Wafers ndiwo makuru ezvigadzirwa zvekugadzirwa kwemasekete akabatanidzwa, discrete semiconductor zvishandiso uye magetsi emagetsi. Zvinopfuura 90% zvemaseketi akabatanidzwa anogadzirwa pamhando yepamusoro-kuchena, emhando yepamusoro wafers.

Wafer gadziriro yemidziyo inoreva maitiro ekugadzira yakachena polycrystalline silicon zvinhu musilicon imwe yekristaro tsvimbo yeimwe dhayamita uye kureba, uyezve kuisa iyo silicon imwe chete yekristaro rod zvinhu kune akatevedzana mechanical processing, makemikari kurapwa uye mamwe maitiro.

Zvishandiso zvinogadzira silicon wafers kana epitaxial silicon wafers zvinosangana nekurongeka kwejometri uye pamusoro pemhando yezvinodiwa uye inopa inodiwa silicon substrate yekugadzira chip.

Iyo yakajairika nzira yekuyerera yekugadzirira silicon wafers ine dhayamita isingasviki 200 mm ndeiyi:

Kukura kwekristaro imwe chete → kuchekeresa → dhayamita rekunze kukunguruka → kuchekerera → kupenya → kugaya → kugaya → kupinza → kukwenenzvera → kuchenesa → epitaxy → kurongedza, nezvimwe.

Iyo huru nzira inoyerera yekugadzirira silicon wafers ine dhayamita ye300 mm ndeiyi inotevera:

Kukura kwekristaro imwe chete → kuchekeresa → dhayamita rekunze → kuchekerera → kupenya → kukuya pamusoro → kukwenya → kupenya kwepamucheto → kupenya kwemativi maviri → kukwenenzvera kwemativi maviri → kuchenesa kwekupedzisira → epitaxy/annealing → kurongedza, nezvimwe.

1.Silicon zvinhu

Silicon isemiconductor material nekuti ine 4 valence electrons uye iri mugroup IVA yeperiodic table pamwe chete nezvimwe zvinhu.

Huwandu hwemaerekitironi evalence musilicon hunoisa pakati peakanaka conductor (1 valence electron) uye insulator (8 valence electrons).

Yakachena silicon haiwanikwe mumasikirwo uye inofanirwa kubviswa uye kucheneswa kuti ive yakachena zvakakwana pakugadzira. Inowanzo kuwanikwa mu silica (silicon oxide kana SiO2) uye mamwe silicates.

Mamwe mafomu eSiO2 anosanganisira girazi, kristaro isina ruvara, quartz, agate uye ziso rekatsi.

Chinhu chekutanga chakashandiswa semiconductor yaive germanium muma1940 uye kutanga kwema1950, asi yakakurumidza kutsiviwa nesilicon.

Silicon yakasarudzwa seyo huru semiconductor zvinhu nekuda kwezvikonzero zvina zvikuru:

Kuwanda kweSilicon Materials: Silicon ndiyo yechipiri yakanyanya kuwanda paPasi, inoverengera 25% yePasi.

Iyo yepamusoro yekunyungudika yesilicon zvinhu inobvumira yakafara process kushivirira: nzvimbo yakanyunguduka yesilicon pa 1412 ° C yakakwirira zvikuru kupfuura nzvimbo yekunyunguduka kwegermanium pa 937 ° C. Iyo yakakwirira yekunyungudika inobvumira silicon kuti imirire maitiro ekupisa kwepamusoro.

Silicon zvinhu zvine yakakura yekushanda tembiricha renji;

Kukura kwechisikigo kwesilicon oxide (SiO2): SiO2 ndeyepamusoro-mhando, yakagadzikana yemagetsi insulating zvinhu uye inoshanda seyakanakisa kemikari chipingamupinyi chekudzivirira silicon kubva kune kunze kusvibiswa. Kugadzikana kwemagetsi kwakakosha kudzivirira kuvuza pakati pemakondakita ari padyo mumaseketi akabatanidzwa. Iko kugona kukura yakagadzikana matete akaturikidzana eSiO2 zvinhu kwakakosha pakugadzirwa kwepamusoro-inoshanda simbi-oxide semiconductor (MOS-FET) zvishandiso. SiO2 ine yakafanana mechanicha zvimiro kune silicon, ichibvumira yakakwirira-tembiricha kugadzirisa pasina yakawandisa silicon wafer warping.

