Imwe Nhanganyaya

Etching mune yakabatanidzwa yedunhu rekugadzira maitiro akakamurwa kuita:

- Kunyorova kwemvura;

-Dry etching.

Mumazuva ekutanga, wet etching yaishandiswa zvakanyanya, asi nekuda kwekugumira mumutsara wehupamhi hwekutonga uye etching directionality, maitiro mazhinji mushure me3μm anoshandisa yakaoma etching. Wet etching inongoshandiswa kubvisa mamwe akakosha maturu akaturikidzana uye akachena masara.

Dry etching inoreva maitiro ekushandisa gaseous kemikari etchants kuita nemidziyo pawafer kuti ibvise chikamu chechinhu chinobviswa uye kugadzira zvigadzirwa zvinoshanduka, izvo zvinobva zvaburitswa kubva mukamuri yekupindura. Etchant inowanzo gadzirwa zvakananga kana zvisina kunanga kubva kuplasma ye etching gasi, saka yakaoma etching inonziwo plasma etching.

1.1 Plasma

Plasma igasi iri munzvimbo isina kusimba ionized inoumbwa nekupenya kwekubuda kwe etching gasi pasi pekuita kwekunze kwemagetsi emagetsi munda (sezvakagadzirwa neredhiyo frequency magetsi). Inosanganisira maerekitironi, ions uye kwazvakarerekera kushanda particles. Pakati pavo, zvidimbu zvinoshanda zvinogona kuita zvakananga kemikari neyakaiswa zvinhu kuti iwane etching, asi iyi yakachena kemikari inowanzoitika inongoitika muhuwandu hushoma hwezvinhu uye haina kutungamira; kana maion ane rimwe simba, anogona kuvharwa nekupopota kwemuviri, asi mwero wekuita kwemuviri wakachena wakadzikira zvakanyanya uye kusarudza kwakashata.

Yakawanda etching yeplasma inopedzwa nekubatanidzwa kwezvimedu zvinoshanda uye ion panguva imwe chete. Muchiitiko ichi, ion bombardment ine mabasa maviri. Imwe ndeyekuparadza zvisungo zveatomu pamusoro pezvinhu zvakavharwa, nokudaro zvichiwedzera mwero wekuti mativi asina kwaakarerekera anobata nawo; imwe yacho ndeyekugogodza zvigadzirwa zvakaiswa pane iyo reaction interface kuti ifambise iyo etchant kuti ibate zvizere pamusoro peiyo yakavharirwa zvinhu, kuti etching ienderere mberi.

Izvo zvigadzirwa zvakaiswa padivi pemadziro eiyo yakamisikidzwa chimiro hachigone kubviswa zvinobudirira neinotungamira ion bombardment, nekudaro ichivharira etching yemadziro emadziro uye kugadzira anisotropic etching.

Chechipiri etching process

2.1 Kunyorova uye Kuchenesa

Wet etching ndeimwe yematekinoroji ekutanga anoshandiswa mukugadzirwa kwedunhu rakasanganiswa. Kunyangwe maitirwo mazhinji ekunyorova etching akatsiviwa neanisotropic yakaoma etching nekuda kweiyo isotropic etching, ichiri kuita basa rakakosha mukuchenesa asina-akakosha masaizi ehukuru. Kunyanya mu etching of oxide kubvisa masara uye epidermal stripping, inoshanda zvakanyanya uye ine hupfumi pane yakaoma etching.

Izvo zvinhu zvekunyorova etching zvinonyanya zvinosanganisira silicon oxide, silicon nitride, single crystal silicon uye polycrystalline silicon. Kunyorova kwesilicon oxide kunowanzo shandisa hydrofluoric acid (HF) semutakuri wemakemikari. Kuti uvandudze kusarudza, dilute hydrofluoric acid yakavharwa neammonium fluoride inoshandiswa mukuita. Kuti uchengetedze kugadzikana kwepH kukosha, zvishoma zveasidhi yakasimba kana zvimwe zvinhu zvinogona kuwedzerwa. Doped silicon oxide iri nyore kuita ngura kupfuura pure silicon oxide. Kubvisa kemikari yakanyorova kunonyanya kushandiswa kubvisa photoresist uye yakaoma mask (silicon nitride). Kupisa phosphoric acid (H3PO4) ndiyo hombe kemikari mvura inoshandiswa kunyorovesa kemikari kubvisa kubvisa silicon nitride, uye ine sarudzo yakanaka yesilicon oxide.

Kucheneswa kwemvura kwakafanana nekunyorova, uye kunyanya kubvisa zvinosvibisa pamusoro pesilicon wafers kuburikidza nemakemikari maitikiro, kusanganisira zvidimbu, organic matter, simbi uye oxides. Iyo yakanyanya kunyorova yekuchenesa imvura yemakemikari nzira. Kunyangwe kuchenesa kwakaoma kunogona kutsiva nzira dzakawanda dzekuchenesa dzakanyorova, hapana nzira inogona kutsiva zvachose kucheneswa kwemvura.

