Kukurumidza Kukura kweSiC Imwe Crystal KushandisaCVD-SiC BulkKunobva kuburikidza neSublimation Method

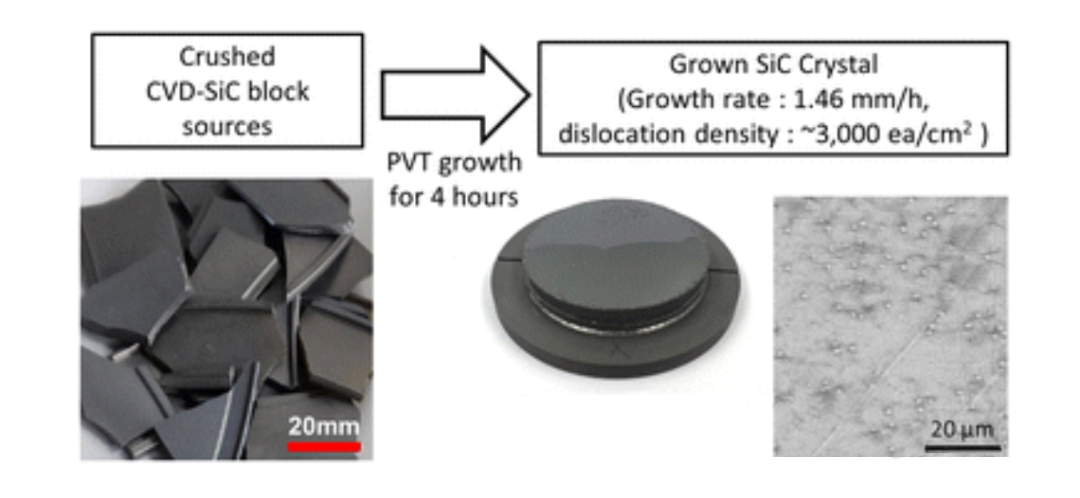

Nokushandisa recycledCVD-SiC inovharaseSiC sosi, makristasi eSiC akabudirira kukura pamwero we1.46 mm/h kuburikidza nePVT nzira. Iyo yakakura crystal's micropipe uye dislocation densities inoratidza kuti kunyangwe yakakura kukura mwero, mhando yekristaro yakanaka.

Silicon carbide (SiC)is wide-bandgap semiconductor ine yakanakisa zvivakwa zvekushandisa mune yakakwira voltage, yakakwirira simba, uye yakakwirira frequency. Kudiwa kwayo kwakakura nekukurumidza mumakore achangopfuura, kunyanya mumunda wesimba semiconductor. Kune magetsi semiconductor applications, SiC single crystals inokura ne sublimating high-purity SiC source at 2100-2500 ° C, yozodzokorodza pakristaro yembeu ichishandisa mhute yekufambisa (PVT) nzira, inoteverwa nekugadzirisa kuwana imwe crystal substrates pamawafers. . Pachivanhu,SiC makristasivanokura vachishandisa nzira yePVT pachiyero chekukura che 0.3 kusvika 0.8 mm / h kudzora crystallinity, iyo inononoka kana ichienzaniswa nemamwe makristasi mamwe anoshandiswa mumasemiconductor applications. Apo makristasi eSiC anokura pakukura kwekukura kwepamusoro achishandisa nzira yePVT, kuora kwehutano kunosanganisira carbon inclusions, kuderedzwa kuchena, kukura kwepolycrystalline, kugadzirwa kwemuganhu wezviyo, uye kuparadzaniswa uye kukanganisa kweporosity hakuna kubviswa. Naizvozvo, kukura nekukurumidza kweSiC hakuna kugadzirwa, uye kuderera kwekukura kweSiC kwave kuri chipingamupinyi chikuru pakugadzirwa kweSiC substrates.

