Mune semiconductor yekugadzira maitiro,etchingtekinoroji inzira yakakosha iyo inoshandiswa kunyatso bvisa zvisingadiwe zvinhu pane substrate kuti iite yakaoma dunhu mapatani. Ichi chinyorwa chinozivisa maviri mainstream etching tekinoroji zvakadzama - capacitively akabatanidza plasma etching (CCP) uye inductively yakabatanidzwa plasma etching (ICP), uye ongorora mashandisiro avo mukuisa zvinhu zvakasiyana.

Capacitively yakabatanidzwa plasma etching (CCP)

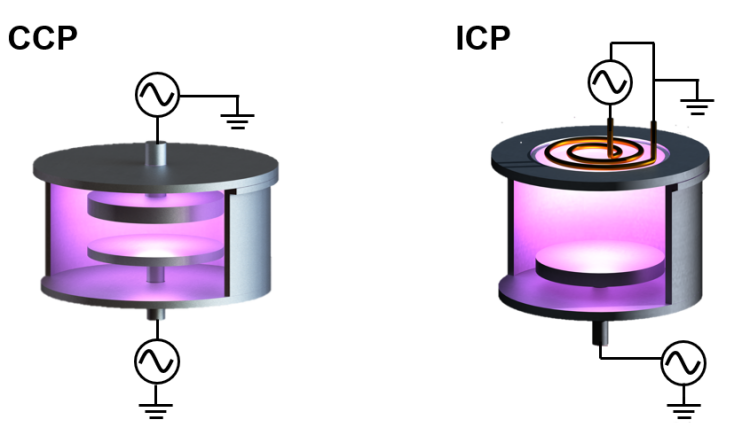

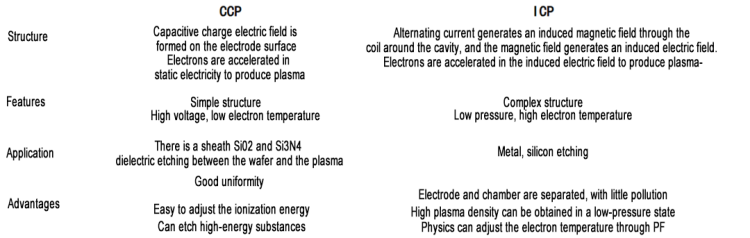

Capacitively yakabatana plasma etching (CCP) inowanikwa nekuisa iyo RF voltage kune maviri anoenderana plate maelectrode kuburikidza nematcher uye DC inovharira capacitor. Maelectrode maviri neplasma pamwe chete zvinoumba capacitor yakaenzana. Mukuita uku, iyo RF voltage inoumba capacitive sheath padyo ne electrode, uye muganho wesheath inoshanduka nekukurumidza oscillation yevoltage. Kana maerekitironi asvika ichi kukurumidza kuchinja sheath, anoratidzwa uye anowana simba, izvo zvinokonzeresa kuparadzaniswa kana ionization yemamorekuru egasi kuumba plasma. CCP etching inowanzoiswa kune zvinhu zvine akakwira makemikari bond simba, senge dielectrics, asi nekuda kweiyo yakaderera etching mwero, inokodzera maapplication anoda kutonga kwakanaka.

Inductively yakabatanidzwa plasma etching (ICP)

