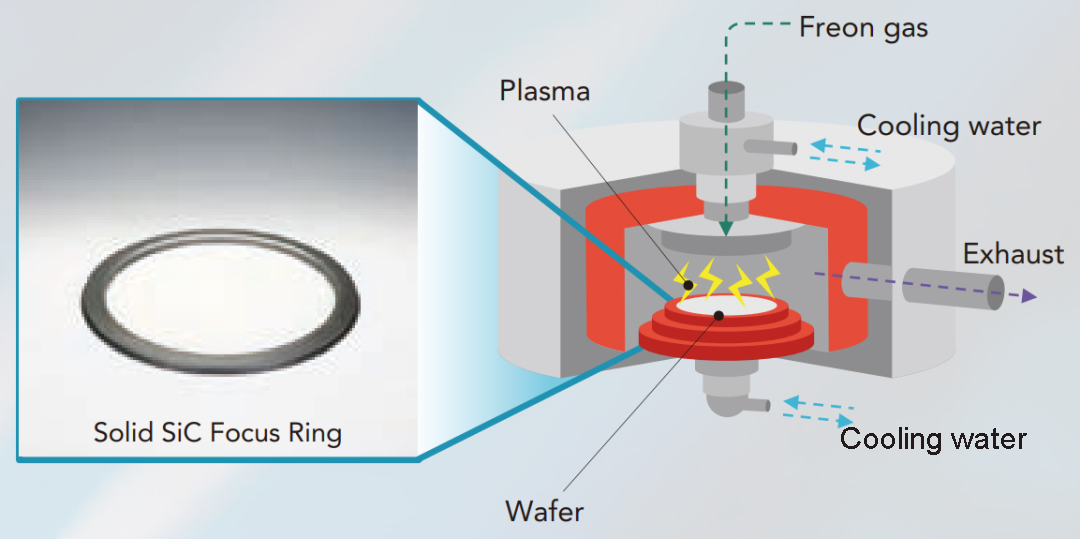

Mumidziyo yeplasma etching, zvinhu zveceramic zvinoita basa rakakosha, kusanganisira iyotarisa mhete.The tarisa mhete, yakaiswa yakatenderedza wafer uye yakanangana nayo, yakakosha pakuisa plasma pawafer nekuisa voltage kune mhete. Izvi zvinowedzera kufanana kwekuita etching.

Kushandiswa kweSiC Focus Mhete muEtching Machines

SiC CVD zvikamumumashini ekucheka, sengetarisa zvindori, gasi showerheads, maplatens, uye zvindori zvemupendero, zvinofarirwa nekuda kweSiC's low reactivity ine chlorine uye fluorine-based etching magasi uye maitiro ayo, zvichiita kuti ive yakanakira zvinhu zveplasma etching michina.

Zvakanakira SiC se Focus Mhete Material

Nekuda kwekuratidzwa kwakananga kuplasma mukamuri yevacuum reaction, mhete dzekutarisa dzinoda kugadzirwa kubva kuplasma-resistant zvinhu. Mhete dzechinyakare dzekutarisa, dzakagadzirwa kubva kusilicon kana quartz, dzinotambura nekusagadzikana etching kuramba mufluorine-based plasmas, zvichitungamira mukuora nekukurumidza uye kudzikisira kugona.

Kuenzanisa Pakati peSi neCVD SiC Focus Rings:

1. Higher Density:Inoderedza etching volume.

2. Wide Bandgap: Inopa yakanakisa insulation.

3. High Thermal Conductivity & Low Expansion Coefficient: Kudzivirira kuvhunduka kwekushisa.

4. Kunaka Kwepamusoro:Kuramba kwakanaka kune mechanical impact.

5. Kuoma Kwepamusoro: Kupfeka uye kusagadzikana-kuora.

SiC inogovera silicon's magetsi conductivity uku ichipa yakakwirira kuramba kune ionic etching. Sezvo yakabatanidzwa yedunhu miniaturization inofambira mberi, kudiwa kwemaitiro ekuita etching kunowedzera. Plasma etching midziyo, kunyanya iyo inoshandisa capacitive yakasanganiswa plasma (CCP), inoda yakakwira plasma simba, kugadzira.SiC yekutarisa zvindorikuwedzera kukurumbira.