Makemikari anowanzoshandiswa pakuchenesa mvura anosanganisira sulfuric acid, hydrochloric acid, hydrofluoric acid, phosphoric acid, hydrogen peroxide, ammonium hydroxide, ammonium fluoride, etc. Mukushandiswa kunoshanda, kemikari imwe kana kupfuura inosanganiswa nemvura yakasvibiswa mune imwe chikamu sezvinodiwa gadzira mhinduro yekuchenesa, seSC1, SC2, DHF, BHF, nezvimwe.

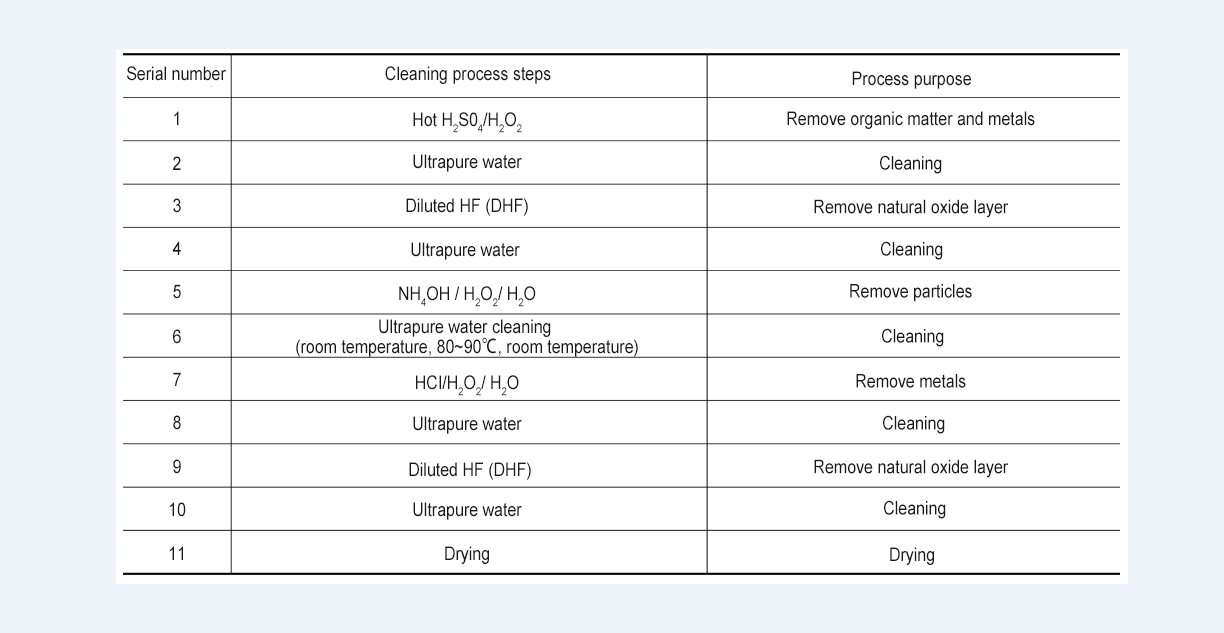

Kuchenesa kunowanzo shandiswa mukuita pamberi peiyo oxide firimu deposition, nekuti kugadzirira kweoxyde firimu kunofanirwa kuitwa pane yakanyatso kuchena silicon wafer pamusoro. Iyo yakajairika silicon wafer yekuchenesa maitiro ndeaya anotevera:

2.2 Dry Etching uye Kuchenesa

2.2.1 Dry Etching

Dry etching muindastiri inonyanya kureva plasma etching, iyo inoshandisa plasma ine inosimudzira chiitiko kuisa chakananga zvinhu. Iyo michina sisitimu mune yakakura-yakakura maitiro ekugadzira inoshandisa yakaderera-tembiricha isiri-equilibrium plasma.

Plasma etching inonyanya kushandisa nzira mbiri dzekuburitsa: capacitive yakasanganiswa discharge uye inductive inosanganiswa kubuda.

Mune capacitively yakabatana discharge mode: plasma inogadzirwa uye inochengetwa mune maviri anoenderana plate capacitor nekunze redhiyo frequency (RF) magetsi. Iyo gasi inodzvinyirira kazhinji yakawanda millitorr kusvika makumi emamiriyoni, uye ionization rate iri pasi pe10-5. Mune inductively yakabatana discharge modhi: kazhinji pane yakaderera gasi dzvinyiriro (makumi emillitorr), iyo plasma inogadzirwa uye inochengetwa ne inductively yakabatanidzwa yekupinza simba. Iko ionization rate inowanzopfuura 10-5, saka inonziwo high-density plasma. Yakakwira-density plasma masosi anogona zvakare kuwanikwa kuburikidza ne electron cyclotron resonance uye cyclotron wave discharge. Yakakwira-density plasma inogona kukwirisa etching rate uye kusarudzwa kweiyo etching process uku ichidzikisa etching kukuvadzwa nekuzvimiririra kudzora ion kuyerera uye ion bombardment simba kuburikidza nekunze RF kana microwave magetsi uye RF bias magetsi ekupa pane substrate.

