Tsvagiridzo yekumashure

Kukosha kwekushandisa kwesilicon carbide (SiC): Seyakafara bandgap semiconductor zvinhu, silicon carbide yakwezva kutarisisa zvakanyanya nekuda kweakanakisa emagetsi zvivakwa (senge hombe bandgap, yakakwirira electron saturation velocity uye thermal conductivity). Izvi zvivakwa zvinoita kuti zvishandiswe zvakanyanya mu-high-frequency, yakakwirira-tembiricha uye yakakwirira-simba mudziyo kugadzira, kunyanya mumunda wemagetsi emagetsi.

Kupesvedzerwa kwekuremara kwekristaro: Pasinei nezvakanakira izvi zveSiC, kukanganisa mumakristasi kunoramba kuri dambudziko guru rinotadzisa kugadzirwa kwemidziyo inoshanda zvakanyanya. Izvi zvinokanganisa zvinogona kukonzera kukanganisa kwechishandiso uye kukanganisa kuvimbika kwechigadzirwa.

X-ray topological imaging tekinoroji: Kuti ugone kukwidziridza kukura kwekristaro uye unzwisise kukanganisa kwekukanganisa pakuita kwechishandiso, zvinodikanwa kuratidza uye kuongorora chikanganiso chigadziriso mumakristasi eSiC. X-ray topological imaging (kunyanya kushandisa synchrotron radiation matanda) yave yakakosha maitiro ehunhu anogona kugadzira yakakwirira-resolution mifananidzo yemukati chimiro chekristaro.

Tsvakurudza mazano

Kubva pane tekinoroji yekuteedzera tekinoroji: Chinyorwa chinokurudzira kushandiswa kweiyo ray tracing simulation tekinoroji zvichibva pane yekumisikidza mutsauko kutevedzera chakakanganisika chinocherechedzwa mumifananidzo yeX-ray chaiyo. Iyi nzira yakaratidza kuti inzira inoshanda yekudzidza zvimiro zvekristaro defects mune dzakasiyana semiconductors.

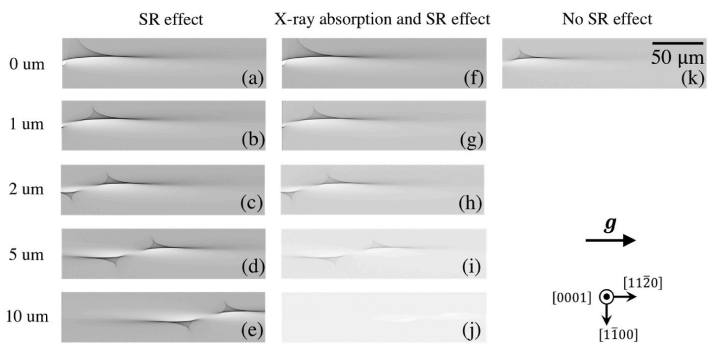

Kuvandudza tekinoroji yekutevedzera: Kuti titevedze zvirinani kubviswa kwakasiyana kwakaonekwa mu4H-SiC uye 6H-SiC makristasi, vaongorori vakavandudza ray tracing simulation tekinoroji uye vakabatanidza mhedzisiro yekuzorodza kwepasi uye kutorwa kwemagetsi.

