Silicon carbide (SiC)zvinhu zvine mabhenefiti ebhendi rakafara, yakakwira yekupisa yekupisa, yakakwira yakakosha kuparara kwemunda simba, uye yakakwira yakazara saturated elektrononi drift velocity, zvichiita kuti ivimbise zvakanyanya mumunda wekugadzira semiconductor. SiC single makristasi anowanzo kugadzirwa kuburikidza neyemuviri vapor transport (PVT) nzira. Matanho chaiwo eiyi nzira anosanganisira kuisa SiC poda pazasi pe graphite crucible uye nekuisa SiC mhodzi crystal kumusoro kwe crucible. The graphitecrucibleinodziirwa kune sublimation tembiricha yeSiC, zvichiita kuti SiC hupfu iparare kuita mhute chikamu zvinhu zvakaita seSi vapor, Si2C, uye SiC2. Pasi pesimba reiyo axial tembiricha gradient, izvi zvinhu zvakanyungudutswa zvinodzika kusvika pamusoro peiyo crucible uye condense pamusoro peiyo SiC mhodzi crystal, ichipenya muSiC imwe makristasi.

Parizvino, dhayamita yekristaro yembeu inoshandiswa mukatiSiC single crystal kukurainoda kuenzanisa chinangwa chekristaro dhayamita. Panguva yekukura, kristaro yembeu inogadziriswa pamubati wembeu kumusoro kwechiputi uchishandisa adhesive. Zvisinei, iyi nzira yekugadzirisa mhodzi yekristaro inogona kutungamirira kune nyaya dzakadai sevhavha mumucheka wekunamatira nekuda kwezvinhu zvakadai sekunyatsonaka kwepamusoro pemuchengeti wembeu uye kufanana kwehuputi hwekunamatira, izvo zvinogona kukonzera kukanganiswa kwehexagonal void. Izvi zvinosanganisira kuvandudza flatness yegraphite plate, kuwedzera kufanana kweiyo adhesive layer ukobvu, uye kuwedzera inochinjika buffer layer. Pasinei nekuedza uku, kuchine nyaya nehukuru hweiyo inonamira layer, uye kune njodzi yembeu yekristaro detachment. Nekutora nzira yekubatanidza iyowaferkune graphite pepa uye kuiputira pamusoro peiyo crucible, kuwanda kweiyo adhesive layer inogona kuvandudzwa, uye dhizaini yewafer inogona kudzivirirwa.

1. Chirongwa chekuedza:

Iwo mawafer anoshandiswa mukuyedza anowanikwa mune zvekutengesa6-inch N-mhando yeSiC wafers. Photoresist inoshandiswa uchishandisa spin coater. Kunamatira kunowanikwa uchishandisa yega-yakagadzirwa mbeu inopisa-press furnace.

1.1 Mbeu yeCrystal Fixation Scheme:

Parizvino, iyo SiC yembeu yekristaro yekunamatira zvirongwa inogona kukamurwa kuita mapoka maviri: adhesive mhando uye kuturika mhando.

