Mhedziso yeSemiconductor process

Iyo semiconductor maitiro anonyanya kusanganisira kushandisa microfabrication uye firimu tekinoroji kubatanidza zvizere machipisi uye zvimwe zvinhu mukati mematunhu akasiyana, senge substrates nemafuremu. Izvi zvinogonesa kutorwa kweanotungamira terminals uye encapsulation nepurasitiki insulating medium kuti iite yakabatanidzwa yakazara, inoratidzwa seyatatu-dimensional chimiro, pakupedzisira ichipedzisa semiconductor packaging process. Pfungwa yeiyo semiconductor process ine chekuitawo neakamanikana tsananguro ye semiconductor chip packaging. Kubva pakuona kwakafara, zvinoreva kurongedza mainjiniya, ayo anosanganisira kubatanidza nekugadzirisa kune substrate, kugadzirisa inoenderana michina yemagetsi, uye kuvaka hurongwa hwakazara nekuita kwakasimba kwakazara.

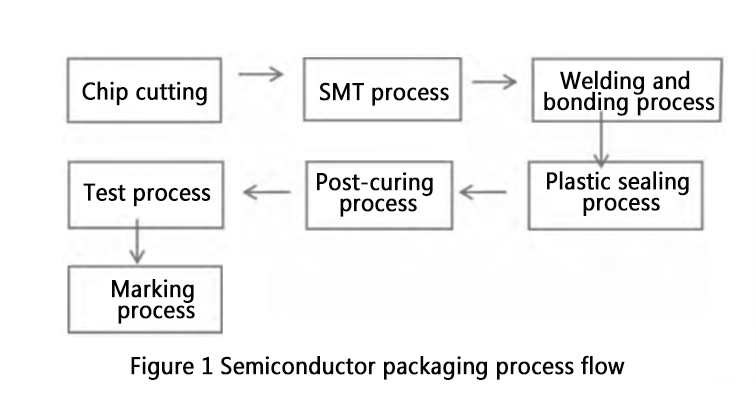

Semiconductor Packaging Process Flow

Iyo semiconductor packaging process inosanganisira akawanda mabasa, sezvakaratidzwa muMufananidzo 1. Imwe neimwe nzira ine zvinodiwa chaizvo uye yakanyatsoenderana nekufamba kwebasa, inoda kuongororwa kwakadzama panguva yechiitiko chinoshanda. Izvo zvirimo ndezvizvi:

1. Chip Kucheka

Mune semiconductor kurongedza maitiro, kucheka chip kunosanganisira kucheka silicon wafers mumachipi ega uye nekukasira kubvisa silicon tsvina kudzivirira zvipingamupinyi kune rinotevera basa uye kutonga kwemhando.

2. Chip Mounting

Iyo chip mounting process inotarisa kudzivirira kukuvadzwa kwedunhu panguva yekukuya nekuisa inodzivirira firimu layer, ichisimbisa kuperera kwedunhu.

3. Wire Bonding Process

Kudzora kunaka kwewaya yekubatanidza maitiro kunosanganisira kushandisa akasiyana mhando dzewaya dzegoridhe kubatanidza iyo chip's bonding pads nemafuremu pads, kuve nechokwadi chekuti chip inogona kubatana kune ekunze maseketi uye kuchengetedza yakazara maitiro kutendeseka. Kazhinji, waya dzegoridhe dzakaiswa doped uye waya dzegoridhe dzakasanganiswa dzinoshandiswa.

Doped Goridhe Waya: Mhando dzinosanganisira GS, GW, uye TS, yakakodzera kune yakakwirira-arc (GS:> 250 μm), yepakati-yakakwirira arc (GW: 200-300 μm), uye yepakati-yakaderera arc (TS: 100-200 μm) kubatana zvichiteerana.

Alloyed Gold Wire: Mhando dzinosanganisira AG2 uye AG3, yakakodzera kune yakaderera-arc bonding (70-100 μm).

Sarudzo dzedhayamita dzewaya idzi dzinobva pa0.013 mm kusvika 0.070 mm. Kusarudza mhando yakakodzera uye dhayamita zvichienderana nezvinodiwa zvekushanda uye zviyero zvakakosha pakutonga kwemhando.

4. Molding Process

Iyo huru yedunhu mukugadzira zvinhu inosanganisira encapsulation. Kudzora kunaka kwekuumbwa kunodzivirira zvikamu, kunyanya kubva kumasimba ekunze anokonzera kukanganisa kwakasiyana. Izvi zvinosanganisira kunyatsoongororwa kwezvikamu zvemuviri.

