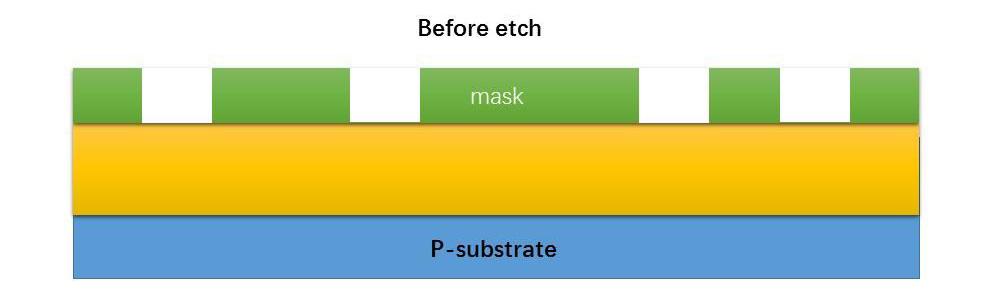

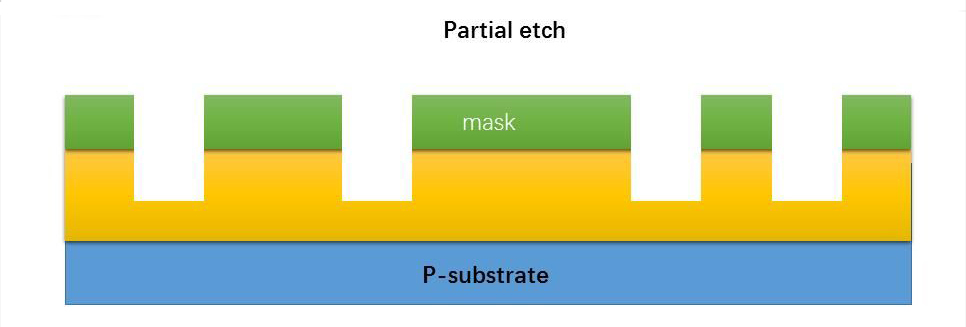

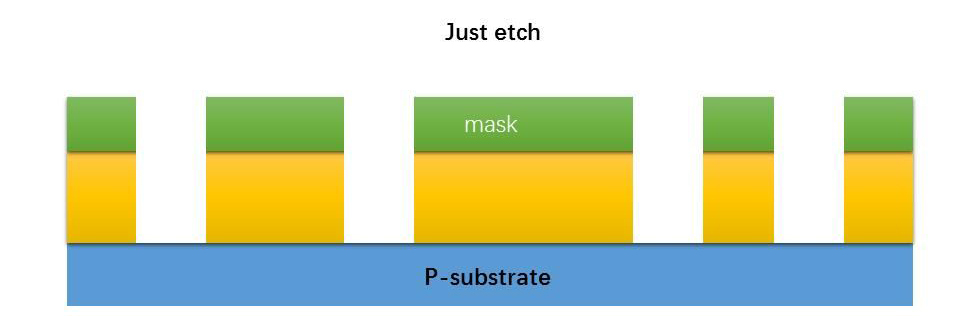

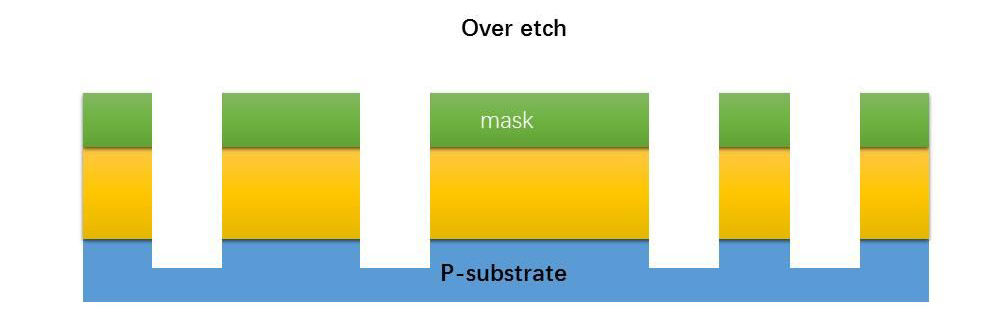

Dry etching process inowanzo sanganisira mana ekutanga maitirwo: pamberi etching, chikamu etching, etching chete, uye pamusoro etching. Hunhu hukuru ndeye etching rate, selectivity, yakakosha dimension, kufanana, uye endpoint yekuona.

Mufananidzo 1 Asati etching

Mufananidzo 2 Partial etching

Mufananidzo 3 Kungonyora chete