Iyo yakaoma etching process ndeiyi inotevera: iyo etching gasi inopinzwa muvacuum reaction chamber, uye mushure mekumanikidza mukamuri yekupindura yakagadzikana, plasma inogadzirwa neredhiyo frequency glow discharge; mushure mekukanganiswa ne-high-speed electrons, inoora kuti ibudise radicals yakasununguka, iyo inopararira pamusoro pe substrate uye inoshambadzirwa. Pasi pekuita kweiyoni bombardment, iyo adsorbed mahara radicals inobata nemaatomu kana mamorekuru ari pamusoro peiyo substrate kuumba gaseous byproducts, ayo anoburitswa kubva mukamuri yekupindura. Iyo nzira inoratidzwa mumufananidzo unotevera:

Dry etching process inogona kukamurwa muzvikamu zvina zvinotevera:

(1)Physical sputtering etching: Iyo inonyanya kutsamira pane ine simba ion muplasma kubhomba pamusoro peiyo yakatemerwa zvinhu. Huwandu hwemaatomu akapushwa hunoenderana nesimba uye kona yezvimedu zvechiitiko. Kana simba nekona zvikaramba zvisina kuchinjwa, sputtering rate yezvinhu zvakasiyana zvinowanzosiyana ne2 kusvika ku3 nguva, saka hapana kusarudza. Iyo reaction process inonyanya kuita anisotropic.

(2)Chemical etching: Plasma inopa gasi-chikamu etching maatomu uye mamorekuru, ayo anoita kemikari nepamusoro pechinhu kuti abudise gasi rinoputika. Iyi chaiyo kemikari inoita ine sarudzo yakanaka uye inoratidza isotropic maitiro pasina kufunga nezve lattice chimiro.

Semuenzaniso: Si (yakasimba) + 4F → SiF4 (gasi), photoresist + O (gasi) → CO2 (gasi) + H2O (gasi)

(3)Ion simba rinofambiswa etching: Ions zvese zvimedu zvinokonzeresa etching uye simba-inotakura zvimedu. Kushanda kwe etching kwezvimedu zvinotakura simba zvakadaro zvinodarika kurongeka kwehukuru hwepamusoro pane kuya kwemuviri kana makemikari etching. Pakati pavo, iyo optimization yemuviri uye kemikari paramita yemaitiro ndiyo musimboti wekudzora etching maitiro.

(4)Ion-barrier composite etching: Inonyanya kureva chizvarwa chepolymer chipingamupinyi chekudzivirira chitubu nezvikamu zvakasanganiswa panguva yekugadzira. Plasma inoda chidziviriro chakadaro kudzivirira maitiro etching emadziro eparutivi panguva yekugadzira. Semuenzaniso, kuwedzera C kuCl uye Cl2 etching inogona kuburitsa chlorocarbon compound layer panguva yekumisikidza kuchengetedza madziro epadivi kubva pakuiswa.

2.2.1 Dry kuchenesa

Dry cleaning inonyanya kureva kuchenesa plasma. Iwo ayoni ari muplasma anoshandiswa kubhomba pamusoro kuti acheneswe, uye maatomu nemamorekuru ari munzvimbo yakabatidzwa anodyidzana nepamusoro kuti acheneswe, kuti abvise uye aite dota refotoresist. Kusiyana neakaomeswa etching, maparamendi ekuchenesa yakaoma kazhinji haasanganisire sarudzo yekutungamira, saka dhizaini dhizaini iri nyore. Mumaitiro makuru ekugadzira, fluorine-based magasi, okisijeni kana hydrogen inonyanya kushandiswa semuviri mukuru weiyo reaction plasma. Mukuwedzera, kuwedzera imwe argon plasma inogona kuwedzera iyo ion bombardment effect, nekudaro ichivandudza kuchenesa.

Mune plasma yakaoma yekuchenesa maitiro, iyo iri kure plasma nzira inowanzoshandiswa. Izvi zvinodaro nekuti mukuchenesa maitiro, zvinotarisirwa kudzikisa bombardment mhedzisiro yeion muplasma kudzora kukuvadzwa kunokonzerwa neiyoni bombardment; uye kukwidziridzwa kuita kwemakemikari emahara radicals kunogona kuvandudza kuchenesa. Remote plasma inogona kushandisa microwaves kugadzira yakagadzikana uye yakakwira-density plasma kunze kwekamuri yekupindura, ichigadzira huwandu hukuru hwemahara radicals anopinda mukamuri yekupindura kuti awane maitiro anodiwa pakuchenesa. Mazhinji emvura yakaoma yekuchenesa gasi muindasitiri inoshandisa fluorine-based magasi, akadai seNF3, uye anopfuura 99% yeNF3 yakaora mumicrowave plasma. Iko kunenge kusisina ion bombardment mhedzisiro mune yakaoma yekuchenesa maitiro, saka zvinobatsira kuchengetedza iyo silicon wafer kubva mukukuvara uye kuwedzera hupenyu hwekamuri yekuita.

Zvitatu zvekunyorova etching nekuchenesa michina

3.1 Tangi-mhando yewafer yekuchenesa muchina

Muchina wekuchenesa-wafer wekuchenesa muchina unonyanya kuumbwa nemberi-kuvhura wafer transfer box transmission module, wafer loading/ unloading transmission module, exhaust air intake module, chemical liquid tank module, deionized water tank module, tangi yekuomesera. module uye control module. Inogona kuchenesa akawanda mabhokisi ewafers panguva imwe chete uye inogona kuwana yakaoma-mukati uye yakaoma-kunze kwewafers.