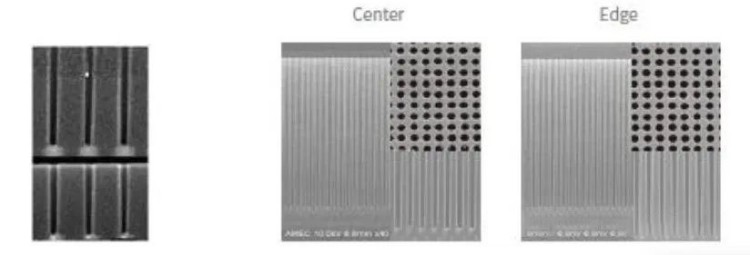

Inductively yakabatanidzwa plasmaetching(ICP) yakavakirwa pamusimboti wekuti alternating current inopfuura nepacoil kugadzira iyo induced magnetic field. Pasi pechiito cheiyi magineti, maerekitironi ari mukamuri rekuita anokwidziridzwa uye anoenderera mberi nekukasira mundima yemagetsi inokonzeresa, pakupedzisira achibonderana neanoita gasi mamorekuru, zvichiita kuti mamorekuru aparadzane kana kuti ionize uye agadzire plasma. Iyi nzira inogona kuburitsa yakakwira ionization rate uye inobvumira iyo plasma density uye bombardment simba kuti rigadziriswe zvakazvimirira, izvo zvinoita.ICP kugadzirisaakakodzera kwazvo etching zvinhu zvine yakaderera kemikari bond simba, senge silicon nesimbi. Uye zvakare, ICP tekinoroji inopawo zvirinani kufanana uye etching rate.

1. Metal etching

Metal etching inonyanya kushandiswa kugadzirisa yekubatanidza uye akawanda-layer simbi wiring. Zvazvinoda zvinosanganisira: high etching rate, high selectivity (yakakura kupfuura 4: 1 yemask layer uye yakakura kupfuura 20: 1 ye interlayer dielectric), high etching uniformity, yakanaka yakakosha dimension control, hapana kukuvara kweplasma, zvishoma zvakasara zvinosvibisa, uye hapana ngura kune simbi. Metal etching inowanzo shandisa inductively yakabatana plasma etching michina.

•Aluminium etching: Aluminium ndiyo inonyanya kukosha waya zvinhu mukati uye kumashure nhanho dzekugadzira chip, ine zvakanakira kushoma kuramba, nyore kuisa uye etching. Aluminium etching inowanzoshandisa plasma inogadzirwa nechloride gasi (yakadai seCl2). Aluminium inopindirana neklorini kuti igadzire volatile aluminum chloride (AlCl3). Mukuwedzera, mamwe halides akadai SiCl4, BCl3, BBr3, CCl4, CHF3, etc. anogona kuwedzerwa kubvisa oxide layer pamusoro aruminiyamu pamusoro kuti nechokwadi etching zvakajairika.

• Tungsten etching: Mu-multi-layer metal wire interconnection structures, tungsten ndiyo simbi huru inoshandiswa pakubatanidza chikamu chepakati chechip. Fluorine-yakavakirwa kana chlorine-yakavakirwa magasi inogona kushandiswa etch simbi tungsten, asi fluorine-based magasi ane kusarudzika kwakashata kwesilicon oxide, nepo chlorine-based magasi (akadai seCCl4) ane sarudzo iri nani. Nitrogen inowanzowedzerwa kune gasi rekuita kuti uwane yakakwira etching glue selectivity, uye okisijeni inowedzerwa kuderedza kabhoni deposition. Etching tungsten ine chlorine-based gasi inogona kuwana anisotropic etching uye yakakwirira kusarudza. Iwo magasi anoshandiswa mukuomesa etching ye tungsten anonyanya SF6, Ar uye O2, pakati peiyo SF6 inogona kuodzwa muplasma kuti ipe fluorine maatomu uye tungsten yemakemikari kuita kuti ibudise fluoride.

