One Overview

Mune yakasanganiswa yedunhu rekugadzira dhizaini, photolithography ndiyo yakakosha nhanho inotaridza nhanho yekubatanidza yemaseketi akabatanidzwa. Basa rekuita uku ndere kuendesa nekutendeka uye kuendesa redunhu graphic ruzivo kubva kumasiki (inonziwo mask) kune semiconductor zvinhu substrate.

Iyo yakakosha musimboti weiyo photolithography process ndeye kushandisa iyo photochemical reaction yephotoresist yakavharwa pamusoro peiyo substrate kurekodha dunhu patani pamaski, nekudaro kuzadzisa chinangwa chekufambisa yakabatanidzwa yedunhu pateni kubva padhizaini kuenda kune substrate.

Iyo yekutanga nzira yephotolithography

Kutanga, photoresist inoshandiswa pane substrate pamusoro uchishandisa muchina wekuputira;

Zvadaro, muchina wephotolithography unoshandiswa kufumura iyo substrate yakavharwa ne photoresist, uye iyo photochemical reaction mechanism inoshandiswa kunyora maski pateni ruzivo rwunotumirwa nemuchina wefotolithography, kupedzisa kutendeseka kutapurirana, kutamisa uye kudzokorora kwemaski patani kune substrate;

Pakupedzisira, mugadziri anoshandiswa kugadzira iyo yakafumurwa substrate kubvisa (kana kuchengetedza) iyo photoresist inosangana nephotochemical reaction mushure mekuratidzwa.

Chechipiri photolithography process

Kuti uendese iyo yakagadzirirwa yedunhu patani pane mask kune iyo silicon wafer, kuchinjisa kunofanirwa kutanga kuwanikwa kuburikidza nekuratidzira, uyezve iyo silicon pateni inofanirwa kuwanikwa kuburikidza ne etching maitiro.

Sezvo kuvhenekerwa kwenzvimbo yephotolithography kunoshandisa yero mwenje sosi iyo photosensitive zvinhu zvisinganzwe, inodaidzwa zvakare kuti yero mwenje nzvimbo.

Photolithography yakatanga kushandiswa muindasitiri yekudhinda uye yaive tekinoroji huru yekutanga kugadzira PCB. Kubva kuma1950s, photolithography yave zvishoma nezvishoma yave tekinoroji yakakura yekuchinjisa maitiro muIC kugadzira.

Iwo akakosha ezviratidzo zvelithography maitiro anosanganisira kugadzirisa, kunzwa, kurongeka kwepamusoro, chiyero chekuremara, nezvimwe.

Chinhu chinonyanya kukosha muchiitiko chephotolithography ndeye photoresist, iyo inonzi photosensitive material. Sezvo kunzwisiswa kweiyo photoresist kunoenderana newavelength yemwenje sosi, akasiyana mafotoresist zvinhu zvinodiwa pakuita photolithography maitiro senge g/i mutsara, 248nm KrF, uye 193nm ArF.

Iyo huru nzira yeyakajairwa photolithography process inosanganisira matanho mashanu

:

-Base firimu kugadzirira;

-Shandisa photoresist uye nyoro kubika;

-Kurongeka, kuratidzwa uye post-exposure baking;

-Kugadzira firimu rakaoma;

-Development kuonekwa.

(1)Base firimu kugadzirira: kunyanya kuchenesa uye kupera mvura. Nekuti chero zvinosvibisa zvinonetesa kunamatira pakati pephotoresist newafer, kunyatso kuchenesa kunogona kuvandudza kunamatira pakati pewafer nephotoresist.

(2)Photoresist kupfeka: Izvi zvinowanikwa nekutenderedza silicon wafer. Akasiyana photoresists anoda akasiyana coating process paramita, kusanganisira kutenderera kumhanya, photoresist ukobvu, uye tembiricha.