Si uye CVD SiC Focus Mhete Paramita:

| Parameter | Silicon (Si) | CVD Silicon Carbide (SiC) |

| Density (g/cm³) | 2.33 | 3.21 |

| Band Gap (eV) | 1.12 | 2.3 |

| Thermal Conductivity (W/cm°C) | 1.5 | 5 |

| Thermal Expansion Coefficient (x10⁻⁶/°C) | 2.6 | 4 |

| Elastic Modulus (GPa) | 150 | 440 |

| Kuoma | Lower | Higher |

Kugadzira Maitiro eSiC Focus Mhete

Mune semiconductor midziyo, CVD (Chemical Vapor Deposition) inowanzoshandiswa kugadzira SiC zvikamu. Mhete dzekutarisa dzinogadzirwa nekuisa SiC mune chaiwo maumbirwo kuburikidza nemhute deposition, ichiteverwa nemakanika kugadzirisa kugadzira chigadzirwa chekupedzisira. Iyo reshiyo yemidziyo yekuisa mhute inogadziriswa mushure mekuyedza kwakawanda, ichiita maparamita senge resistivity inoenderana. Nekudaro, akasiyana etching midziyo inogona kuda mhete dzekutarisa dzine akasiyana resistivities, zvichidikanwa zviyedzo zvitsva zveyero yechinhu chimwe nechimwe, izvo zvinotora nguva uye zvinodhura.

NokusarudzaSiC yekutarisa zvindorikubvaSemicera Semiconductor, vatengi vanogona kuwana mabhenefiti enguva refu yekutsiva uye kuita kwepamusoro pasina kuwedzera kwakanyanya mumutengo.

Rapid Thermal Processing (RTP) Zvikamu

CVD SiC's yakasarudzika yekupisa zvivakwa inoita kuti ive yakakodzera kune RTP application. RTP zvikamu, zvinosanganisira zvindori zvemupendero uye maplatens, zvinobatsira kubva kuCVD SiC. Munguva yeRTP, kupisa kwakanyanya kupisa kunoshandiswa kune ega ega kwenguva pfupi, achiteverwa nekukurumidza kutonhora. CVD SiC edge zvindori, kuve mutete uye kuve nemafuta mashoma ekupisa, haachengete kupisa kwakakosha, zvichiita kuti asakanganiswa nekukurumidza kupisa uye kutonhora maitiro.

Plasma Etching Zvikamu

CVD SiC's high chemical resistance inoita kuti ive yakakodzera etching application. Mazhinji etching makamuri anoshandisa CVD SiC gasi rekugovera mahwendefa kugovera etching magasi, ane zviuru zvemakomba madiki ekuparadzira plasma. Kuenzaniswa nezvimwe zvinhu, CVD SiC ine yakaderera reactivity ine chlorine uye fluorine magasi. Mune yakaoma etching, CVD SiC zvikamu senge mhete dzekutarisa, ICP maplatens, muganhu mhete, uye showerheads zvinowanzo shandiswa.

SiC inotarisa mhete, ine voltage yavo yakashandiswa yeplasma inotarisisa, inofanirwa kuve nekuita kwakakwana. Inowanzo gadzirwa nesilicon, mhete dzekutarisa dzinoratidzwa kune reactive magasi ane fluorine uye chlorine, zvichitungamira mukuora kusingadzivisike. SiC inotarisa mhete, ine kukwirira kwayo kusimba kwekudzivirira, inopa hupenyu hurefu kana ichienzaniswa nemhete dzesilicon.

Lifecycle Kuenzanisa:

SiC Focus Mhete:Yakatsiviwa mazuva gumi nemashanu kusvika makumi maviri.

· Silicon Focus Mhete:Yakatsiviwa mazuva gumi kusvika gumi nemaviri.

Kunyangwe zvindori zveSiC zviri 2 kusvika ku3 zvakapetwa kudhura kupfuura zvindori zvesilicon, iyo yakawedzera kudzoreredza kutenderera inodzikisa yakazara chikamu chekutsiva mutengo, sezvo zvikamu zvese zvekupfeka mukamuri zvinotsiviwa panguva imwe chete kana kamuri yavhurwa kuti itarise mhete yekutsiva.

Semicera Semiconductor's SiC Focus Mhete

Semicera Semiconductor inopa SiC yekutarisa mhete pamitengo iri padyo neiyo yesilicon mhete, ine nguva yekutungamira yeanenge mazuva makumi matatu. Nekubatanidza Semicera's SiC yekutarisa mhete mumidziyo yeplasma etching, kushanda nesimba uye hupenyu hurefu hunovandudzwa zvakanyanya, kuderedza mutengo wekugadzirisa uye kuwedzera hunyanzvi hwekugadzira. Pamusoro pezvo, Semicera inogona kugadzirisa iyo resistivity yekutarisa mhete kuti isangane nezvinodiwa nevatengi.

Nekusarudza SiC yekutarisa mhete kubva kuSemicera Semiconductor, vatengi vanogona kuwana mabhenefiti ekurebesa kutsiva kutenderera uye kuita kwepamusoro pasina kuwedzera kwakanyanya mumutengo.

Nguva yekutumira: Jul-10-2024