1. Nhanganyaya

Maitiro ekuisa zvinhu (raw materials) pamusoro pe substrate zvinhu nenzira dzemuviri kana kemikari inonzi yakaonda firimu kukura.

Zvinoenderana neakasiyana misimboti yekushanda, yakabatanidzwa yedunhu yakaonda firimu deposition inogona kukamurwa kuita:

-Physical Vapor Deposition (PVD);

-Chemical Vapor Deposition (CVD);

-Kuwedzera.

2. Mutete Firimu Kukura Maitiro

2.1 Kuiswa kwehupfu hwemuviri uye kuita kwekupopota

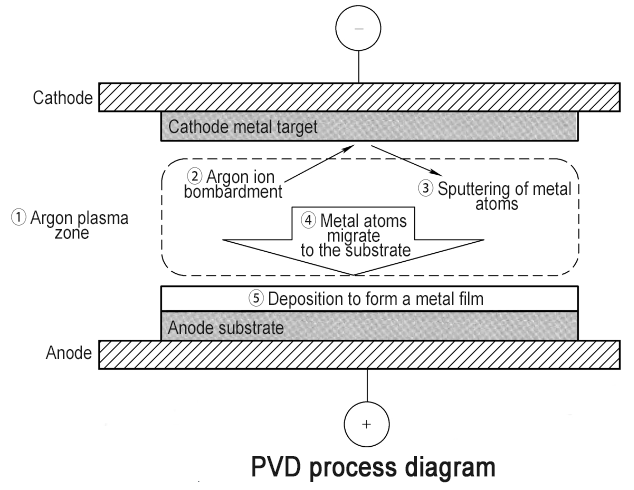

The physical vapor deposition (PVD) process inoreva kushandiswa kwemaitiro emuviri senge vacuum evaporation, sputtering, plasma coating uye molecular beam epitaxy kugadzira firimu rakatetepa pamusoro pechipfuti.

Muindasitiri yeVLSI, tekinoroji inonyanya kushandiswa yePVD ndeye sputtering, iyo inonyanya kushandiswa maelectrodes uye simbi inobatana yemasekete akabatanidzwa. Sputtering inzira umo magasi asingawanzo [senge argon (Ar)] anoiswa muioni (seAr+) pasi pechiito chemunda wemagetsi wekunze pasi pemamiriro ekunze ekuvharisa, uye anobhomba kwainotarirwa zvinhu pasi penzvimbo yakakwirira yemagetsi, kugogodza kunze maatomu kana mamorekuru echinhu chakanangwa, uye wosvika pamusoro pechipfuwo kuti ugadzire firimu rakatetepa mushure mekudhumhana-kusina kubhururuka. Ar ine yakagadzikana makemikari zvimiro, uye ayo ayoni haazoite kemikari nechinhu chakanangwa uye firimu. Sezvo akasanganiswa edunhu machipisi achipinda mu 0.13μm yemhangura yekubatanidza nguva, iyo yemhangura inodzivirira zvinhu layer inoshandisa titanium nitride (TiN) kana tantalum nitride (TaN) firimu. Kudiwa kwehunyanzvi hwekugadzira maindasitiri kwakasimudzira kutsvagisa nekuvandudzwa kwemakemikari reaction sputtering tekinoroji, kureva, mukamuri yekuputira, mukuwedzera kune Ar, kune zvakare reactive gasi nitrogen (N2), zvekuti iyo Ti kana Ta yakabhomba kubva zvinhu zvinonangwa Ti kana Ta zvinosangana neN2 kugadzira inodiwa TiN kana TaN firimu.

Kune nzira nhatu dzinowanzo shandiswa kupfira, dzinoti DC sputtering, RF sputtering uye magnetron sputtering. Sezvo kubatanidzwa kwematunhu akabatanidzwa kunoramba kuchiwedzera, nhamba yezvikamu zve-multi-layer metal wiring iri kuwedzera, uye kushandiswa kwePVD teknolojia iri kuramba ichiwedzera. PVD zvinhu zvinosanganisira Al-Si, Al-Cu, Al-Si-Cu, Ti, Ta, Co, TiN, TaN, Ni, WSi2, nezvimwe.

PVD uye sputtering maitiro anowanzopedzwa mukamuri yakavharwa yakavharwa ine vacuum degree ye 1 × 10-7 kusvika 9 × 10-9 Torr, iyo inogona kuve nechokwadi kuchena kwegasi panguva yekuita; panguva imwe chete, kunze kwemhepo yakakwirira inodiwa kuti ionize gasi risingawanzoiti kuti ribudise simba rakakwirira rinokwana kubhomba chinangwa. Iwo makuru ma paramita ekuongorora PVD uye sputtering maitiro anosanganisira kuwanda kweguruva, pamwe nekushomeka kukosha, kufanana, kupenya kwekupenya uye kushushikana kwefirimu rakaumbwa.

2.2 Chemical Vapor Deposition uye Sputtering process

Chemical vapor deposition (CVD) inoreva tekinoroji umo akasiyana gaseous reactants ane mativi akasiyana dhigirii anoita kemikari pane imwe tembiricha uye kudzvanywa, uye izvo zvinogadzirwa zvinhu zvakasimba zvinoiswa pamusoro peiyo substrate zvinhu kuti iwane yakaonda inodiwa. film. Mune yechinyakare yakabatanidzwa yekugadzira dhizaini yekugadzira, iyo yakawanikwa yakatetepa firimu zvinhu zvinowanzoita senge oxides, nitrides, carbides, kana zvinhu zvakaita sepolycrystalline silicon uye amorphous silicon. Sarudzo epitaxial kukura, iyo inonyanya kushandiswa mushure me45nm node, senge sosi uye drain SiGe kana Si selective epitaxial kukura, iri zvakare CVD tekinoroji.

Iyi tekinoroji inogona kuramba ichigadzira imwe crystal zvinhu zvemhando imwechete kana yakafanana neyekutanga latisi pane imwechete crystal substrate yesilicon kana zvimwe zvinhu padivi pelatisi yekutanga. CVD inoshandiswa zvakanyanya mukukura kwekudzivirira dielectric mafirimu (akadai seSiO2, Si3N4 uye SiON, nezvimwewo) uye mafirimu esimbi (akadai se tungsten, nezvimwewo).