Nekune rumwe rutivi, mishumo ichangoburwa pamusoro pekukurumidza kukura kweSiC yanga ichishandisa high-temperature chemical vapor deposition (HTCVD) nzira panzvimbo pePVT nzira. Nzira yeHTCVD inoshandisa mhute ine Si uye C seSiC sosi mureactor. HTCVD haisati yashandiswa kugadzirwa kwakakura kweSiC uye inoda kumwe kutsvagisa nekusimudzira kutengeserana. Sezvineiwo, kunyangwe pamwero wekukura we ~ 3 mm / h, SiC single crystals inogona kukura nemhando yakanaka yekristaro uchishandisa nzira yeHTCVD. Zvichakadaro, zvikamu zveSiC zvakashandiswa mumasemiconductor maitiro pasi penzvimbo dzakaomarara dzinoda yakanyanya kuchena maitiro ekudzora. Kune semiconductor process applications, ~99.9999% (∼6N) kuchena SiC zvikamu zvinowanzogadzirirwa neCVD process kubva kumethyltrichlorosilane (CH3Cl3Si, MTS). Zvisinei, pasinei nekuchena kwepamusoro kweCVD-SiC zvikamu, zvakaraswa mushure mekushandiswa. Munguva pfupi yapfuura, zvakaraswa CVD-SiC zvikamu zvakaonekwa seSiC masosi ekukura kwekristaro, kunyangwe mamwe maitiro ekudzoreredza anosanganisira kupwanya uye kucheneswa achiri kudikanwa kuti asangane nepamusoro zvinodiwa zvekristaro kukura sosi. Muchidzidzo ichi, takashandisa mabhuroko akaraswa eCVD-SiC kudzokorodza zvinhu senzvimbo yekukura makristasi eSiC. Iyo CVD-SiC mabhuroki ekukura kwekristaro imwe chete akagadzirirwa saizi-inodzorwa akapwanyika mabhuroki, akasiyana zvakanyanya muchimiro uye saizi zvichienzaniswa neyekutengesa SiC poda inowanzoshandiswa muPVT process, saka maitiro eSiC single crystal kukura aitarisirwa kuve zvakanyanya. zvakasiyana. Asati aita SiC single crystal growth experiments, komputa simulations yakaitwa kuti iwane yakakwirira kukura mazinga, uye nzvimbo yekudziya yakagadziridzwa zvinoenderana nekukura kwekristaro imwe chete. Mushure mekukura kwekristaro, makristasi akakura akaongororwa nemuchinjikwa-sectional tomography, micro-Raman spectroscopy, high-resolution X-ray diffraction, uye synchrotron white beam X-ray topography.

