Mazana emaitiro anodiwa kushandura awaferkuita semiconductor. Imwe yemaitiro akakosha ndeyeetching- kureva, kuveza maitiro akanaka edunhu panewafer. Kubudirira kweetchingmaitiro anoenderana nekugadzirisa akasiyana akasiyana mukati meseti yekugovera renji, uye yega yega etching mudziyo unofanirwa kugadzirirwa kushanda pasi pemamiriro akakwana. Yedu etching process mainjiniya anoshandisa yakanakisa kugadzira tekinoroji kupedzisa iyi yakadzama maitiro.

SK Hynix News Center yakabvunzurudza nhengo dzeIcheon DRAM Front Etch, Middle Etch, uye End Etch zvikwata zvehunyanzvi kuti vadzidze zvakawanda nezvebasa ravo.

Etch: Rwendo rweKuvandudza Chigadzirwa

Mukugadzira semiconductor, etching inoreva kuveza mapatani pamafirimu matete. Iwo mapatani anopfapfaidzwa uchishandisa plasma kuumba yekupedzisira danho rekuita. Chinangwa chayo chikuru ndechokupa zvakakwana maitiro chaiwo maererano nekugadzirisa uye kuchengetedza migumisiro yakafanana pasi pemamiriro ose.

Kana matambudziko akaitika mukudhirowa kana fotolithography maitiro, anogona kugadziriswa nekusarudza etching (Etch) tekinoroji. Nekudaro, kana chimwe chinhu chikatadza panguva yekugadzira, mamiriro acho haagone kudzoserwa kumashure. Izvi zvinodaro nekuti chinhu chimwe chete hachigone kuzadzwa munzvimbo yakavezwa. Naizvozvo, mune semiconductor yekugadzira maitiro, etching yakakosha kuona goho rese uye mhando yechigadzirwa.

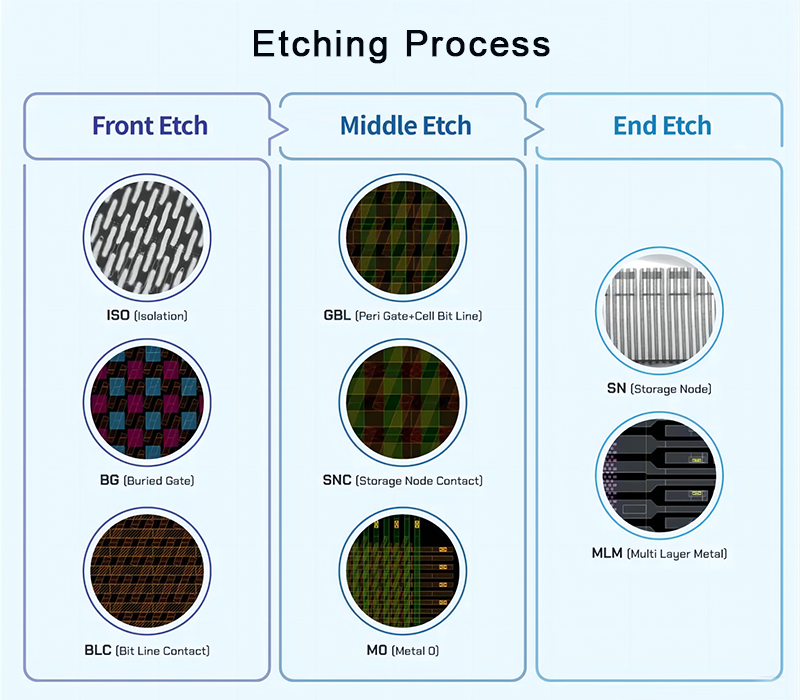

Iyo etching maitiro inosanganisira matanho masere: ISO, BG, BLC, GBL, SNC, M0, SN uye MLM.

Kutanga, iyo ISO (Isolation) nhanho etches (Etch) silicon (Si) pane wafer kugadzira iyo inoshanda sero nzvimbo. Iyo BG (Gedhi Rakavigwa) nhanho inoumba mutsara wekero mutsara (Mutsetse Weshoko) 1 uye gedhi rekugadzira chiteshi chemagetsi. Tevere, iyo BLC (Bit Line Contact) nhanho inogadzira chinongedzo pakati peISO nekoramu kero mutsara (Bit Line) 2 munzvimbo yesero. Iyo GBL (Peri Gedhi + Cell Bit Line) nhanho ichagadzira panguva imwe chete iyo sero column kero mutsara uye gedhi riri munharaunda 3.

