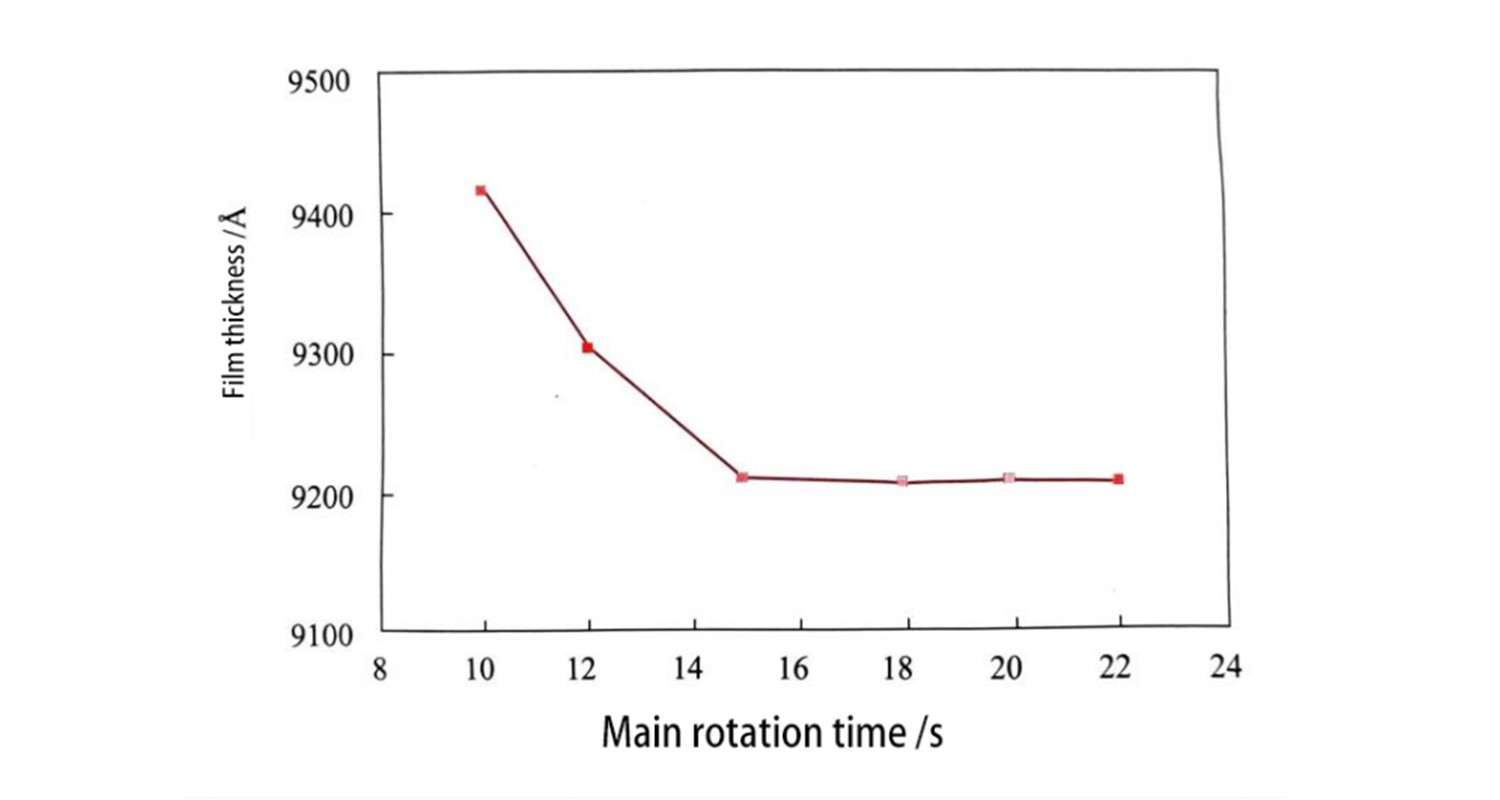

Pesvedzero yenguva huru yekutenderera

Iyo ipfupi iyo huru yekutenderera nguva, iyo yakakura iyo firimu ukobvu. Kana nguva huru yekutenderera ichiwedzerwa, iyo yakaonda iyo firimu inova. Kana ichipfuura 20s, ukobvu hwefirimu hunoramba husina kushanduka. Nokudaro, nguva huru yekutenderera inowanzosarudzwa kuva inopfuura 20 seconds. Hukama huri pakati penguva huru yekutenderera uye ukobvu hwefirimu hunoratidzwa muMufananidzo 2.

