Mukugadzira semiconductor, pane nzira inonzi "etching" panguva yekugadziriswa kwe substrate kana firimu rakaonda rakaumbwa pane substrate. Kuvandudzwa kwehunyanzvi hwekugadzira tekinoroji kwaita basa mukuona kufanotaura kwakaitwa naIntel muvambi Gordon Moore muna 1965 kuti "kusanganiswa kwemagetsi emagetsi kuchapeta mumakore 1.5 kusvika maviri" (inowanzozivikanwa se "Moore's Law").

Etching haisi "yekuwedzera" maitiro sekuisa kana kubatanidza, asi "kubvisa" maitiro. Mukuwedzera, maererano nenzira dzakasiyana-siyana dzekuchera, yakakamurwa kuva mapoka maviri, anoti "wet etching" uye "dry etching". Kuzvitaura zviri nyore, yekutanga inzira yekunyunguduka uye yekupedzisira inzira yekuchera.

Muchikamu chino, tichatsanangura muchidimbu maitiro uye mutsauko wega wega etching tekinoroji, wet etching uye yakaoma etching, pamwe nenzvimbo dzekushandisa iyo imwe neimwe yakakodzera.

Mhedziso ye etching process

Etching tekinoroji inonzi yakatanga kuEurope pakati pezana ramakore rechi 15. Panguva iyoyo, asidhi yakadirwa mundiro yemhangura yakavezwa kuti iparadze mhangura isina chinhu, ichiita intaglio. Nzira dzekurapa dzepamusoro dzinoshandisa mhedzisiro yekuora dzinozivikanwa zvakanyanya se "etching."

Chinangwa cheiyo etching process mukugadzira semiconductor ndeyekucheka substrate kana firimu pane substrate zvinoenderana nekudhirowa. Nekudzokorora matanho ekugadzirira ekugadzira firimu, photolithography, uye etching, iyo planar chimiro chinogadziriswa kuita matatu-dimensional chimiro.

Musiyano pakati pekunyorova etching uye yakaoma etching

Mushure mekuita photolithography, iyo yakafumurwa substrate yakanyorova kana yakaoma yakadzikwa mune etching process.

Wet etching inoshandisa mhinduro kupinza uye kukwenya kubva pamusoro. Kunyange zvazvo nzira iyi inogona kugadziriswa nokukurumidza uye zvakachipa, kuipa kwayo ndeyokuti kunyatsogadzirisa kwakaderera zvishoma. Nokudaro, etching yakaoma yakazvarwa makore ekuma 1970. Dry etching haishandisi mhinduro, asi inoshandisa gasi kurova pasi pe substrate kuti iparadze, iyo inoratidzirwa nepamusoro-soro yekugadzirisa.

"Isotropy" uye "Anisotropy"