Tsvakurudzo yezvinyorwa

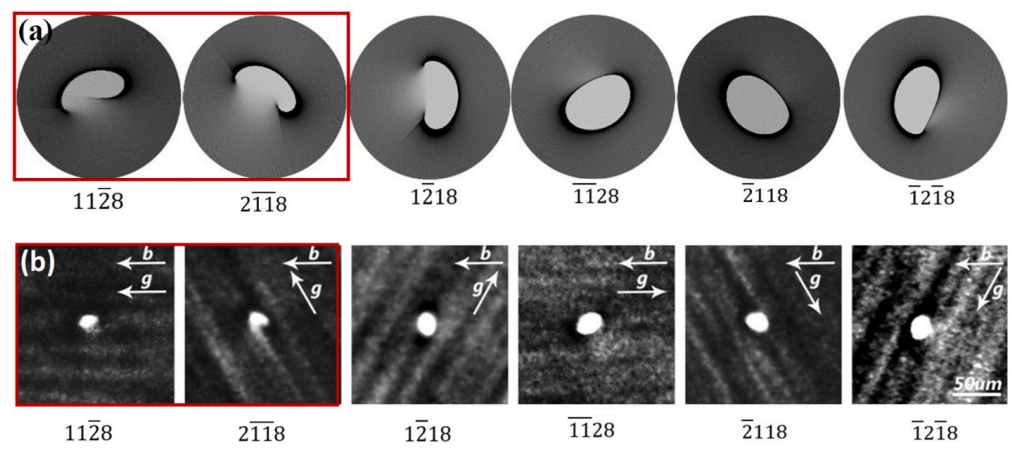

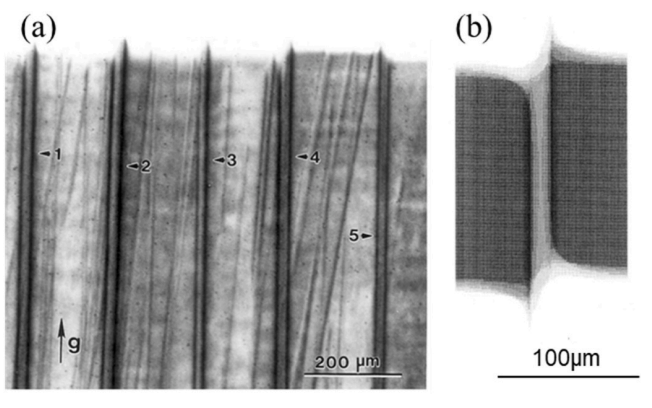

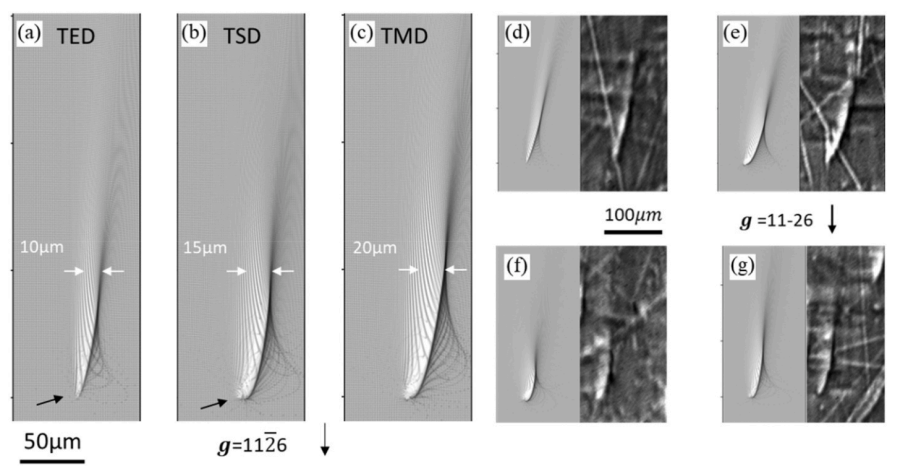

Dislocation mhando yekuongorora: Chinyorwa chinoongorora zvakarongeka maratidziro emhando dzakasiyana dzekusarudzika (senge screw dislocation, edge dislocation, yakasanganiswa dislocation, basal plane dislocations uye Frank-type dislocations) mune akasiyana polytypes eSiC (kusanganisira 4H uye 6H) uchishandisa ray tracing. simulation technology.

Kushandisa tekinoroji yekutevedzera: Kushandiswa kweiyo ray tracing simulation tekinoroji pasi pemamiriro akasiyana edanda senge isina kusimba beam topology uye plane wave topology, pamwe nekuona kunoshanda kudzika kwekupinda kwekumisikidza kuburikidza nesimulation tekinoroji inodzidzwa.

Kusanganiswa kwekuedza uye kuenzanisa: Nokuenzanisa iyo yakaedzwa yakawanikwa X-ray topological mifananidzo nemifananidzo yakafananidzirwa, kunyatsoita tekinoroji yekufananidza pakusarudza rudzi rwekutsakatika, Burgers vector uye kugoverwa kwenzvimbo yekuparadzaniswa mukristaro kunosimbiswa.

Tsvagiridzo mhedziso

Kubudirira kwehunyanzvi hwekuita tekinoroji: Chidzidzo chinoratidza kuti ray tracing simulation tekinoroji inzira yakapusa, isingaparadzi uye isina kujeka yekuburitsa hunhu hwemhando dzakasiyana dzekutsemuka muSiC uye inogona kunyatso kufungidzira kudzika kwekupinda kweiyo dislocation.

3D dislocation configuration ongororo: Kuburikidza tekinoroji yekufananidza, 3D dislocation yekumisikidza ongororo uye density kuyerwa kunogona kuitwa, izvo zvakakosha kuti unzwisise maitiro uye shanduko yekumisikidza panguva yekukura kwekristaro.