Kubika kwakapfava: Kubika kunogona kuvandudza kunamatira pakati pephotoresist uye silicon wafer, pamwe nekufanana kweiyo photoresist ukobvu, iyo inobatsira pakutonga chaiko kweiyo geometric zviyero zveinotevera etching process.

(3)Kurongeka uye kuratidzwa: Kurongeka uye kuratidzwa ndiwo matanho anonyanya kukosha mukugadzirisa photolithography. Ivo vanoreva kubatanidza iyo mask pateni neiyo iripo pateni pawafer (kana yekumberi dhizaini pateni), uye wozoivhenekera nemwenje chaiwo. Simba rechiedza rinoita kuti photosensitive components mu photoresist, nekudaro kuendesa iyo mask pattern kune photoresist.

Iyo midziyo inoshandiswa pakurongeka uye kuratidzwa ndeye photolithography muchina, inova ndiyo inodhura imwe chete chidimbu chekugadzira michina mune yese yakabatanidzwa yedunhu rekugadzira maitiro. Iyo tekinoroji nhanho yemuchina wefotolithography inomiririra mwero wekufambira mberi kwemutsara wese wekugadzira.

Post-exposure baking: inoreva nzira pfupi yekubheka mushure mekuratidzwa, iyo ine mhedzisiro yakasiyana pane yakadzika ultraviolet photoresists uye yakajairika i-line photoresists.

Kune yakadzika ultraviolet photoresist, post-exposure baking inobvisa zvikamu zvekudzivirira mu photoresist, zvichiita kuti photoresist iparadze mumugadziri, saka post-exposure baking inofanirwa;

Kune vakajairwa i-line photoresists, post-exposure baking inogona kuvandudza kunamatira kwephotoresist uye kuderedza mafungu akamira (mafungu akamira achave nemhedzisiro yakaipa pamucheto morphology yephotoresist).

(4)Kugadzira firimu rakaoma: kushandisa mugadziri kunyungudutsa chikamu chinonyungudika chephotoresist (positive photoresist) mushure mekuratidzwa, uye kunyatsoratidza mask pateni nephotoresist pateni.

Iwo akakosha maparamendi eiyo nzira yekusimudzira anosanganisira tembiricha yekuvandudza uye nguva, dhizaini yedhijitari uye kutarisisa, kuchenesa, nezvimwe. Nekugadzirisa akakodzera paramita mukusimudzira, mutsauko wekuparara kwehuwandu pakati pezvakafumurwa uye zvisina kuratidzwa zvikamu zvephotoresist zvinogona kuwedzerwa, nekudaro. kuwana chinodiwa budiriro mhedzisiro.

Kuomarara kunozivikanwawo sekuomesa kubika, inova maitiro ekubvisa yasara solvent, kuvandudza, mvura uye zvimwe zvisingakodzeri zvakasara zvikamu muyakagadzirwa photoresist nekudziisa uye nekudziisa, kuitira kuvandudza kunamatira kweiyo photoresist kune silicon substrate uye. iyo etching kuramba kwephotoresist.

Iyo tembiricha yekuomesa maitiro inosiyana zvichienderana neakasiyana photoresists uye nzira dzekuomesa. Mhedzisiro ndeyekuti iyo photoresist pateni haina kukanganisa uye iyo photoresist inofanira kuitwa yakaoma zvakakwana.

(5)Kuongorora kwebudiriro: Uku kutarisa kukanganisa mune photoresist pateni mushure mekuvandudzwa. Kazhinji, tekinoroji yekucherekedza mifananidzo inoshandiswa kungoongorora otomatiki chip pateni mushure mekuvandudzwa uye kuienzanisa neyekare-yakachengetwa yakaremara-isina standard pateni. Kana chero mutsauko ukawanikwa, unofungidzirwa kuti hauna kukwana.

Kana huwandu hwekuremara huchipfuura humwe kukosha, iyo silicon wafer inotongwa kunge yakundikana bvunzo yekuvandudza uye inogona kuraswa kana kugadzirwazve sezvakakodzera.