Mufananidzo 4 Pamusoro pekucheka

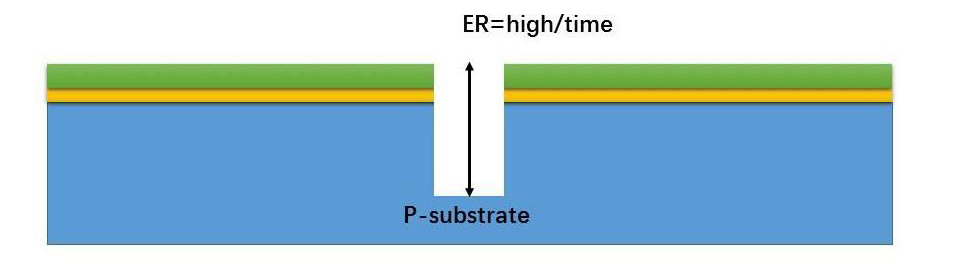

(1) Etching rate: kudzika kana ukobvu hweiyo etched material yakabviswa pane imwe unit nguva.

Mufananidzo 5 Etching rate diagram

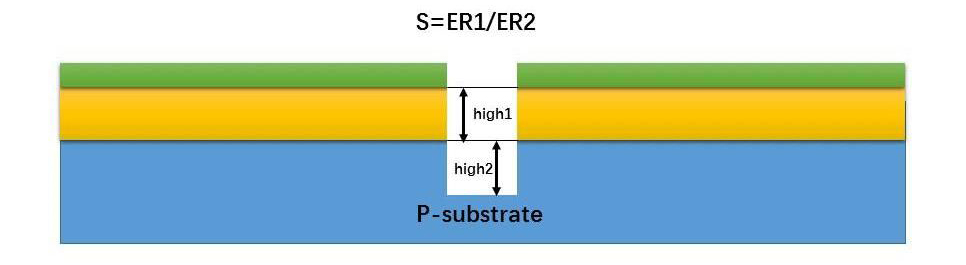

(2) Kusarudzwa: chiyero che etching mareti eakasiyana etching zvinhu.

Mufananidzo 6 Selectivity diagram

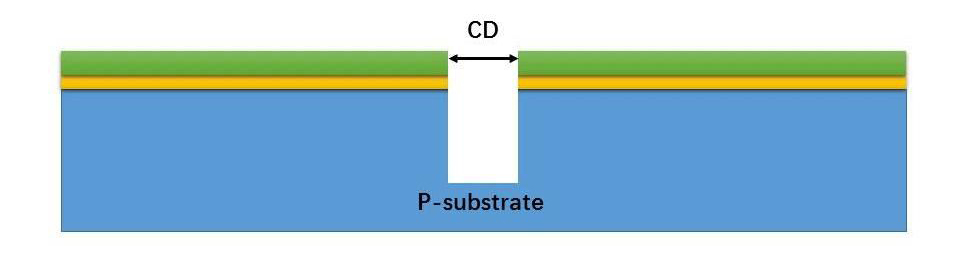

(3) Chiyero chakakosha: ukuru hwepateni mune imwe nzvimbo mushure mekuti etching yapera.