Mufananidzo 2: Hukama pakati penguva huru yekutenderera uye ukobvu hwefirimu

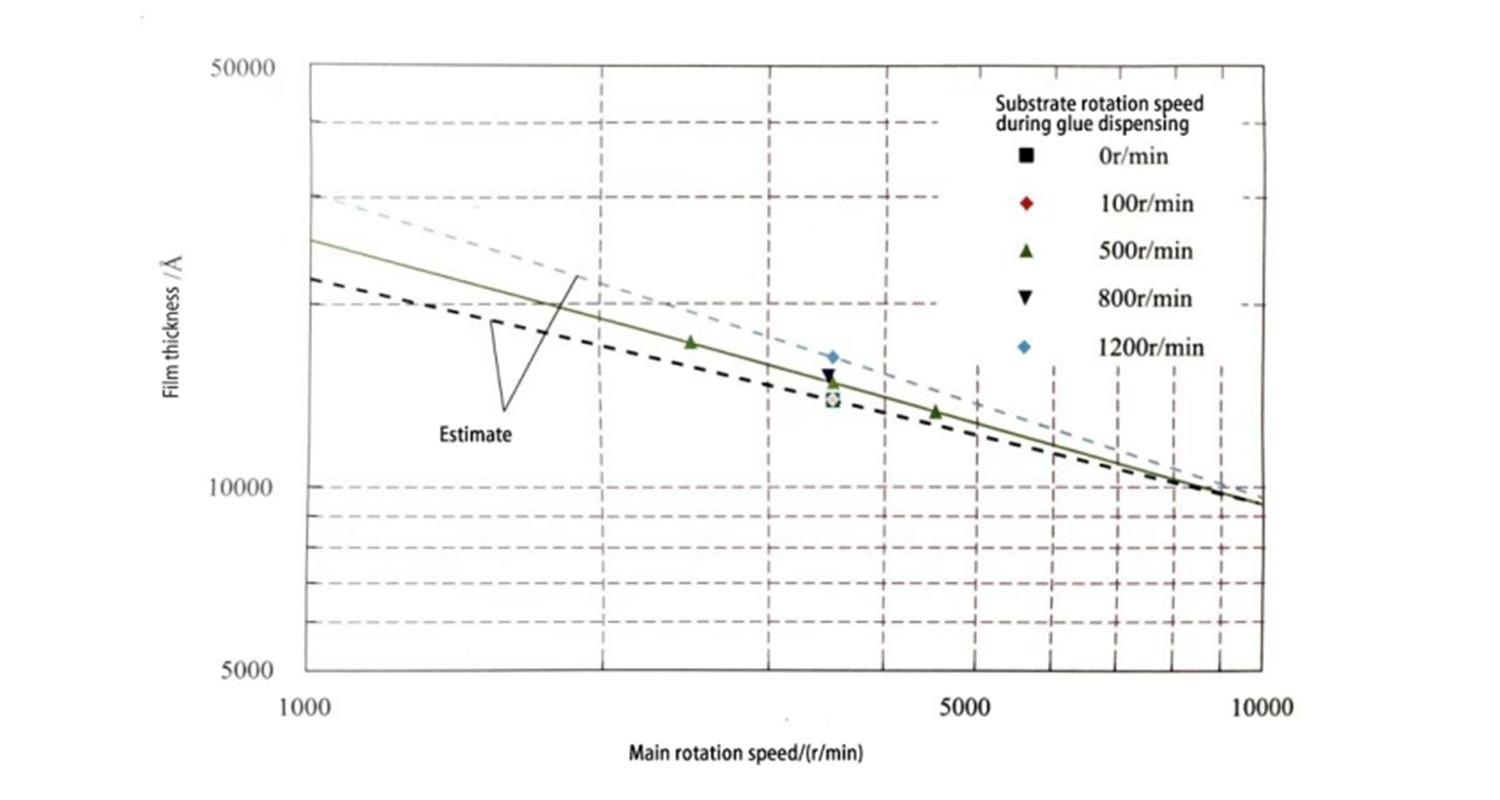

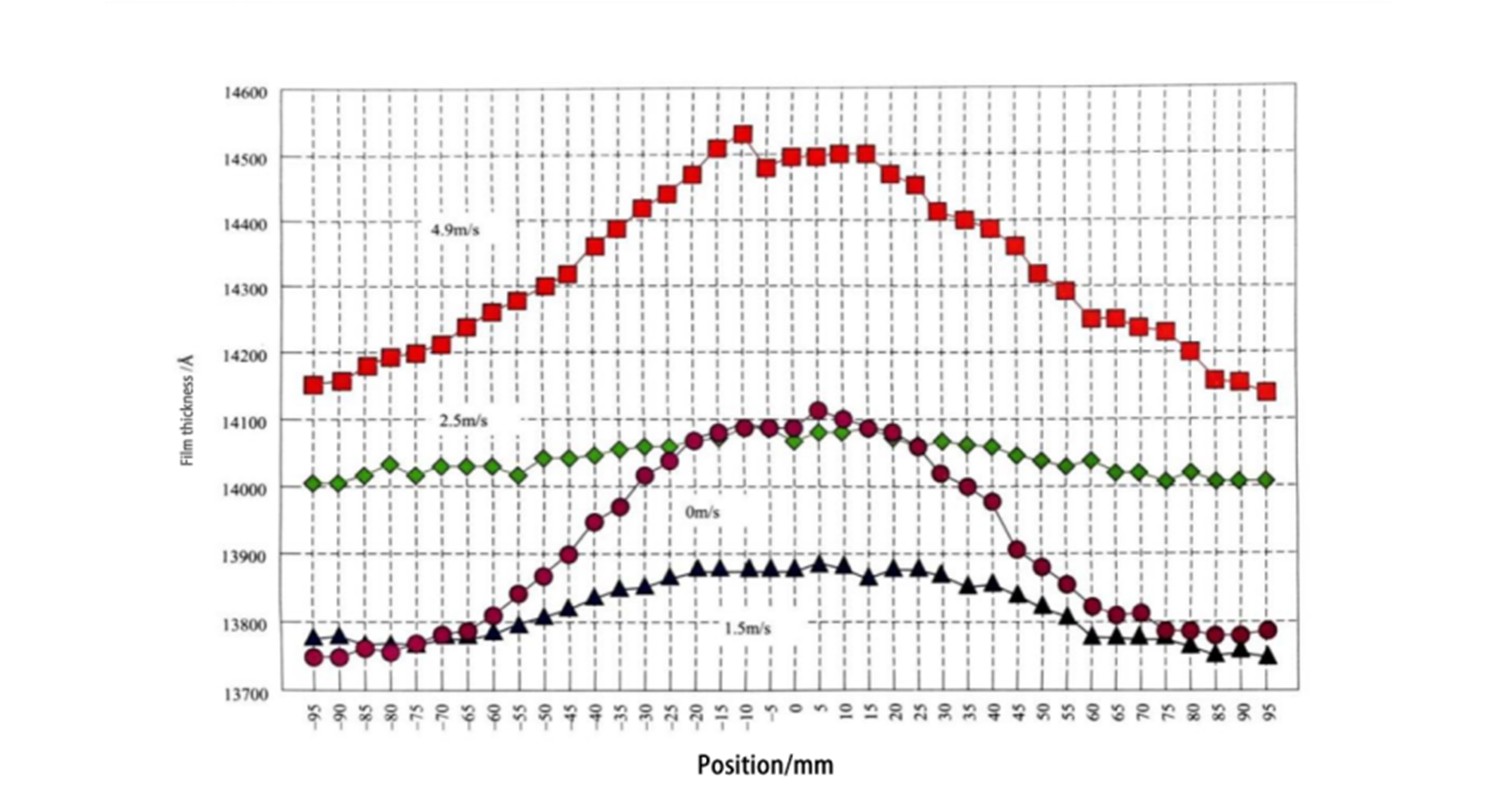

Kana iyo photoresist ikadonhedzwa pasubstrate, kunyangwe iyo inozotevera yekutenderera yekumhanya yakafanana, kumhanya kwekutenderera kwesubstrate panguva yekudonha kunokanganisa kukora kwefirimu rekupedzisira. Ukobvu hwefirimu refotoresist hunowedzera nekuwedzera kweiyo substrate kutenderera kumhanya panguva yekudonha, izvo zvinokonzerwa nekufurira kwekunyungudika kwekunyungudika kana photoresist yavhurwa mushure mekudonha. Mufananidzo 3 unoratidza hukama pakati pehukobvu hwefirimu uye iyo huru yekutenderera kumhanya pane akasiyana substrate kutenderera kumhanya panguva yekudonha kwephotoresist. Zvinogona kuonekwa kubva pamufananidzo kuti nekuwedzera kwekutenderera kwekutenderera kweiyo inodonha substrate, iyo firimu ukobvu inoshanduka nekukurumidza, uye musiyano unonyanya kuoneka munzvimbo ine yakaderera main kutenderera kumhanya.