Muchirongwa chekugadzira chedunhu chakabatanidzwa, maitiro mazhinji haachinjike, uye photolithography ndeimwe yemaitiro mashoma anogona kugadziriswa zvakare.

Matatu mafotomasks uye photoresist zvinhu

3.1 Photomask

Iyo photomask, inozivikanwawo se photolithography mask, inyanzvi inoshandiswa mukuita photolithography yekubatanidza wedunhu wafer kugadzira.

Iyo photomask yekugadzira maitiro ndeyekushandura iyo yekutanga dhizaini data inodiwa pakugadzira wafer yakagadzirwa neyakasanganiswa yedunhu dhizaini mainjiniya kuita data fomati iyo inogona kuzivikanwa nelaser patani jenareta kana electron beam exposure equipment kuburikidza nemask data processing, kuti iburitswe ne. midziyo iri pamusoro apa pane photomask substrate zvinhu zvakaputirwa nephotosensitive zvinhu; zvino inogadziriswa kuburikidza neakatevedzana maitiro akadai sekusimudzira uye etching kugadzirisa iyo pateni pane substrate zvinhu; pakupedzisira, inoongororwa, inogadziriswa, yakacheneswa, uye firimu-laminated kuti iite mask chigadzirwa uye inoendeswa kune yakasanganiswa yedunhu mugadziri kuti ishandiswe.

3.2 Photoresist

Photoresist, inozivikanwawo se photoresist, ndeye photosensitive zvinhu. Iyo photosensitive components mairi ichaita shanduko yemakemikari pasi pekuvhenekera kwechiedza, nekudaro zvichikonzera shanduko muhuwandu hwekuparara. Basa rayo guru ndere kuendesa pateni pane mask kune substrate senge wafer.

Kushanda mutemo we photoresist: Kutanga, iyo photoresist yakaputirwa pa substrate uye isati yabikwa kuti ibvise solvent;

Chechipiri, iyo mask inoratidzirwa kuchiedza, zvichiita kuti mafotosensitive zvikamu muchikamu chakafumurwa chiite kemikari reaction;

Zvadaro, kubikwa kwemashure-kuratidzwa kunoitwa;

Pakupedzisira, iyo photoresist inonyungudutswa zvishoma kuburikidza nekuvandudzwa (kune yakanaka photoresist, nzvimbo yakazaruka inonyungudutswa; kune negative photoresist, nzvimbo isina kuvharwa inonyungudutswa), nekudaro inoona kuendeswa kweiyo yakabatanidzwa yedunhu pateni kubva kumasiki kuenda kune substrate.

Izvo zvikamu zve photoresist zvinonyanya zvinosanganisira firimu-inogadzira resin, photosensitive chikamu, trace additives uye solvent.

Pakati pavo, iyo firimu-inogadzira resin inoshandiswa kupa mechanical properties uye etching resistance; iyo photosensitive chikamu inosangana nekuchinja kwemakemikari pasi pechiedza, zvichikonzera kuchinja kwehuwandu hwekuparara;

Trace additives zvinosanganisira dhayi, viscosity enhancers, nezvimwewo, izvo zvinoshandiswa kuvandudza mashandiro ephotoresist; zvinonyungudutsa zvinoshandiswa kunyungudutsa zvikamu uye kuzvisanganisa zvakaenzana.

Iwo mafotoresist parizvino ari mukushandiswa kwakakura anogona kukamurwa kuita echinyakare photoresists uye makemikari akawedzera photoresists zvinoenderana neiyo photochemical reaction mechanism, uye inogona zvakare kukamurwa kuita ultraviolet, yakadzika ultraviolet, yakanyanyisa ultraviolet, electron beam, ion beam uye X-ray photoresists zvinoenderana ne photosensitivity wavelength.