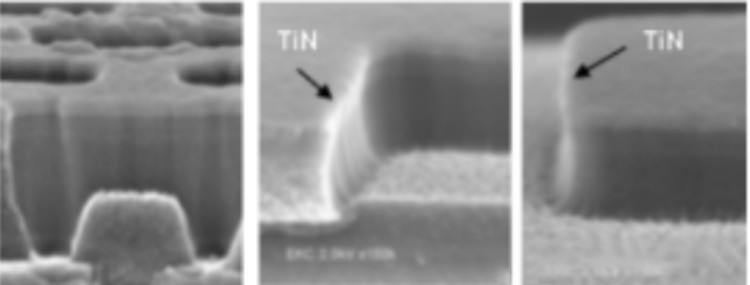

• Titanium nitride etching: Titanium nitride, sechinhu chakaoma chemasikisi, chinotsiva chinyakare silicon nitride kana oxide mask mune mbiri damascene process. Titanium nitride etching inonyanya kushandiswa mune yakaoma mask yekuvhura maitiro, uye chikuru chekuita chigadzirwa ndiTiCl4. Kusarudzwa pakati pemasikisi echinyakare uye pasi-k dielectric layer haina kukwirira, izvo zvinozotungamira pakuonekwa kwearc-shaped profile pamusoro peiyo yakaderera-k dielectric layer uye kuwedzera kwe groove upamhi mushure mekucheka. Nharaunda pakati pemitsara yesimbi yakadhipotwa idiki zvakanyanya, iyo inokonzeresa kudonha kwebhiriji kana kuputsika kwakananga.

2. Insulator etching

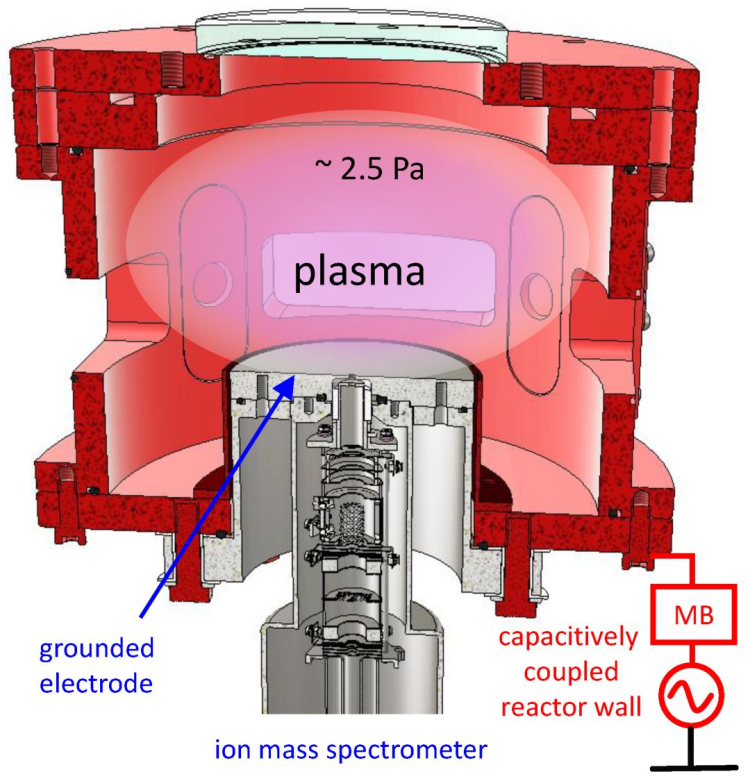

Chinhu che insulator etching chinowanzoita dielectric zvinhu zvakaita sesilicon dioxide kana silicon nitride, iyo inoshandiswa zvakanyanya kugadzira maburi ekusangana uye maburi echiteshi kubatanidza mativi edunhu akasiyana. Dielectric etching inowanzo shandisa etcher yakavakirwa pamusimboti wecapacitively yakasanganiswa plasma etching.