Kazhinji, zvichienderana nekudzvanywa kwechikamu, CVD inogona kukamurwa kuita mumhepo kumanikidza kemikari vapor deposition (APCVD), sub-atmosphere pressure kemikari vapor deposition (SAPCVD) uye yakaderera kumanikidza kemikari vapor deposition (LPCVD).

Zvinoenderana nemhando yekushisa, CVD inogona kukamurwa kuita tembiricha yepamusoro / yakaderera tembiricha oxide firimu kemikari vapor deposition (HTO / LTO CVD) uye nekukurumidza thermal kemikari vapor deposition (Rapid Thermal CVD, RTCVD);

Zvinoenderana nemhinduro sosi, CVD inogona kukamurwa kuita silane-based CVD, polyester-based CVD (TEOS-based CVD) uye simbi organic kemikari vapor deposition (MOCVD);

Zvinoenderana nechikamu chesimba, CVD inogona kukamurwa kuita thermal kemikari vapor deposition (Thermal CVD), plasma yakawedzera kemikari vapor deposition (Plasma Enhanced CVD, PECVD) uye yakakwira density plasma kemikari vapor deposition (High Density Plasma CVD, HDPCVD). Munguva pfupi yapfuura, inoyerera kemikari vapor deposition (Flowable CVD, FCVD) ine yakanakisa gap yekuzadza kugona yakagadziridzwa zvakare.

Mafirimu akasiyana eCVD-akakura ane akasiyana zvimiro (senge kemikari, dielectric kugara, tension, kusagadzikana uye breakdown voltage) uye inogona kushandiswa zvakasiyana zvichienderana neyakasiyana maitiro ezvinodiwa (senge tembiricha, nhanho yekuvhara, kuzadza zvinodiwa, nezvimwewo).

2.3 Atomic layer deposition process

Atomic layer deposition (ALD) inoreva kuiswa kweatomu layer ne layer pane substrate material nekukura imwe atomic film layer by layer. Iyo yakajairika ALD inotora nzira yekuisa gasious precursors mu reactor nenzira inotsinhanisa pulsed.

Semuenzaniso, kutanga, reaction precursor 1 inounzwa mu substrate surface, uye mushure memakemikari adsorption, imwechete atomic layer inoumbwa pane substrate pamusoro; ipapo precursor 1 inosara pane substrate pamusoro uye mukamuri yekupindura inopombwa nepombi yemhepo; ipapo reaction precursor 2 inounzwa mukati me substrate pamusoro, uye kemikari inopindirana neye precursor 1 adsorbed pane substrate pamusoro kuti ibudise inoenderana neyakaonda firimu zvinhu uye zvinoenderana ne-zvigadzirwa pane substrate pamusoro; apo precursor 1 inobata zvachose, maitiro acho achabva angogumira, inova iyo yekuzvimisikidza hunhu hweAlD, uye ipapo iyo yasara reactants uye ne-zvigadzirwa zvinobviswa kugadzirira nhanho inotevera yekukura; nekudzokorora maitiro ari pamusoro nguva dzose, kuiswa kwezvinhu zvitete zvefirimu zvakakura zvakaturikidzana nemaatomu ega zvinogona kuwanikwa.

Ose ari maviri ALD neCVD inzira dzekuunza gaseous kemikari reaction sosi kuti iite kemikari pane substrate pamusoro, asi mutsauko ndewekuti gasious reaction sosi yeCVD haina hunhu hwekuzvimisikidza kukura. Zvinogona kuoneka kuti kiyi yekugadzira tekinoroji yeALD ndeyekutsvaga precursors ine yekuzvimisikidza maitiro ekuita.

2.4 Epitaxial Process

Epitaxial process inoreva maitiro ekukura akanyatso kurongeka imwechete crystal layer pane substrate. Kazhinji kutaura, iyo epitaxial maitiro ndeyekurisa kristaro layer ine yakafanana lattice yekumisikidza seyepakutanga substrate pane imwechete crystal substrate. Epitaxial process inoshandiswa zvakanyanya mukugadzira semiconductor, senge epitaxial silicon wafers mune yakabatanidzwa yedunhu indasitiri, yakamisikidzwa sosi uye inodhonza epitaxial kukura kweMOS transistors, epitaxial kukura pane LED substrates, nezvimwe.

Zvinoenderana nenzvimbo dzakasiyana dzenzvimbo yekukura, nzira dzekukura epitaxial dzinogona kukamurwa kuita solid phase epitaxy, liquid phase epitaxy, uye vapor phase epitaxy. Mukugadzirwa kwedunhu rakasanganiswa, nzira dzinowanzoshandiswa epitaxial dzakasimba chikamu epitaxy uye vapor phase epitaxy.

Solid phase epitaxy: inoreva kukura kweimwe crystal layer pane substrate uchishandisa yakasimba sosi. Semuenzaniso, kupisa kwekupisa mushure mekudyarwa kweion ichokwadi chakasimba chikamu epitaxy process. Panguva yekuisirwa ion, maatomu esilicon esilicon wafer anoputirwa nemaion akaiswa simba repamusoro, achisiya nzvimbo dzawo dzekutanga dzelatisi uye kuita amorphous, achigadzira pamusoro amorphous silicon layer. Mushure mekupisa kwekupisa kwepamusoro-soro, maatomu eamorphous anodzokera kunzvimbo dzawo dzelattice uye anoramba achienderana neatomic crystal orientation mukati me substrate.

Nzira dzekukura dze vapor phase epitaxy dzinosanganisira chemical vapor phase epitaxy, molecular beam epitaxy, atomic layer epitaxy, etc. Mukugadzirwa kwedunhu rakasanganiswa, kemikari vapor phase epitaxy ndiyo inonyanya kushandiswa. Nheyo yemakemikari vapor phase epitaxy yakangofanana neyemakemikari vapor deposition. Ose ari maviri maitiro anoisa akaonda mafirimu nemakemikari anoita pamusoro pemawaferi mushure mekusanganiswa kwegasi.

Musiyano ndewekuti nekuti kemikari mhute chikamu epitaxy inokura imwe chete crystal layer, ine zvakakwirira zvinodiwa zvekusachena zviri mumidziyo uye kuchena kweiyo wafer pamusoro. Iyo yekutanga kemikari vapor chikamu epitaxial silicon process inoda kuitwa pasi pemamiriro ekushisa kwakanyanya (kupfuura 1000 ° C). Nekuvandudzwa kwemidziyo yekushandisa, kunyanya kutorwa kwevacuum yekamuri yekutsinhana tekinoroji, kuchena kwegomba remidziyo uye pamusoro pesilicon wafer kwakagadziridzwa zvakanyanya, uye silicon epitaxy inogona kuitwa pakadzika tembiricha (600-700 °). C). Iyo epitaxial silicon wafer process ndeyekurisa imwe crystal silicon pamusoro peiyo silicon wafer.