Zvina photolithography midziyo

Photolithography tekinoroji yakapinda mukati mekuvandudza maitiro ekusangana/pedyo lithography, optical projection lithography, nhanho-uye-kudzokorora lithography, scanning lithography, immersion lithography, uye EUV lithography.

4.1 Kubata / Kuswedera Lithography Machine

Bata lithography tekinoroji yakaonekwa muma1960 uye yakashandiswa zvakanyanya muma1970s. Yakanga iri nzira huru yelithography munguva yemadiki-akabatanidzwa maseketi uye ainyanya kushandiswa kugadzira maseketi akabatanidzwa ane saizi yehukuru kupfuura 5μm.

Mune yekubata / padyo lithography muchina, wafer inowanzoiswa pane inodzorwa nemaoko yakachinjika chinzvimbo uye inotenderera yekushanda. Mushandi anoshandisa discrete field microscope kuti panguva imwe chete aone nzvimbo yemask uye wafer, uye nemaoko anodzora chinzvimbo chetabhenakeri yekubatanidza mask uye wafer. Mushure mekunge chifukidziro uye mask zvaenderana, izvo zviviri zvichatsikirirwa pamwe chete kuitira kuti maski ibatane zvakananga nephotoresist pamusoro pechifukidziro.

Mushure mekubvisa chinangwa chemicroscope, wafer yakadzvanywa uye mask zvinofambiswa kutafura yekuratidzwa kuti ionekwe. Chiedza chinobudiswa nemercury rambi chinosanganiswa uye chakafanana nemasiki kuburikidza nelenzi. Sezvo iyo maski iri kutarisana zvakananga neiyo photoresist layer pane wafer, iyo mask pattern inotamirwa kune photoresist layer pachiyero che1: 1 mushure mekuratidzwa.

Bata lithography midziyo ndiyo yakapfava uye yakanyanya hupfumi Optical lithography midziyo, uye inogona kuwana kuratidzwa kweiyo sub-micron chimiro saizi magirafu, saka ichiri kushandiswa mudiki-batch chigadzirwa kugadzira uye murabhoritari tsvagiridzo. Mune yakakura-yakakura yakabatanidzwa yedunhu kugadzirwa, proximity lithography tekinoroji yakaunzwa kudzivirira kuwedzera kwemitengo yelithography inokonzerwa nekusangana kwakananga pakati pemask uye wafer.

Proximity lithography yaishandiswa zvakanyanya muma1970 panguva yemadiki-akabatanidzwa maseketi uye nguva yekutanga yepakati-mwero akabatanidzwa maseketi. Kusiyana nekubata lithography, iyo mask iri padhuze lithography haina kutarisana zvakananga nephotoresist pawafer, asi gap rakazadzwa nenitrogen rinosara. Iyo maski inoyangarara pane nitrogen, uye saizi yepakati pakati pemaski newaferi inotarwa neiyo nitrogen pressure.

Sezvo pasina kutarisana kwakananga pakati pechifukidziro uye mask padhuze lithography, zvikanganiso zvakaunzwa panguva yelithography process zvakaderedzwa, nekudaro kuderedza kurasikirwa kwemask uye kugadzirisa goho rewafer. Mupedyo lithography, mukaha uripo pakati pewafer nemask inoisa wafer mudunhu reFresnel diffraction. Kuvapo kwe diffraction kunoganhurira kumwe kuvandudzwa kwekugadziriswa kweproximity lithography midziyo, saka tekinoroji iyi inonyanya kukodzera kugadzirwa kwemaseketi akabatanidzwa ane saizi inodarika 3μm.