2.Wafer kugadzirira

Semiconductor wafers anochekwa kubva kune yakawanda semiconductor zvinhu. Iyi semiconductor zvinhu inonzi crystal rod, inokura kubva pahombe yepolycrystalline uye isina kuvharwa mukati memukati.

Kushandura chivharo chepolycrystalline kuita kristaro hombe uye kuchipa kwakaringana kutaridzika kwekristaro uye huwandu hwakakodzera hweN-mhando kana P-mhando doping inonzi kukura kwekristaro.

Matekinoroji akajairika ekugadzira imwechete crystal silicon ingots yesilicon wafer kugadzirira ndiyo nzira yeCzochralski uye nzira yekunyungudutsa nzvimbo.

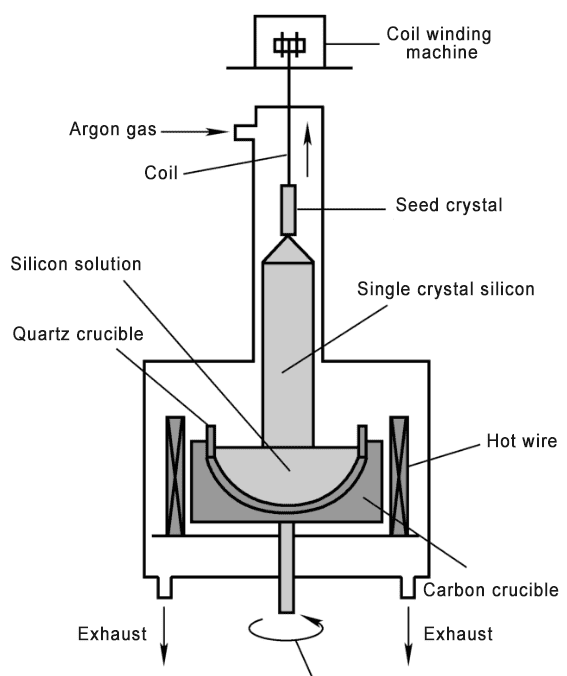

2.1 Czochralski nzira uye Czochralski single crystal furnace

Iyo Czochralski (CZ) nzira, inozivikanwawo seCzochralski (CZ) nzira, inoreva maitiro ekushandura yakanyungudutswa semiconductor-giredhi silicon fluid kuita yakasimba single-crystal silicon ingots ine chaiyo kristaro kutarisisa uye kudonhedzwa muN-mhando kana P- type.

Parizvino, inopfuura 85% yeimwe crystal silicon inokura uchishandisa nzira yeCzochralski.

A Czochralski single crystal furnace inoreva chigadziriso chinonyungudutsa yakakwira-kuchena polysilicon zvinhu mumvura nekudziya mune yakavharwa yakakwira vacuum kana isingawanzo gasi (kana inert gasi) yekudzivirira, uye yobva yazvisanganisa kuti igadzire imwe crystal silicon zvinhu nezvimwe zvekunze. dimensions.

Musimboti wekushanda weiyo imwe kristaro choto ndiyo yemuviri maitiro epolycrystalline silicon zvinhu kudzokorora mune imwechete crystal silicon zvinhu munzvimbo yemvura.

Iyo CZ single crystal furnace inogona kukamurwa kuita zvikamu zvina: choto chemuviri, mechini yekufambisa sisitimu, kudziyisa uye tembiricha yekudzora system, uye gasi kutapurirana system.

Muviri wechoto unosanganisira chivharo chevira, mbeu yekristaro axis, quartz crucible, doping spoon, chivharo chekristaro yembeu, uye hwindo rekutarisa.