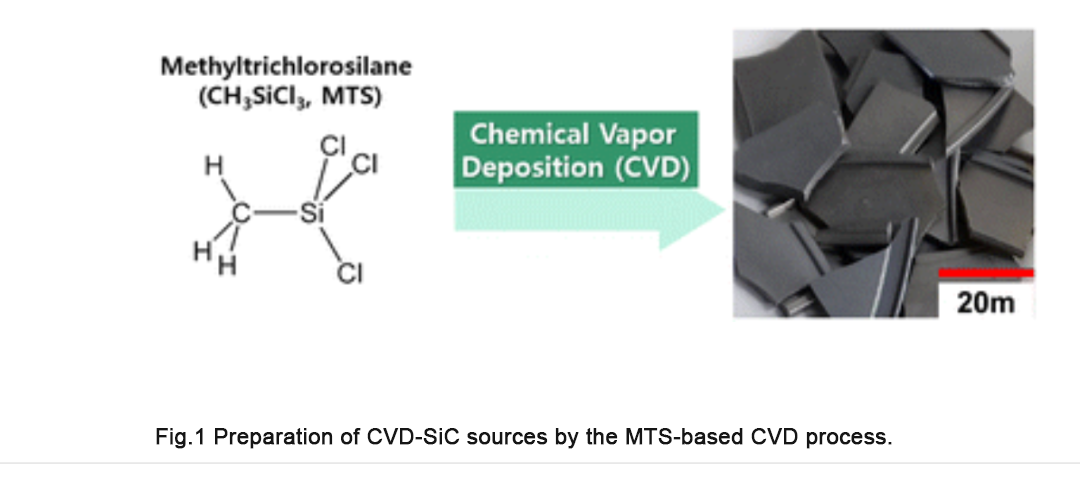

Mufananidzo 1 unoratidza iyo CVD-SiC sosi inoshandiswa pakukura kwePVT yeSiC makristasi muchidzidzo ichi. Sezvinotsanangurwa musumo, zvikamu zveCVD-SiC zvakagadziriswa kubva kuMTS neCVD maitiro uye zvakagadzirirwa semiconductor kushandiswa kuburikidza nekugadzirisa kwemagetsi. N yakadonhedzwa muCVD maitiro kuti iwane conductivity ye semiconductor process application. Mushure mekushandiswa mumitambo ye semiconductor, zvikamu zveCVD-SiC zvakapwanyika kuti zvigadzirire chitubu chekukura kwekristaro, sezvinoratidzwa mumufananidzo 1. Iyo CVD-SiC sosi yakagadzirwa semahwendefa ane avhareji yehupamhi hwe ~ 0.5 mm uye chiyero chechidimbu chekukura. 49.75 mm.

Mufananidzo 1: CVD-SiC sosi yakagadzirwa neMTS-based CVD process.

Mufananidzo 1: CVD-SiC sosi yakagadzirwa neMTS-based CVD process.

