1. Nhanganyaya

Ion implantation ndeimwe yematanho makuru mukubatanidzwa kwedunhu kugadzira. Inoreva maitiro ekumhanyisa danda reion kune rimwe simba (kazhinji muhuwandu hwekeV kusvika kuMeV) uye wozoipinza mukati mechinhu chakasimba chekushandura chimiro chemuviri wepamusoro pechinhu. Muchikamu chedunhu chakabatanidzwa, chinhu chakasimba chinowanzo silicon, uye iyo yakasimwa isina kuchena ions inowanzova boron ions, phosphorus ions, arsenic ions, indium ions, germanium ions, nezvimwewo. Ioni dzakasimwa dzinogona kushandura conductivity yepasi pevhu rakaoma. zvinhu kana kugadzira PN junction. Kana iyo saizi yemasekete akabatanidzwa yakaderedzwa kusvika kune-sub-micron era, iyo ion implantation process yakashandiswa zvakanyanya.

Muchirongwa chekugadzira chedunhu chakabatanidzwa, kuisirwa ion kunowanzo shandiswa kune zvakadzika zvakavigwa zvitubu, reverse doped matsime, chikumbaridzo voltage kugadziridzwa, sosi uye dhiraivha yekuwedzera kuisirwa, sosi uye dhiraivha implantation, polysilicon gedhi doping, kugadzira PN junctions uye resistors / capacitors, nezvimwe. Mukugadzira silicon substrate zvinhu pane insulators, iyo yakavigwa oxide layer inoumbwa nepamusoro-concentration oxygen ion implantation, kana hungwaru. kucheka kunowanikwa nepamusoro-concentration hydrogen ion implantation.

Kudyara kweion kunoitwa neinosimirira, uye iyo inonyanya kukosha maitiro paramita idosi uye simba: iyo dosi inosarudza iyo yekupedzisira yekumisikidza, uye simba rinotarisa huwandu (kureva, kudzika) kweion. Zvinoenderana neyakasiyana dhizaini yedhizaini, mamiriro ekuisirwa akakamurwa kuita yakakwira-dose yakakwira-simba, yepakati-dose yepakati-simba, yepakati-dose yakaderera-simba, kana yakakwira-dose yakaderera-simba. Kuti uwane iyo yakanakira kuisirwa mhedzisiro, akasiyana maimplanter anofanirwa kuve akashongedzerwa akasiyana maitiro ezvinodiwa.

Mushure mekudyarwa kweioni, zvinowanzodikanwa kuti upinde mukupisa-kupisa kwepamusoro kugadzirisa kukuvadzwa kwelatisi kwakakonzerwa nekuisa ion uye kumisa maion ekusachena. Mune echinyakare akabatanidzwa edunhu maitirwo, kunyangwe tembiricha yeannealing ine simba guru pane doping, tembiricha yeiyo ion implantation process pachayo haina kukosha. Pane tekinoroji node pazasi 14nm, mamwe maion implantation maitiro anofanirwa kuitwa munzvimbo yakaderera kana yepamusoro tembiricha kuti ichinje mhedzisiro yekukuvara kwelatisi, nezvimwe.

2. ion implantation process

2.1 Basic Misimboti

Ion implantation inzira yedoping yakagadziridzwa muma1960 iyo iri pamusoro pechinyakare nzira dzekuparadzira mune dzakawanda zvinhu.

Misiyano mikuru pakati peion implantation doping uye yechinyakare diffusion doping ndeiyi inotevera:

(1) Kugoverwa kwekusvibiswa kwekusachena munharaunda yedoped kwakasiyana. Iyo yepamusoro yekusachena yekumisikidzwa kweion implantation inowanikwa mukati mekristaro, nepo peak kusachena kusanganiswa kwekupararira kuri pamusoro pekristaro. (2) Ion implantation inzira inoitwa pakamuri tembiricha kana kunyange yakaderera tembiricha, uye nguva yekugadzira ipfupi. Diffusion doping inoda kurapwa kwenguva refu kwepamusoro-tembiricha. (3) Ion kuisirwa kunobvumira kushanduka uye kwakaringana kusarudzwa kwezvinhu zvakasimwa. (4) Sezvo tsvina ichikanganiswa nekupisa kwekupisa, waveform inogadzirwa neion implantation mukristaro iri nani pane waveform inoumbwa nekupararira mukristaro. (5) Ion kuisirwa kazhinji inongoshandisa photoresist semasiki zvinhu, asi diffusion doping inoda kukura kana kuiswa kwefirimu rehumwe ukobvu semask. (6) Ion implantation yakanyatso kutsiva kupararira uye yave iyo huru doping maitiro mukugadzirwa kwemasekete akabatanidzwa nhasi.