Iyo mhango yevira ndeyekuona kuti tembiricha muchoto inogoverwa zvakaenzana uye inogona kubvisa kupisa zvakanaka; iyo seed crystal shaft inoshandiswa kufambisa kristaro yembeu kuti iende kumusoro uye pasi uye kutenderera; tsvina inoda kuiswa dope yakaiswa mu doping spoon;

Chivharo chekristaro chembeu ndechekudzivirira mbeu yekristaro kubva pakusvibiswa. Iyo mechanical transmission system inonyanya kushandiswa kudzora kufamba kwekristini yembeu uye crucible.

Kuti uone kuti iyo silicon mhinduro haina oxidized, iyo vacuum dhigirii muchoto inodiwa kuve yakakwira zvakanyanya, kazhinji pazasi 5 Torr, uye kuchena kweiyo yakawedzera inert gasi kunofanirwa kunge kuri pamusoro pe99.9999%.

Chidimbu chekristaro imwe chete yesilicon ine inodiwa yekristaro yekumisikidza inoshandiswa semhodzi yekristaro kukura silicon ingot, uye yakakura silicon ingot yakafanana neyakafanana yemhodzi yekristaro.

Mamiriro ezvinhu painterface pakati pesilicon yakanyungudutswa uye imwechete crystal silicon mhodzi yekristaro inoda kunyatsodzorwa. Mamiriro aya anovimbisa kuti iyo yakatetepa yesilicon inogona kunyatso dzokorora chimiro chemhodzi yekristaro uye pakupedzisira inokura kuita hombe imwe hombe yesilicon ingot.

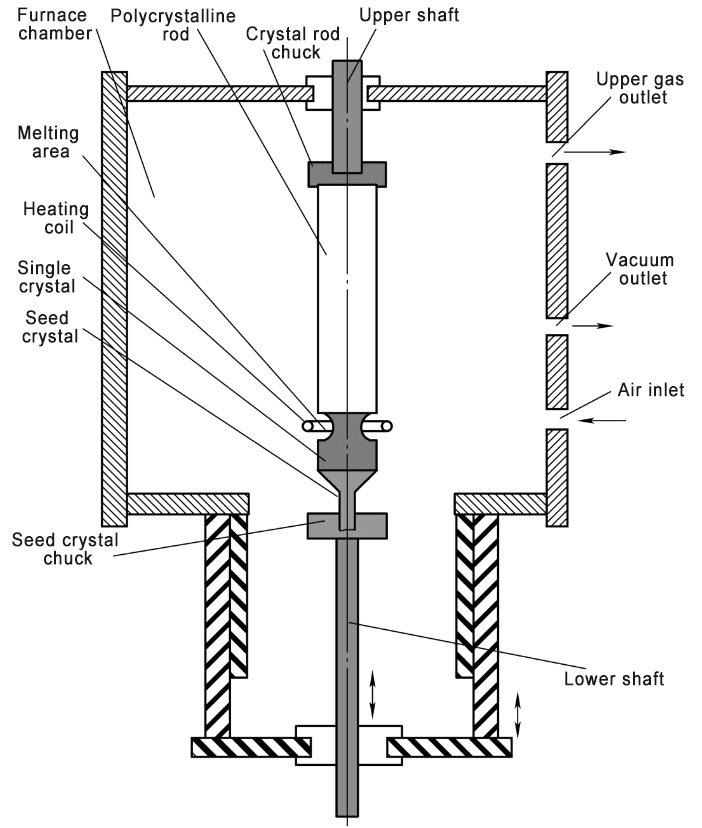

2.2 Zone Melting Method uye Zone Melting Imwe Crystal Furnace

Iyo nzira yekuyangarara (FZ) inogadzira imwechete crystal silicon ingots ine yakaderera kwazvo oksijeni yemukati. Iyo yekuyangarara zone nzira yakagadziridzwa muma1950s uye inogona kuburitsa yakachena yakasarudzika crystal silicon kusvika parizvino.

Iyo zone inonyungudutsa imwe crystal furnace inoreva choto chinoshandisa musimboti wekunyunguduka kuburitsa nzvimbo yakamanikana yekunyunguduka mutsvimbo yepolycrystalline kuburikidza nepamusoro-tembiricha yakatetepa yakavharwa nzvimbo yepolycrystalline tsvimbo yevira yemuviri mune yakakwira vacuum kana isingawanzo quartz chubhu gasi. kuchengetedza nharaunda.

