1.About Integrated Circuits

1.1 Pfungwa uye kuberekwa kwemasekete akabatanidzwa

Integrated Circuit (IC): inoreva mudziyo unobatanidza midziyo inoshanda senge transistors uye diode ine passive zvinhu senge resistors uye capacitor kuburikidza neakatevedzana emhando dzekugadzirisa maitiro.

Seketi kana sisitimu "yakasanganiswa" pane semiconductor (yakadai sesilicon kana macompounds akadai segallium arsenide) wafer zvinoenderana nekumwe kubatanidzwa kwedunhu uye wozoiswa mugoko kuita mabasa chaiwo.

Muna 1958, Jack Kilby, uyo aitarisira kuita miniaturization yemidziyo yemagetsi paTexas Instruments (TI), akaronga zano remaseketi akabatanidzwa:

"Sezvo zvinhu zvese zvakaita sema capacitor, resistors, transistors, nezvimwe zvichigona kugadzirwa kubva kune chimwe chinhu, ndakafunga kuti zvinokwanisika kuzvigadzira pachidimbu che semiconductor zvinhu uye wozobatanidza kuti dziite dunhu rakazara."

Musi waGunyana 12 naGunyana 19, 1958, Kilby akapedza kugadzira uye kuratidzira kwechikamu-shift oscillator uye trigger, zvichiteerana, zvichiratidza kuzvarwa kwedunhu rakabatanidzwa.

Muna 2000, Kilby akapiwa Mubairo weNobel muFizikisi. Dare reNobel Prize rakambotaura kuti Kilby "akavaka hwaro hweruzivo rwemazuva ano ruzivo."

Mufananidzo uri pazasi unoratidza Kilby uye yake yakabatanidzwa yedunhu patent:

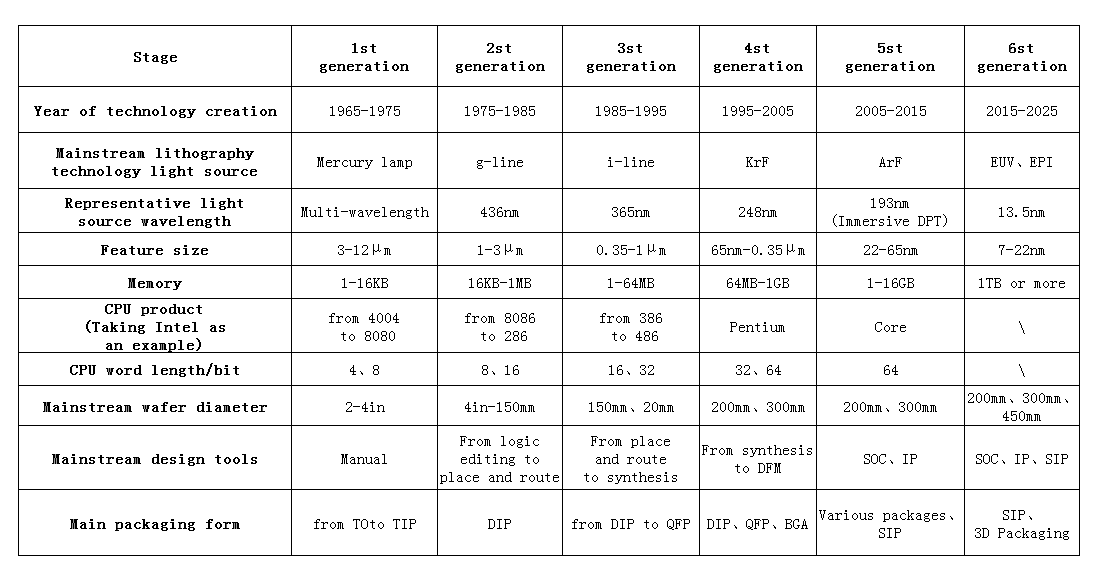

1.2 Kuvandudza tekinoroji yekugadzira semiconductor

Iyi inotevera nhamba inoratidza matanho ekusimudzira semiconductor yekugadzira tekinoroji:

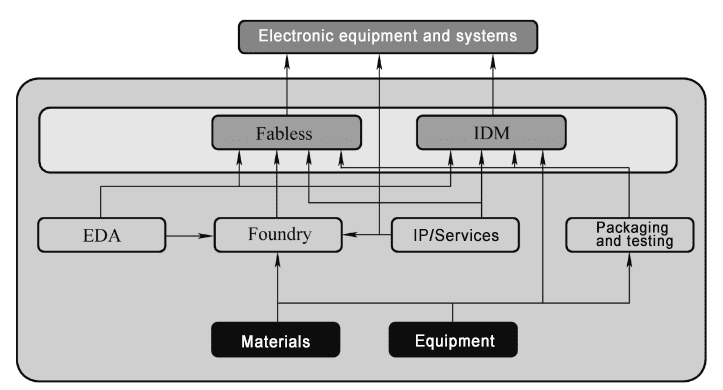

1.3 Integrated Circuit Industry Chain

Kuumbwa kweiyo semiconductor indasitiri chain (kunyanya akasanganiswa maseketi, kusanganisira discrete zvishandiso) inoratidzwa mumufananidzo uri pamusoro:

- Fabless: Kambani inogadzira zvigadzirwa pasina mutsara wekugadzira.