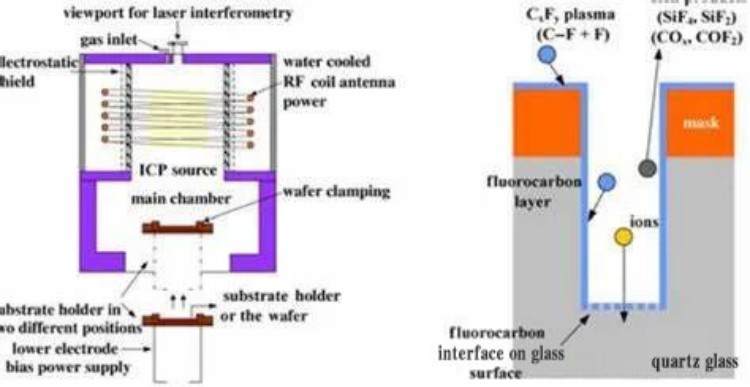

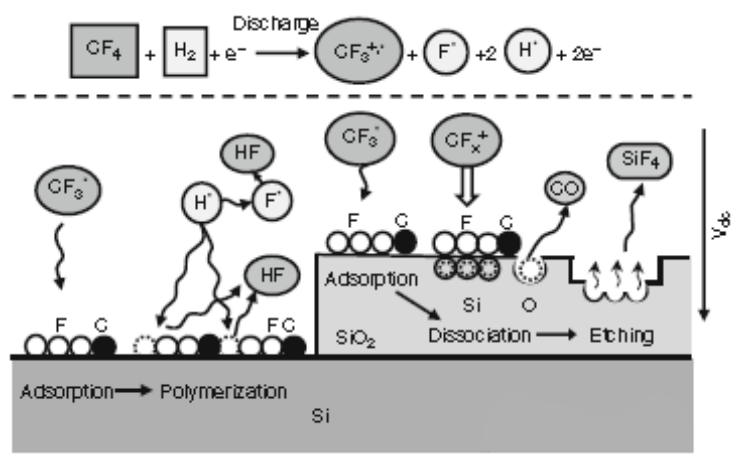

• Plasma etching yesilicon dioxide firimu: Silicon dioxide firimu rinowanzoiswa uchishandisa etching magasi ane fluorine, akadai CF4, CHF3, C2F6, SF6 uye C3F8. Iyo kabhoni iri mu etching gasi inogona kuita neokisijeni iri muoxyde layer kuti ibudise byproducts CO uye CO2, nokudaro ichibvisa okisijeni muokisidhi layer. CF4 ndiyo inonyanya kushandiswa etching gasi. Kana CF4 yadhumhana nemaerekitironi ane simba guru, maion akasiyana, radicals, maatomu uye mahara radicals anogadzirwa. Fluorine yemahara radicals inogona kuita kemikari neSiO2 uye Si kuti ibudise volatile silicon tetrafluoride (SiF4).

• Plasma etching yesilicon nitride firimu: Silicon nitride firimu rinogona kuiswa pachishandiswa plasma etching neCF4 kana CF4 yakasanganiswa gasi (ine O2, SF6 uye NF3). Kune Si3N4 firimu, apo CF4-O2 plasma kana imwe gasi plasma ine F maatomu inoshandiswa pakucheka, etching rate yesilicon nitride inogona kusvika 1200Å/min, uye etching selectivity inogona kusvika pa20:1. Chigadzirwa chikuru chinoputika silicon tetrafluoride (SiF4) iri nyore kubviswa.