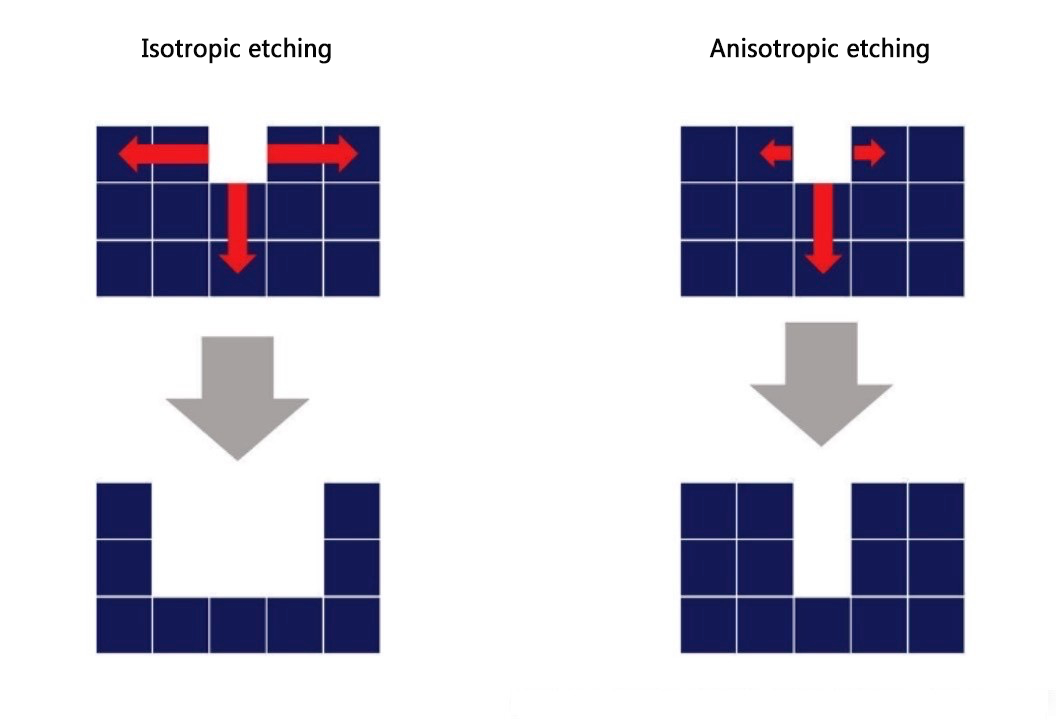

Pakuunza mutsauko pakati pekunyorova uye kuomeswa kwemazwi, mazwi akakosha ndeekuti "isotropic" uye "anisotropic". Isotropy zvinoreva kuti hunhu hwematter uye nzvimbo haashanduke negwara, uye anisotropy zvinoreva kuti chimiro chechinhu nechadenga chinosiyana negwara.

Isotropic etching zvinoreva kuti etching inoenderera nechiyero chakafanana kutenderedza imwe nzvimbo, uye anisotropic etching zvinoreva kuti etching inoenderera nenzira dzakasiyana dzakatenderedza imwe nzvimbo. Semuyenzaniso, mukugadzira panguva yekugadzira semiconductor, anisotropic etching inowanzosarudzwa kuitira kuti chete kwainotarirwa kunokweshwa, ichisiya mamwe madirections.

Mifananidzo ye "Isotropic Etch" uye "Anisotropic Etch"

Mifananidzo ye "Isotropic Etch" uye "Anisotropic Etch"

Wet etching uchishandisa makemikari.

Wet etching inoshandisa kemikari kuita pakati pekemikari uye substrate. Neiyi nzira, anisotropic etching haigoneke, asi yakanyanya kuoma kupfuura isotropic etching. Pane zvakawanda zvirambidzo pakusanganiswa kwemhinduro uye zvinhu, uye mamiriro akadai seye substrate tembiricha, kugadziriswa kwemhinduro, uye huwandu hwekuwedzera hunofanirwa kudzorwa zvakanyanya.

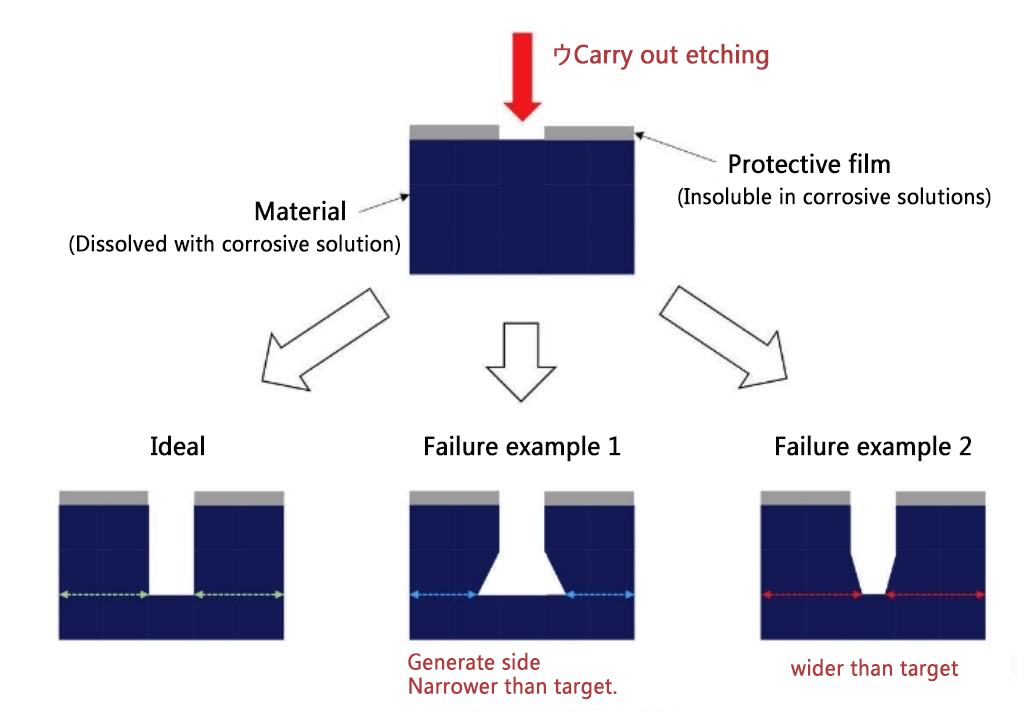

Hazvina mhosva kuti mamiriro acho akagadziridzwa sei, wet etching yakaoma kuwana yakanaka kugadzirisa pazasi 1 μm. Chimwe chikonzero cheizvi ndiko kudiwa kwekudzora mativi etching.