- IDM: Yakabatanidzwa Mugadziri Wechishandiso, yakasanganiswa mudziyo mugadziri;

- IP: Circuit module mugadziri;

- EDA: Electronic Dhizaini otomatiki, yemagetsi dhizaini otomatiki, kambani inonyanya kupa maturusi ekugadzira;

- Foundry; Wafer foundry, inopa masevhisi ekugadzira chip;

-Kurongedza uye kuyedza makambani ekutanga: kunyanya kushandira Fabless uye IDM;

- Zvishandiso uye makambani emidziyo yakakosha: kunyanya kupa zvinhu zvinodiwa uye michina yemakambani ekugadzira chip.

Zvigadzirwa zvikuru zvinogadzirwa uchishandisa semiconductor tekinoroji zvakasanganiswa maseketi uye discrete semiconductor zvishandiso.

Zvigadzirwa zvikuru zvemaseketi akabatanidzwa zvinosanganisira:

-Kushandisa Zvakananga Zvikamu Zvikamu (ASSP);

- Microprocessor Unit (MPU);

- Memory

-Kushandisa Yakananga Yakabatanidzwa Circuit (ASIC);

- Analog Circuit;

- General logic circuit (Logical Circuit).

Izvo zvakakosha zvigadzirwa zve semiconductor discrete zvishandiso zvinosanganisira:

- Diode;

- Transistor;

- Simba Chidimbu;

- High-Voltage Device;

- Microwave mudziyo;

- Optoelectronics;

- Sensor mudziyo (Sensor).

2. Integrated Circuit Manufacturing Process

2.1 Chip Manufacturing

Mazana kana makumi ezviuru emachipisi chaiwo anogona kugadzirwa panguva imwe chete pasilicon wafer. Huwandu hwemachipisi pasilicon wafer hunoenderana nerudzi rwechigadzirwa uye saizi yechip yega yega.

Silicon wafers inowanzonzi substrates. Hupamhi hwesilicon wafers hwave huchiwedzera nekufamba kwemakore, kubva isingasviki 1 inch pakutanga kusvika kune inowanzo shandiswa 12 inches (anenge 300 mm) ikozvino, uye iri kuita shanduko kusvika 14 inches kana 15 inches.

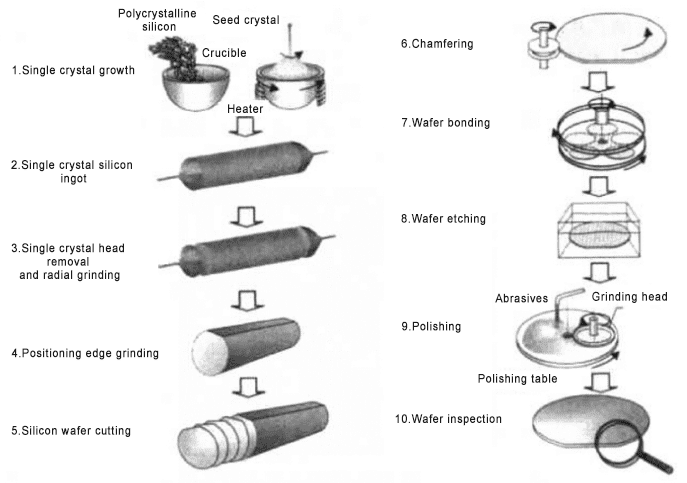

Kugadzira chip kunowanzo kukamurwa kuita matanho mashanu: silicon wafer kugadzirira, silicon wafer kugadzira, chip kuyedza / kutora, kusangana uye kurongedza, uye yekupedzisira kuyedzwa.

(1)

Kugadzirira kweSilicon wafer:

Kugadzira iyo mbishi, silicon inotorwa kubva mujecha uye inonatswa. Imwe nzira yakakosha inoburitsa silicon ingots yedhayamita yakakodzera. Iyo ingots inozochekwa kuita matete silicon wafers ekugadzira microchips.

Wafers akagadzirirwa kune zvakatemwa, sekunyoresa kumucheto zvinodiwa uye mazinga ekusvibiswa.

(2)Silicon wafer kugadzira:

Iyo inozivikanwawo sekugadzira chip, iyo isina silicon wafer inosvika pasilicon wafer yekugadzira chirimwa uye yobva yapfuura nekusiyana kuchenesa, kugadzira firimu, photolithography, etching uye doping matanho. Iyo yakagadziridzwa silicon wafer ine yakazara seti yakasanganiswa maseketi akaiswa zvachose pane iyo silicon wafer.

(3)Kuedza uye kusarudzwa kwesilicon wafers:

Mushure mekugadzirwa kwesilicon wafer kwapera, ma silicon wafers anotumirwa kunzvimbo yekuyedza / yemhando, uko machipisi ega anoongororwa uye nekuyedzwa nemagetsi. Machipisi anogamuchirwa uye asingagamuchirwe anobva agadziriswa, uye akaremara machipisi anomakwa.