Mashandisirwo eramangwana: Ray tracing simulation tekinoroji inotarisirwa kuiswazve kune yakakwirira-simba topology pamwe nerabhoritari-yakavakirwa X-ray topology. Uye zvakare, iyi tekinoroji inogona zvakare kukwidziridzwa kune yekufananidza yekuremara maitiro emamwe mapolytypes (akadai se15R-SiC) kana zvimwe semiconductor zvinhu.

Mufananidzo Overview

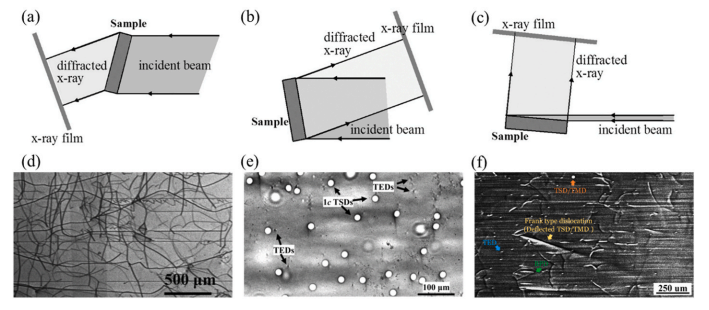

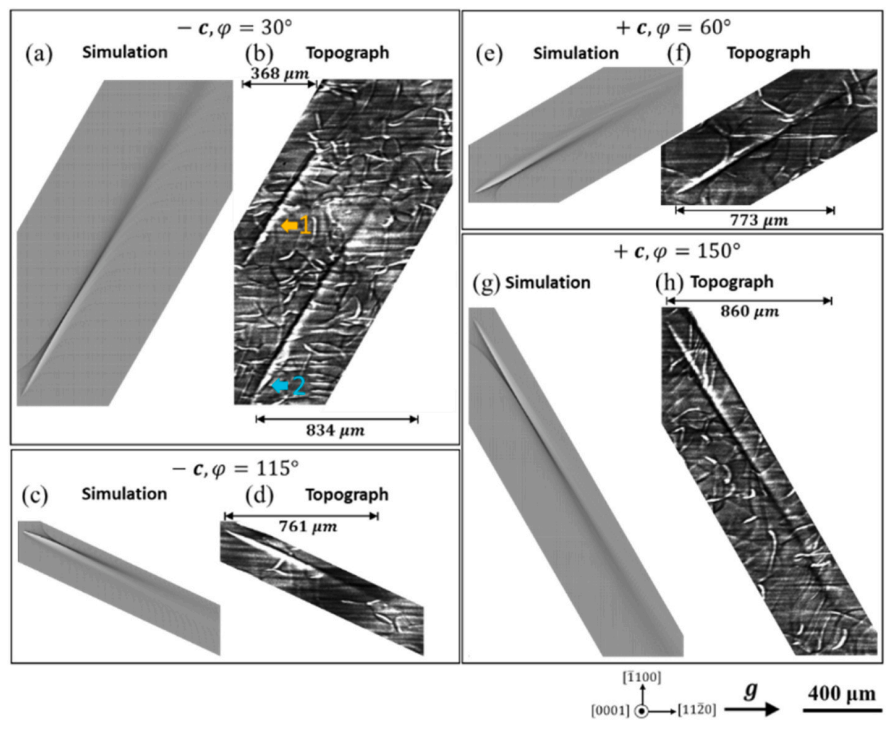

Mufananidzo 1: Schematic diagram ye synchrotron radiation X-ray topological imaging setup, kusanganisira kutumira (Laue) geometry, reverse reflection (Bragg) geometry, uye mafuro chiitiko geometry. Aya majeometri anonyanya kushandiswa kurekodha X-ray topological mifananidzo.

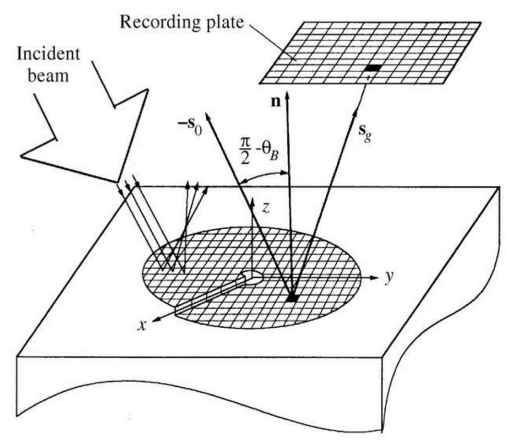

Mufananidzo 2: Schematic diagram yeX-ray diffraction yenzvimbo yakakanganiswa yakapoteredza screw dislocation. Ichi chifananidzo chinotsanangura hukama pakati pechiitiko danda (s0) neiyo diffracted danda (sg) ine ndege yemunharaunda diffraction yakajairika (n) uye yemunharaunda Bragg angle (θB).