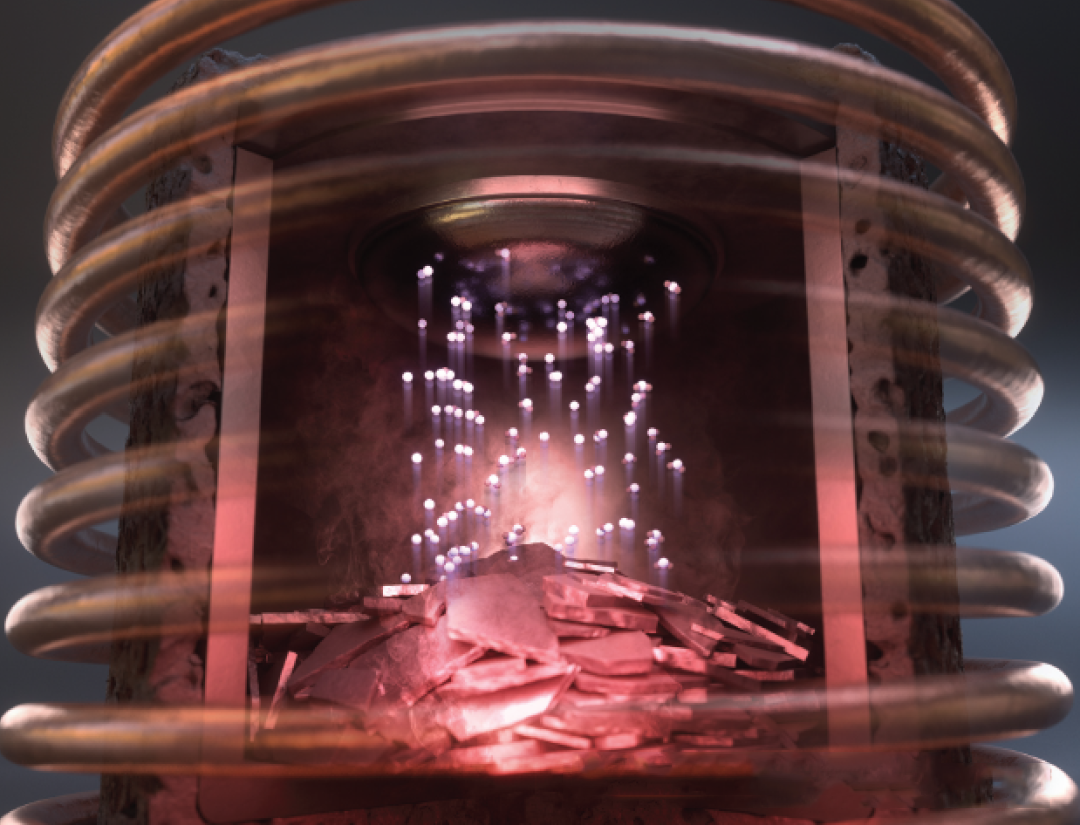

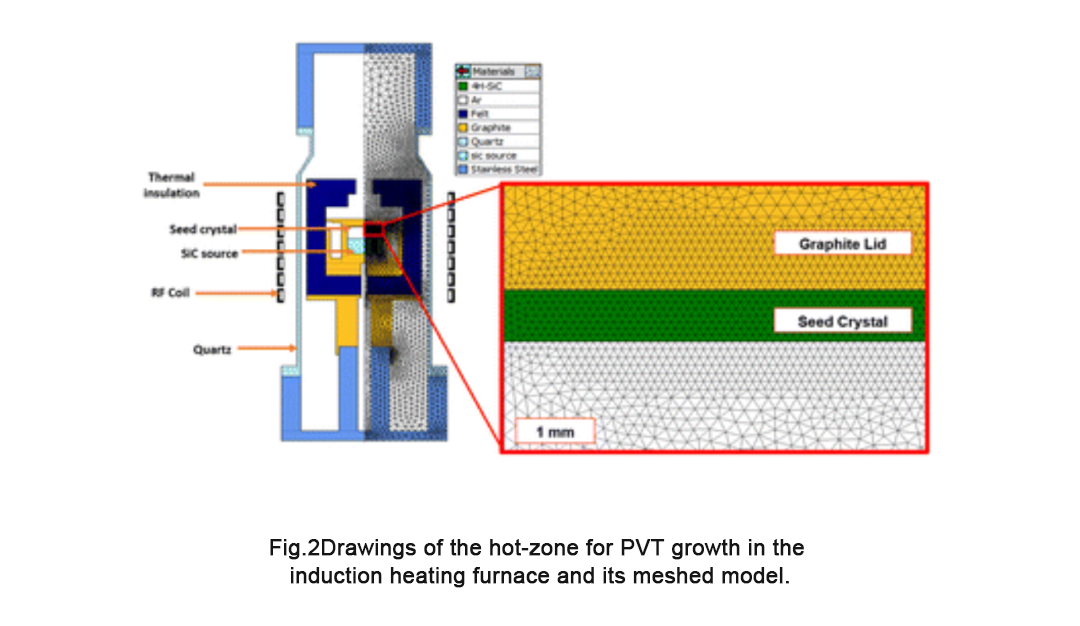

Uchishandisa iyo CVD-SiC sosi inoratidzwa muMufananidzo 1, makristasi eSiC akakura nenzira yePVT muchoto chekupisa. Kuti uongorore kugoverwa kwekushisa munzvimbo inopisa, kodhi yekutengeserana yeVR-PVT 8.2 (STR, Republic of Serbia) yakashandiswa. Rereactor ine thermal zone yakaumbwa se 2D axisymmetric modhi, sezvakaratidzwa muFigure 2, ine mesh modhi yayo. Zvinhu zvose zvinoshandiswa mukufananidza zvinoratidzwa muMufananidzo 2, uye zvinhu zvavo zvakanyorwa muTebhu 1. Kubva pamigumisiro yekufananidza, makristasi eSiC akakura achishandisa nzira yePVT pahutanho hwekushisa hwe2250-2350 ° C muAr atmosphere. 35 Tora kwemaawa mana. A 4 ° off-axis 4H-SiC wafer yakashandiswa semhodzi yeSiC. Makristasi akakura akaongororwa ne micro-Raman spectroscopy (Witec, UHTS 300, Germany) uye yakakwirira-resolution XRD (HRXRD, X'Pert-PROMED, PANalytical, Netherlands). Kusachena kwakadzika mumakristasi eSiC akakura akaongororwa achishandisa simba rechipiri ion mass spectrometry (SIMS, Cameca IMS-6f, France). Iyo dislocation density yemakristasi akakura akaongororwa uchishandisa synchrotron chena beam X-ray topography paPohang Light Source.

Mufananidzo 2: Thermal zone dhizaini uye mesh modhi yePVT kukura mune induction yekupisa choto.

Mufananidzo 2: Thermal zone dhizaini uye mesh modhi yePVT kukura mune induction yekupisa choto.