Kana chiitiko ion danda rine rimwe simba rinobhomba chipfuro chakasimba (kazhinji chipfuwo), maion nemaatomu ari panzvimbo yakatariswa anozosangana kwakasiyana siyana, uye kuendesa simba kumaatomu anonangwa neimwe nzira kufadza kana kuonisa. ivo. Ioni dzinogonawo kurasikirwa nehumwe huwandu hwesimba kuburikidza nekufambisa kwekukurumidza, uye pakupedzisira kuparadzirwa nemaatomu anonangwa kana kumira muchinhu chakanangwa. Kana iyoni inoiswa jekiseni ichirema, maion mazhinji anobaiwa muchinangwa chakasimba. Kusiyana neizvi, kana ioni dzakaiswa jekiseni dzakareruka, akawanda eiyoni anojairwa anobvondomoka kubva panzvimbo yakatarwa. Zvikurukuru, aya maion ane simba guru akaiswa muchinangwa achadhumhana nemaatomu eretisi nemaerekitironi muchinangwa chakasimba kusvika kumadhigirii akasiyana. Pakati pawo, kudhumhana pakati pemaion nemaatomu akasimba anotariswa anogona kutariswa sekudhumhana kwe elastic nekuti ari padhuze mukuwanda.

2.2 Mitemo mikuru yekuisirwa ion

Ion implantation inzira inoshanduka iyo inofanirwa kusangana neyakaomarara chip dhizaini uye kugadzirwa zvinodiwa. Yakakosha ion implantation parameters ndeiyi: dose, renji.

Dose (D) inoreva huwandu hweiyoni inobaiwa pachikamu chechikamu chesilicon wafer pamusoro, mumaatomu pa square centimita (kana maion pa square centimita). D inogona kuverengerwa neinotevera formula:

Ipo D ndiyo yekudyara dose (nhamba yeioni / unit nzvimbo); t inguva yekusima; Ndini danda razvino uno; q ndiyo mutero unotakurwa neion (chaji imwechete ndeye 1.6×1019C[1]); uye S ndiyo nzvimbo yekusimwa.

Chimwe chezvikonzero chikuru nei ion implantation yave yakakosha tekinoroji mukugadzirwa kwesilicon wafer ndeyekuti inogona kudzokorodza kudyara muyero mumwechete wetsvina musilicon wafers. Iyo inosimira inozadzisa chinangwa ichi nerubatsiro rwechaji yakanaka yeion. Kana iyo ion yetsvina yakanaka ikaita danda reion, kuyerera kwayo kunonzi ion beam current, iyo inoyerwa mumA. Uwandu hwepakati uye hushoma huripo huri 0.1 kusvika 10 mA, uye huwandu hwemhepo yakakwirira ndeye 10 kusvika 25 mA.

Hukuru hweiyo ion beam ikozvino ndiyo yakakosha shanduko mukutsanangura iyo dose. Kana iyo yazvino ichiwedzera, nhamba yeatomu yekusachena yakasimwa pane imwe unit nguva inowedzerawo. Kukwirisa kwazvino kunobatsira kuwedzera goho resilicon wafer (kupinza maion akawanda panguva yekugadzirwa kweyuniti), asi zvinokonzeresa matambudziko akafanana.

3. ion implantation equipment

3.1 Chimiro Chekutanga

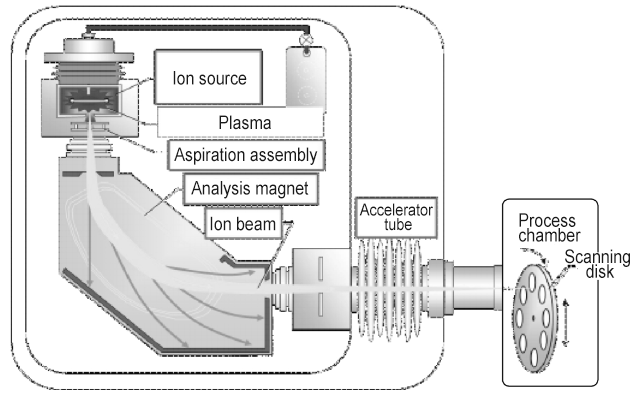

Ion implantation midziyo inosanganisira 7 basic modules:

① ion sosi uye munyu;

② mass analyzer (kureva analytical magineti);

③ accelerator chubhu;

④ kuongorora dhisiki;

⑤ electrostatic neutralization system;

⑥ process chamber;

⑦ dose control system.