3.2 Trench Wafer Etcher

3.3 Single Wafer Wet Processing Equipment

Zvinoenderana neakasiyana maitirwo ezvinangwa, imwechete wafer wet process michina inogona kukamurwa kuita mapoka matatu. Chikamu chekutanga ndecheimwe wafer yekuchenesa michina, iyo zvinangwa zvekuchenesa zvinosanganisira zvimedu, organic matter, natural oxide layer, tsvina yesimbi nezvimwe zvinosvibisa; chikamu chechipiri ndecheimwe wafer yekukwesha michina, ine chinangwa chikuru chekubvisa zvimedu pamusoro pechingwa; chikamu chechitatu ndeye single wafer etching equipment, iyo inonyanya kushandiswa kubvisa mafirimu matete. Zvinoenderana neakasiyana maitirwo ezvinangwa, imwe wafer etching michina inogona kupatsanurwa mumhando mbiri. Rudzi rwekutanga ndeye mild etching equipment, iyo inonyanya kushandiswa kubvisa pamusoro pemafirimu ekukuvadzwa kwezvikamu zvinokonzerwa ne-high-energy ion implantation; rudzi rwechipiri chibayiro chokubvisa midziyo, iyo inonyanya kushandiswa kubvisa zvipingamupinyi zvakasara mushure mekutetepa kwewafer kana kemikari mechanical polishing.

Kubva pamaonero ezvakaita muchina wekuvaka, iyo yekutanga dhizaini yemarudzi ese e-single-wafer wet process equipment yakafanana, inowanzove nezvikamu zvitanhatu: main frame, wafer transfer system, chamber module, chemical liquid supply uye transfer module, software system. uye electronic control module.

3.4 Single Wafer Yekuchenesa Equipment

Iyo imwechete wafer yekuchenesa midziyo yakagadzirwa zvichibva pane yechinyakare RCA yekuchenesa nzira, uye maitiro ayo chinangwa chekuchenesa zvimedu, organic zvinhu, zvakasikwa oxide layer, tsvina yesimbi uye zvimwe zvinosvibisa. Panyaya yekushandiswa kwemaitiro, imwe wafer yekuchenesa michina parizvino inoshandiswa zvakanyanya kumberi-kumagumo uye kumashure-kumagumo maitiro eyakasanganiswa yedunhu rekugadzira, kusanganisira kuchenesa isati yasvika uye mushure mekugadzirwa kwefirimu, kuchenesa mushure mekuisa plasma, kuchenesa mushure mekuisirwa ion, kuchenesa mushure memakemikari. mechanical polishing, uye kuchenesa mushure mekuisa simbi. Kunze kweyepamusoro-tembiricha phosphoric acid process, imwe chete wafer yekuchenesa michina inowirirana nemaitiro ese ekuchenesa.

3.5 Single Wafer Etching Equipment

Chinangwa chekugadzira imwe wafer etching michina inonyanya kutetepa firimu etching. Zvinoenderana nechinangwa chekuita, inogona kupatsanurwa muzvikamu zviviri, zvinoti, mwenje etching midziyo (inoshandiswa kubvisa iyo pamusoro bhaisikopo kukuvadzwa layer inokonzerwa ne-high-energy ion implantation) uye chibayiro chekubvisa midziyo (inoshandiswa kubvisa chipingamupinyi mushure mewafer. kuonda kana makemikari mechanical polishing). Izvo zvinhu zvinoda kubviswa mukuita izvi zvinowanzo sanganisira silicon, silicon oxide, silicon nitride uye simbi firimu layer.

Ina yakaoma etching uye yekuchenesa michina

4.1 Kurongwa kwemidziyo yeplasma etching

Pamusoro peiyo ion sputtering etching midziyo iri padhuze nekwakachena kwemuviri kuita uye degumming midziyo iri padyo neakachena kemikari reaction, plasma etching inogona kukamurwa kuita zvikamu zviviri zvinoenderana neyakasiyana chizvarwa cheplasma uye kudzora matekinoroji:

-Capacitively Coupled Plasma (CCP) etching;

-Inductively Coupled Plasma (ICP) etching.

4.1.1 CCP

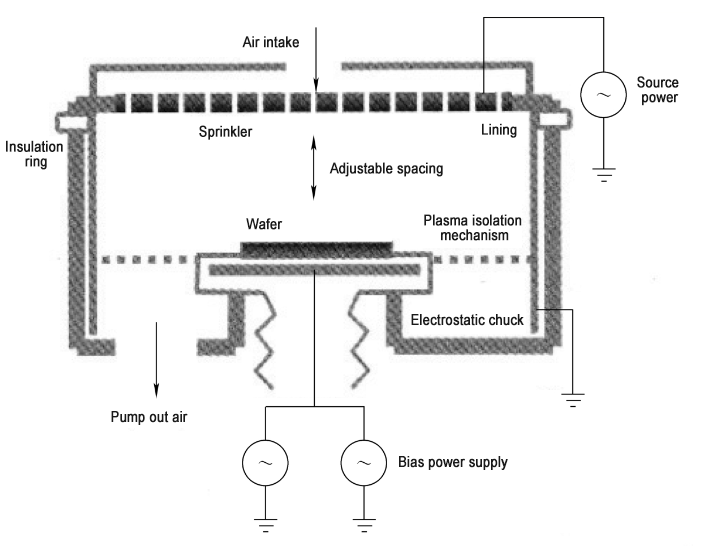

Capacitively yakabatana plasma etching ndeyekubatanidza redhiyo frequency magetsi kune imwe kana ese ari maviri epamusoro uye ezasi maelectrode mukamuri yekupindura, uye plasma iri pakati pemahwendefa maviri inoumba capacitor mune yakareruka yakaenzana dunhu.