Kana ichienzaniswa neyekutanga silicon substrate, iyo epitaxial silicon layer ine kuchena kwepamusoro uye kushomeka kwelatisi, nekudaro inovandudza goho rekugadzira semiconductor. Uye zvakare, ukobvu hwekukura uye doping kusungirirwa kweiyo epitaxial silicon layer inokura pasilicon wafer inogona kugadzirwa zviri nyore, izvo zvinounza kuchinjika kune dhizaini yechishandiso, sekudzikisa substrate kuramba uye kuwedzera substrate kuparadzaniswa. Iyo yakamisikidzwa sosi-drain epitaxial process itekinoroji inoshandiswa zvakanyanya mune yepamusoro logic tekinoroji node.

Zvinoreva maitiro eepitaxially kukura doped germanium silicon kana silicon mune sosi uye dhiza matunhu eMOS transistors. Izvo zvakakosha zvekuunza iyo yakamisikidzwa sosi-drain epitaxial process inosanganisira: kukura pseudocrystalline layer ine kushushikana nekuda kwelattice adaptation, kuvandudza chiteshi chekutakura kufamba; in-situ doping of the source and draining inogona kuderedza kupikisa kweparasitic ye source-drain junction uye kuderedza hurema hwe-high-energy ion implantation.

3. dzakaonda firimu kukura midziyo

3.1 Vacuum evaporation michina

Vacuum evaporation inzira yekunamira iyo inopisa zvinhu zvakasimba mukamuri yevacuum kuti iite kuti inyunguduke, inyungudike kana kuti sublimate, yobva yaita condense nekuisa pamusoro pechinhu chesubstrate pane imwe tembiricha.

Kazhinji ine zvikamu zvitatu, zvinoti vacuum system, evaporation system uye yekudziya system. Iyo vacuum system ine vacuum pombi uye vacuum pombi, uye basa rayo guru nderekupa inokodzera vacuum nharaunda yekubuda. Iyo evaporation system ine evaporation tafura, chikamu chekudziya uye chikamu chekuyera tembiricha.

Zvinhu zvinonangwa kuti zvibudiswe (zvakadai seAg, Al, zvichingodaro) zvinoiswa patafura yekubuda; chikamu chekuyeresa nekuyeresa tembiricha ndeye yakavharwa-loop system inoshandiswa kudzora tembiricha ye evaporation kuti ive nechokwadi chekubuda kwemhepo. Iyo yekudziya system ine yewafer nhanho uye inodziya chikamu. Iyo wafer nhanho inoshandiswa kuisa iyo substrate pairi iyo firimu rakatetepa rinoda kunyungudutswa, uye chikamu chekudziya chinoshandiswa kuona substrate kudziyisa uye tembiricha kuyerwa kwemhinduro kutonga.

Nzvimbo yevacuum ndiyo inonyanya kukosha mumamiriro ekuputira evaporation, iyo inobatana nehuwandu hwekubuda uye kunaka kwefirimu. Kana iyo vacuum dhigirii isingazadzise zvinodiwa, maatomu akafukidzwa kana mamorekuru anodhumhana kazhinji nemamorekuru egasi asara, zvichiita kuti nzira yavo yemahara ive diki, uye maatomu kana mamorekuru anopararira zvakanyanya, nekudaro achichinja mafambiro uye kuderedza firimu. chiyero chekugadzira.

Pamusoro pezvo, nekuda kwekuvapo kwemamorekuru egasi etsvina yakasara, firimu rakaiswa rakasvibiswa zvakanyanya uye harina kunaka, kunyanya kana chiyero chekumanikidza chekamuri chikasasangana neyakajairwa uye paine kuvuza, mhepo inodonhedza mukamuri yevacuum. , iyo ichava nemigumisiro yakakomba pamhando yefirimu.

Mamiriro ezvimiro zvevacuum evaporation midziyo inoona kuti kufanana kwejasi pane makuru-saizi substrates kwakashata. Kuti uvandudze kufanana kwayo, nzira yekuwedzera sosi-substrate chinhambwe uye kutenderedza iyo substrate inowanzogamuchirwa, asi kuwedzera sosi-substrate chinhambwe kunopira mwero wekukura uye kuchena kwefirimu. Panguva imwecheteyo, nekuda kwekuwedzera kwenzvimbo yevacuum, chiyero chekushandisa che evaporated chinoderedzwa.

3.2 DC muviri mhute deposition midziyo

Direct current physical vapor deposition (DCPVD) inozivikanwawo se cathode sputtering kana vacuum DC two-stage sputtering. Iyo inonangwa zvinhu zvevacuum DC sputtering inoshandiswa secathode uye iyo substrate inoshandiswa seanode. Vacuum sputtering ndeyekugadzira plasma neionizing iyo gasi rekuita.

Izvo zvinopomerwa zvimedu mu plasma zvinokurumidzirwa mumunda wemagetsi kuti uwane humwe huwandu hwesimba. Zvimedu zvine simba rakakwana zvinobhomba pamusoro pechinhu chakanangwa, zvekuti maatomu anonangwa anoparadzirwa kunze; maatomu akapfapfaidzwa nerimwe simba rekinetic anofamba akananga kune substrate kuumba firimu rakatetepa pamusoro pe substrate. Gasi rinoshandiswa pakupfira rinowanzova gasi risingawanzoitiki, senge argon (Ar), saka firimu rinoumbwa nekupfira harizosvibiswa; uyezve, iyo atomiki radius yeargon inonyanya kukodzera kupfira.

Hukuru hwezvimedu zvinopopotera hunofanirwa kunge huri pedyo nehukuru hwemaatomu anonangwa kuti aparadzwe. Kana zvimedu zvakakura zvakanyanya kana zviduku, sputtering inobudirira haigoni kuumbwa. Pamusoro pehukuru hweatomu, huwandu hweatomu huchakanganisawo kunaka kwekupopota. Kana sputtering particle sosi yanyanya kupfava, maatomu anonangwa haazopushwa; kana sputtering particles zvakanyanyisa, chinangwa chichave "chakakotama" uye chinangwa hachizoputi.