(4)Gungano uye kurongedza:

Mushure mekuyedzwa kwewaferi / kurongedza, mawafesi anopinda mugungano uye nhanho yekurongedza kurongedza machipisi ega mune inodzivirira chubhu package. Rutivi rwekumashure rwechifukidzo rwakagadzika kuderedza kukora kwe substrate.

Firimu repurasitiki gobvu rinonamirwa kuseri kwechimedu chimwe nechimwe, uye ipapo chipande chine dhaimondi-chakapinzwa chesaha chinoshandiswa kupatsanura machipisi pawafe imwe neimwe pamwe nemitsetse yevanyori kudivi remberi.

Firimu repurasitiki riri kuseri kwesilicon wafer rinochengetedza silicon chip kubva pakudonha. Muchigadzirwa chegungano, machipisi akanaka anotsikirirwa kana kubviswa kuti aumbe pasuru yegungano. Gare gare, iyo chip inonamirwa mupurasitiki kana ceramic shell.

(5)Muedzo wekupedzisira:

Kuti ive nechokwadi chekushanda kwechip, yega yega yakasanganiswa yedunhu inoedzwa kuti isangane nemugadziri wemagetsi uye ezvakatipoteredza hunhu parameter zvinodiwa. Mushure mekuyedzwa kwekupedzisira, chip inotumirwa kumutengi kunoungana munzvimbo yakatsaurirwa.

2.2 Maitiro eDivisheni

Integrated circuit kugadzira maitiro anowanzo kukamurwa kuita:

Kumberi-kumagumo: Iyo yekumberi-yekupedzisira maitiro anowanzo inoreva maitiro ekugadzira emidziyo senge transistors, kunyanya kusanganisira magadzirirwo ekuzviparadzanisa nevamwe, chimiro chegedhi, sosi uye dhizaini, maburi ekusangana, nezvimwe.

Kumashure-kumagumo: Iyo yekumashure-yekupedzisira maitiro anonyanya kureva kuumbwa kwemitsara yekubatanidza iyo inogona kuendesa masaini emagetsi kune akasiyana midziyo pane chip, kunyanya kusanganisira maitirwo akadai sedhielectric deposition pakati pemitsara yekubatanidza, simbi yekugadzira mutsara, uye inotungamira padhi.

Mid-stage: Kuti uvandudze mashandiro e transistors, advanced tekinoroji node mushure me45nm / 28nm shandisa yakakwira-k gedhi dielectrics uye simbi gedhi maitiro, uye kuwedzera ekutsiva gedhi maitiro uye emunharaunda yekubatanidza maitiro mushure meiyo transistor sosi uye dhizaini chimiro chagadzirwa. Aya maitiro ari pakati pekutanga-yekupedzisira maitiro uye kumashure-yekupedzisira maitiro, uye haashandiswe mumaitiro echinyakare, saka anonzi epakati-nhanho maitiro.

Kazhinji, nzira yekugadzirira gomba ndiyo mutsara wekuparadzanisa pakati pekutanga-kuguma maitiro uye kumashure-kumagumo maitiro.

Bata gomba: gomba rakaiswa vertically musilicon wafer yekubatanidza yekutanga-layer simbi yekubatanidza mutsara uye substrate mudziyo. Iyo yakazadzwa nesimbi senge tungsten uye inoshandiswa kutungamira mudziyo electrode kune simbi yekubatanidza layer.

Kuburikidza neHole: Ndiyo nzira yekubatanidza pakati pematanho maviri ari padyo ematare ekubatanidza mitsara, iri mudielectric layer pakati pemarata maviri esimbi, uye inowanzozadzwa nesimbi semhangura.

Mupfungwa yakafara:

Front-end process: Mupfungwa yakafara, yakasanganiswa yedunhu kugadzirwa kunofanirwawo kusanganisira kuyedzwa, kurongedza uye mamwe matanho. Kuenzaniswa nekuedza uye kurongedza, chikamu uye kubatanidza kugadzira ndiyo chikamu chekutanga chekubatanidza dunhu rekugadzira, pamwe chete kunonzi semberi-yekupedzisira maitiro;

Back-end process: Kuedza uye kurongedza kunonzi kumashure-yekupedzisira maitiro.

3. Mashoko Okuwedzera

SMIF: Yakajairwa Mechanical Interface

AMHS: Automated Material Kubata System

OHT: Pamusoro Hoist Kuendesa

FOUP: Mberi Kuvhura Yakabatana Pod, Yakasarudzika kusvika 12 inch (300mm) zvitete

Zvinonyanya kukosha,Semicera inogona kupagraphite zvikamu, yakapfava/yakaoma,silicon carbide zvikamu, CVD silicon carbide zvikamu,uyeSiC/TaC yakavharwa zvikamuine yakazara semiconductor process mumazuva makumi matatu.Isu tinotarisira nemoyo wose kuve shamwari yako yenguva refu muChina.

Nguva yekutumira: Aug-15-2024