Kune maviri ekutanga matekinoroji akadaro:

Imwe ndeyekutanga plasma etching, iyo inobatanidza iyo RF magetsi kune yepamusoro electrode uye yakaderera electrode panowanikwa wafer. Nekuti iyo plasma inogadzirwa neiyi nzira haizogadzira yakakora zvakakwana ion sheath pamusoro pechifukidziro, simba reion bombardment rakaderera, uye rinowanzo shandiswa mumiitiro senge silicon etching inoshandisa zvidimbu zvinoshanda seiyo huru etchant.

Imwe yacho ndeyekutanga reactive ion etching (RIE), iyo inobatanidza magetsi eRF kune yakaderera electrode panowanikwa wafer, uye inodzika electrode yepamusoro nenzvimbo yakakura. Iyi tekinoroji inogona kuumba gobvu ion sheath, iyo inokodzera dielectric etching process inoda yakakwira ion simba kuti itore chikamu mukuita. Pahwaro hwekutanga reactive ion etching, iyo DC magineti perpendicular kuRF yemagetsi munda inowedzerwa kuita ExB Drift, iyo inogona kuwedzera mukana wekudhumhana kwemaerekitironi uye gasi zvimedu, nekudaro zvinobudirira kuvandudza plasma kusungwa uye etching rate. Iyi etching inonzi magnetic field enhanced reactive ion etching (MERIE).

Aya matatu ari pamusoro petekinoroji ane chinokanganisa chakajairwa, ndiko kuti, iyo plasma concentration uye simba rayo harigone kudzorwa zvakasiyana. Semuyenzaniso, kuti uwedzere etching rate, iyo nzira yekuwedzera iyo RF simba inogona kushandiswa kuwedzera iyo plasma kusungwa, asi iyo yakawedzera RF simba inozokonzeresa kuwedzera kweiyo ion simba, izvo zvinokonzeresa kukuvadza kumidziyo iri pa. chimedu. Mumakore gumi apfuura, capacitive coupling tekinoroji yakatora dhizaini yeakawanda RF masosi, ayo akabatana nepamusoro uye epasi maelectrode zvichiteerana kana ese ari maviri kune yakaderera electrode.

Nekusarudza uye kuenzanisa akasiyana maRF ma frequency, iyo electrode nharaunda, nzvimbo, zviwanikwa uye mamwe akakosha paramita anorongedzerwa pamwe chete, iyo plasma yekumisikidza uye ion simba rinogona kuparadzaniswa zvakanyanya sezvinobvira.

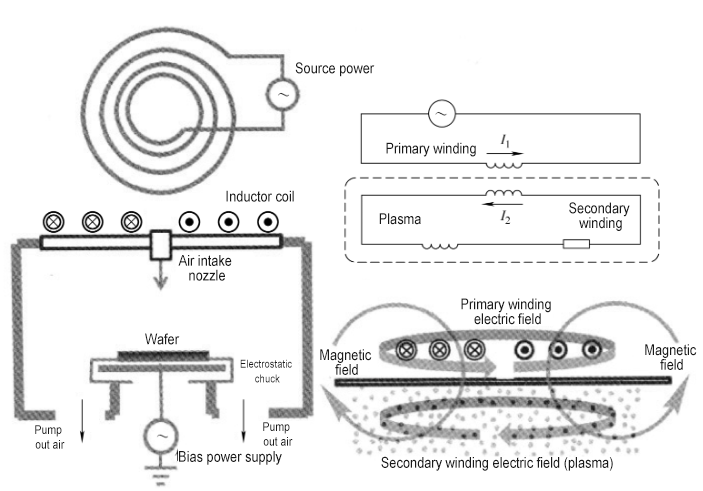

4.1.2 ICP

Inductively yakabatana plasma etching ndeyekuisa imwe kana akawanda seti emakoiri akabatana neredhiyo frequency magetsi pa kana kutenderedza kamuri yekupindura. Iyo inotsinhanisa magineti inogadzirwa neredhiyo frequency ikozvino mukoiri inopinda mukamuri yekupindura nepahwindo redielectric kuti ikurumidze maerekitironi, nekudaro ichigadzira plasma. Muchikamu chakareruka chakaenzana (transformer), iyo coil ndiyo yekutanga mhepo inductance, uye plasma ndiyo yechipiri mhepo inductance.

Iyi nzira yekubatanidza inogona kuwana plasma concentration iyo inopfuura imwe yerodhi yehukuru yakakwirira kupfuura capacitive coupling pane yakaderera. Uye zvakare, iyo yechipiri RF magetsi emagetsi akabatana nenzvimbo yewafer seyakarerekera simba rekupa ion bombardment simba. Naizvozvo, iyo ion concentration inotsamira pane kwainopa magetsi eiyo coil uye iyo ion simba rinoenderana neyakarerekera simba rekupa, nekudaro kuwana kwakanyatso kudzika kwekugadzirisa uye simba.