Chinhu chinonangwa chinoshandiswa muDCPVD chinofanira kunge chiri kondakita. Izvi zvinodaro nekuti kana maargon ions ari mugasi anobhomba zvinhu zvakanangwa, anozobatana zvakare nemaerekitironi ari pamusoro pechinhu chakanangwa. Kana chinhu chiri kutariswa chiri kondakita sesimbi, maerekitironi anopedzwa nekubatanidzwazve uku anozadzikiswa nyore nyore nemagetsi uye maerekitironi emahara mune zvimwe zvikamu zvechinhu chakanangwa kuburikidza nekufambiswa kwemagetsi, kuitira kuti pamusoro pechinhu chakanangwa se yose inoramba ichipomerwa zvakaipa uye sputtering inochengetwa.

Kusiyana neizvi, kana chinhu chinonangwa chiri chivhariso, mushure mekunge maerekitironi ari pamusoro pechinhu chakanangwa abatanidzwazve, maerekitironi emahara mune zvimwe zvikamu zvechinhu chakanangwa haagone kuzadzikiswa nemafambisirwo emagetsi, uye kunyangwe machaji akanaka achaungana pa pamusoro pechinhu chakanangwa, zvichiita kuti icho chinonangwa chikwanise kusimuka, uye chajiro isina kunaka yechinhu chakanangwa inoshaikwa kusvika yanyangarika, zvinozopedzisira zvaita kuti kupere.

Naizvozvo, kuitira kugadzira insulating zvinhu zvakare kushandiswa pakupopota, zvinodikanwa kutsvaga imwe nzira yekupopota. Radio frequency sputtering inzira yekupopota iyo yakakodzera kune ese ari maviri conductive uye asiri-conductive zvinangwa.

Chimwe chinokanganisa cheDCPVD ndechekuti magetsi ekudzimisa akakwira uye bombardment rerekitironi pa substrate rakasimba. Nzira inoshanda yekugadzirisa dambudziko iri ndeye kushandisa magnetron sputtering, saka magnetron sputtering ndeyechokwadi inoshanda kukosha mumunda wemaseketi akabatanidzwa.

3.3 RF Physical Vapor Deposition Equipment

Radio frequency physical vapor deposition (RFPVD) inoshandisa redhiyo frequency simba senzvimbo yekuvhundutsa uye inzira yePVD inokodzera zvakasiyana siyana zvesimbi nezvisiri zvesimbi.

Mafambiro akajairika emagetsi eRF anoshandiswa muRFPVD ndeye 13.56MHz, 20MHz, uye 60MHz. Iwo akanaka uye asina kunaka matenderedzwa eRF magetsi emagetsi anoonekwa achinjana. Apo chinangwa chePVD chiri muchikamu chakanaka chehafu, nokuti chinangwa chepamusoro chiri panzvimbo yakanaka, maerekitironi ari mumhepo yemhepo achayerera achienda kune chinangwa chepamusoro kuti aite neutralize chaji yakanaka yakaunganidzwa pamusoro payo, uye kunyange kuramba ichiunganidza maerekitironi, kuita kuti chiso chayo chive chakashata; kana nhangemutange yekupopota iri munhafu hafu cycle, maion ari positive anoenda akananga kwaanovavarira uye obva adzoreredzwa zvishoma pane chinongedzo.

Chinhu chinonyanya kukosha ndechekuti kumhanya kwemaerekitironi mumunda wemagetsi eRF kunokurumidza kupfuura kuya kwemaion akanaka, nepo nguva yeyakanaka uye isina kunaka hafu kutenderera kwakafanana, saka mushure mekutenderera kwakazara, nzvimbo inotariswa ichave. "mambure" akachajwa zvisina kunaka. Nokudaro, mumatambo mashomanana ekutanga, kukanganisa kusina kunaka kwechinangwa chepamusoro kunoratidza kuwedzera kwemaitiro; mushure mezvo, nzvimbo yakatarisa inosvika kune yakagadzikana yakashata inogona; mushure mezvo, nekuti kubhadharisa kwakashata kwechinangwa kune chinosemesa maerekitironi, huwandu hwechaji yakanaka uye yakaipa inogamuchirwa neelectrode inotariswa inoita kuenzana, uye chipfuro chinopa chaji yakagadzikana isina kunaka.

Kubva pane zvataurwa pamusoro apa, zvinogona kuonekwa kuti maitiro ekugadzirwa kwemagetsi akaipa haanei nechokuita nehupfumi hwechinhu chinotarirwa pachacho, saka nzira yeRFPVD haigoni kugadzirisa dambudziko rekuputira kwezvinangwa zvekudzivirira, asiwo inonyatsoenderana. nezvakajairwa simbi conductor zvinangwa.

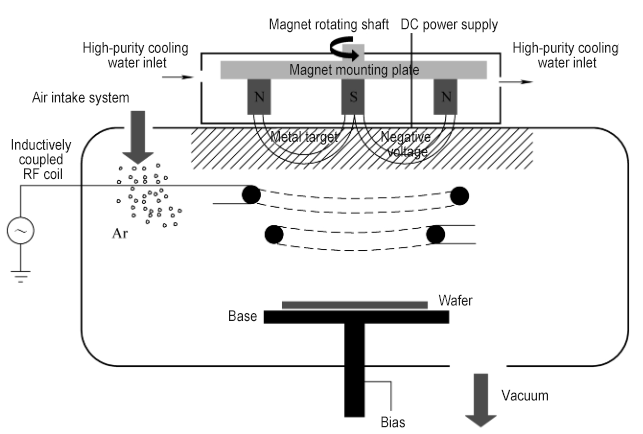

3.4 Magnetron sputtering midziyo

Magnetron sputtering inzira yePVD inowedzera magineti kuseri kwechinangwa. Iwo akawedzera magineti uye iyo DC magetsi emagetsi (kana AC magetsi ekupa) system inoumba magnetron sputtering sosi. Iyo sputtering sosi inoshandiswa kugadzira inopindirana magetsi emagetsi mukamuri, kutora uye kudzikamisa mafambiro emagetsi muplasma mukati mekamuri, kuwedzera nzira yekufamba kwemaerekitironi, uye nekudaro kuwedzera kusungirirwa kweplasma, uye pakupedzisira kuwana zvakawanda. deposition.