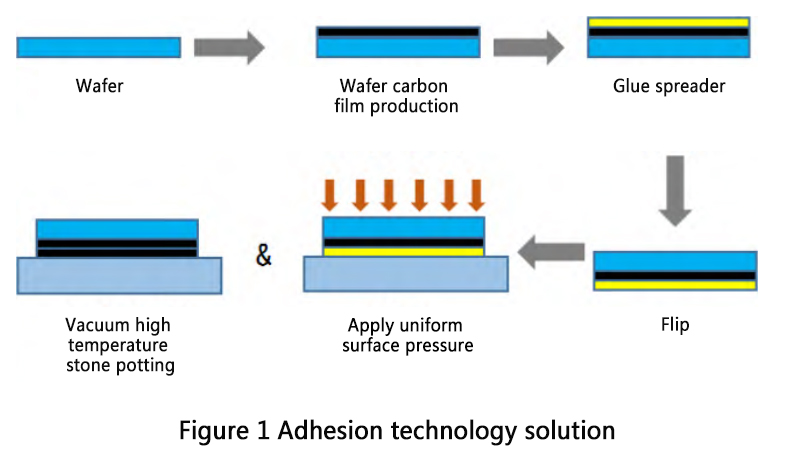

Adhesive Type Scheme (Mufananidzo 1): Izvi zvinosanganisira kubatanidza iyoSiC waferkune girafu ndiro ine pepa re graphite sevhavha yekubvisa mikaha pakati peSiC waferuye girafu ndiro. Muchigadzirwa chaicho, simba rekubatanidza pakati pe graphite bepa uye girafu ndiro harina simba, zvichiita kuti inogara iine mbeu yekristal detachment panguva yekukura kwekupisa kwepamusoro, zvichiita kuti kukura kukundikana.

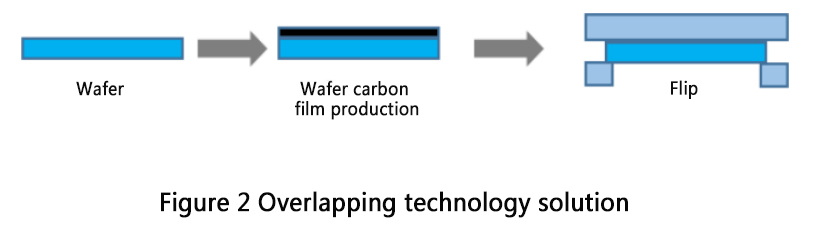

Suspension Type Scheme (Mufananidzo 2): Kazhinji, dense kabhoni firimu inogadzirwa pamusoro pekubatanidza pamusoro peSiC wafer uchishandisa glue carbonization kana nzira dzekuputira. TheSiC waferinobva yasungirirwa pakati pema graphite plates oiswa pamusoro pe graphite crucible, kuitira kugadzikana ukuwo kabhoni firimu rinodzivirira wafer. Nekudaro, kugadzira iyo kabhoni firimu kuburikidza nekuputira inodhura uye haina kukodzera kugadzirwa kwemaindasitiri. Iyo glue carbonization nzira inoburitsa isingaenderane kabhoni firimu mhando, zvichiita kuti zviome kuwana zvakakwana dense kabhoni firimu rine yakasimba adhesion. Pamusoro pezvo, kusungirira magirafu maplateti kunoderedza inobudirira nzvimbo yekukura yewafer nekuvhara chikamu chepamusoro payo.

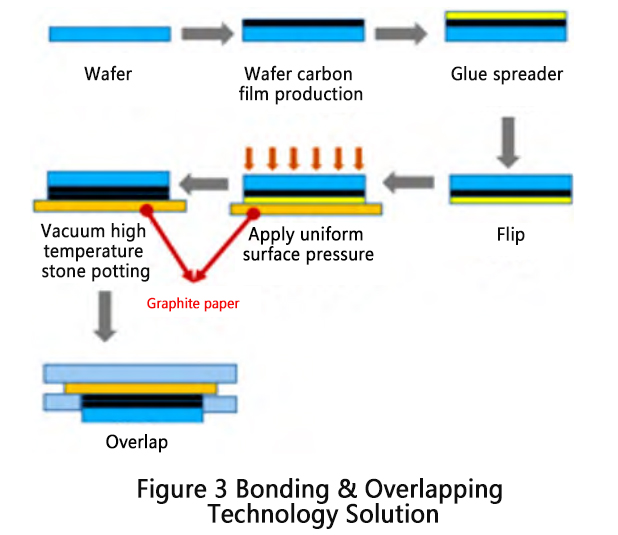

Kubva pane zvirongwa zviviri zviri pamusoro, chirongwa chitsva chekunamatira uye chinopindirana chinokurudzirwa (Mufananidzo 3):

Firimu rakati dende kabhoni rinogadzirwa pamusoro pekubatana kweSiC wafer uchishandisa nzira yeglue carbonization, kuve nechokwadi kuti hapana mwenje wakakura unobuda pasi pekuvhenekerwa.

Iyo SiC wafer yakafukidzwa nekabhoni firimu inosungirirwa kune graphite bepa, ine bonding surface iri iyo carbon film side. Iyo yekunamatira layer inofanirwa kuoneka yakafanana dema pasi pechiedza.

