Silicon carbide (SiC) substrates ine akawanda hurema hunodzivirira kunanga kugadzirisa. Kugadzira chip wafers, imwe chaiyo-crystal firimu inofanira kukura paSiC substrate kuburikidza ne epitaxial process. Iyi firimu inozivikanwa se epitaxial layer. Zvinenge zvese zveSiC zvishandiso zvinoonekwa pane epitaxial zvinhu, uye yepamusoro-mhando homoepitaxial SiC zvinhu zvinoumba hwaro hweSiC mudziyo kuvandudza. Kuitwa kwe epitaxial zvinhu zvinotarisa zvakananga kushanda kweSiC zvishandiso.

Yakakwirira-ikozvino uye yakakwirira-yakavimbika SiC zvishandiso zvinoisa zvakaomesesa zvinodiwa pamusoro pepamusoro morphology, defect density, doping kufanana, uye ukobvu kufanana kwe.epitaxialzvinhu. Kuwana hukuru-hukuru, yakaderera-hurema density, uye yakakwirira-yakafanana SiC epitaxy yave yakakosha mukusimudzira indasitiri yeSiC.

Kugadzira epamusoro-mhando yeSiC epitaxy inotsamira pamatanho epamberi uye michina. Parizvino, iyo inonyanya kushandiswa nzira yeSiC epitaxial kukura ndeyeChemical Vapor Deposition (CVD).CVD inopa chaiyo kutonga pamusoro pe epitaxial firimu ukobvu uye doping concentration, yakaderera defect density, mwero wekukura mwero, uye otomatiki maitiro ekutonga, zvichiita kuti ive yakavimbika tekinoroji yekubudirira kushambadzira maapplication.

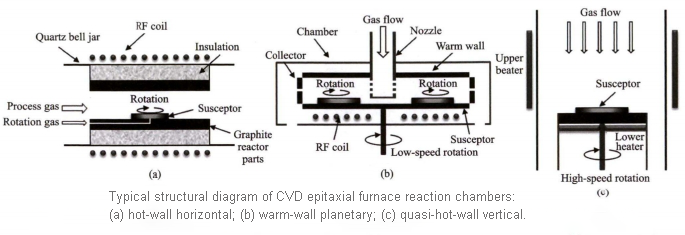

SiC CVD epitaxykazhinji inoshandisa inopisa-madziro kana inodziya-madziro CVD michina. Kukura kwekushisa kwepamusoro (1500-1700 ° C) kunovimbisa kuenderera mberi kwe4H-SiC crystalline fomu. Zvichienderana nehukama pakati pekuyerera kwegasi uye substrate pamusoro, makamuri ekuita eaya maCVD masisitimu anogona kukamurwa kuita akachinjika uye akatwasuka zvimiro.

Hunhu hweSiC epitaxial furnaces hunonyanya kutongwa pazvinhu zvitatu: epitaxial kukura kuita (kusanganisira ukobvu kufanana, doping uniform, defect rate, uye kukura kwekukura), tembiricha yekushanda kwemidziyo (kusanganisira kudziya / kutonhora mitengo, yakanyanya tembiricha, uye tembiricha yakafanana. ), uye mutengo-kushanda (kusanganisira mutengo weyuniti uye huwandu hwekugadzira).

Kusiyana Pakati peMatatu Matatu eSiC Epitaxial Growth Furnaces

1.Hot-wall Horizontal CVD Systems:

-Features:Kazhinji inoratidzira imwe-wafer yakakura-saizi yekukura masisitimu inofambiswa negasi inotenderera inotenderera, kuwana yakanakisa intra-wafer metrics.

-Representative Model:LPE's Pe1O6, inokwanisa otomatiki wafer kurodha / kurodha pa900 ° C. Inozivikanwa nekukura kwemazinga, mapfupi epitaxial cycles, uye inopindirana intra-wafer uye inter-run performance.

-Performance:Kune 4-6 inch 4H-SiC epitaxial wafers ane ukobvu ≤30μm, inowana intra-wafer ukobvu husina kufanana ≤2%, doping concentration isiri-uniformity ≤5%, defect density ≤1 cm-², uye isina hurema. nzvimbo yepamusoro (2mm × 2mm masero) ≥90%.

-Domestic Manufacturers: Makambani akaita seJingsheng Mechatronics, CETC 48, North Huachuang, uye Nasset Intelligent vakagadzira zvakafanana-wafer SiC epitaxial michina ine yakasimudzwa kugadzirwa.