Mufananidzo 3: Hukama pakati pemukobvu wefirimu uye huru yekutenderera kumhanya pane akasiyana substrate kutenderera kumhanya panguva yekuparadzira photoresist.

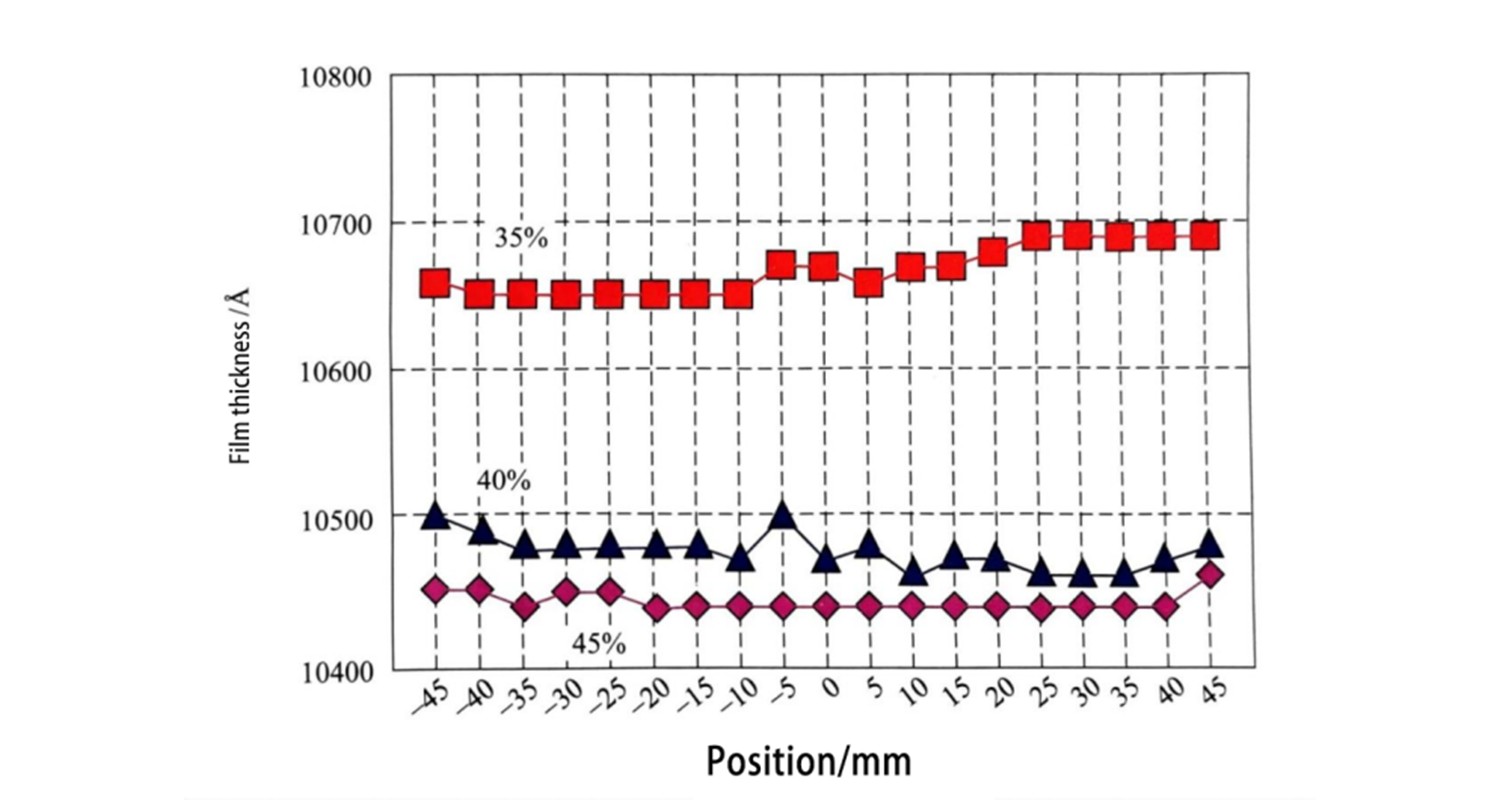

Mhedzisiro yekunyorova panguva yekupfeka

Kana hunyoro huchiderera, kukora kwefirimu kunowedzera, nokuti kuderera kwehunyoro kunokurudzira kubuda kweiyo solvent. Nekudaro, iyo firimu ukobvu kugovera hakuchinje zvakanyanya. Mufananidzo 4 unoratidza hukama pakati pekunyorova uye kugoverwa kwefirimu ukobvu panguva yekupfeka.

Mufananidzo 4: Hukama pakati pehunyoro uye kugovera kwefirimu ukobvu panguva yekupfeka