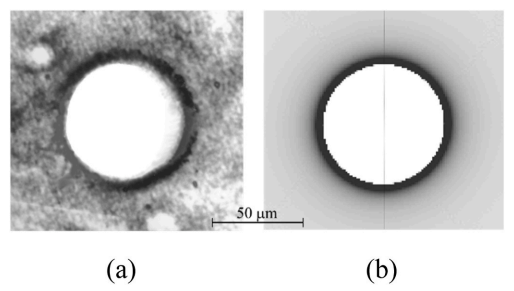

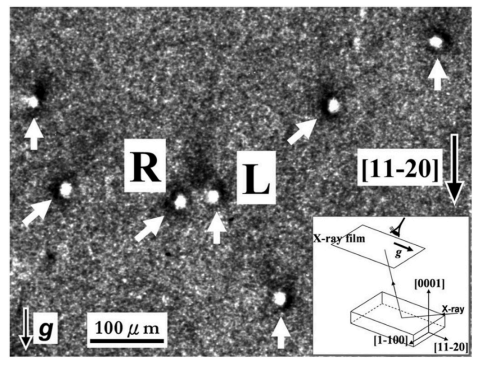

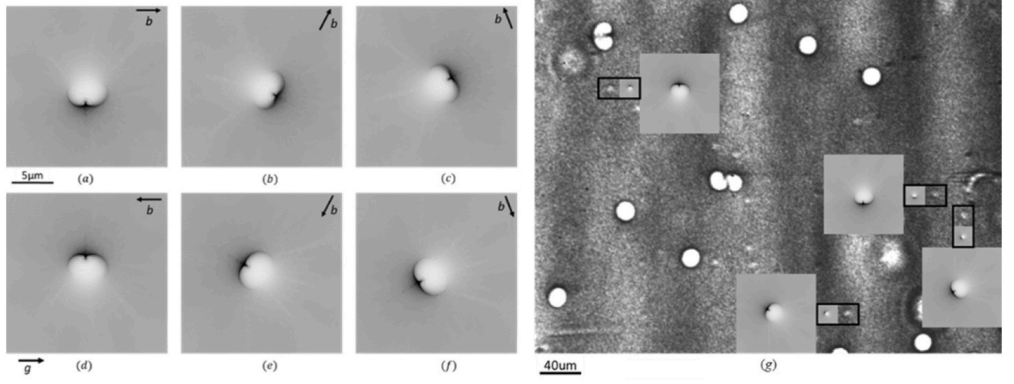

Fig. 3: Back-reflection X-ray topography mifananidzo ye micropipes (MPs) pane 6H-SiC wafer uye kusiyana kwekufananidza screw dislocation (b = 6c) pasi pemamiriro akafanana e diffraction.

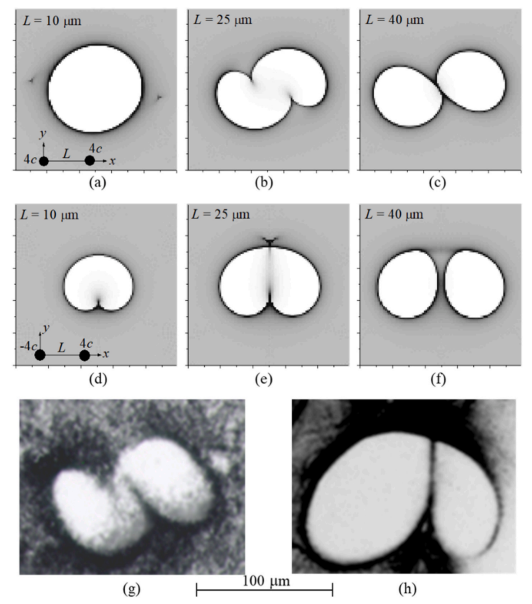

Mufananidzo 4: Micropipe pairs mumashure-reflection topography mufananidzo we6H-SiC wafer. Mifananidzo yemaMP mamwechete ane nzvimbo dzakasiyana uye maMP mumativi akasiyana anoratidzwa neray tracing simulations.

