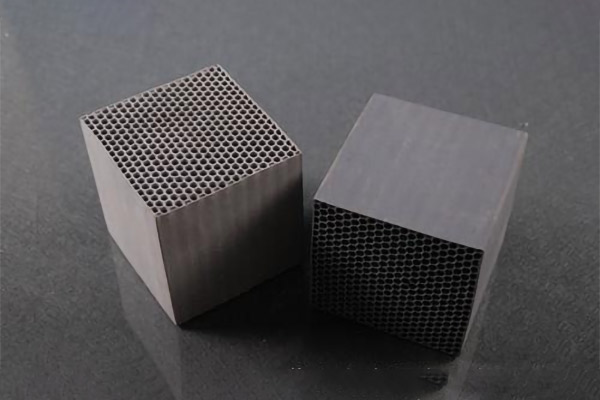

[Pfupiso tsananguro] Atmospheric pressure sinteredsilicon carbideis a non-metallic carbide yakasanganiswa nesilicon uye carbon covalent bonds, uye kuoma kwayo ndeyechipiri kune diamond uye boron carbide. Iyo kemikari formula ndeyeSiC. Makristasi asina ruvara, bhuruu uye dema pakutaridzika kana akaiswa oxidized kana aine tsvina.

Atmospheric pressure yakanyurasilicon carbideis a non-metallic carbide ine silicon uye kabhoni covalent bond, uye kuoma kwayo ndeyechipiri kune diamond uye boron carbide. Iyo kemikari formula ndeyeSiC. Makristasi asina ruvara, bhuruu uye dema pakutaridzika kana akaiswa oxidized kana aine tsvina. Iyo deformation yesilicon carbidenedhaimani chimiro chinowanzonzi emery. Kuomarara kwe emery kuri pedyo nedhaimondi, kugadzikana kwakanaka kwekupisa, kugadzikana kune hydroxy acid aqueous solution uye yakanyura sulfuric acid, uye kusagadzikana kune yakasanganiswa asidhi kana phosphoric asidhi yeconcentrated hydrogen acid uye nitric acid. Alkalis inonyunguduka mumhepo ine mhango inosiyanisa. Yakakamurwa kuita syntheticsilicon carbideuye yakasikwa silicon carbide. Natural silicon carbide, inozivikanwa secarbonite, inonyanya kuwanikwa mu kimberlite uye volcanic amphibolite, asi huwandu hwayo hudiki uye haina kukosha kwekuchera.

Industrial atmospheric pressure yakanyurasilicon carbidemusanganiswa we -SiC uye -SiC uye inouya nemavara maviri: dema uye girini. Yakachena silicon carbide haina ruvara, ine tsvina itema, girini, bhuruu, yero. Hexagonal uye cubic zviyo muganho, iyo kristaro iplate, komboni mbiru. Girazi rinopenya, density 3.17-3.47G/CM3, Morse kuoma 9.2, maikorosikopu zvakare pa 30380 ~ 33320MPa melting point: atmospheric 2050 yakatanga kusiyanisa, kupora mhepo 2600 yakatanga kusiyanisa. Iyo elastic coefficient ndeye 466, 480MPa. Iyo tensile simba ndeye 171.5MPa. Iyo yekumanikidza simba ndeye 1029MPa. Mutsara wekuwedzera coefficient ndeye (25~ 1000) 5.010 ~ 6/, uye thermal conductivity (20) ndeye 59w/(mk). Kugadzikana kwemakemikari, kuvira muHCI, H2SO4, HF haizoparari.

Zvinoenderana nekushandiswa kwakasiyana, mhepo yekumanikidza sintered silicon carbide yakakamurwa kuita abrasive, refractory data, deoxidizer, yemagetsi silicon carbide zvichingodaro. Iyo SiC yemukati yeabrasive silicon carbide haifanire kunge iri pasi pe98%. Refractories ine silicon carbide yakakamurwa kuita: (1) advanced refractory data black silicon carbide, iyo SiC yemukati yakangofanana nekukuya silicon carbide. (2) Secondary refractory data black silicon carbide, SiC content inopfuura 90%. (3) Zviri mukati medema silicon carbide uye SiC mune yakaderera-giredhi refractories haisi pasi pe83%. Zviri mukati mesilicon carbide uye SiC inoshandiswa mu deoxidizer inowanzodiwa kuti ive pamusoro pe90%. Nekudaro, kabhoni maindasitiri graphitization furnace insulation, silicon carbide yemukati inopfuura 45% yekurapa inogona zvakare kushandiswa sesimbi yekugadzira deoxidizer. Silicon carbide ye deoxidizing agent ine marudzi maviri ehupfu chimiro uye molding block. Powder deoxidizer black silicon carbide kazhinji ine particle size ye 4~0.5 mm uye 0.5 ~ 0.1 mm. Electric utility silicon carbide ine mapoka maviri makuru. (1) Iyo yakasvibira silicon carbide inoshandiswa kumagetsi ekudziya zvinhu yakangofanana neyakasvibira silicon carbide inoshandiswa pakukuya. (2) Silicon carbide yekusunga ine zvakakosha zvemagetsi zvinodikanwa, izvo zvakasiyana neblack silicon carbide yekukuya data refractory.

Kushandiswa kwemhepo yekumanikidza sintered silicon carbide

Atmospheric pressure sintered silicon carbide zvigadzirwa zvine mabasa akakosha senge tembiricha yakakwira, kuramba kupfeka, kupisa kupisa, kupisa moto, kuramba nemwaranzi, yakanakisa magetsi uye yekupisa conductivity, nezvimwewo, uye yakashandiswa zvakanyanya mumadhipatimendi akasiyana ehupfumi hwenyika. MuChina, green silicon carbide inonyanya kushandiswa seabrasive. Black silicon carbide inoshandiswa kugadzira matombo ekukuya, ayo anowanzo shandiswa kucheka nekukuya zvinhu zvine simba rakaderera, segirazi, ceramics, dombo, refractories, uye zvakare pakukuya simbi dzakakandwa uye zvisiri-ferrous simbi zvinhu. Kukuya kunogadzirwa negirini silicon carbide kunonyanya kushandiswa kukuya simende carbide, titanium alloy, optical girazi, uye zvakare pakukuya cylinder liner uye high-speed simbi maturusi. Cubic silicon carbide abrasives inongoshandiswa kune yekupedzisira-chaiyo kugaya kwemadiki mabearings. Kupfeka kuramba kweturbine impellers kunogona kuvandudzwa zvakanyanya nekuisa SIC poda pavari ne electroplating. Uchishandisa mechanical pressure kusunda cubic SiC200 mill uye W28 micro-powder kune humburumbira madziro einjini yekupisa mukati, hupenyu hwehumburumbira hunogona kudarika zvakapetwa kaviri.

Nguva yekutumira: Oct-11-2023