Mufananidzo 7 Critical dimension diagram

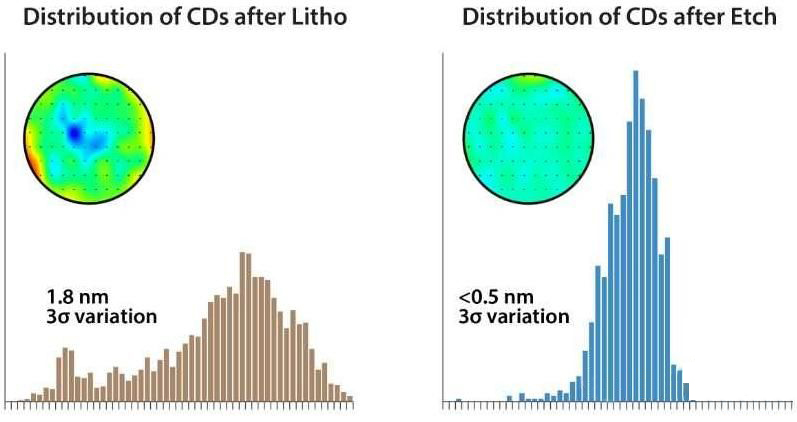

(4) Uniformity: kuyera kufanana kweiyo yakakosha etching dimension (CD), kazhinji inoratidzwa nemepu yakazara yeCD, fomula ndeiyi: U=(Max-Min)/2*AVG.

Mufananidzo 8 Uniformity Schematic Diagram

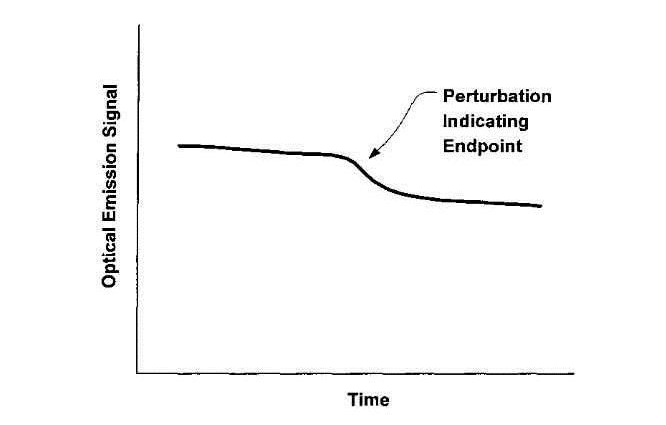

(5) Kupera kwekuona pfungwa: Panguva yekugadzira, shanduko yesimba rechiedza inogara ichionekwa. Kana kumwe kusimba kwechiedza kuchikwira kana kudonha zvakanyanya, iyo etching inomiswa kuratidza kupera kweimwe layer yefirimu etching.

Mufananidzo 9 End point schematic diagram

Mukuoma etching, iyo gasi inonakidzwa nepamusoro frequency (kunyanya 13.56 MHz kana 2.45 GHz). Pakumanikidzwa kwe1 kusvika ku100 Pa, nzira yayo yemahara ine mamirimita akati wandei kusvika masendimita akati wandei. Kune matatu makuru emhando dzekuoma etching:

•Physical dry etching: yakakwirisa zvimedu zvemuviri kupfeka wafer pamusoro

•Kemikari yakaoma etching: gasi rinosangana nemakemikari newafer pamusoro

•Kemikari yemuviri yakaoma etching: etching yemuviri maitiro ane makemikari maitiro