4.2 Stepper uye Repeater

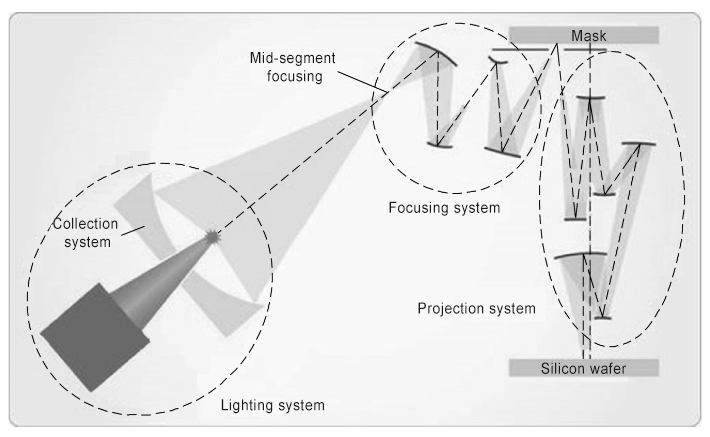

Iyo stepper ndeimwe yemidziyo yakakosha munhoroondo yewafer lithography, iyo yakasimudzira iyo sub-micron lithography process mukugadzirwa kwakawanda. Iyo stepper inoshandisa yakajairwa static exposure field ye 22mm × 22mm uye optical projection lens ine reshiyo yekudzikisa ye5: 1 kana 4: 1 kuendesa pateni pane mask kune wafer.

Iyo nhanho-uye-inodzokorora lithography muchina kazhinji inoumbwa neiyo exposure subsystem, workpiece nhanho subsystem, mask nhanho subsystem, yekutarisa / leveling subsystem, alignment subsystem, main frame subsystem, wafer transfer subsystem, mask transfer subsystem. , yemagetsi subsystem, uye software subsystem.

Iyo yakajairika yekushanda maitiro enhanho-uye-inodzokorora lithography muchina ndeiyi inotevera:

Chekutanga, iyo wafer yakaputirwa nephotoresist inotamirwa kune workpiece tafura nekushandisa wafer transfer subsystem, uye mask kuti iburitswe inotamirwa kune mask tafura uchishandisa mask transfer subsystem;

Zvadaro, sisitimu inoshandisa iyo inotarisisa/leveling subsystem kuti iite multi-point urefu kuyerwa pawafer pane workpiece nhanho kuwana ruzivo rwakaita sehurefu uye kurerekera kona yechiso chewafer kuti iburitswe, kuitira kuti nzvimbo yekuratidzwa iyo wafer inogona kugara ichidzorwa mukati mekudzika kwechinangwa chekufungidzira panguva yekuratidzwa;Mushure meizvozvo, iyo sisitimu inoshandisa alignment subsystem kurongedza mask uye wafer kuitira kuti panguva yekuratidzwa maitiro, iko kurongeka kweiyo maski mufananidzo uye wafer pateni yekuchinjisa inogara iri mukati mezvido zvekufukidzira.

Chekupedzisira, nhanho-uye-kuratidzwa chiito cheiyo wafer pamusoro pese inopedzwa zvinoenderana neyakatemwa nzira yekuona iyo pateni yekufambisa basa.

Iyo inotevera stepper uye scanner lithography muchina wakavakirwa pane iri pamusoro pekutanga kushanda maitiro, kunatsiridza kutsika → kuratidzwa kune scanning → kuratidzwa, uye kutarisa / kuenzanisa → kurongeka → kuratidzwa pane mbiri-nhanho modhi kuyera (kutarisisa / kuyera → kurongeka) uye kuongorora. exposure in parallel.

Kuenzaniswa nedanho-uye-scan lithography muchina, nhanho-uye-inodzokorora lithography muchina haidi kuwana synchronous reverse scanning yemask uye wafer, uye haidi tafura yekuvheneka mask uye synchronous scanning control system. Nokudaro, chimiro chacho chiri nyore, mari yacho inenge yakaderera, uye kushanda kwakavimbika.