Sezvo nzira dzeHTCVD nePVT dzichikura makristasi pasi pegasi-solid phase equilibrium pamberi pekukura, kubudirira kukurumidza kukura kweSiC nenzira yeHTCVD kwakakonzera dambudziko rekukurumidza kukura kweSiC nePVT nzira muchidzidzo ichi. Iyo HTCVD nzira inoshandisa gasi sosi inoyerera-inodzorwa zviri nyore, nepo PVT nzira inoshandisa yakasimba sosi isingadzore zvakananga kuyerera. Kuyerera kweyero yakapihwa kumberi kwekukura muPVT nzira inogona kudzorwa neiyo sublimation mwero weiyo yakasimba sosi kuburikidza nekushisa kugovera kutonga, asi kunyatso kudzora kwekugovera tembiricha mumasisitimu ekukura anoshanda hakusi nyore kuwana.

Nekuwedzera tembiricha yekupisa muPVT reactor, chiyero chekukura cheSiC chinogona kuwedzerwa nekuwedzera sublimation mwero weiyo sosi. Kuti uwane yakagadzikana kukura kwekristaro, kudzora tembiricha kumberi kwekukura kwakakosha. Kuti uwedzere chiyero chekukura pasina kugadzira polycrystals, yakakwirira-tembiricha gradient inoda kuwanikwa pamberi pekukura, sezvakaratidzwa neSiC kukura kuburikidza neHTCVD nzira. Kusakwana vertical heat conduction kuseri kwechivharo kunofanira kubvisa kupisa kwakaunganidzwa pakukura mberi kuburikidza nemwaranzi yekushisa kusvika pakukura kwepamusoro, zvichiita kuti pave nekuumbwa kwepamusoro pepamusoro, kureva, polycrystalline kukura.

Ose ari maviri ekutamisa hukuru uye recrystallization maitiro muPVT nzira akafanana zvakanyanya neHTCVD nzira, kunyangwe iwo akasiyana muSiC sosi. Izvi zvinoreva kuti kukura nekukurumidza kweSiC kunogoneka zvakare kana iyo sublimation rate yeSiC sosi yakakwira zvakakwana. Nekudaro, kuwana emhando yepamusoro SiC single crystals pasi pemamiriro ekukura kwepamusoro kuburikidza nePVT nzira ine matambudziko akati wandei. Hupfu hwekutengesa kazhinji hune musanganiswa wezvimedu zvidiki nezvihombe. Nekuda kwekusiyana kwesimba repamusoro, zvidimbu zvidiki zvine huwandu hwakanyanya hwekusachena uye husina kusimba pamberi pezvimedu zvakakura, zvichiita kuti kuve nekusachena kwakanyanya mumatanho ekutanga ekukura kwekristaro. Pamusoro pezvo, seSiC yakasimba inoora kuita mhando dzemhute seC uye Si, SiC2 neSi2C pakupisa kwakanyanya, C yakasimba inoumba zvisingadzivisiki apo SiC sosi inodzika muPVT nzira. Kana iyo yakaumbwa yakasimba C idiki uye yakareruka zvakakwana, pasi pemamiriro ekukura nekukurumidza, madiki C particles, anozivikanwa se "C guruva," anogona kutakurwa kuenda kune crystal surface nechisimba chakasimba chekufambisa, zvichiita kuti inclusions mukriststal yakakura. Naizvozvo, kuderedza kusvibiswa kwesimbi uye guruva reC, saizi yeSiC sosi inofanirwa kudzorwa kusvika padhayamita isingasviki 200 μm, uye chiyero chekukura hachifanirwe kudarika ~ 0.4 mm / h kuchengetedza kunonoka kufambisa uye kusasanganisa kuyerera. C huruva. Metal tsvina uye C guruva zvinotungamira mukushatiswa kweakakura SiC crystals, izvo zvipingamupinyi zvikuru mukukura nekukurumidza kweSiC kuburikidza nePVT nzira.