4.2 Plasma Etching Equipment

Anenge ese etchants mune yakaoma etching anogadzirwa zvakananga kana zvisina kunanga kubva kuplasma, saka yakaoma etching inowanzonzi plasma etching. Plasma etching imhando yeplasma etching mupfungwa yakafara. Mune maviri ekutanga flat-plate reactor madhizaini, imwe ndeyekugadzika ndiro pane wafer uye imwe ndiro yakabatana neRF sosi; imwe yacho inopesana. Mune yaimbova dhizaini, nzvimbo yeplate yepasi inowanzo hombe pane nzvimbo yeplate yakabatana neRF sosi, uye kudzvanywa kwegasi mureactor kwakakwira. Iyo ion sheath yakaumbwa pamusoro pechifukidziro yakaonda kwazvo, uye wafer inoratidzika kunge "yakanyudzwa" muplasma. Etching inonyanya kupedzwa nekuita kwemakemikari pakati pezvimedu zvinoshanda muplasma uye pamusoro peiyo etched zvinhu. Simba reion bombardment idiki kwazvo, uye kutora chikamu mu etching kwakadzikira. Iyi dhizaini inonzi plasma etching mode. Mune imwe dhizaini, nekuti dhigirii rekutora ion bombardment yakakura, inonzi reactive ion etching mode.

4.3 Reactive Ion Etching Equipment

Reactive ion etching (RIE) inoreva maitiro etching umo zvidimbu zvinoshanda uye maion anochaja anotora chikamu mukuita panguva imwe chete. Pakati pavo, zvikamu zvinoshingaira zvinonyanya kusarerekera (zvinozivikanwawo semahara radicals), nepamusoro-soro (inenge 1% kusvika 10% yegasi rekugadzirisa), izvo zvinonyanya zvikamu zve etchant. Zvigadzirwa zvinogadzirwa nemakemikari reaction pakati pavo uye etched zvinhu zvinogona kunyungudutswa uye zvakananga kutorwa kubva mukamuri yekupindura, kana kuunganidzwa pane yakatemerwa pamusoro; nepo maion anochajiwa ari padanho rakaderera (10-4 kusvika 10-3 yegasi rekuisa), uye ivo vanokwidziridzwa nemagetsi munda weiyo ion sheath yakaumbwa pamusoro pechimedu kuti chibhomba iyo yakatemerwa pamusoro. Pane mabasa maviri makuru ezvimedu zvinochajiswa. Imwe ndeyekuparadza chimiro cheatomu chechinhu chakavharidzirwa, nekudaro kukurumidza kukurumidza iyo iyo inoshanda particles inobata nayo; imwe yacho ndeyekubhomba uye kubvisa zvakaunganidzwa reaction zvigadzirwa kuitira kuti etched zvinhu zvibatane zvizere neanoshanda particles, kuitira kuti etching ienderere mberi.

Nekuti maion haatore chikamu zvakananga mukuita etching (kana kuverengera chikamu chidiki kwazvo, senge kubviswa kwebhomba uye kunangana kwemakemikari etching yemaion anoshanda), kutaura chaiko, iyo etching iri pamusoro inofanirwa kunzi ion-inobatsira etching. Zita reactive ion etching harina chokwadi, asi richiri kushandiswa nanhasi. Michina yekutanga yeRIE yakaiswa mukushandiswa muma1980s. Nekuda kwekushandiswa kweiyo imwe chete RF magetsi uye yakapusa kuita kamuri dhizaini, ine painogumira maererano neiyo etching chiyero, kufanana uye kusarudza.

4.4 Magnetic Munda Yakasimbiswa Reactive Ion Etching Equipment

Iyo MERIE (Magnetically Enhanced Reactive Ion Etching) chishandiso chigadziriso chinogadzirwa nekuwedzera DC magineti kune flat-panel RIE mudziyo uye inoitirwa kuwedzera etching rate.

Midziyo yeMERIE yakaiswa mukushandiswa pamwero wakakura muma1990, apo imwe-wafer etching michina yakanga yave iyo inonyanya kushandiswa muindasitiri iyi. Kunyanya kukanganisa kweMERIE midziyo ndeyekuti kugoverwa kwenzvimbo inhomogeneity yeplasma yekumisikidzwa kunokonzerwa nemagineti inotungamira kune yazvino kana voltage misiyano mune yakabatanidzwa yedunhu mudziyo, nekudaro ichikonzera kukuvara kwechishandiso. Sezvo kukuvara uku kunokonzerwa nekukasira inhomogeneity, kutenderera kwemagineti hakugone kuibvisa. Sezvo saizi yemasekete akabatanidzwa ari kuramba achidzikira, kukuvadzwa kwechishandiso chavo kuri kuwedzera kutarisisa plasma inhomogeneity, uye tekinoroji yekuwedzera chiyero chekusimudzira nekusimudzira magineti zvishoma nezvishoma yakatsiviwa neakawanda-RF simba rekupa planar reactive ion etching tekinoroji, iyo iri, capacitively yakabatana plasma etching tekinoroji.