Mukuwedzera, nokuti maerekitironi akawanda akasungwa pedyo nepamusoro pechinangwa, bombardment ye substrate nema electrons inoderedzwa, uye tembiricha ye substrate inoderedzwa. Kuenzaniswa neiyo flat-plate DCPVD tekinoroji, chimwe chezvinhu zviri pachena zvemagineti yemuviri vapor deposition tekinoroji ndeyekuti iyo ignition discharge voltage yakadzikira uye yakagadzikana.

Nekuda kweiyo yakakwira plasma yekumisikidza uye yakakura goho rekupopota, inogona kuwana yakanakisa deposition kunyatsoita, deposition ukobvu kudzora mune yakakura saizi renji, chaiyo yekumisikidza kudzora uye yakaderera ignition voltage. Naizvozvo, magnetron sputtering iri munzvimbo ine simba mune yazvino simbi firimu PVD. Iyo yakapusa magnetron sputtering sosi dhizaini ndeyekuisa boka remagineti kumashure kweiyo flat target (kunze kwevacuum system) kuti ibudise magineti inoenderana nenzvimbo yakanangwa munzvimbo yenzvimbo panzvimbo yakanangwa.

Kana magineti echigarire akaiswa, simba rayo remagineti rinenge rakagadziriswa, zvichiita kuti pave neyakagadzika magineti kugovera pane inotarirwa nzvimbo mukamuri. Zvinhu chete munzvimbo dzakananga dzechinangwa zvinoputirwa, chiyero chekushandiswa kwechinangwa chakaderera, uye kufanana kwefirimu rakagadzirirwa kwakashata.

Pane imwe mukana wekuti simbi yakapwanyiwa kana zvimwe zvimedu zvidzorerwe kumashure pane zvakanangwa, zvobva zvaungana kuita zvidimbu uye kugadzira kusvibiswa. Naizvozvo, zvekutengesa magineti sputtering masosi anonyanya kushandisa inotenderera magineti dhizaini kuvandudza firimu kufanana, chiyero chekushandiswa kwechinangwa, uye kuzara kwakanangana nekupopota.

Zvakakosha kuenzanisa zvinhu zvitatu izvi. Kana iyo chiyero ikasabatwa zvakanaka, inogona kuguma nekufanana kwefirimu kwakanaka uku ichideredza zvakanyanya chiyero chekushandiswa kwechinangwa (kupfupisa hupenyu hwakanangwa), kana kutadza kuzadzisa chinangwa chakazara chekuputira kana kuzara kwakanangana nekuora, izvo zvinokonzeresa matambudziko panguva yekuputika. process.

Mune magnetron PVD tekinoroji, zvinodikanwa kuti utarise iyo inotenderera magineti yekufamba, chimiro chechinangwa, chinangwa chekutonhora system uye magnetron sputtering sosi, pamwe nekumisikidzwa kwechigadziko chinotakura wafer, senge wafer adsorption uye tembiricha kutonga. Muchirongwa chePVD, tembiricha yechipfu inodzorwa kuti iwane chimiro chekristaro chinodiwa, saizi yezviyo uye kutaridzika, pamwe nekugadzikana kwekuita.

Sezvo kupisa kwekushisa pakati peshure kwechifukidzo uye pamusoro pechigadziko kunoda kudzvanywa, kazhinji muhurongwa hweTorr yakati wandei, uye kudzvanywa kwekushanda kwekamuri kunowanzo kurongeka kwemamTorr akati wandei, kumanikidza kumusana. yewaferi yakakura kupfuura kudzvanywa kuri pamusoro peiyo wafer, saka mechanical chuck kana electrostatic chuck inodiwa kuisa uye kudzikisira wafer.

Iyo mechanic chuck inovimba nehuremu hwayo uye mupendero wewafer kuti iite basa iri. Kunyange zvazvo iine zvakanakira chimiro chakareruka uye kusanzwa kune zvinhu zvechifukidziro, iyo yemucheto mhedzisiro yewafer iri pachena, iyo isingakodzeri kune yakasimba kutonga kwezvikamu. Naizvozvo, yakatsiviwa zvishoma nezvishoma ne electrostatic chuck muIC kugadzira maitiro.

Kune maitiro asina kunyanya kutarisisa tembiricha, isiri-adsorption, isiri-kumucheto yekubata masherufu nzira (hapana mutsauko wekumanikidza pakati pepamusoro nepasi penzvimbo yewaferi) inogona kushandiswa zvakare. Munguva yePVD maitiro, kamuri yekamuri uye pamusoro pezvikamu zvinosangana ne plasma zvichaiswa uye zvakavharwa. Kana iyo yakadhindwa firimu ukobvu inodarika muganho, iyo firimu inotsemuka uye kubvarura, zvichikonzera matambudziko echikamu.

Naizvozvo, kurapwa kwepamusoro kwezvikamu zvakaita senge lining ndiyo kiyi yekuwedzera muganhu uyu. Surface sandblasting uye aluminium spraying inzira mbiri dzinowanzo shandiswa, chinangwa chekuwedzera kushata kwepamusoro kusimbisa kubatana pakati pefirimu nepamusoro pevhu.

3.5 Ionization Physical Vapor Deposition Equipment

Nekuenderera mberi kwekuvandudza tekinoroji yemicroelectronics, saizi yemhando iri kuita diki nediki. Sezvo tekinoroji yePVD isingakwanise kudzora mafambiro ezvimedu, kugona kwePVD kupinda nemumakomba uye mitsetse yakamanikana ine yakakwira mareshiyo inogumira, zvichiita kuti kuwedzerwa kushandiswa kwechinyakare PVD tekinoroji kuwedzere kupikiswa. Muchirongwa chePVD, sezvo chikamu chechikamu chepore groove chinowedzera, kuvharika kuri pazasi kunodzikira, kuchiita maeves-senge akarembera chimiro pakona yepamusoro, uye achigadzira iyo isina kusimba yekuvhara pakona yepasi.

Ionized physical vapor deposition tekinoroji yakagadziridzwa kugadzirisa dambudziko iri. Inotanga plasmatize maatomu esimbi akapushwa kubva pachinangwa nenzira dzakasiyana, yobva yagadzirisa bias voltage yakatakurwa pawafer kuti idzore kwainoenda uye simba reiyoni yesimbi kuti iwane yakagadzikana inotungamira simbi ion kuyerera kugadzira firimu rakatetepa, nekudaro kuvandudza. kufukidzwa kwepasi pematanho ehupamhi hwepamusoro kuburikidza nemakomba uye nhete nzira.