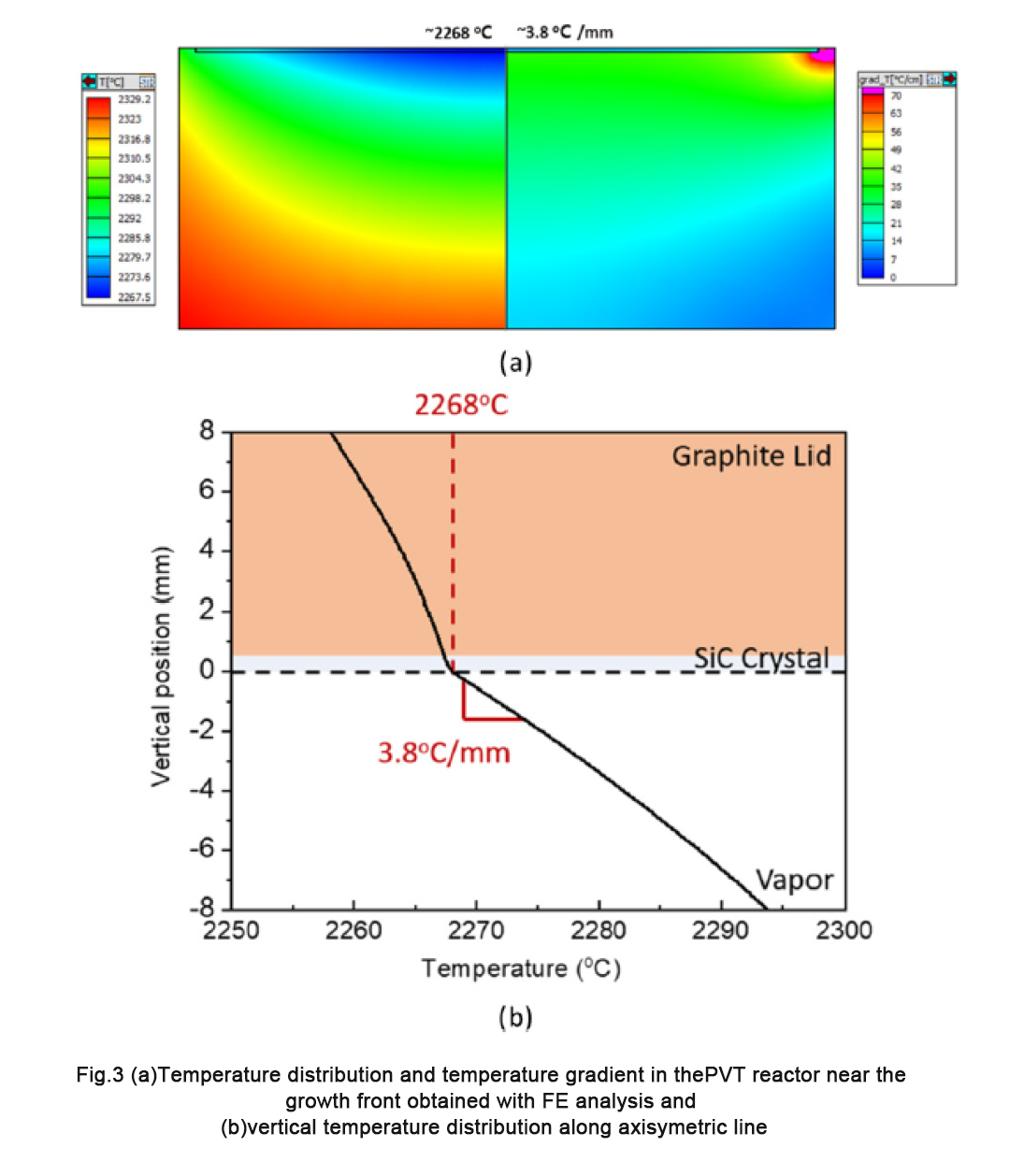

Muchidzidzo ichi, yakapwanyika CVD-SiC zvinyorwa pasina zvidimbu zvidiki zvakashandiswa, kubvisa guruva reC rinoyangarara pasi pekutamisa kwakasimba kwehuwandu. Nekudaro, iyo yekupisa nzvimbo chimiro chakagadzirwa uchishandisa multiphysics simulation-yakavakirwa PVT nzira yekukurumidza kukurumidza SiC kukura, uye inoteedzerwa tembiricha kugovera uye tembiricha gradient inoratidzwa muFigure 3a.

Mufananidzo 3: (a) Kugovera tembiricha uye tembiricha gradient pedyo nekukura kumberi kwePVT reactor inowanikwa neinogumira chekuongorora chinhu, uye (b) yakatwasuka tembiricha kugovera pamwe neaxisymmetric mutsara.