Mushure mekunge IC tekinoroji yapinda 0.25μm, kushandiswa kwedanho-uye-kudzokorora lithography kwakatanga kudzikira nekuda kwezvakanakira nhanho-uye-scan lithography mu scanning exposure field size and exposure uniformity. Parizvino, ichangoburwa nhanho-uye-inodzokorora lithography yakapihwa naNikon ine static exposure munda yekuona yakakura seye nhanho-uye-scan lithography, uye inokwanisa kugadzira anopfuura mazana maviri mawafer paawa, iine yakanyanya kunaka kugadzirwa. Rudzi urwu rwemuchina welithography parizvino unonyanya kushandiswa kugadzira asiri-akakosha IC layer.

4.3 Stepper Scanner

Iko kushandiswa kwedanho-uye-scan lithography kwakatanga muma1990s. Nekugadzirisa zvakasiyana-siyana zviedza zvemwenje, nhanho-uye-scan tekinoroji inogona kutsigira akasiyana maitiro tekinoroji node, kubva pa365nm, 248nm, 193nm kunyudzwa kuenda kuEUV lithography. Kusiyana nenhanho-uye-inodzokorora lithography, iyo-imwe-munda kuratidzwa kwenhanho-uye-scan lithography inotora dynamic scanning, ndiko kuti, iyo mask plate inopedza iyo scanning movement synchronously inoenderana newafer; mushure mekuratidzwa kwemunda kwazvino kwapera, wafer inotakurwa neiyo workpiece nhanho uye yakatsikwa kune inotevera scanning munda chinzvimbo, uye kudzokororwa kuratidzwa kunoenderera; dzokorora nhanho-uye-scan kuratidzwa kakawanda kusvikira minda yese yewafer yaburitswa.

Nekugadzirisa mhando dzakasiyana dzemwenje masosi (senge i-line, KrF, ArF), stepper-scanner inogona kutsigira dzinenge dzese tekinoroji node dzeiyo semiconductor yekumberi-yekupedzisira maitiro. Typical silicon-based CMOS maitiro atora stepper-scanner muhuwandu hukuru kubva 0.18μm node; iyo yakanyanyisa ultraviolet (EUV) lithography michina ikozvino inoshandiswa mukuita node pazasi 7nm inoshandisawo stepper-scanning. Mushure mekugadzirisa zvishoma, iyo stepper-scanner inogona zvakare kutsigira kutsvagisa uye kusimudzira uye kugadzirwa kweakawanda asiri-silicon-based maitiro seMEMS, magetsi maturusi, uye RF zvishandiso.

Vagadziri vakuru venhanho-uye-scan projection lithography michina inosanganisira ASML (Netherlands), Nikon (Japan), Canon (Japan) uye SMEE (China). ASML yakatanga TWINSCAN series of step-and-scan lithography machines muna 2001. Inotora maitiro maviri ekugadzirisa maitiro, iyo inogona kunyatsogadzirisa chiyero chekubuda kwemidziyo uye yakave inonyanya kushandiswa kwepamusoro-kuguma lithography machine.

4.4 Kunyudza Lithography

Zvinogona kuonekwa kubva kuRayleigh formula kuti, kana kuratidzwa kwewavelength kunoramba kusina kuchinjwa, nzira inoshanda yekuwedzera kugadzirisa kugadzirisa kwekufungidzira ndeyekuwedzera nhamba yeaperture ye imaging system. Pamagadzirirwo ekufungidzira ari pasi pe45nm zvichikwira, iyo ArF yakaoma exposure nzira haichakwanisa kuzadzisa zvinodiwa (nekuti inotsigira iyo yakanyanya imaging resolution ye65nm), saka zvinodikanwa kusuma nzira yekunyudza lithography. Muchinyakare lithography tekinoroji, yepakati pakati pelenzi nephotoresist imhepo, nepo kunyudza lithography tekinoroji inotsiva mhepo yemhepo nemvura (kazhinji ultrapure mvura ine refractive index ye1.44).