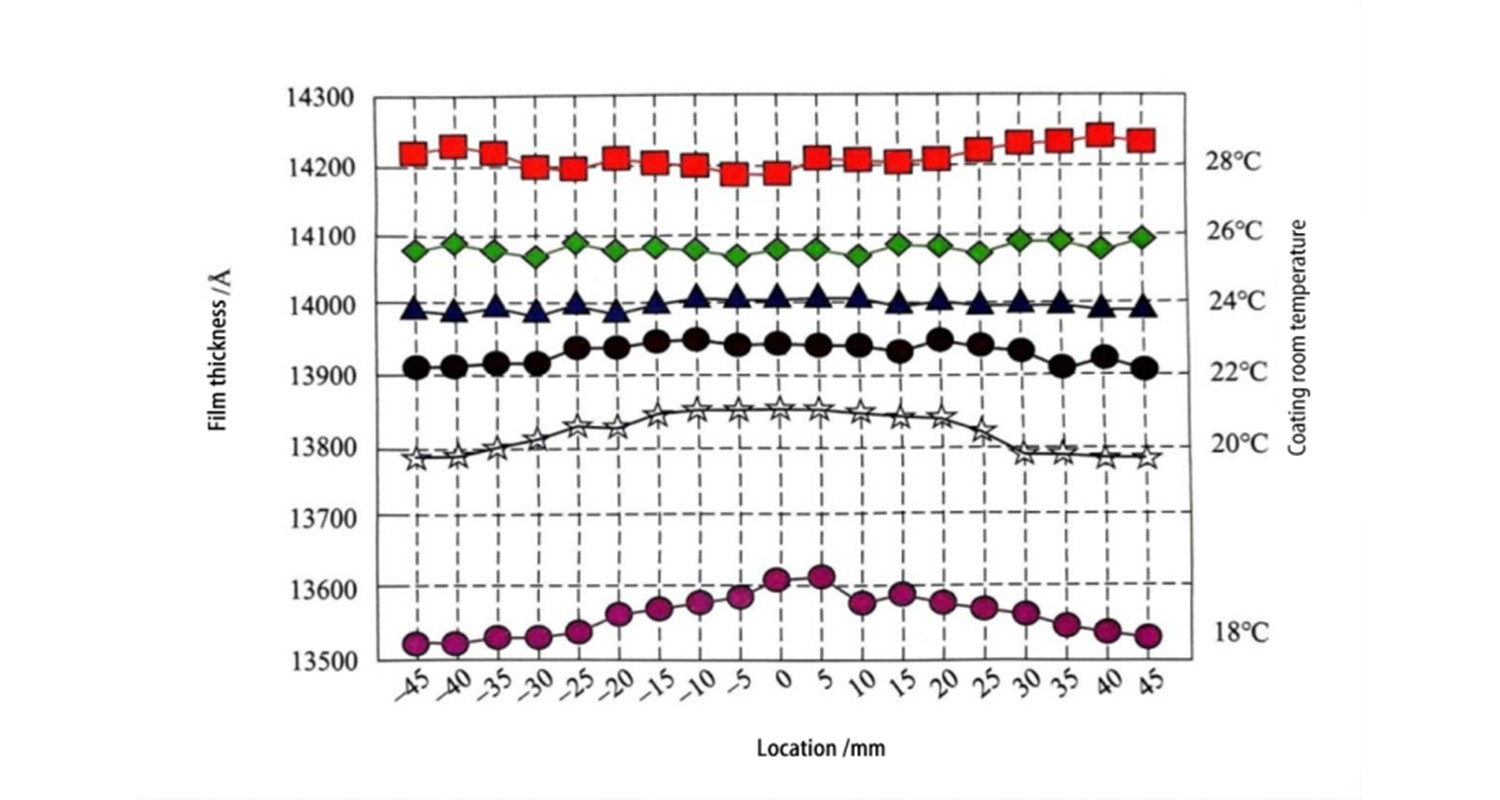

Mhedzisiro yekushisa panguva yekupfeka

Kana tembiricha yemukati ichikwira, ukobvu hwefirimu hunowedzera. Zvinogona kuonekwa kubva Figure 5 kuti photoresist firimu ukobvu kuparadzirwa kuchinja kubva convex kuti concave. Iyo curve yemufananidzo inoratidzawo kuti iyo yakanyanya kufanana inowanikwa kana tembiricha yemukati iri 26 ° C uye tembiricha yephotoresist iri 21 ° C.

Mufananidzo 5: Hukama pakati petembiricha uye firimu ukobvu kugovera panguva yekupfeka

Mhedzisiro yekukurumidza kupera panguva yekupfeka

Mufananidzo 6 unoratidza hukama pakati pekumhanya kwekupedza uye kuparadzirwa kwefirimu. Kana pasina kupera, zvinoratidza kuti pakati pechingwa chinowanzoita gobvu. Kuwedzera kukurumidza kwekupera kunovandudza kufanana, asi kana yakawedzera zvakanyanya, kufanana kunoderera. Zvinogona kuonekwa kuti kune yakakosha kukosha kwekumhanya kwekupedza.