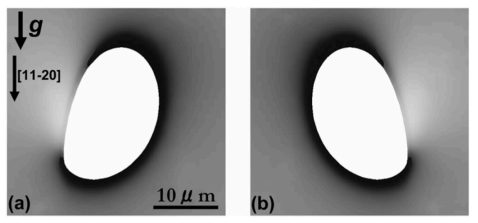

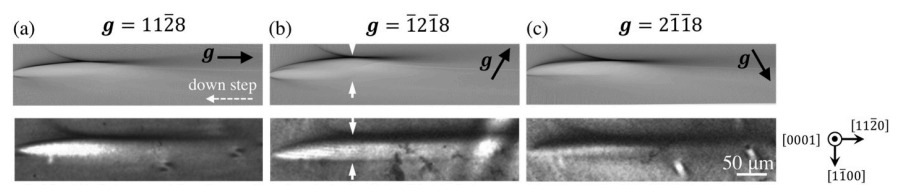

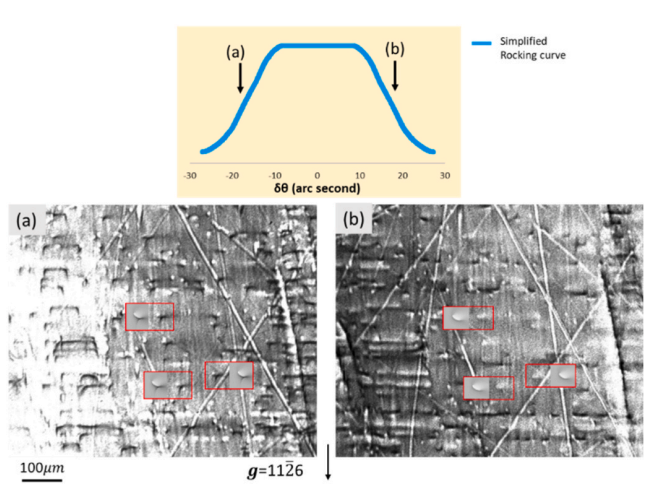

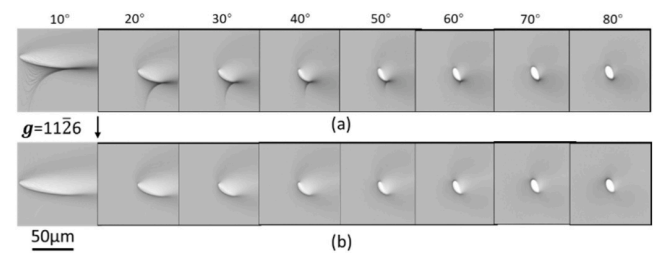

Mufananidzo 5: Chiitiko chemafuro X-ray topography mifananidzo yekuvhara-core screw dislocations (TSDs) pane 4H-SiC wafer inoratidzwa. Iyo mifananidzo inoratidza yakawedzera kumucheto musiyano.

Fig. 6: Ray tracing simulations yemafuro emafuro X-ray topography mifananidzo yeruboshwe nerudyi 1c TSDs pa4H-SiC wafer inoratidzwa.