Muchokwadi, immersion lithography tekinoroji inoshandisa kupfupisa kwewavelength yemwenje sosi mushure mekunge mwenje wapfuura nepakati pemvura kuvandudza kugadziriswa, uye kupfupisa reshiyo ndiyo refractive index yemvura yepakati. Kunyangwe iyo yekunyudza lithography muchina imhando yenhanho-uye-scan lithography muchina, uye yayo yekushandisa system mhinduro haina kuchinja, iko kugadziridzwa uye kuwedzera kweArF nhanho-uye-scan lithography muchina nekuda kwekuunzwa kwekiyi matekinoroji ane hukama. kunyudza.

Kubatsira kwekunyudza lithography ndeyekuti, nekuda kwekuwedzera kwenhamba yeaperture yehurongwa, kugona kwekufungidzira kweiyo stepper-scanner lithography muchina inovandudzwa, iyo inogona kusangana nemaitiro ekuda kwekufungidzira kugadzirisa pazasi 45nm.

Sezvo muchina wekunyudza lithography uchiri kushandisa ArF mwenje sosi, kuenderera kwemaitiro acho kunovimbiswa, kuchengetedza iyo R&D mutengo wemwenje sosi, zvishandiso uye maitiro. Pahwaro uhwu, yakasanganiswa neakawanda magiraidhi uye computational lithography tekinoroji, muchina wekunyudza lithography unogona kushandiswa pamanodhi e22nm uye pazasi. Muchina weEUV lithography usati waiswa zviri pamutemo mukugadzirwa kwakawanda, muchina wekunyudza lithography wanga washandiswa zvakanyanya uye waigona kuzadzisa zvinodiwa zve7nm node. Nekudaro, nekuda kwekuiswa kwemvura yekunyudza, kuoma kweinjiniya kwemidziyo pachayo kwakawedzera zvakanyanya.

Tekinoroji dzayo dzakakosha dzinosanganisira kunyudza mvura yekupa uye kudzoreredza tekinoroji, kunyudza mvura yemumunda kugadzirisa tekinoroji, kunyudza lithography kusvibiswa uye hurema hwekudzora tekinoroji, kusimudzira uye kugadzirisa kweakanyanya-hombe manhamba kunyudzwa kunyudzwa kwema lenses, uye yekufungidzira mhando yekuona tekinoroji pasi pemamiriro ekunyudzwa.

Parizvino, yekushambadzira ArFi nhanho-uye-scan lithography michina inonyanya kupihwa nemakambani maviri, anoti ASML yeNetherlands neNikon yekuJapan. Pakati pavo, mutengo weimwe ASML NXT1980 Di ingangoita 80 miriyoni euros.

4.5 Yakanyanya Ultraviolet Lithography Machine

Kuti uvandudze kugadzirisa kwephotolithography, iyo exposure wavelength inozopfupikiswa mushure meiyo excimer light source yagamuchirwa, uye yakanyanyisa ultraviolet mwenje ine wavelength ye10 kusvika 14 nm inounzwa seyakajeka mwenje sosi. Iyo yavelength yeyakanyanya ultraviolet mwenje ipfupi zvakanyanya, uye inofungidzira optical sisitimu inogona kushandiswa inowanzo umbwa nema multilayer mafirimu anoratidza seMo/Si kana Mo/Be.

Pakati pavo, theoretical maximum reflectivity yeMo/Si multilayer firimu muwavelength renji ye13.0 kusvika 13.5nm ingangoita 70%, uye theoretical maximum reflectivity yeMo/Be multilayer firimu pane ipfupi wavelength ye11.1nm ingangoita 80%. Kunyangwe kuratidzwa kweMo/Be multilayer firimu rekuratidzira kwakakwira, Be ine muchetura zvakanyanya, saka kutsvagisa pazvinhu zvakadaro kwakasiiwa pakugadzira tekinoroji yeEUV.Iyo yazvino EUV lithography tekinoroji inoshandisa Mo/Si multilayer firimu, uye exposure wavelength yakatemerwawo kuve 13.5nm.