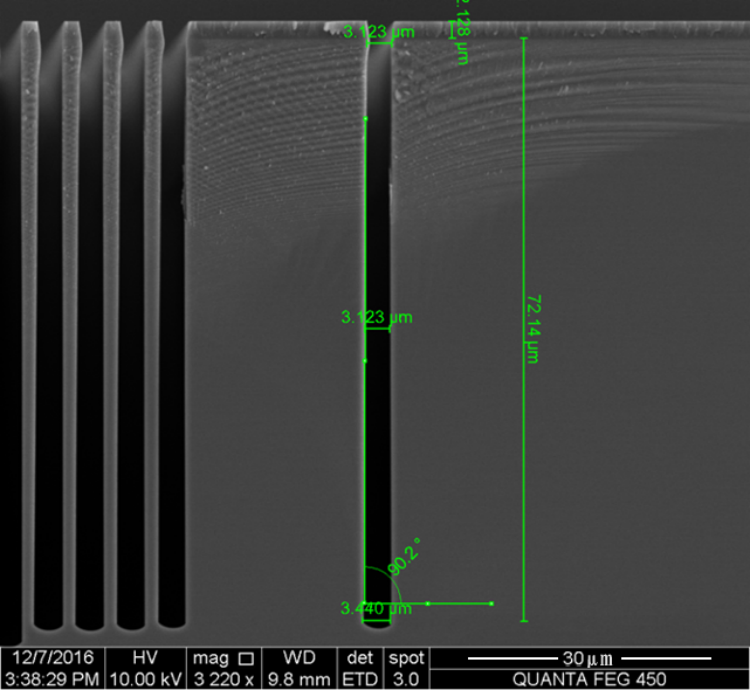

3. Single crystal silicon etching

Single crystal silicon etching inonyanya kushandiswa kugadzira shallow trench isolation (STI). Iyi nzira inowanzobatanidza nzira yekubudirira uye huru etching maitiro. Nzira yekubudirira inoshandisa SiF4 uye NF gasi kubvisa oxide layer pamusoro peimwe crystal silicon kuburikidza neiyoni yakasimba bombardment uye kemikari chiito che fluorine elements; iyo huru etching inoshandisa hydrogen bromide (HBr) seyakanyanya etchant. Iyo bromine radicals yakaora neHBr munzvimbo yeplasma inoita nesilicon kuti iite volatile silicon tetrabromide (SiBr4), nokudaro ichibvisa silicon. Imwe crystal silicon etching inowanzo shandisa inductively yakabatana plasma etching muchina.

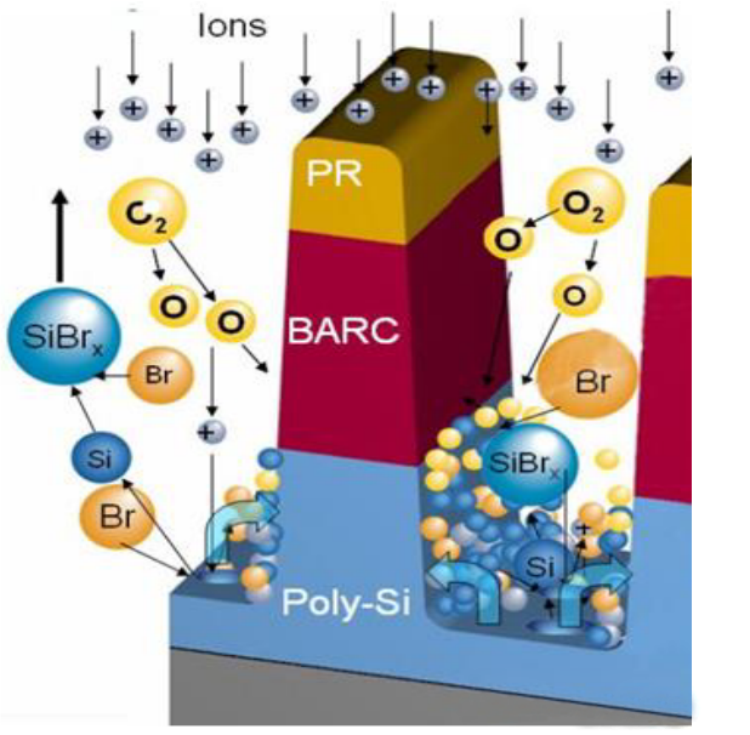

4. Polysilicon Etching

Polysilicon etching ndeimwe yeakakosha maitiro anosarudza saizi yegedhi rema transistors, uye saizi yegedhi inokanganisa zvakananga kuita kwemaseketi akabatanidzwa. Polysilicon etching inoda yakanaka selectivity ratio. Halogen magasi akadai seklorini (Cl2) anowanzo shandiswa kuita anisotropic etching, uye ane yakanaka selectivity ratio (kusvika 10: 1). Bromine-based magasi akadai sehydrogen bromide (HBr) anogona kuwana yakakwirira selectivity ratio (kusvika 100: 1). Musanganiswa weHBr neklorini uye okisijeni unogona kuwedzera mwero wekucheka. Izvo zvinogadziriswa zvigadzirwa zvehalogen gasi uye silicon zvakaiswa pamadziro emadziro kuita basa rekudzivirira. Polysilicon etching inowanzo shandisa inductively yakabatana plasma etching muchina.

Kunyangwe iri capacitively yakabatana plasma etching kana inductively yakabatana plasma etching, imwe neimwe ine yayo yakasarudzika mabhenefiti uye hunyanzvi hunhu. Kusarudza yakakodzera etching tekinoroji haingogone kuvandudza kugadzirwa kwakanaka, asi zvakare kuve nechokwadi chegoho rechigadzirwa chekupedzisira.

Nguva yekutumira: Nov-12-2024