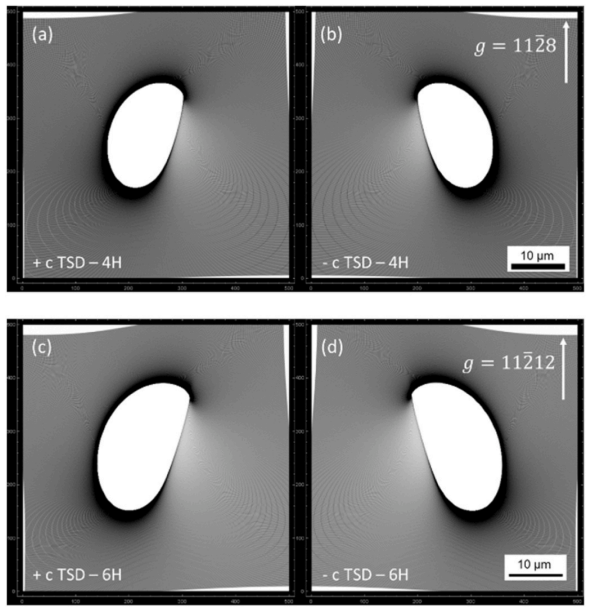

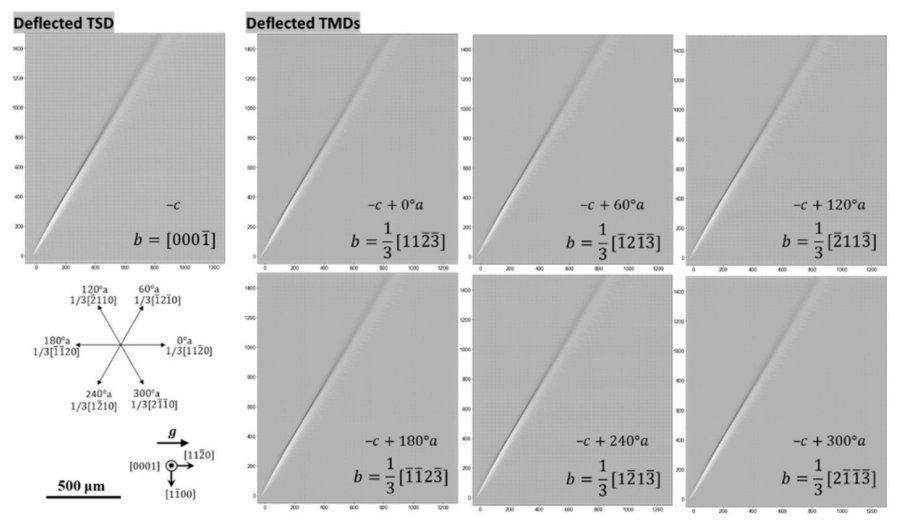

Mufananidzo 7: Ray tracing simulations yeTSDs mu4H-SiC uye 6H-SiC inoratidzwa, ichiratidza kuparadzaniswa neBurgers vectors yakasiyana uye polytypes.

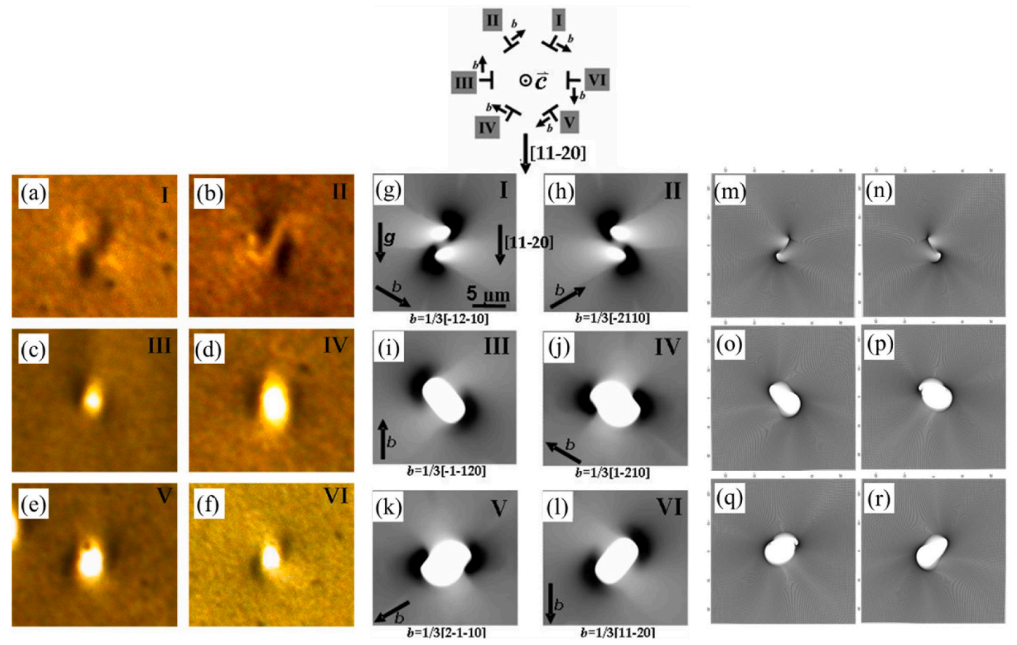

Mufananidzo 8: Inoratidza chiitiko chemafuro X-ray topological mifananidzo yemhando dzakasiyana dze threading edge dislocations (TEDs) pa 4H-SiC wafers, uye TED topological mifananidzo inofananidzwa uchishandisa ray tracing method.

Mufananidzo 9: Inoratidza X-ray back-reflection topological mifananidzo yemhando dzakasiyana-siyana dzeTED pa4H-SiC wafers, uye yakafananidzirwa TED kusiyana.

Fig. 10: Inoratidza ray tracing simulation mifananidzo yezvakasanganiswa threading dislocations (TMDs) ine chaiwo Burgers vectors, uye yekuedza topological mifananidzo.