All modules ari munzvimbo yevacuum yakagadzwa neiyo vacuum system. Iyo yekutanga dhizaini dhizaini yeiyo ion implanter inoratidzwa mumufananidzo uri pazasi.

(1)Ion source:

Kazhinji mune imwechete vacuum chamber seyekusveta electrode. Izvo zvisina kuchena zvakamirira kuiswa jekiseni zvinofanirwa kunge zviripo mune ion state kuitira kuti idzorwe uye ikurumidzwe nemunda wemagetsi. Iyo inonyanya kushandiswa B+, P+, As+, nezvimwewo inowanikwa neionizing maatomu kana mamorekuru.

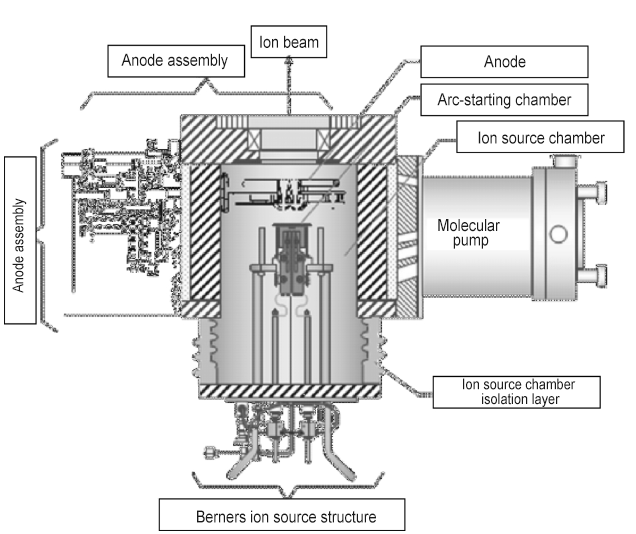

Izvo zvitubu zvetsvina zvinoshandiswa BF3, PH3 neASH3, zvichingodaro, uye zvimiro zvavo zvinoratidzwa mumufananidzo uri pazasi. Maerekitironi anoburitswa nefilament anodhumhana nemaatomu egasi kuti abudise ayoni. Ma electrons anowanzo kugadzirwa nekupisa tungsten filament source. Semuenzaniso, iyo Berners ion sosi, iyo cathode filament yakaiswa mune arc chamber ine gasi inlet. Rusvingo rwemukati rwekamuri yearc ndiyo anode.

Kana iyo gasi inotangwa, yakakura ikozvino inopfuura nepakati pefilament, uye voltage ye100 V inoshandiswa pakati peiyo yakanaka uye yakaipa electrode, iyo inoburitsa maerekitironi emagetsi akapoteredza filament. Positive ions inogadzirwa mushure mekunge maerekitironi ane simba guru adhumhana nekwakabva gasi mamorekuru.

Iyo magineti yekunze inoshandisa magineti yakaenzana kune filament kuti iwedzere ionization uye kudzikamisa plasma. Mune arc chamber, kune imwe mugumo maererano ne filament, pane negative charged reflector inoratidzira maerekitironi kumashure kuti ivandudze chizvarwa uye kushanda zvakanaka kwemaerekitironi.

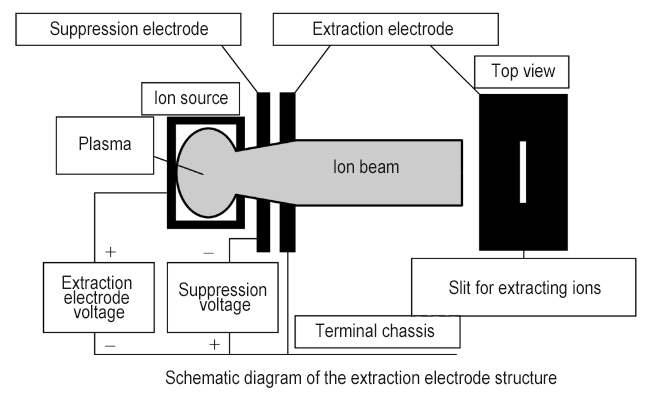

(2)Absorption:

Inoshandiswa kuunganidza ion yakanaka inogadzirwa mukamuri yearc yeiyo ion sosi uye kuigadzira kuita danda reion. Sezvo arc chamber iri anode uye cathode ichidzvanyirirwa zvisina kunaka pa electrode yekusveta, munda wemagetsi unogadzirwa unodzora maion akanaka, zvichiita kuti afambe akananga kugerodhi yekusveta uye anoburitswa kubva pakatsemuka ion, sezvakaratidzwa mumufananidzo uri pasi apa. . Iyo yakakura simba remunda wemagetsi, iyo yakakura simba rekinetic iro ion rinowana mushure mekukurumidza. Kune zvakare kudzvanya vhezheni pa electrode yekusveta kudzivirira kukanganisa kubva kumaerekitironi muplasma. Panguva imwecheteyo, iyo yekudzvanya electrode inogona kuumba ion kuita ion danda uye kuaisa mune inofananidzwa ion danda rukova kuitira kuti ipfuure nepakati peinomisikidza.

(3)Mass analyzer:

Panogona kunge paine akawanda marudzi emaion anogadzirwa kubva kune iyo ion sosi. Pasi pekuwedzera kweanode voltage, iyo ions inofamba nekumhanya kukuru. Maion akasiyana ane maatomu mashoma mayuniti uye akasiyana-siyana-kuchaji reshiyo.

(4)Accelerator chubhu:

Kuti uwane kumhanya kwepamusoro, simba repamusoro rinodiwa. Pamusoro pemunda wemagetsi wakapihwa neanode uye mass analyzer, munda wemagetsi wakapihwa muchubhu yekumhanyisa unodiwawo kuti uwedzere. Iyo accelerator chubhu ine akatevedzana emagetsi akaparadzaniswa nedielectric, uye iyo yakaipa voltage pama electrode inowedzera mukutevedzana kuburikidza neyakatevedzana yekubatanidza. Iyo yakakwirira iyo yakazara voltage, iyo yakakura kukurumidza kunowanikwa nemaion, ndiko kuti, yakakura simba rakatakurwa. Simba repamusoro rinogona kubvumira maion etsvina kubayiwa zvakadzika mukati mesilicon wafer kuti iite yakadzika junction, nepo simba rakaderera rinogona kushandiswa kugadzira kudzika kwakadzika.

(5)Kuongorora dhisiki

Iyo yakanangwa ion danda kazhinji idiki kwazvo mudhayamita. Iyo dhayamita yebeam yepakati danda ikozvino inomisikidza inenge 1 cm, uye iyo yedanda hombe yazvino implanter inosvika masendimita matatu. Iyo yese silicon wafer inofanirwa kuvharwa ne scanning. Kudzokororwa kweiyo dosi kuisirwa kunotemwa nekuongorora. Kazhinji, kune marudzi mana eimplanter scanning system:

① electrostatic scanning;

② mechanical scanning;

③ hybrid scanning;

④ parallel scanning.

(6)Static magetsi neutralization system:

Munguva yekusimwa, iyo ion danda inorova silicon wafer uye inoita kuti charge iunganidze pane mask. Iko kuunganidzwa kwechaji kunoshandura chiyero chekuchaja muion danda, zvichiita kuti nzvimbo yedanda ive yakakura uye kugoverwa kwedosi kusaenzana. Inogona kutopaza nepakati peiyo oxide layer uye kukonzera kutadza kwechishandiso. Ikozvino, iyo silicon wafer uye ion danda zvinowanzoiswa munzvimbo yakagadzikana yakakwirira-density plasma inonzi plasma electron shower system, inogona kudzora kuchaja kwesilicon wafer. Iyi nzira inobvisa maerekitironi kubva muplasma (kazhinji argon kana xenon) mukamuri yearc iri munzira yeion beam uye pedyo nesilicon wafer. Iyo plasma inosefa uye maerekitironi echipiri chete ndiwo anogona kusvika pamusoro pesilicon wafer kuti aite kuti chaji yakanaka.

(7)Process cavity:

Iko jekiseni remaion matanda musilicon wafers kunoitika mukamuri yekugadzira. Imba yekugadzira chikamu chakakosha cheiyo yekumisikidza, inosanganisira scanning system, terminal station ine vacuum kiyi yekurodha nekuburitsa silicon wafers, silicon wafer transfer system, uye komputa inodzora system. Pamusoro pezvo, kune mamwe maturusi ekutarisa madosi uye kudzora chiteshi mhedzisiro. Kana mechaniki scanning ikashandiswa, iyo terminal chiteshi ichave yakakura. Iyo vacuum yekamuri yegadziriro inopombwa kune kudzvinyirirwa kwepasi kunodiwa nemaitiro neakawanda-nhanho mechaniki pombi, turbomolecular pombi, uye pombi yekumisikidza, iyo inowanzoita 1 × 10-6Torr kana zvishoma.