Mufananidzo 6: Hukama pakati pekumhanya kwekupedza uye kugovera kwefirimu ukobvu

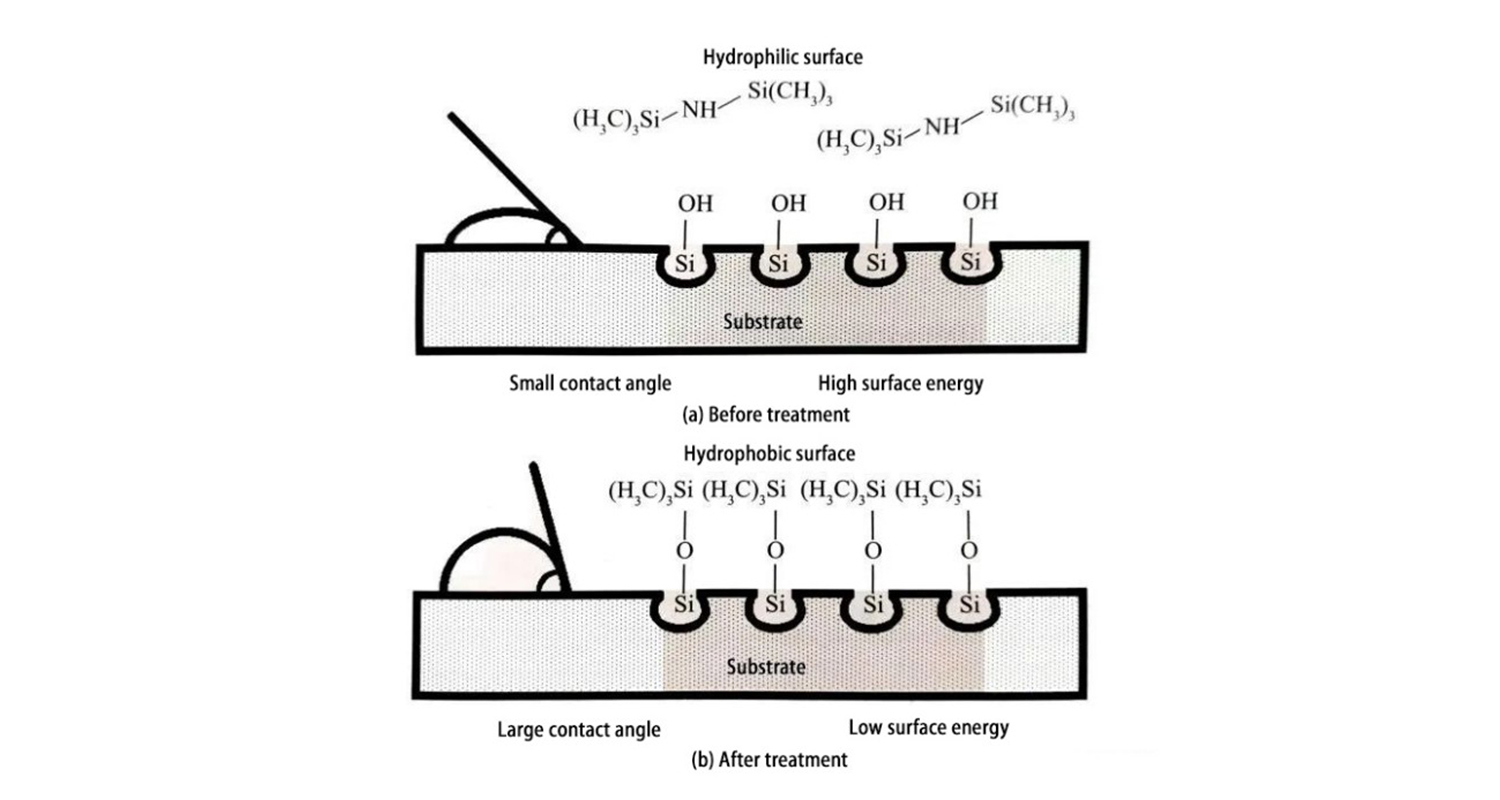

HMDS kurapwa

Kuti aite kuti photoresist iwedzere kuvharika, wafer inoda kurapwa nehexamethyldisilazane (HMDS). Kunyanya kana unyoro hunosungirirwa pamusoro peSi oxide firimu, silanol inoumbwa, iyo inoderedza kusungirirwa kwephotoresist. Kuti ubvise unyoro uye kuora silanol, jira rinowanzopisa kusvika 100-120 ° C, uye mhute HMDS inounzwa kuti iite kemikari. The reaction mechanism inoratidzwa muFigure 7. Kuburikidza neHMDS kurapwa, iyo hydrophilic pamusoro ine diki yekusangana angle inova hydrophobic pamusoro ine hombe yekubata angle. Kupisa iyo wafer inogona kuwana yakakwirira photoresist adhesion.