Chishandiso chekugadzira chinofambisa tsvimbo yepolycrystalline kana choto chekudziya muviri kuti ifambise nzvimbo inonyungudika uye zvishoma nezvishoma inopenya kuita imwe kristaro tsvimbo.

Hunhu hwekugadzirira tsvimbo imwe chete yekristaro nenzira yekunyungudutsa nzvimbo ndeyekuti kuchena kwepolycrystalline matanda kunogona kuvandudzwa mukuita kwekristalllization mune imwechete crystal rods, uye kukura kwedoping yetsvimbo zvinhu zvakanyanya yunifomu.

Idzo mhando dzenzvimbo inonyungudutsa imwe crystal furnaces inogona kukamurwa kuita mhando mbiri: inoyangarara nzvimbo inonyungudutsa imwe crystal furnaces inovimba nekukakavadzana kwepasi uye yakatwasuka nzvimbo inonyungudutsa imwe crystal mavira. Mumashandisirwo anoshanda, nzvimbo inonyunguduka imwe kristaro mavira anowanzo tora inoyangarara nzvimbo yekunyungudika.

Iyo zone inonyungudutsa imwe kristaro choto inogona kugadzirira yakakwirira-kuchena yakaderera-okisijeni imwe kristaro silicon pasina kudiwa kwecrucible. Inonyanya kushandiswa kugadzirira yakakwirira-resistivity (> 20kΩ · cm) imwe crystal silicon uye kuchenesa nzvimbo inonyungudutsa silicon. Zvigadzirwa izvi zvinonyanya kushandiswa mukugadzira discrete magetsi emagetsi.

Iyo zone inonyungudutsa imwe kristaro choto ine kamuri yevira, shaft yepamusoro uye yakaderera shaft (mechanical transmission chikamu), crystal rod chuck, mbeu yekristaro chuck, yekudziya coil (yakakwira frequency jenareta), gasi ports (vacuum port, gasi inopinza, yekumusoro gasi kubuda), nezvimwe.

Muchigadziro chekamuri yevira, kutenderera kwemvura kunotonhora kunorongwa. Mugumo wezasi wepamusoro shaft yeimwe crystal furnace ndeye crystal rod chuck, iyo inoshandiswa kusungira tsvimbo yepolycrystalline; kumucheto kwepamusoro kwechitsiko chezasi imbeu crystal chuck, iyo inoshandiswa kusungira mbeu yekristaro.

A high-frequency power supply anopiwa kune inopisa coil, uye nzvimbo yakamanikana yakanyunguduka inoumbwa mutsvimbo ye polycrystalline kubva kumucheto wezasi. Panguva imwecheteyo, mashizha epamusoro uye ezasi anotenderera uye achidzika, kuitira kuti nzvimbo inonyunguduka ijekeswe mukristaro imwe chete.

Zvakanakira nzvimbo yekunyungudutsa imwe crystal furnace ndeyokuti haigoni kungovandudza kuchena kwekristaro imwe yakagadzirirwa, asiwo kuita kuti tsvimbo doping iwedzere yunifomu, uye tsvimbo imwe chete yekristaro inogona kucheneswa kuburikidza nemaitiro akawanda.

Izvo zvakashata zveiyo zone kunyunguduka imwe crystal furnace yakakwira maitiro emitengo uye diki dhayamita yekiristaro imwe yakagadzirwa. Parizvino, iyo yakakura dhayamita yekristaro imwechete inogona kugadzirirwa ndeye 200mm.

Kureba kwese kwenzvimbo inonyunguduka imwe kristaro yevira yemidziyo yakakwira, uye kurohwa kwemasanhu ekumusoro neakadzika kwakarebesa, saka matanda ekristaro akareba anogona kukura.

3. Wafer processing uye midziyo

Iyo kristaro tsvimbo inoda kuenda kuburikidza neakatevedzana maitiro ekugadzira silicon substrate inosangana nezvinodiwa zvekugadzira semiconductor, kureva wafer. The basic process of processing is:

Kudonha, kucheka, kucheka, mucheka wafer annealing, chamfering, kugaya, kupukuta, kuchenesa uye kurongedza, nezvimwe.