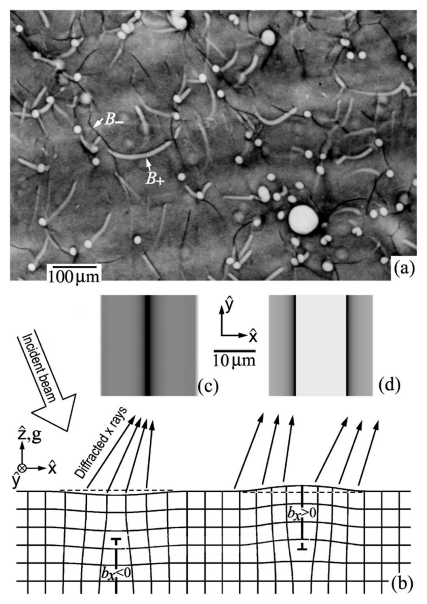

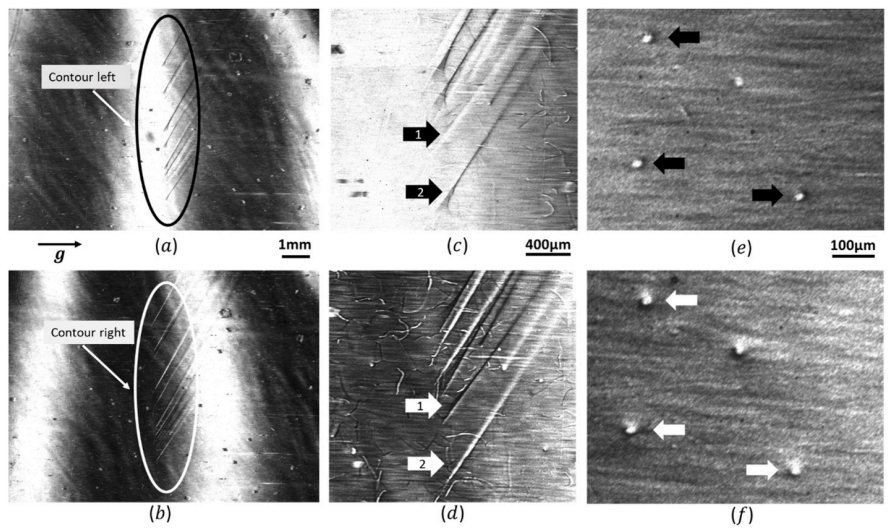

Mufananidzo 11: Inoratidza kumashure-reflection topological images of basal plane dislocations (BPDs) pa4H-SiC wafers, uye dhiyabhorosi dhiyagiramu yesimulated edge dislocation kusiyana kwakasiyana.

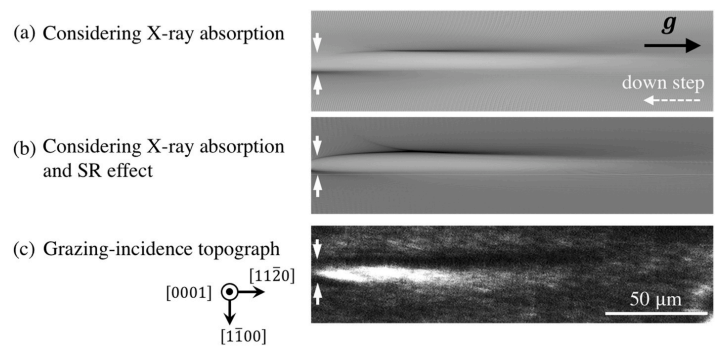

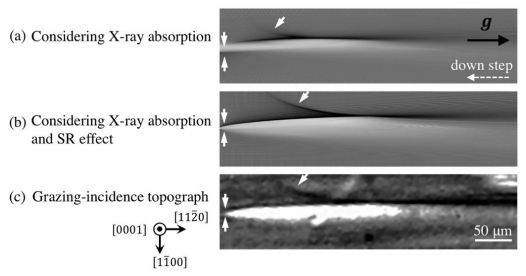

Fig. 12: Inoratidza ray tracing simulation mifananidzo yekurudyi-ruoko helical BPDs pakadzika kwakasiyana uchifunga nezvekuzorora kwepamusoro uye photoelectric absorption effects.

Fig. 13: Inoratidza ray tracing simulation mifananidzo yekurudyi-ruoko helical BPDs pakadzika kwakasiyana, uye mafuro chiitiko X-ray topological mifananidzo.