Mufananidzo 7: HMDS maitiro ekuita

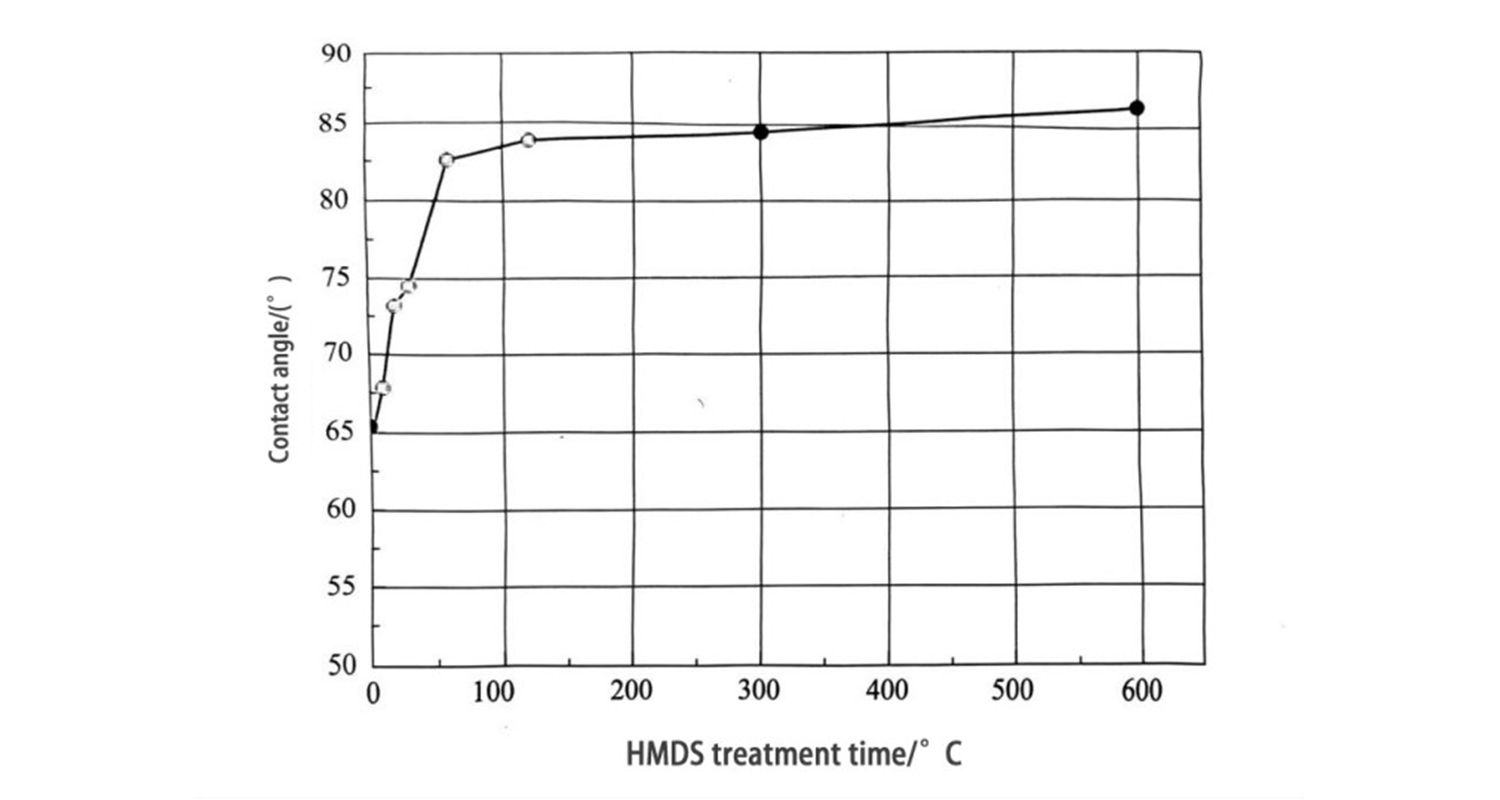

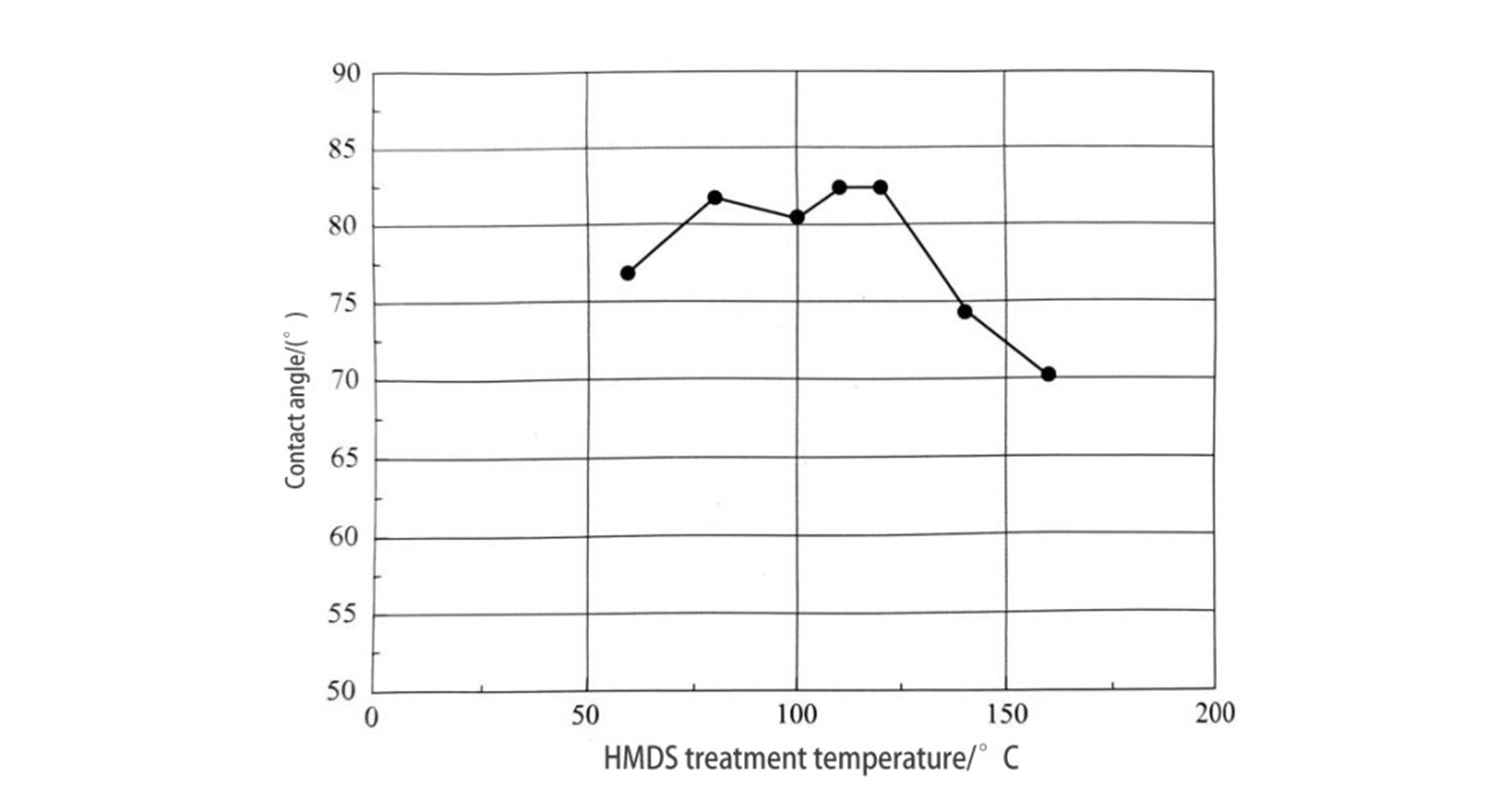

Mhedzisiro yekurapa kweHMDS inogona kucherechedzwa nekuyera kona yekubata. Mufananidzo 8 unoratidza hukama pakati peHMDS nguva yekurapa uye kuonana kona (tembiricha yekurapa 110 ° C). Iyo substrate ndeyeSi, iyo HMDS yekurapa nguva yakakura kupfuura 1min, iyo yekusangana angle yakakura kupfuura 80 °, uye mhedzisiro yekurapa yakagadzikana. Mufananidzo 9 unoratidza hukama pakati peHMDS tembiricha yekurapa uye kuonana kona (nguva yekurapa 60s). Kana tembiricha yadarika 120 ℃, kona yekubata inodzikira, zvichiratidza kuti HMDS inoora nekuda kwekupisa. Naizvozvo, kurapwa kweHMDS kunowanzoitwa pa100-110 ℃.

Mufananidzo 8: Ukama pakati peHMDS nguva yekurapa

uye kuonana kona (tembiricha yekurapa 110 ℃)

Mufananidzo 9: Hukama pakati peHMDS tembiricha yekurapa uye yekuona kona (nguva yekurapa 60s)