3.1 Wafer Annealing

Mukugadzira polycrystalline silicon uye Czochralski silicon, single crystal silicon ine oxygen. Pane imwe tembiricha, iyo okisijeni iri mucrystal silicon imwe chete ichapa maerekitironi, uye okisijeni yacho inoshandurwa kuita vanopa oxygen. Aya maerekitironi achasangana nekusachena musilicon wafer uye anokanganisa resistivity yesilicon wafer.

Annealing furnace: inoreva choto chinosimudza tembiricha muchoto kusvika 1000-1200°C munzvimbo yehydrogen kana argon. Nekuchengetedza kudziya uye kutonhora, iyo okisijeni iri pedyo nechepamusoro pesimbi yakakwenenzverwa silicon wafer inonyungudutswa uye inobviswa kubva pamusoro payo, zvichiita kuti okisijeni iwedzere nekudzika.

Midziyo yekugadzira inonyungudutsa diki diki pamusoro peiyo silicon wafers, inoderedza huwandu hwetsvina padyo nepamusoro peiyo silicon wafers, inoderedza kuremara, uye inoumba nzvimbo yakachena pamusoro pesilicon wafers.

The annealing vira inodaidzwa zvakare kuti moto wepamusoro-soro nekuda kwekupisa kwayo. Iyo indasitiri zvakare inodana iyo silicon wafer annealing process getttering.

Silicon wafer annealing vira rakakamurwa kuita:

-Horizontal annealing choto;

-Vertical annealing choto;

-Rapid annealing choto.

Musiyano mukuru uripo pakati pechoto chekumisikidza chakachinjika nechoto chekumisikidza chakatwasuka ndiyo nzira yekumisikidza yekamuri yekupindura.

Kamuri yekuita yevira yakachinjika yevira yakachinjika yakarongedzwa, uye batch yesilicon wafers inogona kurongedzerwa mukamuri yekupindura yevira rekuvharisa kuti rivhare panguva imwe chete. Nguva yekuvharisa inowanzoita maminetsi makumi maviri kusvika makumi matatu, asi chamber yekudziya inoda nguva yakareba yekudziisa kuti isvike tembiricha inodiwa nemaitiro ekuvharisa.

Maitirwo echoto chekumisikidza anealing zvakare anotora nzira yekuisa panguva imwe chete batch yesilicon wafers mukamuri yekupindura yeannealing vira yekurapa annealing. Iyo reaction chamber ine vertical chimiro dhizaini, iyo inobvumira iyo silicon wafers kuti iiswe muchikepe chequartz munzvimbo yakachinjika.

Panguva imwecheteyo, sezvo chikepe chequartz chichigona kutenderera sese mukamuri yekupindura, tembiricha yekudziya yekamuri yekupindura yakafanana, kugovera tembiricha pasilicon wafer yunifomu, uye ine yakanakisa annealing yunifomu hunhu. Zvisineyi, mutengo wechoto chemoto wakakwira kupfuura wechoto chehorizontal annealing.

Kurumidza kuvharisa mwenje unoshandisa halogen tungsten rambi kupisa zvakananga silicon wafer, iyo inokwanisa kuwana nekukurumidza kupisa kana kutonhora mukati mehupamhi hwe1 kusvika 250 ° C/s. Mwero wekudziya kana kutonhora unokurumidza kupfuura wevira rechinyakare. Zvinongotora masekonzi mashoma kupisa tembiricha yekamuri yekupindura kusvika pamusoro pe1100 ° C.

—————————————————————————————————————————————————— ——

Semicera inogona kupagraphite zvikamu,kupfava/kuomarara kunzwa,silicon carbide zvikamu, CVD silicon carbide zvikamu,uyeSiC/TaC yakavharwa zvikamuine yakazara semiconductor process mumazuva makumi matatu.

Kana iwe uchifarira zviri pamusoro semiconductor zvigadzirwa, ndapota usazeza kutibata nesu panguva yekutanga.

Tel: +86-13373889683

WhatsAPP: +86-15957878134

Email: sales01@semi-cera.com

Nguva yekutumira: Aug-26-2024