Undercutting chiitiko chinonziwo undercutting. Kunyangwe kana zvichitarisirwa kuti zvinhu zvichanyungudutswa chete mugwara rakamira (yakadzika kutungamira) nekunyorova etching, hazvibviri kudzivirira zvachose mhinduro kubva pakurova mativi, saka kuparara kwezvinhu munzira yakafanana kunoenderera mberi. . Nekuda kwechiitiko ichi, wet etching inoburitsa zvisina tsarukano zvikamu zvakatetepa pane zvakanangwa hupamhi. Nenzira iyi, kana uchigadzira zvigadzirwa zvinoda kunyatso kudzora ikozvino, kubereka kwakaderera uye iko kurongeka hakuna kuvimbika.

Mienzaniso Yekutadza Kunogoneka muWet Etching

Mienzaniso Yekutadza Kunogoneka muWet Etching

Nei yakaoma etching yakakodzera micromachining

Tsanangudzo yeInoenderana Art Dry etching yakakodzera anisotropic etching inoshandiswa mumasemiconductor ekugadzira maitiro anoda yakakwirira-chaiyo kugadzirisa. Dry etching inowanzonzi reactive ion etching (RIE), iyo inogonawo kusanganisira plasma etching uye sputter etching mupfungwa yakafara, asi chinyorwa ichi chichatarisa paRIE.

Kuti utsanangure kuti sei anisotropic etching iri nyore neyakaoma etching, ngatitarisei zvakanyanya maitiro eRIE. Zviri nyore kunzwisisa nekupatsanura maitiro ekuomesa etching uye kukwenya kubva substrate kuita marudzi maviri: "chemical etching" uye "physical etching".

Kemikari etching inoitika mumatanho matatu. Chekutanga, magasi anoshanda ari adsorbed pamusoro. Zvigadzirwa zveaction zvinozoumbwa kubva kune reaction gasi uye substrate zvinhu, uye pakupedzisira maitiro ekuita anobviswa. Mune inotevera etching yemuviri, iyo substrate inomisikidzwa yakatwasuka pasi nekuisa argon gasi rakamira kune substrate.

Kemikari etching inoitika isotropically, nepo etching yemuviri inogona kuitika anisotropically nekudzora gwara rekushandisa gasi. Nekuda kweiyo etching yemuviri, yakaoma etching inobvumira kutonga kwakawanda pamusoro peiyo etching nzira pane kunyorova etching.

Yakaoma uye yakanyorova etching inodawo mamiriro akaenzana akasimba seyakanyorova etching, asi ine yakakwira kuberekana pane kunyorova etching uye ine zvakawanda zviri nyore-kudzora zvinhu. Naizvozvo, hapana kupokana kuti yakaoma etching inonyanya kubatsira mukugadzirwa kwemaindasitiri.

Nei Wet Etching Ichiri Kudikanwa

Paunenge uchinge wanzwisisa iyo inoita seine masimba ese yakaoma etching, unogona kushamisika kuti nei wet etching ichiripo. Nekudaro, chikonzero chiri nyore: kunyorova etching kunoita kuti chigadzirwa chidhure.

Musiyano mukuru pakati pekuoma etching uye wet etching mutengo. Makemikari anoshandiswa mukunyorova etching haana kudhura kudaro, uye mutengo wemidziyo pachayo unonzi ungangoita 1/10 weiyo yakaoma etching michina. Mukuwedzera, iyo nguva yekugadzirisa ipfupi uye akawanda substrates anogona kugadziriswa panguva imwe chete, kuderedza mari yekugadzira. Nekuda kweizvozvo, tinokwanisa kuchengetedza mutengo wezvigadzirwa zvakaderera, zvichitipa mukana pamusoro pevakwikwidzi vedu. Kana izvo zvinodikanwa zvekugadzirisa kurongeka zvisina kukwirira, makambani mazhinji anozosarudza wet etching ye rough mass production.

Iyo etching process yakaunzwa senzira inoita basa mu microfabrication tekinoroji. Iyo etching process yakakamurwa kuita wet etching uye yakaoma etching. Kana mari yakakosha, yekare iri nani, uye kana microprocessing iri pasi pe1 μm inodiwa, iyo yekupedzisira iri nani. Nenzira yakanaka, nzira inogona kusarudzwa zvichienderana nechigadzirwa chinogadzirwa uye mari, pane kuti ndeipi iri nani.

Nguva yekutumira: Kubvumbi-16-2024