Nzira nhatu huru dziri kushandiswa parizvino: ceramic kurongedza, kurongedza epurasitiki, uye echinyakare kurongedza. Kutonga chikamu chemhando yega yega yekurongedza kwakakosha kusangana nepasirese chip kugadzirwa zvinodiwa. Munguva yekuita, hunyanzvi hwakakwana hunodiwa, sekupisa chip uye lead furemu isati yavharirwa ne epoxy resin, kuumba, uye post-mold kurapa.

5. Post-Curing Process

Mushure mekugadzirisa, kurapa kwemashure kunodiwa, kutarisa pakubvisa chero zvinhu zvakawandisa zvakatenderedza maitiro kana pasuru. Kudzora kwehunhu kwakakosha kuti udzivise kukanganisa maitiro ese emhando uye chitarisiko.

6.Kuedza Maitiro

Kana maitiro apfuura apera, huwandu hwese hwekuita hunofanirwa kuyedzwa uchishandisa tekinoroji yekuyedza uye zvivakwa. Iyi nhanho inosanganisira kurekodha kwakadzama kwedata, tichitarisa kuti chip inoshanda zvakajairwa zvichienderana nehuwandu hwekuita kwayo. Tichifunga nezve mutengo wakakwira wemidziyo yekuyedza, zvakakosha kuti uchengetedze hutongi hwemhando mumatanho ese ekugadzira, kusanganisira kuongorora kwekuona uye kuyedzwa kwekuita kwemagetsi.

Kuyedzwa Kwekuita Kwemagetsi: Izvi zvinosanganisira kuyedza maseketi akasanganiswa uchishandisa otomatiki bvunzo michina uye kuona kuti dunhu rega rega rakanyatso batana pakuyedzwa kwemagetsi.

Kuongorora Kwekuona: Vanamazvikokota vanoshandisa maikorosikopu kunyatsoongorora machipisi akapedzwa akapetwa kuti vaone kuti haana hurema uye anosangana nemiyero yemhando yekurongedza semiconductor.

7. Kucherekedza Maitiro

Maitiro ekumaka anosanganisira kuendesa machipisi akaedzwa kunzvimbo yekuchengetera yakapedzwa kuti igadziriswe kwekupedzisira, kuongororwa kwemhando, kurongedza, uye kutumira. Iyi nzira inosanganisira matanho makuru matatu:

1) Electroplating: Mushure mekugadzira inotungamira, anti-corrosion material inoshandiswa kudzivirira oxidation uye corrosion. Electroplating deposition tekinoroji inowanzo shandiswa sezvo mitoo yakawanda inogadzirwa nemarata.

2) Kupeta: Iyo yakagadziriswa inotungamira inozoumbwa, ine yakabatanidzwa yedunhu tambo yakaiswa mune inotungamira kugadzira chishandiso, ichidzora iyo inotungamira chimiro (J kana L rudzi) uye pamusoro-yakaiswa packaging.

3) Laser Printing: Chekupedzisira, zvigadzirwa zvakaumbwa zvinodhindwa nedhizaini, iyo inoshanda sechiratidzo chakakosha cheiyo semiconductor yekurongedza maitiro, sezvakaratidzwa mumufananidzo 3.

Matambudziko uye Mazano

Kudzidza kwema semiconductor kurongedza maitiro kunotanga nekutarisa kweiyo semiconductor tekinoroji kuti unzwisise misimboti yayo. Tevere, kuongorora iyo yekurongedza kuyerera inovavarira kuve nechokwadi chekudzora panguva yekushanda, uchishandisa yakanatswa manejimendi kudzivirira nyaya dzenguva dzose. Muchirevo chekusimudzira kwemazuva ano, kuona zvinonetsa mumasemiconductor ekurongedza maitiro kwakakosha. Inokurudzirwa kutarisisa pane zvemhando yekudzora zvinhu, kunyatsobata mapoinzi akakosha kuti uwedzere kunaka kwemaitiro.

Kuongorora kubva pakuona kwehutongi hwemhando, kune matambudziko akakura panguva yekuitwa nekuda kwemaitiro akawanda ane chaiwo emukati uye zvinodiwa, chimwe nechimwe chichipesvedzera chimwe. Kudzora kwakasimba kunodiwa panguva yekushandisa inoshanda. Nekutora mafungire ebasa ane hungwaru uye kushandisa matekinoroji epamusoro, semiconductor packaging process quality uye tekinoroji mazinga anogona kuvandudzwa, kuve nechokwadi chakakwana chekushanda kwekushandisa uye kuwana zvakanakisa zvikomborero zvese. (sezvinoratidzwa muFigure 3).

Nguva yekutumira: May-22-2024