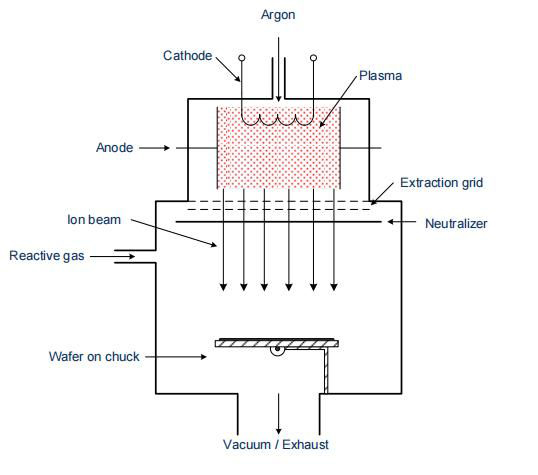

1. Ion danda rekucheka

Ion beam etching (Ion Beam Etching) inzira yakaoma yekugadzira iyo inoshandisa yakakwirira-simba argon ion danda ine simba rinoita 1 kusvika 3 keV kuvhenekera pamusoro pezvinhu. Simba reiyo danda rinoita kuti ribate uye ribvise zvinhu zvepamusoro. Iyo etching maitiro ndeye anisotropic mune yakamira kana oblique chiitiko ion matanda. Zvisinei, nekuda kwekushayikwa kwayo kwekusarudza, hapana mutsauko wakajeka pakati pezvigadzirwa pamatanho akasiyana. Iwo magasi anogadzirwa uye zvinhu zvakamisikidzwa zvakapedzwa nepombi yevacuum, asi sezvo maitiro ekuita asiri magasi, zvimedu zvinoiswa pawafer kana madziro ekamuri.

Kudzivirira kuumbwa kwezvikamu, yechipiri gasi inogona kuiswa mukamuri. Iyi gasi ichaita neiyo argon ions uye inokonzera muviri uye kemikari etching process. Chikamu chegasi chinozosangana nechinhu chepamusoro, asi chinozobatanawo neakakwenenzverwa zvimedu kuumba gasi byproducts. Anenge marudzi ese ezvishandiso anogona kugadzirwa nenzira iyi. Nekuda kwemwaranzi yakatwasuka, kupfeka pamadziro emadziro kudiki kwazvo (yakakwirira anisotropy). Nekudaro, nekuda kwekusarudzika kwayo uye kunonoka etching mwero, maitiro aya haawanzo shandiswa mune yazvino semiconductor kugadzira.

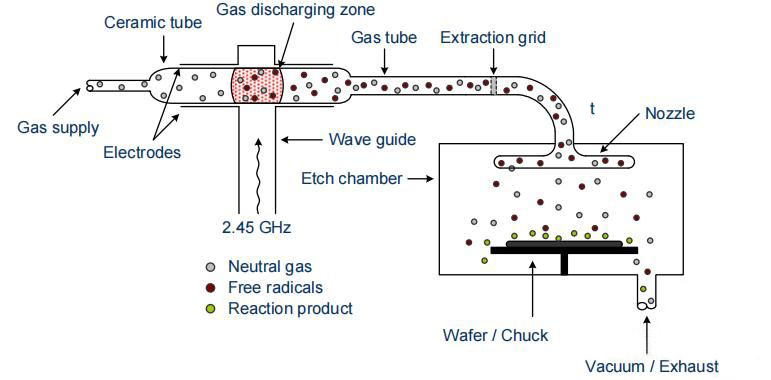

2. Plasma etching

Plasma etching is absolute chemical etching process, inozivikanwawo sekemikari yakaoma etching. Kubatsira kwayo ndeyekuti haikonzeri kukuvara kweion kune wafer pamusoro. Sezvo mhando dzinoshanda mumagetsi etching dzakasununguka kufamba uye etching process is isotropic, iyi nzira yakakodzera kubvisa iyo yose firimu layer (somuenzaniso, kuchenesa kuseri kwemashure mushure mekupisa oxidation).

A downstream reactor imhando ye reactor inowanzoshandiswa paplasma etching. Mune ino reactor, iyo plasma inogadzirwa nekukanganisa ionization mune yakakwira-frequency yemagetsi ndima ye2.45GHz uye yakaparadzaniswa newafer.