Kuenzaniswa neyakajairwa nzvimbo yekudziya yekukura makristasi eSiC pachiyero chekukura che 0.3 kusvika 0.8 mm/h pasi petembiricha diki isingasviki 1 °C/mm, marongero enzvimbo inodziya muchidzidzo ichi ane tembiricha yakakura kwazvo ~ ~ 3.8 °C/mm pakupisa kwekukura kwe ~2268°C. Kukosha kwekushisa kwekushisa muchidzidzo ichi kunofananidzwa nekukura nokukurumidza kweSiC pamwero we 2.4 mm / h uchishandisa nzira yeHTCVD, apo kupisa kwekushisa kunogadzirirwa ~ 14 ° C / mm. Kubva pakugoverwa kwekushisa kwepamusoro kunoratidzwa muMufananidzo 3b, takasimbisa kuti hapana reverse tembiricha gradient iyo inogona kuumba polycrystals yaivepo pedyo nekukura mberi, sezvinotsanangurwa mumabhuku.

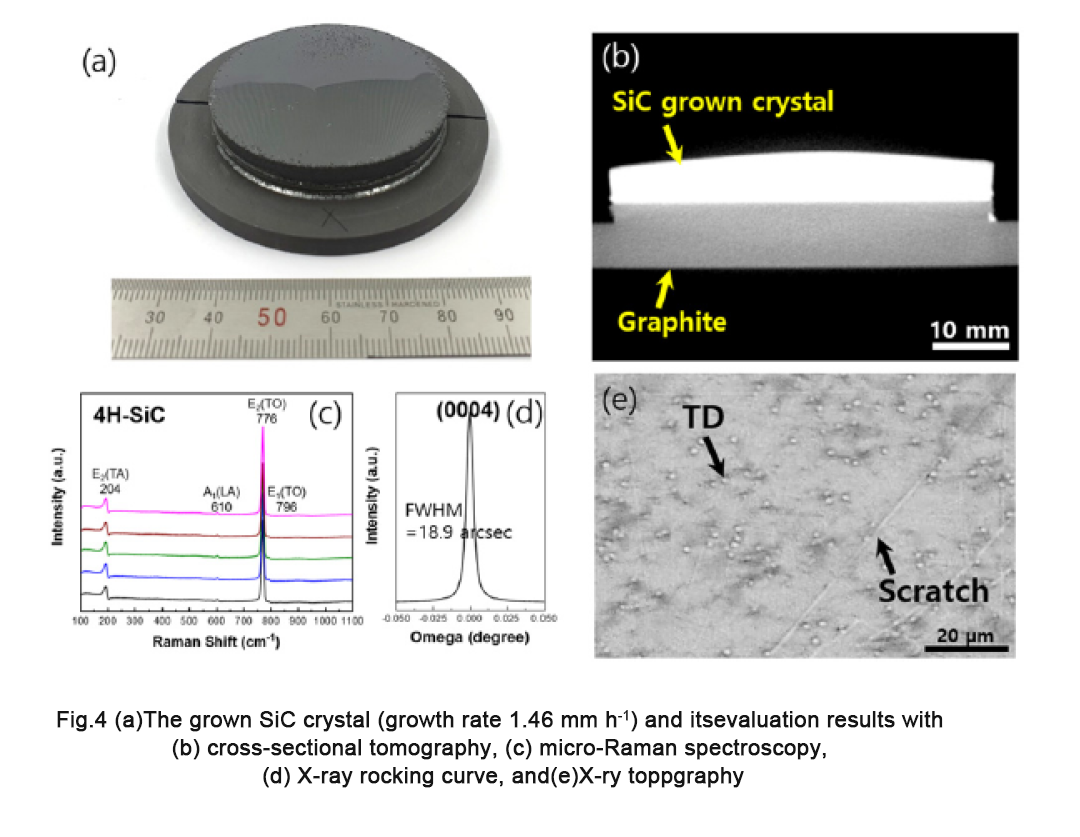

Uchishandisa chirongwa chePVT, makristasi eSiC akakura kubva kuCVD-SiC sosi kwemaawa mana, sezvakaratidzwa muMifananidzo 2 uye 3. Mumiririri weSiC crystal kukura kubva kuSiC yakakura inoratidzwa mumufananidzo 4a. Ukobvu uye kukura kweiyo SiC crystal inoratidzwa muMufananidzo 4a ndeye 5.84 mm uye 1.46 mm/h, zvichiteerana. Mhedzisiro yeSiC sosi pamhando, polytype, morphology, uye kuchena kweiyo yakakura SiC crystal inoratidzwa muFigure 4a yakaongororwa, sezvakaratidzwa muFigure 4b-e. Iyo muchinjika-chikamu tomography mufananidzo muFigure 4b inoratidza kuti kukura kwekristaro kwaive kwakaumbwa-kuumbwa nekuda kweiyo suboptimal kukura mamiriro. Nekudaro, iyo micro-Raman spectroscopy muFigure 4c yakaratidza yakura kristaro sechikamu chimwe chete che4H-SiC isina chero polytype inclusions. Iyo FWHM kukosha kwe (0004) peak yakawanikwa kubva kuX-ray rocking curve analysis yaive 18.9 arcseconds, ichisimbisawo kunaka kwekristaro.

Mufananidzo wechina e) X-ray topography.