4.5 Yakanyatso batanidza plasma etching michina

Capacitively coupling plasma (CCP) etching midziyo inogadzira plasma mukamuri yekupindura kuburikidza necapacitive coupling nekuisa redhiyo frequency (kana DC) magetsi emagetsi mundiro ye electrode uye inoshandiswa kupinza. Iyo etching musimboti yakafanana neiyo reactive ion etching michina.

Iyo yakareruka schematic dhizaini yeCCP etching michina inoratidzwa pazasi. Iyo inowanzo shandisa maviri kana matatu RF masosi eakasiyana ma frequency, uye mamwe anoshandisa DC magetsi emagetsi. Kuwanda kwemagetsi eRF ndeye 800kHz ~ 162MHz, uye anowanzo shandiswa 2MHz, 4MHz, 13MHz, 27MHz, 40MHz uye 60MHz. RF magetsi emagetsi ane frequency ye2MHz kana 4MHz inowanzonzi yakaderera-frequency RF masosi. Izvo zvinowanzobatanidzwa kune yakaderera electrode panowanikwa wafer. Ivo vanonyanya kushanda mukudzora ion simba, saka ivo vanonziwo bias simba rekushandisa; RF magetsi emagetsi ane frequency pamusoro pe27MHz anonzi akakwira-frequency RF masosi. Dzinogona kubatanidzwa kune imwe yepamusoro electrode kana yakaderera electrode. Ivo vanonyanya kushanda mukudzora plasma concentration, saka ivo vanonzi zvakare sosi emagetsi magetsi. Iyo 13MHz RF magetsi epakati uye anowanzo kutorwa kunge ane ese ari pamusoro pemabasa asi asina kusimba. Ziva kuti kunyangwe iyo plasma yekumisikidza uye simba zvichigona kugadziridzwa mukati meimwe tambo nesimba reRF masosi emhando dzakasiyana (iyo inonzi decoupling effect), nekuda kwehunhu hwecapacitive coupling, haigone kugadziridzwa uye kudzorwa zvakazvimirira.

Iko kugoverwa kwesimba kwemaion kune zvakakosha pakuita kwakadzama kwe etching uye kukuvadzwa kwechishandiso, saka kusimudzira tekinoroji yekugonesa ion simba rekugovera yave imwe yeakakosha mapoinzi epamusoro etching michina. Parizvino, matekinoroji akashandiswa zvinobudirira mukugadzira anosanganisira akawanda-RF hybrid drive, DC superposition, RF yakasanganiswa neDC pulse bias, uye synchronous pulsed RF kubuda kweiyo bias magetsi uye sosi magetsi.

CCP etching midziyo ndeimwe yemhando mbiri dzinonyanya kushandiswa dzeplasma etching michina. Inonyanya kushandiswa mukugadzira etching ye dielectric zvinhu, senge gedhi padivi uye yakaoma mask etching pamberi peiyo logic chip process, yekubata gomba etching mukati mechikamu chepakati, mosaic uye aluminium pad etching kumashure kumashure, pamwe chete. etching yemakomba akadzika, maburi akadzika uye maburi ekubatanidza waya mu 3D flash memory chip process (kutora silicon nitride / silicon oxide chimiro semuenzaniso).

Pane matambudziko maviri makuru uye nzira dzekuvandudza dzakatarisana neCCP etching michina. Chekutanga, mukushandiswa kweiyo yakanyanya kukwira ion simba, iyo etching kugona kweiyo yakakwira chikamu reshiyo zvimiro (senge gomba uye groove etching ye3D flash memory inoda chiyero chepamusoro kupfuura 50: 1). Iyo yazvino nzira yekuwedzera iyo bias simba rekuwedzera iyo ion simba yashandisa RF magetsi anosvika zviuru gumi watts. Tichifunga nezvehuwandu hwekupisa hwakagadzirwa, kutonhora uye tembiricha yekudzora tekinoroji yekamuri yekupindura inoda kuramba ichivandudzwa. Chechipiri, panofanirwa kuve nebudiriro mukugadzirwa kwemagasi matsva ekugadzirisa zvakanyanya kugadzirisa dambudziko rekugonesa etching.