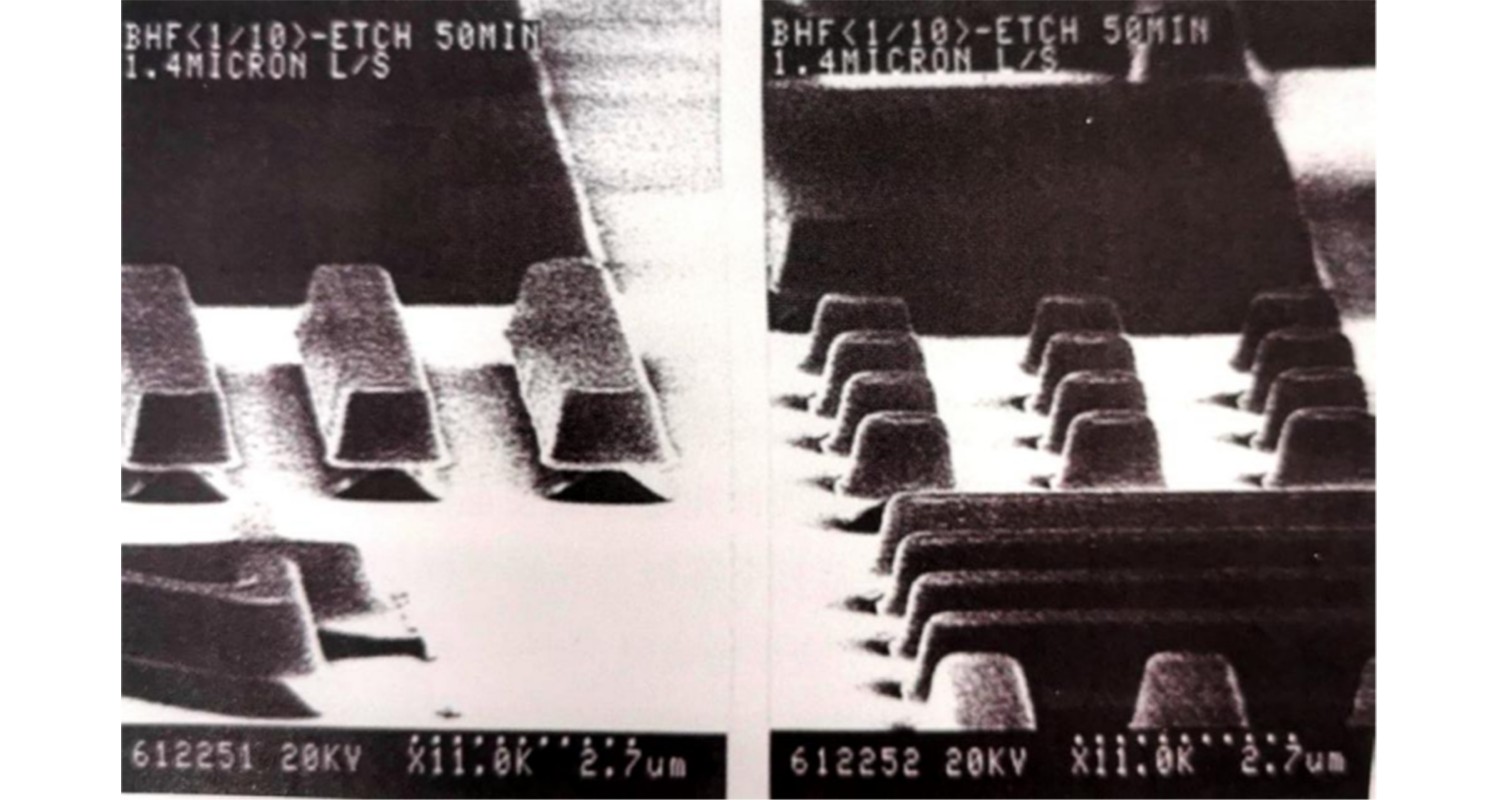

Kurapa kweHMDS kunoitwa pasilicon substrate ine oxide firimu kuti iite photoresist pateni. Iyo oxide firimu inozoiswa ne hydrofluoric acid ine buffer yakawedzerwa, uye inowanikwa kuti mushure mekurapwa kweHMDS, iyo photoresist pateni inogona kuchengetedzwa kubva pakudonha. Mufananidzo 10 unoratidza mhedzisiro yeHMDS kurapwa (pattern size i1um).

Mufananidzo 10: HMDS kurapwa maitiro (pattern saizi i1um)