Munzvimbo yekuburitsa gasi, zvimedu zvakasiyana zvinogadzirwa nekuda kwekukanganisa uye kunakidzwa, kusanganisira mahara radicals. Mahara radicals maatomu asina kwaakarerekera kana mamorekuru ane maerekitironi asina unsaturated, saka ane reactive zvakanyanya. Muchirongwa cheplasma etching, mamwe magasi asina kwaakarerekera, akadai setetrafluoromethane (CF4), anowanzo shandiswa, ayo anounzwa munzvimbo inobuditsa gasi kugadzira marudzi anoshanda neionization kana kuora.

Semuenzaniso, muCF4 gasi, inounzwa munzvimbo yekuburitsa gasi uye yakaora kuita fluorine radicals (F) uye kabhoni difluoride mamorekuru (CF2). Saizvozvo, fluorine (F) inogona kuora kubva kuCF4 nekuwedzera oxygen (O2).

2 CF4 + O2 —> 2 COF2 + 2 F2

Iyo fluorine morekuru inogona kupatsanurwa kuita maviri akazvimirira maatomu efluorine pasi pesimba renzvimbo yekuburitsa gasi, imwe neimwe iri fluorine yemahara radical. Sezvo atomu imwe neimwe yefluorine ine maerekitironi manomwe evalence uye inoda kuzadzisa kugadzirwa kwemagetsi kwegasi inert, ese ari kuita zvakanyanya. Kuwedzera kune kwaakarerekera fluorine mahara radicals, pachava nekuchajiswa zvimedu zvakaita seCF + 4, CF + 3, CF + 2, nezvimwewo munzvimbo inobuda gasi. Zvadaro, zvese izvi zvimedu uye mahara radicals zvinounzwa mukamuri yekumisikidza kuburikidza neceramic chubhu.

Iwo akachajiswa zvimedu anogona kuvharwa nekubvisa gratings kana kubatanidzwazve mukuita kwekugadzira asina kwaarerekera mamorekuru kudzora maitiro avo mukamuri yekumisikidza. Fluorine yemahara radicals ichaitawo kudzokororwa zvishoma, asi ichiri kushanda zvakakwana kuti ipinde mukamuri yekumisikidza, inobata kemikari pane wafer pamusoro uye kukonzera kubviswa kwezvinhu. Mamwe mativi asina kwaakarerekera haatore chikamu mukuita etching uye anopedzwa pamwe chete nezvinoita zvigadzirwa.

Mienzaniso yemafirimu matete anogona kuiswa muplasma etching:

• Silicon: Si + 4F—> SiF4

• Silicon dioxide: SiO2 + 4F—> SiF4 + O2

• Silicon nitridi: Si3N4 + 12F—> 3SiF4 + 2N2

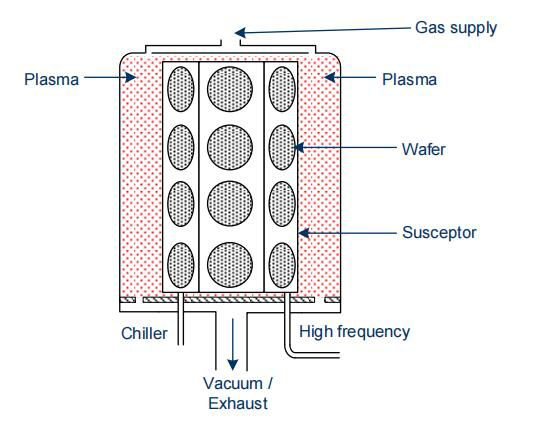

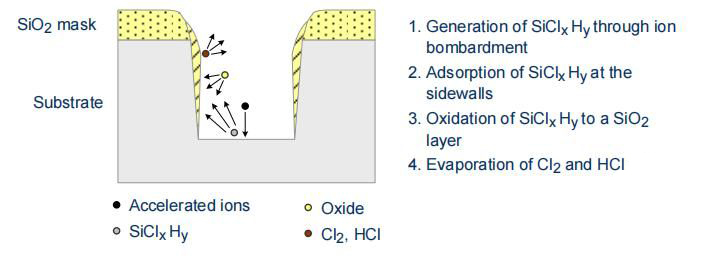

3.Reactive ion etching (RIE)