Iyo yakajairika ionized metal plasma tekinoroji ndeyekuwedzerwa kweredhiyo frequency coil mukamuri. Mukati mekuita, kumanikidzwa kwekushanda kwekamuri kunochengetwa kune imwe nzvimbo yakakwirira (5 kusvika ku10 nguva yakajairika yekushanda). Munguva yePVD, redhiyo frequency coil inoshandiswa kugadzira yechipiri plasma dunhu, umo iyo argon plasma concentration inowedzera nekuwedzera kweredhiyo frequency simba uye gasi kudzvanywa. Kana maatomu esimbi aputika kubva pachinangwa achipfuura nemudunhu iri, anodyidzana nepamusoro-density argon plasma kuita maion esimbi.

Kuisa RF sosi pawafer carrier (senge electrostatic chuck) kunogona kuwedzera kusarerekera pawafer kukwezva simbi yakanaka maion kuzasi kwepore groove. Iyi inotungamira simbi ion inoyerera perpendicular kune wafer pamusoro inovandudza nhanho yepasi kufukidzwa kweyakakwira chikamu ratio pores uye nhete nzira.

Rusaruro rusina kunaka rwunoiswa pawafer runokonzeresawo kuti ayoni abhombe pamusoro pewafer (reverse sputtering), izvo zvinonetesa chimiro chakarembera chemuromo wepore groove uye kuputika firimu rinoiswa kuzasi kumadziro emakona kumakona epasi pepore. groove, nekudaro ichisimudzira nhanho yekuvhara pamakona.

3.6 Atmospheric Pressure Chemical Vapor Deposition Equipment

Atmospheric pressure chemical vapor deposition (APCVD) midziyo inoreva mudziyo unopfapfaidza gaseous reaction source inogara ichimhanya pamusoro penzvimbo inodziya yakaoma substrate pasi penzvimbo ine dzvinyiriro iri pedyo nemhepo, zvichiita kuti reaction source iite kemikari pa. iyo substrate pamusoro, uye chinoitwa chigadzirwa chinoiswa pane substrate pamusoro kuti iite firimu rakatetepa.

APCVD midziyo ndiyo yekutanga CVD michina uye ichiri kushandiswa zvakanyanya mukugadzira maindasitiri nekutsvaga kwesainzi. APCVD midziyo inogona kushandiswa kugadzira mafirimu matete senge single crystal silicon, polycrystalline silicon, silicon dioxide, zinc oxide, titanium dioxide, phosphosilicate girazi, uye borophosphosilicate girazi.

3.7 Yakaderera Kudzvinyirira Chemical Vapor Deposition Equipment

Low-pressure chemical vapor deposition (LPCVD) midziyo inoreva midziyo inoshandisa gasi zvinhu zvakasvibirira kuita kemikari pamusoro peiyo substrate yakasimba pasi peinopisa (350-1100°C) uye yakaderera-pressure (10-100mTorr) nharaunda, uye iyo reactants inoiswa pane substrate pamusoro kuti iite firimu rakatetepa. Midziyo yeLPCVD inogadzirwa pahwaro hweAPCVD kuvandudza mhando yemafirimu matete, kuvandudza kugovera kwakafanana kwehunhu hwema paramita senge firimu ukobvu uye resistivity, uye kunatsiridza kugadzirwa kwakanaka.

Chinhu chayo chikuru ndechekuti munzvimbo yakaderera-inopisa yekupisa, gasi rinoita kemikari pamusoro peiyo wafer substrate, uye zvigadzirwa zvinogadziriswa zvinoiswa pane substrate kuti iite firimu rakatetepa. Midziyo yeLPCVD ine zvakanakira mukugadzirira mafirimu matete emhando yepamusoro uye inogona kushandiswa kugadzira mafirimu matete akadai sesilicon oxide, silicon nitride, polysilicon, silicon carbide, gallium nitride uye graphene.

Kuenzaniswa neAPCVD, iyo yakaderera-kumanikidza kuita nharaunda yeLPCVD midziyo inowedzera inorehwa yemahara nzira uye diffusion coefficient yegasi mukamuri yekupindura.

Iyo reaction gasi uye inotakura gasi mamorekuru mukamuri yekupindura inogona kugoverwa zvakaenzana munguva pfupi, nekudaro inovandudza zvakanyanya kufanana kwefirimu ukobvu, resistivity kufanana uye nhanho kufukidzwa kwefirimu, uye kushandiswa kwegasi rekuita kudiki zvakare. Mukuwedzera, iyo yakaderera-kudzvanywa nharaunda zvakare inomhanyisa kumhanya kwekutapurirana kwezvinhu zvegasi. Kusachena uye maitiro ezvigadzirwa zvakaparadzaniswa kubva kune substrate zvinogona kukurumidza kutorwa kubva munzvimbo yekuita kuburikidza nemuganhu wemuganhu, uye gasi rinoita rinokurumidza kupfuura nepakati pemuganhu kusvika kune substrate pamusoro pekuita, nokudaro zvinobudirira kudzvinyirira self-doping, kugadzirira. mafirimu emhando yepamusoro ane mawere ekuchinja, uye zvakare anovandudza kugadzirwa kwakanaka.

3.8 Plasma Yakavandudza Chemical Vapor Deposition Equipment

Plasma yakagadziridzwa kemikari vapor deposition (PECVD) inzvimbo inoshandiswa zvakanyanyahin film deposition tekinoroji. Munguva yemaitiro eplasma, gaseous precursor inoiswa ionized pasi pechiito cheplasma kuti iumbe mapoka anonakidzwa anoshanda, ayo anopararira kune substrate pamusoro uye obva aita kemikari kuita kuti apedze kukura kwefirimu.

Zvinoenderana nehuwandu hwechizvarwa cheplasma, plasma inoshandiswa muPECVD inogona kukamurwa kuita marudzi maviri: radio frequency plasma (RF plasma) uye microwave plasma (Microwave plasma). Parizvino, radio frequency inoshandiswa muindastiri inowanzo 13.56MHz.

Iko kuunzwa kweredhiyo frequency plasma inowanzo kupatsanurwa kuita marudzi maviri: capacitive coupling (CCP) uye inductive coupling (ICP). Iyo capacitive coupling nzira inowanzova yakananga plasma reaction method; nepo inductive coupling nzira inogona kuva yakananga plasma nzira kana kure kure plasma nzira.