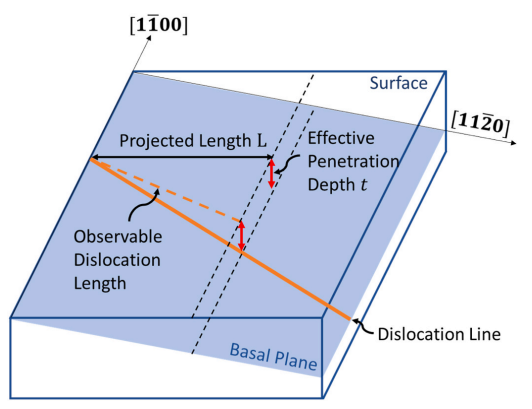

Fig. 14: Inoratidza dhiyabhorosi dhiyagiramu yebasal plane dislocations munzira ipi neipi pa4H-SiC wafers, uye maitiro ekuona kudzika kwekupinda nekuyera kureba kwekufungidzira.

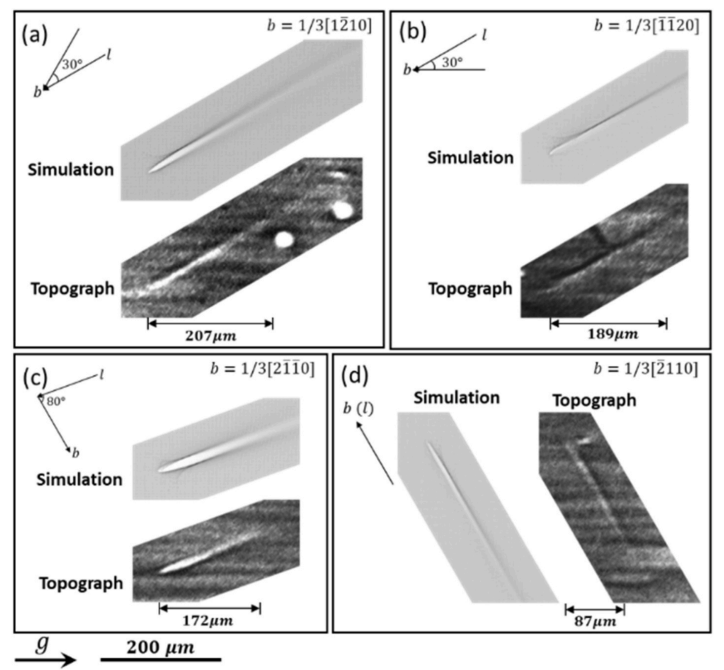

Fig. 15: Kusiyana kweBPDs neBurgers vectors yakasiyana-siyana uye nzira dzemutsara mune chiitiko chemafuro X-ray topological mifananidzo, uye inofananidzwa neray tracing simulation results.

Mufananidzo 16: The ray tracing simulation image yerudyi-ruoko rwakatsauka TSD pane 4H-SiC wafer, uye chiitiko chemafuro X-ray topological image inoratidzwa.

Mufananidzo 17: The ray tracing simulation uye yekuedza mufananidzo weTSD yakatsauka pane 8 ° offset 4H-SiC wafer inoratidzwa.

Fig. 18: The ray tracing simulation mifananidzo yeTSD yakatsauka uye TMDs ine akasiyana maBurgers vectors asi mutsara wakafanana unoratidzwa.

Fig. 19: The ray tracing simulation image of Frank-type dislocations, uye mafuro anoenderana chiitiko X-ray topological image inoratidzwa.

Mufananidzo 20: Iyo yakatumirwa chena beam X-ray topological mufananidzo wemicropipe pane 6H-SiC wafer, uye ray tracing simulation mufananidzo unoratidzwa.

Mufananidzo 21: Chiitiko chemafuro monochromatic X-ray topological image of axially cut sample of 6H-SiC, uye ray tracing simulation image yeBPDs inoratidzwa.

Mufananidzo 22: inoratidza ray tracing simulation mifananidzo yeBPDs mu6H-SiC axially cut samples pamakona akasiyana ezviitiko.

Mufananidzo 23: inoratidza ray tracing simulation mifananidzo yeTED, TSD uye TMDs mu6H-SiC axially cut samples pasi pemafuro chiitiko geometry.

Mufananidzo 24: inoratidza X-ray topological mifananidzo yeTSD yakatsauka kumativi akasiyana emutsara we isoclinic pane 4H-SiC wafer, uye ray inoenderana nemifananidzo yekufananidza.

Chinyorwa ichi ndechekugoverana kwedzidzo chete. Kana pane kukanganisa, tapota taura nesu kuti tibvise.

Nguva yekutumira: Jun-18-2024