(8)Dosage control system:

Chaiyo-nguva yedosi yekutarisa mune ion implanter inoitwa nekuyera iro danda reion rinosvika kune silicon wafer. Iyo ion beam current inoyerwa pachishandiswa sensor inonzi Faraday cup. Mune yakapfava Faraday system, kune ikozvino sensor muion danda nzira inoyera ikozvino. Nekudaro, izvi zvinopa dambudziko, sezvo danda reion rinosangana nesensor uye richigadzira maerekitironi echipiri izvo zvinozoguma nekuverenga zvisirizvo zvazvino. A Faraday system inogona kudzvanya maerekitironi echipiri uchishandisa magetsi kana magineti minda kuwana danda rechokwadi kuverenga ikozvino. Ikozvino kuyerwa neFaraday system inodyiswa mune yemagetsi dosi controller, iyo inoshanda seyazvino accumulator (iyo inoramba ichiunganidza yakayerwa danda ikozvino). Mutongi anoshandiswa kubatanidza huwandu hwemazuva ano kune inoenderana nguva yekusimwa uye kuverenga nguva inodiwa kune imwe dosi.

3.2 Kugadzirisa kukanganisa

Kudyarwa kweion kunogogodza maatomu kunze kweiyo lattice chimiro uye kukuvadza silicon wafer lattice. Kana iyo dosi yakasimwa yakakura, iyo yakasimwa layer inova amorphous. Pamusoro pezvo, iwo maion akadyarwa haatore nzvimbo dzesilicon, asi gara munzvimbo dzelattice gap. Izvi zvinosvibisa zvemukati zvinokwanisa kushandiswa chete mushure mekuita kwekupisa kwepamusoro-soro.

Annealing inogona kupisa iyo yakasimwa silicon wafer kugadzirisa retice kukanganisa; inogona zvakare kufambisa maatomu ekusachena kune maretiti uye kuamisa. Tembiricha inodiwa kugadzirisa kukanganiswa kweretisi ingangoita 500°C, uye tembiricha inodiwa kuita maatomu etsvina ingangoita 950°C. Iko kushandiswa kwetsvina kwakabatana nenguva uye tembiricha: iyo nguva yakareba uye yakakwirira tembiricha, zvakanyanya kusvibiswa kunoitwa. Pane nzira mbiri dzekutanga dzeannealing silicon wafers:

① kupisa-kupisa kwechoto annealing;

② kukurumidza thermal annealing (RTA).

Kupisa tembiricha yechoto annealing: Kupisa tembiricha yevira inzira yechinyakare yekumisikidza, inoshandisa tembiricha yekupisa kupisa silicon wafer kusvika 800-1000 ℃ uye kuichengeta kwemaminetsi makumi matatu. Patembiricha iyi, maatomu esilicon anodzokera kunzvimbo yeretisi, uye maatomu ekusachena anogona zvakare kutsiva maatomu esilicon opinda muretisi. Nekudaro, kurapwa kwekupisa panguva yekudziya uye nguva kunotungamira mukupararira kwetsvina, chiri chinhu icho yemazuva ano IC yekugadzira indasitiri isingadi kuona.

Rapid Thermal Annealing: Rapid thermal annealing (RTA) inobata zvimedu zvesilicon zvine kukurumidza kukwira kwekushisa uye nguva pfupi patembiricha yakananga (kazhinji 1000 ° C). Kuwedzeredza kweakaisirwa silicon wafers kunowanzoitwa mukukurumidza kupisa processor neAr kana N2. Iyo yekukurumidza tembiricha yekukwira maitiro uye nguva pfupi inogona kukwidziridza kugadziridzwa kwehurema hwelatisi, activation yetsvina uye inhibition yekusachena kupararira. RTA inogona zvakare kuderedza kupfupika kwakawedzera kupararira uye ndiyo nzira yakanakisa yekudzora kudzika kwejunction mune isina kudzika junction implants.

—————————————————————————————————————————————————— ————————————-

Semicera inogona kupagraphite zvikamu, kupfava/kuomarara kunzwa, silicon carbide zvikamu, CVD silicon carbide zvikamu,uyeSiC/TaC yakavharwa zvikamunemazuva makumi matatu.

Kana iwe uchifarira zviri pamusoro semiconductor zvigadzirwa,ndapota usazeza kutibata nesu panguva yekutanga.

Tel: +86-13373889683

WhatsAPP: +86-15957878134

Email: sales01@semi-cera.com

Nguva yekutumira: Aug-31-2024