Mukugadzira semiconductor maitiro, PECVD inowanzo shandiswa kurima mafirimu matete pamasubstrates ane simbi kana zvimwe zvimiro zvinonzwa tembiricha. Semuyenzaniso, mumunda wekumashure-yekupedzisira simbi yekubatanidza maseketi akabatanidzwa, sezvo sosi, gedhi uye madhiraini zvimiro zvechigadzirwa zvakaumbwa mukumberi-kumagumo maitiro, kukura kwemafirimu akaonda mumunda wekubatanidzwa kwesimbi kunoenderana. kune zvipingamupinyi zvakanyanya zvekupisa bhajeti, saka inowanzopedzwa nerubatsiro rweplasma. Nekugadzirisa plasma process parameters, kuwanda, kuumbwa kwemakemikari, kusvibiswa kwemukati, mechanical toughness uye stress parameters yefirimu yakaonda inokura nePECVD inogona kugadziriswa uye kugadziriswa mukati meimwe nzvimbo.

3.9 Atomic Layer Deposition Equipment

Atomic layer deposition (ALD) tekinoroji yakatetepa yekuisa firimu inokura nguva nenguva muchimiro che quasi-monoatomic layer. Hunhu hwayo ndehwekuti ukobvu hwefirimu rakaiswa hunogona kunyatso gadziridzwa nekudzora huwandu hwekukura. Kusiyana neyemakemikari vapor deposition (CVD) maitiro, maviri (kana anopfuura) anotangira muAlD maitiro anochinjana kupfuura nepakati peiyo substrate pamusoro uye anonyatso kuparadzaniswa nekucheneswa kwegasi isingawanzo.

Iwo maviri precursors haasanganise uye asangane muchikamu chegasi kuti aite kemikari, asi anongoita kuburikidza nemakemikari adsorption pane substrate pamusoro. Muchikamu chega chega cheALD, huwandu hweprecursor adsorbed pane substrate surface ine hukama nehuwandu hwemapoka anoshanda pane substrate surface. Kana mapoka anoshingaira ari pamusoro pe substrate apera, kunyange kana yakawandisa yeprecursor ikaunzwa, kemikari adsorption haizoitike pane substrate pamusoro.

Izvi zvinodaidzwa kuti surface self-limiting reaction. Iyi dhizaini inoita kuti ukobvu hwefirimu ukure mukutenderera kwega kwega kweiyo ALD maitiro anogara aripo, saka maitiro eALD ane zvakanakira kurongeka ukobvu kutonga uye yakanaka firimu nhanho kufukidzwa.

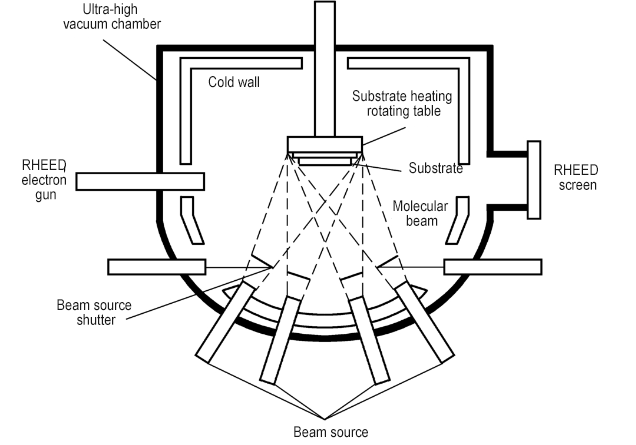

3.10 Molecular Beam Epitaxy Equipment

Molecular Beam Epitaxy (MBE) system inoreva epitaxial mudziyo unoshandisa imwe kana anopfuura anopisa simba matanda eatomu kana mamolecular matanda kupfapfaidza pane inopisa substrate pamusoro pane imwe spidhi pasi pe-ultra-high vacuum mamiriro, uye adsorb uye kutama pane substrate pamusoro. kuti epitaxially kukura imwe crystal yakaonda mafirimu pamwe chete nekristaro axis nzira ye substrate zvinhu. Kazhinji, pasi pemamiriro ekudziya nechoto chejeti chine nhovo yekupisa, danda sosi rinogadzira danda reatomu kana danda remamorekuru, uye firimu rinokura rakaturikidzana nejira pamwe nekristaro axis kutungamira kweiyo substrate zvinhu.

Hunhu hwayo hwakadzikira epitaxial kukura tembiricha, uye ukobvu, chimiro, chimiro chemakemikari uye kusachena kusungirirwa kunogona kunyatsodzorwa pamwero weatomu. Kunyange zvazvo MBE yakabva mukugadzirwa kwemasemiconductor ultra-thin single crystal films, kushandiswa kwayo kwawedzera kusvika kune zvakasiyana-siyana zvezvinhu zvakadai sesimbi uye insulating dielectrics, uye inogona kugadzirira III-V, II-VI, silicon, silicon germanium (SiGe). ), graphene, oxides uye organic mafirimu.

Iyo molecular beam epitaxy (MBE) system inonyanya kuumbwa neye-ultra-high vacuum system, molecular beam sosi, substrate inogadzirisa uye yekudziya system, sampuli yekufambisa sisitimu, in-situ yekutarisa system, yekudzora system, uye bvunzo. system.

Iyo vacuum system inosanganisira vacuum pombi (mechanical pumps, molecular pumps, ion pombi, uye condensation pombi, nezvimwewo) uye akasiyana mavharuvhu, ayo anogona kugadzira iyo yekupedzisira-yakakwira vacuum kukura nharaunda. Iyo inowanzo kuwanikwa vacuum degree ndeye 10-8 kusvika 10-11 Torr. Iyo vacuum system inonyanya kuve nemakamuri matatu ekushanda ekutsvaira, anoti sampuli jekiseni kamuri, pretreatment uye pamusoro pekuongorora kamuri, uye imba yekukura.