Reactive ion etching ikemikari-yemuviri etching maitiro ayo anogona kunyatso kudzora kusarudza, etching mbiri, etching rate, kufanana uye kudzokorora. Inogona kuwana isotropic uye anisotropic etching profiles uye saka ndeimwe yeakanyanya kukosha maitiro ekuvaka akasiyana akaonda mafirimu mukugadzira semiconductor.

Munguva yeRIE, chidimbu chinoiswa pane yakakwirira-frequency electrode (HF electrode). Kuburikidza nekukanganisa ionization, plasma inogadzirwa umo maerekitironi emahara uye maion anochajiwa aripo. Kana simba rakanaka rikaiswa kuHF electrode, maerekitironi emahara anoungana panzvimbo ye electrode uye haakwanise kusiya erekitirodhi zvakare nekuda kwekubatana kwawo kwerekitironi. Naizvozvo, maelectrodes anochajirwa ku -1000V (bias voltage) kuitira kuti maion anononoka arege kutevera kukurumidza kuchinja munda wemagetsi kune electrode ine chaji isina kunaka.

Munguva yeion etching (RIE), kana iyo nzira yemahara yeiyoni yakakwira, vanorova wafer pamusoro peinenge perpendicular direction. Nenzira iyi, iyo yakakurumidza ion inogogodza kunze zvinhu uye kugadzira kemikari inopindirana kuburikidza nekubata kwemuviri. Sezvo lateral sidewall isingakanganisike, iyo etch mbiri inoramba iine anisotropic uye kupfeka kwepamusoro kudiki. Nekudaro, iyo selectivity haina kunyanya kukwirira nekuti iyo etching yemuviri maitiro inoitikawo. Pamusoro pezvo, kukurumidza kweiyoni kunokonzeresa kukuvadzwa kune wafer pamusoro, izvo zvinoda kupisa kwekupisa kugadzirisa.

Iyo kemikari chikamu cheiyo etching process inopedzwa nemahara radicals inobata nepamusoro uye maion achirova zvinhu izvo kuti zvirege kudzoreredza pawafer kana madziro ekamuri, kudzivirira chiitiko chekudzokorora senge ion beam etching. Paunenge uchiwedzera kudzvinyirira kwegasi mukamuri ye etching, iyo nzira yemahara yeioni inoderedzwa, iyo inowedzera nhamba yekudhumhana pakati peiyoni uye mamorekuru egasi, uye ion inopararira munzira dzakasiyana. Izvi zvinoguma nekushomeka kwakananga etching, zvichiita kuti etching process iwedzere makemikari.

Anisotropic etch profiles inowanikwa nekupfuura pamadziro panguva yesilicon etching. Okisijeni inounzwa mukamuri yekumisikidza, iyo inopindirana nesilicon yakamiswa kuti igadzire silicon dioxide, inoiswa pamadziro eparutivi. Nekuda kweiyoni bhomba, iyo oxide layer panzvimbo yakachinjika inobviswa, ichibvumira iyo lateral etching process kuti ienderere mberi. Iyi nzira inogona kudzora chimiro cheiyo etch profiles uye kudzika kwemadziro emadziro.