Iro graphite bepa rinosungirirwa nema graphite mahwendefa uye rakamiswa pamusoro pe graphite crucible yekukura kwekristaro.

1.2 Adhesive:

Iyo viscosity yephotoresist inonyanya kukanganisa iyo firimu ukobvu kufanana. Panguva imwecheteyo yekumhanyisa kumhanya, yakaderera viscosity inoguma mutete uye mamwe mayunifomu ekunamira mafirimu. Naizvozvo, yakaderera-viscosity photoresist inosarudzwa mukati mezvinodiwa zvekushandisa.

Munguva yekuedza, zvakaonekwa kuti viscosity ye carbonizing adhesive inokanganisa simba rekubatanidza pakati pe carbon film uye wafer. High viscosity inoita kuti zviome kushandisa zvakafanana uchishandisa spin coater, nepo yakaderera viscosity inokonzeresa isina kusimba yekubatanidza, zvichiita kuti kabhoni bhaisikopo riparare panguva dzinotevera dzekubatanidza maitiro nekuda kwekunamira kuyerera uye kunze kumanikidza. Kuburikidza nekutsvakurudza kwekuedza, viscosity ye carbonizing adhesive yakatemwa kuva 100 mPa · s, uye bonding adhesive viscosity yakaiswa ku 25 mPa · s.

1.3 Kushanda Vacuum:

Maitiro ekugadzira iyo kabhoni firimu paSiC wafer inosanganisira carbonizing iyo inonamira layer paSiC wafer pamusoro, iyo inofanirwa kuitwa munzvimbo isina vacuum kana argon-yakachengetedzwa. Mhedzisiro yekuedza inoratidza kuti nharaunda-yakachengetedzwa argon inonyanya kuita kabhoni firimu kusikwa pane yakakwirira vacuum nharaunda. Kana nzvimbo yevacuum ikashandiswa, iyo vacuum level inofanirwa kunge iri ≤1 Pa.

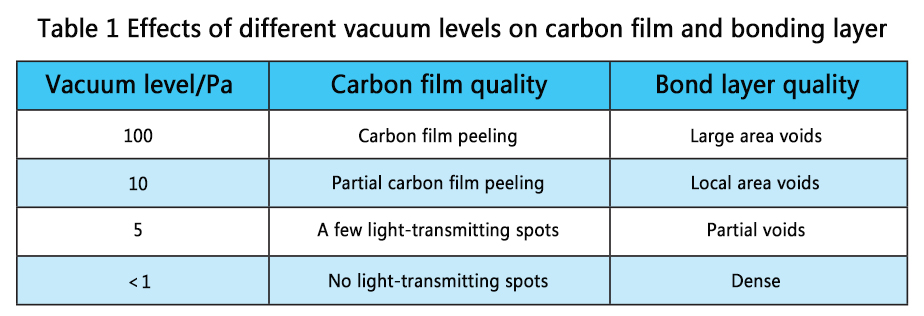

Maitiro ekubatanidza iyo SiC mhodzi kristaro inosanganisira kubatanidza iyo SiC wafer kune graphite plate/graphite bepa. Tichifunga nezve erosive mhedzisiro yeokisijeni pane graphite zvinhu pakupisa kwakanyanya, maitiro aya anoda kuitwa pasi pevacuum mamiriro. Mhedzisiro yemazinga akasiyana evacuum pane adhesive layer yakadzidzwa. Migumisiro yekuedza inoratidzwa muTebhu 1. Zvinogona kuonekwa kuti pasi pemamiriro ekudzivirira pasi, mamolekemu eokisijeni ari mumhepo haana kubviswa zvachose, zvichiita kuti zvive zvisina kukwana zvakanamatira. Kana iyo vacuum level iri pazasi pe10 Pa, iyo erosive mhedzisiro yeokisijeni mamorekuru pane inonamira layer inodzikiswa zvakanyanya. Kana iyo vacuum level iri pazasi 1 Pa, iyo erosive mhedzisiro inobviswa zvachose.

Nguva yekutumira: Jun-11-2024