4.6 Inductively Coupled Plasma Etching Equipment

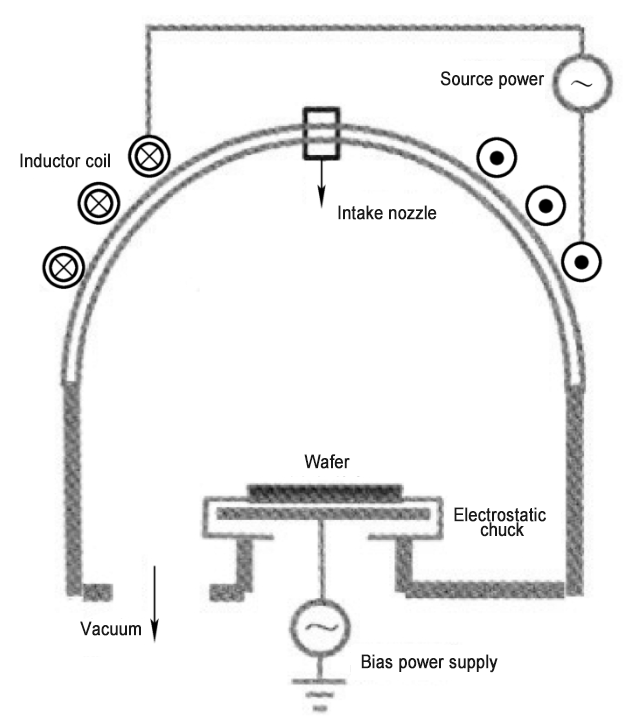

Inductively coupled plasma (ICP) etching equipment mudziyo unobatanidza simba reredhiyo frequency power sosi kupinda mukamuri rekuita muchimiro chemagnetic field kuburikidza neinductor coil, zvobva zvagadzira plasma yekupinza. Yayo etching musimboti zvakare ndeye generalized reactive ion etching.

Kune maviri makuru marudzi eplasma sosi dhizaini yeICP etching michina. Imwe ndeye transformer yakasanganiswa plasma (TCP) tekinoroji yakagadziridzwa uye inogadzirwa naLam Research. Iyo inductor coil inoiswa pane dielectric hwindo ndege pamusoro pekamuri yekuita. Iyo 13.56MHz RF siginecha inogadzira inochinjika magineti mucoil iyo inotenderera kune dielectric hwindo uye radially inosiyana neiyo coil axis sepakati.

Iyo magineti inopinda mukamuri yekupindura kuburikidza nehwindo redhielectric, uye iyo inochinjika magineti inogadzira inochinjika yemagetsi munda wakafanana neiyo dielectric hwindo mukamuri yekupindura, nekudaro inowana kuparadzaniswa kweiyo etching gasi uye kugadzira plasma. Sezvo musimboti uyu uchigona kunzwisiswa seshanduko ine inductor coil seyokutanga mhepo uye plasma iri mukamuri yekupindura seyechipiri mhepo inotenderera, ICP etching inotumidzwa zita reizvi.

Mukana mukuru weTCP tekinoroji ndeyekuti chimiro chiri nyore kukwira kumusoro. Semuenzaniso, kubva pa200mm wafer kuenda kune 300mm wafer, TCP inogona kuchengetedza yakafanana etching maitiro nekungowedzera saizi yecoil.

Imwe plasma source dhizaini ndeye decoupled plasma source (DPS) tekinoroji yakagadziridzwa uye inogadzirwa neApplied Materials, Inc. yekuUnited States. Iyo inductor coil ine matatu-dimensionally ronda pahemispherical dielectric hwindo. Nheyo yekugadzira plasma yakafanana neiyo yambotaurwa TCP tekinoroji, asi gasi dissociation kunyatsoita kwakakwira, izvo zvinoita kuti uwane yakakwira plasma concentration.

Sezvo kushanda kweiyo inductive coupling kugadzira plasma kwakakwira kupfuura iyo capacitive coupling, uye plasma inonyanya kugadzirwa munzvimbo iri padyo nedielectric hwindo, plasma yayo inotemerwa zvakanyanya nesimba reiyo sosi simba rekupa rakabatana kune inductor. coil, uye simba reion riri musheath yeion riri pamusoro pechifukidziro rinonyanya kutariswa nesimba reiyo bias simba rekupa, saka kusungirirwa uye simba reiyoni. inogona kudzorwa yakazvimirira, nekudaro ichiwana kubatanidza.

ICP etching midziyo ndeimwe yemhando mbiri dzinonyanya kushandiswa dzeplasma etching michina. Inonyanya kushandiswa kugadzira silicon kudzika migero, germanium (Ge), polysilicon gedhi zvimiro, simbi gedhi zvimiro, yakaomeswa nesilicon (Strained-Si), waya dzesimbi, simbi pads (Pads), mosaic etching simbi yakaoma masks uye akawanda maitiro mukati. akawanda imaging tekinoroji.

Pamusoro pezvo, nekusimuka kwematatu-dimensional integrated circuits, CMOS image sensors uye micro-electro-mechanical systems (MEMS), pamwe nekukurumidza kuwedzera kwekushandiswa kwe kuburikidza nesilicon vias (TSV), maburi mahombe akakura uye yakadzika silicon etching ine akasiyana morphologies, vagadziri vazhinji vakatangisa etching michina yakagadziridzwa yakanangana neaya maapplication. Hunhu hwayo hwakakura etching kudzika (makumi kana kunyange mazana emamicrons), saka inonyanya kushanda pasi peyakakwira gasi kuyerera, kudzvanywa kwakanyanya uye yakakwirira simba mamiriro.

—————————————————————————————————————————————————— ————————————-

Semicera inogona kupagraphite zvikamu, kupfava/kuomarara kunzwa, silicon carbide zvikamu, CVD silicon carbide zvikamu,uyeSiC/TaC yakavharwa zvikamunemazuva makumi matatu.

Kana iwe uchifarira zviri pamusoro semiconductor zvigadzirwa,ndapota usazeza kutibata nesu panguva yekutanga.

Tel: +86-13373889683

WhatsAPP: +86-15957878134

Email: sales01@semi-cera.com

Nguva yekutumira: Aug-31-2024