2.Warm-wall Planetary CVD Systems:

-Features:Shandisa mabhesi ekuronga mapuraneti ekukura kwe-multi-wafer pabatch, uchivandudza zvakanyanya kubuda.

-Representative Models:Aixtron's AIXG5WWC (8x150mm) uye G10-SiC (9x150mm kana 6x200mm) akatevedzana.

-Performance:Kune 6-inch 4H-SiC epitaxial wafer ane ukobvu ≤10μm, inowana inter-wafer ukobvu kutsauka ± 2.5%, intra-wafer ukobvu husina kufanana 2%, inter-wafer doping concentration kutsauka ± 5%, uye intra-wafer doping. concentration non-uniformity <2%.

-Matambudziko:Kugamuchirwa kwakaganhurirwa mumisika yemumba nekuda kwekushaikwa kwedhata rekugadzira batch, zvipingamupinyi zvehunyanzvi mukupisa uye kuyerera kwemunda wekutonga, uye inoenderera R&D pasina hukuru-hukuru kuita.

3. Quasi-hot-wall Vertical CVD Systems:

- Features:Shandisa rubatsiro rwekunze rwemuchina kune yakakwira-kumhanya substrate kutenderera, kuderedza muganho ukobvu uye kuvandudza epitaxial kukura mwero, ine mabhenefiti echisikigo mukudzora kukanganisa.

- Representative Models:Nuflare's single-wafer EPIREVOS6 uye EPIREVOS8.

-Performance:Inowana huwandu hwekukura pamusoro pe50μm/h, defect density control iri pasi pe0.1 cm-², uye intra-wafer ukobvu uye doping concentration isiri-uniformity ye1% ne2.6% zvichiteerana.

-Kuvandudza Mumba:Makambani akaita seXingsandai neJingsheng Mechatronics akagadzira michina yakafanana asi haana kuwana kushandiswa kwakakura.

Summary

Imwe neimwe yemhando mitatu yezvimiro zveSiC epitaxial yekukura midziyo ine hunhu hwakasiyana uye inogara yakatarwa musika zvikamu zvinoenderana nezvinodiwa zvekushandisa. Kupisa-wall horizontal CVD inopa ekupedzisira-inokurumidza kukura mazinga uye yakaenzana mhando uye kufanana asi ine yakaderera kugadzirwa kwekuita nekuda kwekamwe-wafer kugadzirisa. Warm-wall planetary CVD inosimudzira zvakanyanya kugadzirwa asi inotarisana nematambudziko mu-multi-wafer consistency control. Quasi-hot-wall vertical CVD inokunda mukuremara nechimiro chakaoma uye inoda kuchengetedzwa kwakawanda uye ruzivo rwekushanda.

Sezvo indasitiri inoshanduka, iterative optimization uye kukwidziridzwa mune izvi zvigadziriso zvemidziyo zvinotungamira kune kuwedzera kwakanatswa, kutamba mabasa akakosha mukusangana akasiyana epitaxial wafer maratidziro ekukora uye kuremara zvinodiwa.

Zvakanakira uye Zvakaipa Kwezvakasiyana SiC Epitaxial Kukura Mafurnaces

| Furnace Type | Zvakanakira | Zvakaipa | Representative Manufacturers |

| Kupisa-madziro Horizontal CVD | Kukurumidza kukura mwero, chimiro chiri nyore, kugadzirisa kuri nyore | Nguva pfupi yekugadzirisa | LPE (Italy), TEL (Japan) |

| Warm-wall Planetary CVD | Yakakwira kugadzirwa kwesimba, inoshanda | Complex chimiro, yakaoma consistency control | Aixtron (Germany) |

| Quasi-hot-wall Vertical CVD | Yakanakisa kuremara kutonga, kureba kwekugadzirisa kutenderera | Chimiro chakaoma, chakaoma kuchengetedza | Nuflare (Japan) |

Nekuenderera mberi kwekusimudzira indasitiri, aya matatu marudzi emidziyo anozoitwa iterative dhizaini optimization uye kukwidziridzwa, zvichitungamira kune yakawedzera kunatswa masisitimu anoenderana akasiyana epitaxial wafer maratidziro ekukora uye kuremara zvinodiwa.

Nguva yekutumira: Jul-19-2024