Iyo SNC (Storage Node Contract) nhanho inoenderera mberi nekugadzira kubatana pakati penzvimbo inoshanda uye yekuchengetedza node 4. Zvadaro, iyo M0 (Metal0) nhanho inoumba nzvimbo dzekubatanidza dzeperipheral S/D (Storage Node) 5 uye nzvimbo dzekubatanidza. pakati peiyo column kero mutsara uye yekuchengetedza node. Iyo SN (Storage Node) nhanho inosimbisa huwandu hweyuniti, uye inotevera MLM (Multi Layer Metal) nhanho inogadzira ekunze magetsi uye wiring yemukati, uye iyo yose etching (Etch) engineering process inopedzwa.

Tichifunga kuti etching (Etch) matekinoroji anonyanya kuita maitiro ekuita semiconductors, dhipatimendi reDRAM rakakamurwa kuita zvikwata zvitatu: Front Etch (ISO, BG, BLC); Pakati Etch (GBL, SNC, M0); End Etch (SN, MLM). Zvikwata izvi zvakakamurwawo zvichienderana nenzvimbo dzekugadzira uye nzvimbo dzemidziyo.

Zvinzvimbo zvekugadzira zvine basa rekutonga nekuvandudza maitiro ekugadzira mayuniti. Nzvimbo dzekugadzira dzinoita basa rakakosha mukuvandudza goho uye mhando yechigadzirwa kuburikidza nekusiyana kwekutonga uye mamwe matanho ekugadzirisa ekugadzira.

Equipment zvinzvimbo zvine basa rekutonga nekusimbisa zvigadzirwa zvekugadzira kudzivirira matambudziko anogona kuitika panguva ye etching process. Basa guru rezvinzvimbo zvemidziyo ndere kuona kushanda kwakakwana kwemidziyo.

Kunyangwe mabasa acho akajeka, zvikwata zvese zvinoshandira kune chinangwa chakafanana - ndiko kuti, kubata nekuvandudza maitiro ekugadzira uye zvine chekuita nemidziyo yekuvandudza goho. Kuti izvi zviitike, timu yega yega inogovanisa zvayakawana uye nzvimbo dzekuvandudza, uye inobatirana kuvandudza mashandiro ebhizinesi.

Maitiro ekutarisana nematambudziko e miniaturization tekinoroji

SK Hynix yakatanga kugadzirwa kwakawanda kwe8Gb LPDDR4 DRAM zvigadzirwa zve10nm (1a) kirasi maitiro muna Chikunguru 2021.

Semiconductor ndangariro yedunhu mapatani apinda munguva ye10nm, uye mushure mekuvandudzwa, imwe DRAM inogona kugarisa anenge zviuru gumi maseru. Naizvozvo, kunyangwe mukuita etching, iyo process margin haina kukwana.

Kana gomba rakaumbwa (Hole) 6 riri diki zvakanyanya, rinogona kuita se "risina kuvhurwa" uye rakavharira chikamu chepasi chechip. Mukuwedzera, kana gomba rakaumbwa rakanyanya kukura, "bhiriji" rinogona kuitika. Kana mukaha uri pakati pemakomba maviri usina kukwana, "kusunga" kunoitika, zvichikonzera matambudziko ekubatana mumatanho anotevera. Sezvo semiconductors inowedzera kunatswa, huwandu hwehukuru hwegomba huri kudzikira zvishoma nezvishoma, uye njodzi idzi dzichabviswa zvishoma nezvishoma.

Kugadzirisa matambudziko ari pamusoro apa, etching tekinoroji nyanzvi dzinoramba dzichivandudza maitiro, kusanganisira kugadzirisa iyo nzira yekubikira uye APC7 algorithm, uye kuunza hutsva hwe etching tekinoroji senge ADCC8 uye LSR9.

Sezvo zvinodiwa nevatengi zvichiwedzera kusiyana, rimwe dambudziko rabuda - maitiro ekugadzirwa kwezvinhu zvakawanda. Kuti usangane nezvinodiwa nevatengi zvakadaro, iyo yakagadziridzwa maitiro emamiriro echigadzirwa chimwe nechimwe anofanirwa kusetwa akaparadzana. Iri idambudziko rakakosha kune mainjiniya nekuti ivo vanofanirwa kugadzira tekinoroji yekugadzira yakawanda kusangana nezvinodiwa zveese akamiswa mamiriro uye akasiyana mamiriro.

Kuti izvi zviitike, mainjiniya eEtch akaunza tekinoroji ye "APC offset" 10 yekubata zvakasiyana-siyana zvinobva pane zvakakosha zvigadzirwa (Core Zvigadzirwa), uye yakatanga nekushandisa "T-index system" kubata zvakakwana zvigadzirwa zvakasiyana. Kuburikidza nekuedza uku, sisitimu yagara ichivandudzwa kuti isangane nezvinodiwa zvekugadzirwa kwezvinhu zvakawanda.

Nguva yekutumira: Jul-16-2024