Iyo yekuenzanisira jekiseni kamuri inoshandiswa kuendesa sampuli kune yekunze nyika kuti ive nechokwadi chepamusoro vacuum mamiriro emamwe makamuri; iyo pretreatment uye yekumusoro yekuongorora kamuri inobatanidza iyo sampuli jekiseni kamuri uye yekukura imba, uye basa rayo guru nderekufanogadzirisa sampuli (yakanyanya-tembiricha degassing kuti ive nehutsanana hwakakwana hweiyo substrate pasi) uye kuita yekutanga ongororo pamusoro sampuli yakanatswa; Imba yekukura ndiyo chikamu chepakati cheMBE system, inonyanya kuumbwa nechoto chevira uye inoenderana nevhavha gungano, sampuli yekudzora koni, inotonhorera sisitimu, inoratidzira yakakwira simba electron diffraction (RHEED), uye in-situ yekutarisa system. . Imwe michina yekugadzira MBE ine akawanda ekukura kamuri masisitimu. Iyo schematic dhizaini yeMBE midziyo chimiro inoratidzwa pazasi:

MBE yesilicon zvinhu inoshandisa yakakwirira-kuchena silicon seyakagadzirwa, inokura pasi pekupedzisira-yakakwirira vacuum (10-10~10-11Torr) mamiriro, uye tembiricha yekukura i600~900℃, ine Ga (P-mhando) uye Sb ( N-mhando) semadoping sources. Anowanzo shandiswa doping masosi akadai P, As uye B haawanzo shandiswa sematanda masosi nekuti anonetsa kubuda.

Iyo reaction chamber yeMBE ine Ultra-yakakwirira vacuum nharaunda, iyo inowedzera inorehwa yemahara nzira yemamorekuru uye inoderedza kusvibiswa uye oxidation pamusoro pechinhu chinokura. Iyo epitaxial zvinhu zvakagadzirirwa zvine yakanaka pamusoro morphology uye kufanana, uye inogona kugadzirwa kuva multilayer chimiro chine doping dzakasiyana kana dzakasiyana zvinhu.

Tekinoroji yeMBE inowana kudzokororwa kwekukura kwe-ultra-thin epitaxial layers ine ukobvu hweatomu imwe chete layer, uye maonerwo ari pakati peepitaxial layers ane materu. Inokurudzira kukura kweIII-V semiconductors uye mamwe akawanda-component heterogeneous zvinhu. Parizvino, iyo MBE sisitimu yave yemhando yepamusoro dhizaini yekugadzira chizvarwa chitsva chemichina yemicrowave uye optoelectronic zvishandiso. Izvo zvakaipira zveMBE tekinoroji inononoka firimu kukura mwero, yakakwira vacuum zvinodiwa, uye yakakwirira michina nemidziyo yekushandisa mari.

3.11 Vapor Phase Epitaxy System

Iyo vapor phase epitaxy (VPE) system inoreva epitaxial yekukura mudziyo inotakura gasi komisheni kuenda kune substrate uye inowana imwechete crystal material layer ine imwechete lattice kurongeka se substrate kuburikidza nemakemikari maitiro. Epitaxial layer inogona kuva homoepitaxial layer (Si/Si) kana heteroepitaxial layer (SiGe/Si, SiC/Si, GaN/Al2O3, nezvimwewo). Parizvino, tekinoroji yeVPE yakashandiswa zvakanyanya muminda yekugadzirira nanomaterial, zvishandiso zvemagetsi, semiconductor optoelectronic zvishandiso, solar photovoltaics, uye maseketi akabatanidzwa.

Typical VPE inosanganisira atmospheric pressure epitaxy uye kuderedzwa pressure epitaxy, ultra-high vacuum chemical vapor deposition, metal organic chemical vapor deposition, etc. Mapoinzi akakosha muhunyanzvi hweVPE maitiro echamber dhizaini, gas flow mode uye kufanana, kufanana kwetembiricha uye kutonga chaiko, kudzora kudzvinyirira uye kugadzikana, chidimbu uye chirema chekudzora, nezvimwe.

Parizvino, iyo nzira yekuvandudza yeakajairika yekutengesa VPE masisitimu yakakura wafer kurodha, zvizere otomatiki kutonga, uye chaiyo-nguva yekutarisa tembiricha uye kukura maitiro. VPE masisitimu ane zvimiro zvitatu: vertical, horizontal uye cylindrical. Iyo nzira dzekudziya dzinosanganisira kudziyisa kupisa, yakakwirira-frequency induction heat uye infrared radiation heat.

Parizvino, VPE masisitimu anonyanya kushandisa horizontal disc zvimiro, izvo zvine hunhu hwekufanana kwakanaka kweepitaxial firimu kukura uye hombe wafer kurodha. VPE masisitimu anowanzo kuve nezvikamu zvina: reactor, inodziya system, gasi nzira system uye control system. Nekuti nguva yekukura yeGaAs neGaN epitaxial mafirimu yakati rebei, induction kudziyisa uye kudziyisa kupisa kunonyanya kushandiswa. Musilicon VPE, gobvu epitaxial firimu kukura kunonyanya kushandisa induction kudziyisa; mutete epitaxial firimu kukura kunonyanya kushandisa infrared kudziyisa kuti iwane chinangwa chekukurumidza kukwira kwekushisa / kudonha.

3.12 Liquid Phase Epitaxy System

Liquid Phase Epitaxy (LPE) system inoreva epitaxial kukura midziyo inonyungudutsa zvinhu kuti zvikure (senge Si, Ga, As, Al, nezvimwewo) uye dopants (seZn, Te, Sn, nezvimwewo) mu simbi ine yakaderera nzvimbo yekunyungudika (yakadai seGa, In, nezvimwewo), kuitira kuti solute izere kana kuti supersaturated musolvent, uyezve iyo imwe kristaro substrate. yakasangana nemhinduro, uye solute inonatswa kubva kune yakanyungudika zvishoma nezvishoma ichitonhora pasi, uye chidimbu chekristaro zvinhu zvine chimiro chekristaro uye lattice inogara yakafanana neyeiyo substrate inokura pamusoro peiyo substrate.

Iyo LPE nzira yakatsanangurwa naNelson et al. muna 1963. Inoshandiswa kukura Si mafirimu akaonda uye single crystal zvinhu, pamwe chete semiconductor zvinhu zvakadai semapoka eIII-IV uye mercury cadmium telluride, uye inogona kushandiswa kugadzira zvigadzirwa zvakasiyana-siyana zve optoelectronic, microwave zvishandiso, semiconductor zvishandiso uye masero ezuva. .

—————————————————————————————————————————————————— ————————————-

Semicera inogona kupagraphite zvikamu, kupfava/kuomarara kunzwa, silicon carbide zvikamu, CVD silicon carbide zvikamu,uyeSiC/TaC yakavharwa zvikamunemazuva makumi matatu.

Kana iwe uchifarira zviri pamusoro semiconductor zvigadzirwa,ndapota usazeza kutibata nesu panguva yekutanga.

Tel: +86-13373889683

WhatsAPP: +86-15957878134

Email: sales01@semi-cera.com

Nguva yekutumira: Aug-31-2024