Prebaking

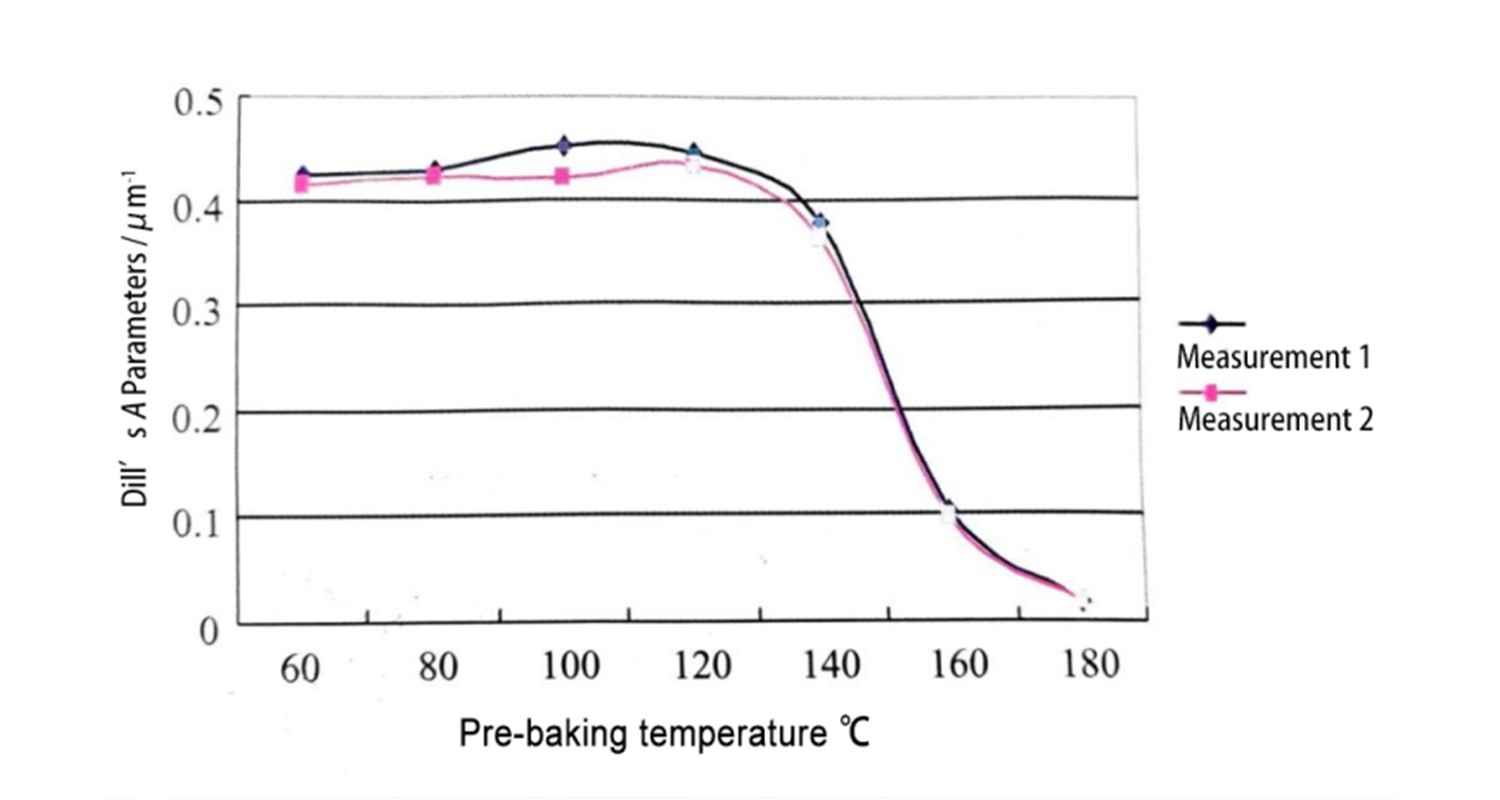

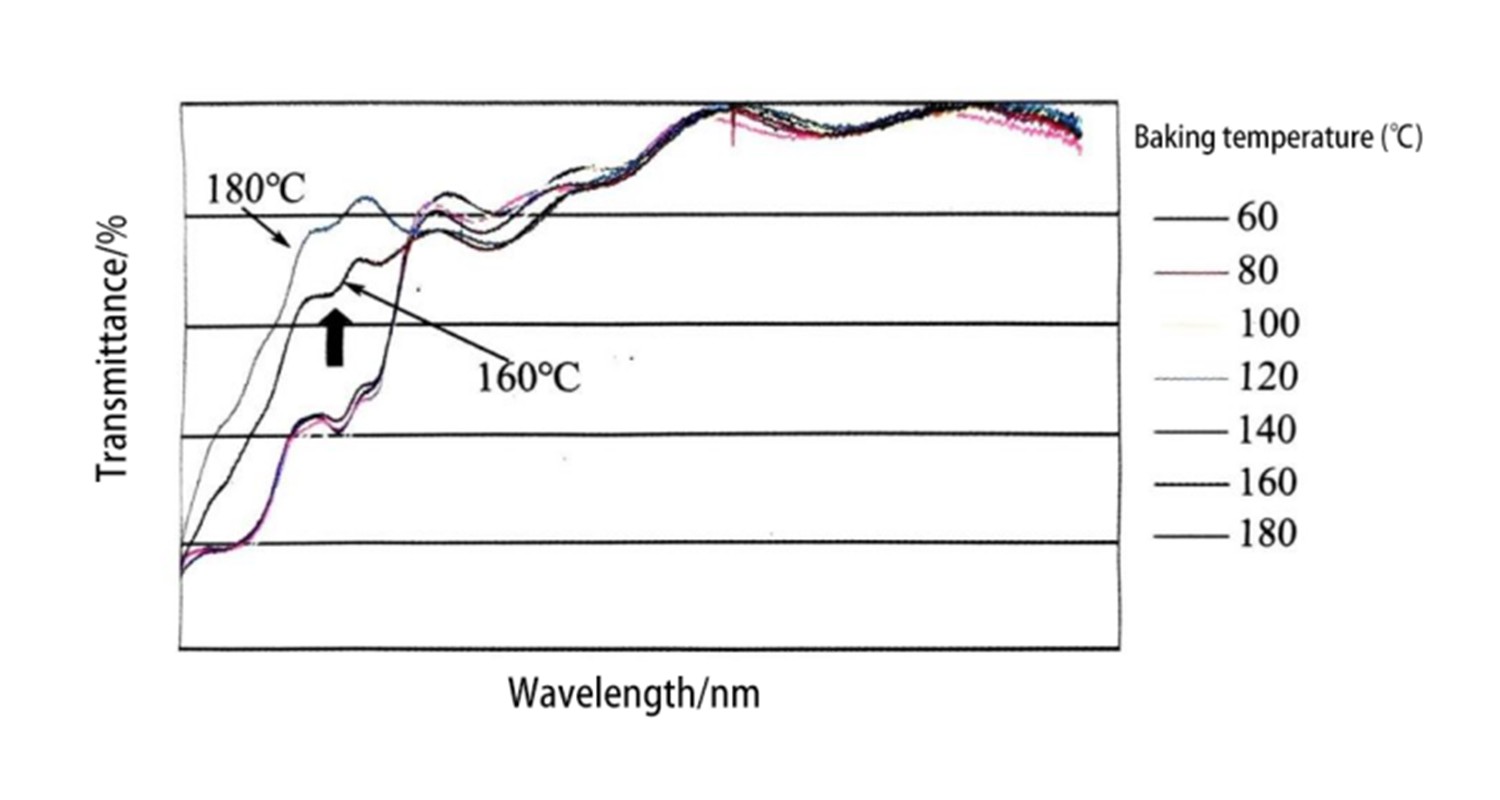

Panguva imwe chete yekutenderera, kukwira kwetembiricha yekubikira, kudiki kwemukobvu wefirimu, izvo zvinoratidza kuti kana tembiricha yekubika yakakwirisa, mvura inonyungudika inobuda, zvichikonzera kukora kwefirimu. Mufananidzo 11 unoratidza hukama pakati pekushisa kwekutanga kwekubika uye Dill's A parameter. Iyo A parameter inoratidza kusungirirwa kweiyo photosensitive agent. Sezvinogona kuonekwa kubva pamufananidzo, apo kutonhora kwekutanga-kubika kunokwira kusvika pamusoro pe 140 ° C, iyo A parameter inoderera, zvichiratidza kuti iyo photosensitive agent inoora pakupisa kwepamusoro kupfuura iyi. Mufananidzo 12 unoratidza iyo spectral transmittance pane akasiyana pre-kubika tembiricha. Pa160 ° C uye 180 ° C, kuwedzera kwekutapurirana kunogona kucherechedzwa muwavelength renji ye300-500nm. Izvi zvinosimbisa kuti iyo photosensitive agent yakabikwa uye yakaora pakupisa kwakanyanya. Kupisa kwekutanga kwekubika kune zvakakosha zvakakosha, izvo zvinotarirwa nemaitiro echiedza uye kunzwa.

Mufananidzo 11: Ukama pakati pekupisa kwekutanga kubika uye Dill's A parameter

(yakayerwa kukosha kweOFPR-800/2)

Mufananidzo 12: Spectral transmittance pane dzakasiyana pre-kubika tembiricha

(OFPR-800, 1um firimu ukobvu)

Muchidimbu, iyo spin coating nzira ine yakasarudzika mabhenefiti senge kunyatso kudzora kwehukobvu hwefirimu, kudhura kwekuita, hunyoro hwekuita mamiriro, uye mashandiro ari nyore, saka ine zvakakosha mhedzisiro mukuderedza kusvibiswa, kuchengetedza simba, nekuvandudza mutengo wekuita. Mumakore achangopfuura, spin coating yanga ichiwedzera kutariswa, uye kushandiswa kwayo kwakapararira zvishoma nezvishoma kune dzakasiyana siyana.

Nguva yekutumira: Nov-27-2024