Iyo mainstream yakanyanyisa ultraviolet mwenje sosi inoshandisa laser-yakagadzirwa plasma (LPP) tekinoroji, iyo inoshandisa yakakwirira-yakasimba lasers kufadza inopisa-yakanyunguduka Sn plasma kuburitsa chiedza. Kwenguva yakareba, simba uye kuwanikwa kwechiedza sosi anga ari mabhodhoro anorambidza kushanda kweEUV lithography michina. Kuburikidza neiyo master oscillator simba amplifier, predictive plasma (PP) tekinoroji uye in-situ yekuunganidza girazi rekuchenesa tekinoroji, simba uye kugadzikana kweEUV magetsi masosi zvakagadziridzwa zvakanyanya.

Muchina weEUV lithography unonyanya kuumbwa ne subsystems senge mwenje sosi, mwenje, chinangwa lens, workpiece nhanho, mask nhanho, wafer alignment, kutarisa / level, kufambisa kwemask, wafer transmission, uye vacuum furemu. Mushure mekupfuura nepakati pekuvhenekesa system inoumbwa neakawanda-layer coated reflectors, yakanyanyisa ultraviolet mwenje inovhenekerwa pane inopenya mask. Chiedza chinoratidzwa nemasikisi chinopinda mu optical total reflection imaging system inoumbwa nenhevedzano yezviratidziro, uye pakupedzisira mufananidzo unoratidzwa wemasiki unoratidzwa pamusoro pechifukidziro chiri munzvimbo ine vacuum.

Iyo yekuratidzwa nzvimbo yekuona uye yekufungidzira ndima yekuona yemuchina weEUV lithography ese ari arc-arc, uye nhanho-ne-nhanho nzira yekuongorora inoshandiswa kuwana yakazara wafer exposure yekuvandudza chiyero chekubuda. ASML's most advanced NXE series EUV lithography muchina inoshandisa exposure light sosi ine wavelength ye13.5nm, chifukidzo chinopenya (6° oblique chiitiko), 4x kuderedza inoratidzira fungidziro yechinangwa system ine 6-mirror chimiro (NA=0.33), a scanning ndima yekuona ye26mm × 33mm, uye vacuum exposure nharaunda.

Kuenzaniswa nemichina yekunyudza lithography, iyo imwechete exposure resolution yeEUV lithography michina inoshandisa yakanyanyisa ultraviolet mwenje masosi yakagadziridzwa zvakanyanya, iyo inogona kunyatso kudzivirira iyo yakaoma nzira inodiwa kuti akawanda photolithography igadzire yakakwirira-resolution giraidhi. Parizvino, iyo imwechete exposure resolution yeNXE 3400B lithography muchina ine nhamba aperture ye0.33 inosvika 13nm, uye chiyero chekubuda chinosvika 125 zvidimbu / h.

Kuti zvizadzise zvinodikanwa zvekuwedzera kuwedzera kweMutemo waMoore, mune ramangwana, michina yeEUV lithography ine manhamba aperture ye0.5 ichatora chirongwa chekufungidzira chine chepakati chekuvharira mwenje, uchishandisa asymmetric magnification ye0.25 times/0.125 nguva, uye iyo kutarisisa nzvimbo yekutarisa ichaderedzwa kubva pa26m × 33mm kusvika 26mm × 16.5mm, uye iyo single exposure resolution inogona kusvika pazasi 8nm.

—————————————————————————————————————————————————— ————————————

Semicera inogona kupagraphite zvikamu, kupfava/kuomarara kunzwa, silicon carbide zvikamu, CVD silicon carbide zvikamu,uyeSiC/TaC yakavharwa zvikamuine yakazara semiconductor process mumazuva makumi matatu.

Kana iwe uchifarira zviri pamusoro semiconductor zvigadzirwa,ndapota usazeza kutibata nesu panguva yekutanga.

Tel: +86-13373889683

WhatsAPP: +86-15957878134

Email: sales01@semi-cera.com

Nguva yekutumira: Aug-31-2024