Iyo etch rate inokanganiswa nezvinhu zvakaita sekumanikidza, HF jenareta simba, gasi rekuita, chaiyo gasi kuyerera uye tembiricha yewafer, uye mutsauko wayo unochengetwa pazasi 15%. Anisotropy inowedzera nekuwedzera HF simba, kudzikira kudzvanywa uye kudzikira tembiricha. Kufanana kweiyo etching process inotarwa negasi, electrode spacing uye electrode zvinhu. Kana kureba kwe electrode kuri kudiki, plasma haigone kuparadzirwa zvakaenzana, zvichikonzera kusafanana. Kuwedzera kureba kwe electrode kunoderedza chiyero che etching nekuti plasma inogoverwa muhuwandu hombe. Carbon ndiyo inofarirwa neelectrode material nekuti inoburitsa plasma yakavharwa yunifomu kuitira kuti mupendero wewafer ukanganiswe nenzira imwechete nepakati pechipfuwo.

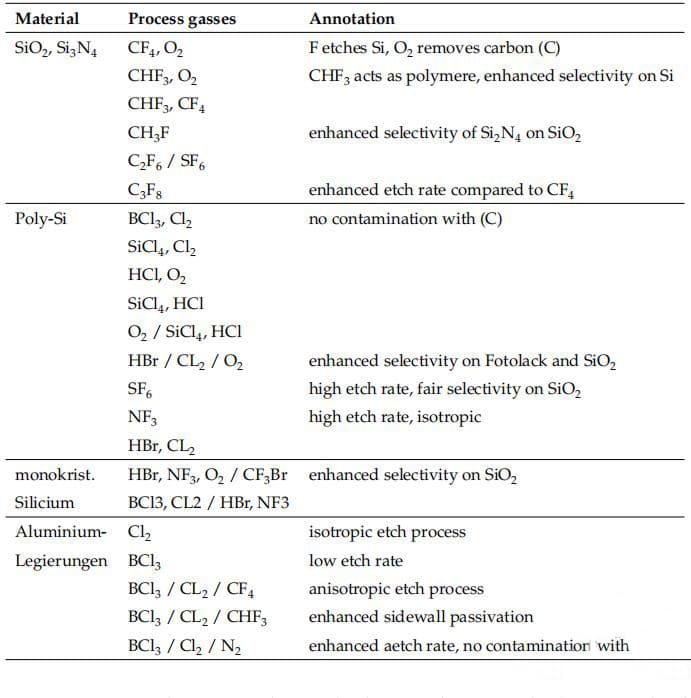

Iyo nzira gasi inoita basa rakakosha mukusarudza uye etching rate. Kune silicon nesilicon makomisheni, fluorine uye chlorine inonyanya kushandiswa kuita etching. Kusarudza gasi rakakodzera, kugadzirisa gasi kuyerera uye kudzvanywa, uye kudzora mamwe ma paramita akadai setembiricha uye simba mukuita kunogona kuwana inodiwa etch rate, selectivity, uye kufanana. Iko optimization yeaya ma parameter anowanzo kugadziridzwa kune akasiyana maapplication uye zvinhu.

Iyo etching process haina kuganhurirwa kune rimwe gasi, gasi musanganiswa, kana yakagadziriswa maitiro paramita. Semuenzaniso, iyo yekuzvarwa oxide pa polysilicon inogona kubviswa kutanga neyakakura etch chiyero uye yakaderera selectivity, nepo polysilicon inogona kunyorwa gare gare ine yakakwira selectivity maererano nezvikamu zvepasi.

—————————————————————————————————————————————————— ————————————

Semicera inogona kupagraphite zvikamu, kupfava/kuomarara kunzwa, silicon carbide zvikamu,CVD silicon carbide zvikamu,uyeSiC/TaC yakavharwa zvikamu nemazuva makumi matatu.

Kana iwe uchifarira zviri pamusoro semiconductor zvigadzirwa,ndapota usazeza kutibata nesu panguva yekutanga.

Tel: +86-13373889683

WhatsAPP:+86-15957878134

Email: sales01@semi-cera.com

Nguva yekutumira: Sep-12-2024