Mufananidzo 4e unoratidza danda jena X-ray topografia inoratidza makwara uye shinda inotsemuka mune yakakwenenzverwa wafer yecrystal yakura. Iyo dislocation density yekristaro yakakura yakayerwa kuva ~ 3000 ea / cm², yakakwira zvishoma pane kubviswa kwedhizaini yembeu yekristaro, yaive ~ 2000 ea / cm². Iyo kristaro yakakura yakasimbiswa kuve ine yakaderera dislocation density, inofananidzwa nekristaro mhando yewafers ekutengesa. Sezvineiwo, kukurumidza kukura kweSiC crystals yakawanikwa uchishandisa iyo PVT nzira ine yakapwanyika CVD-SiC sosi pasi pehombe tembiricha gradient. Iwo makomba eB, Al, uye N mukristaro yakura aive 2.18 × 10¹⁶, 7.61 × 10¹⁵, uye 1.98 × 10¹⁹ maatomu/cm³, zvichiteerana. Iko kusanganiswa kweP mukristaro yakakura yaive pasi peyero yekuona (<1.0 × 10¹⁴ maatomu/cm³). Kusachena kwacho kwaive kwakadzikira zvakakwana kune vatakuri vanochaja, kunze kweN, iyo yaive nemaune doped panguva yeCVD maitiro.

Kunyange zvazvo kukura kwekristal muchidzidzo ichi kwaive kuduku-kuchitarisa zvigadzirwa zvekutengeserana, kuratidzwa kwakabudirira kwekukurumidza kweSiC kukura nemhando yakanaka yekrisiti uchishandisa CVD-SiC sosi kuburikidza nePVT nzira ine zvakakosha. Sezvo CVD-SiC masosi, kunyangwe iwo akanakisa zvivakwa, ari mutengo-kukwikwidza nekudzokorora zvinhu zvakaraswa, isu tinotarisira kushandiswa kwavo kwakapararira sechivimbiso cheSiC sosi kutsiva SiC poda masosi. Kushandisa CVD-SiC masosi ekukurumidza kukura kweSiC, optimize tembiricha kugovera muPVT system inodiwa, zvichiunza mimwe mibvunzo yekutsvagisa ramangwana.

Mhedziso

Muchidzidzo ichi, kuratidzwa kwakabudirira kwekukurumidza kweSiC crystal kukura uchishandisa yakapwanyika CVD-SiC blocks pasi pepamusoro-tembiricha gradient mamiriro kuburikidza nePVT nzira yakawanikwa. Sezvineiwo, kukura nekukurumidza kweSiC makristasi kwakaonekwa nekutsiva iyo SiC sosi nePVT nzira. Iyi nzira inotarisirwa kuwedzera zvakanyanya hukuru hwekugadzirwa kweSiC single crystals, pakupedzisira kuderedza mutengo weyuniti yeSiC substrates uye kukurudzira kushandiswa kwakapararira kwepamusoro-kushanda kwemagetsi emagetsi.

Nguva yekutumira: Jul-19-2024