Epitaxial layer ndeye chaiyo imwe crystal film inokura pawafer ne ep · itaxial process, uye substrate wafer uye epitaxial firimu inonzi epitaxial wafer. Nekukura iyo silicon carbide epitaxial layer pane conductive silicon carbide substrate, iyo silicon carbide homogeneous epitaxial wafer inogona kugadziridzwa zvakare muSchottky diodes, MOSFETs, IGBTs uye mamwe magetsi emagetsi, pakati peiyo 4H-SiC substrate ndiyo inonyanya kushandiswa.

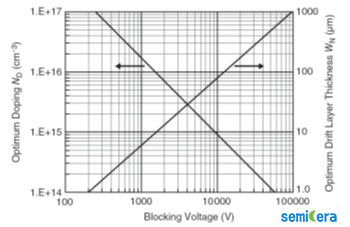

Nekuda kweakasiyana ekugadzira maitiro esilicon carbide simba mudziyo uye yechinyakare silicon simba mudziyo, haigone kugadzirwa zvakananga pasilicon carbide single crystal material. Zvimwe zvemhando yepamusoro epitaxial zvinhu zvinofanirwa kukura pane conductive single crystal substrate, uye zvishandiso zvakasiyana zvinofanirwa kugadzirwa pane epitaxial layer. Nokudaro, kunaka kwe epitaxial layer kune simba guru pakushanda kwechigadzirwa. Iko kunatsiridzwa kwekuita kweakasiyana magetsi maturusi zvakare kunoisa kumberi kwepamusoro zvinodiwa kune ukobvu hweepitaxial layer, doping concentration uye hurema.

FIG. 1. Hukama pakati pekuisa doping uye ukobvu hwe epitaxial layer ye unipolar mudziyo uye inovharira voltage.

Nzira dzekugadzirira dzeSIC epitaxial layer dzinonyanya kusanganisira evaporation kukura nzira, liquid phase epitaxial growth (LPE), molecular beam epitaxial growth (MBE) uye chemical vapor deposition (CVD). Parizvino, kemikari vapor deposition (CVD) ndiyo nzira huru inoshandiswa kugadzirwa kwakakura mumafekitori.

| Kugadzirira nzira | Zvakanakira nzira | Kuipa kwemaitiro |

|

Liquid Phase Epitaxial Kukura

(LPE)

|

Simple midziyo zvinodiwa uye yakaderera-mutengo kukura nzira. |

Zvakaoma kudzora morphology yepamusoro ye epitaxial layer. Iyo midziyo haigone epitaxialize akawanda mawafer panguva imwe chete, ichidzikamisa kugadzirwa kwehuwandu. |

|

Molecular Beam Epitaxial Growth (MBE)

|

Yakasiyana SiC crystal epitaxial layers inogona kukura pakadzika tembiricha yekukura |

Equipment vacuum zvinodiwa zvakakwirira uye zvinodhura. Slow kukura mwero we epitaxial layer |

|

Chemical Vapor Deposition (CVD) |

Nzira inonyanya kukosha yekugadzirwa kwehuwandu mumafekitari. Chiyero chekukura chinogona kunyatsodzorwa kana uchikura gobvu epitaxial layers. |

SiC epitaxial layers ichine hurema hwakasiyana hunokanganisa hunhu hwechishandiso, saka epitaxial yekukura maitiro eSiC inoda kuramba ichigadziriswa.TaCzvinodiwa, ona SemiceraTaC chigadzirwa) |

|

Evaporation kukura nzira

|

Uchishandisa midziyo yakafanana seSiC crystal kudhonza, maitiro acho akasiyana zvishoma nekudhonza kwekristaro. Midziyo yakakura, mutengo wakaderera |

Kusaenzana evaporation yeSiC inoita kuti zviome kushandisa kubuda kwayo kuti ikure epitaxial layers yemhando yepamusoro. |

FIG. 2. Kufananidza nzira huru dzekugadzirira epitaxial layer

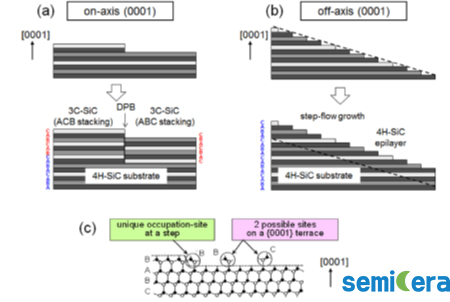

Pa-off-axis {0001} substrate ine imwe inorereka Engle, sezvinoratidzwa mumufananidzo 2(b), density yedanho repamusoro rakakura, uye saizi yenhanho yepasi idiki, uye crystal nucleation haisi nyore kuita. zvinoitika pachinhanho chepamusoro, asi zvinowanzoitika pakubatanidza danho. Muchiitiko ichi, pane imwe chete nucleating kiyi. Naizvozvo, iyo epitaxial layer inogona kunyatso dzokorora kurongeka kweiyo substrate, nekudaro kubvisa dambudziko rekugarisana kwemhando dzakawanda.

FIG. 3. Physical process diagram ye4H-SiC danho rekudzora epitaxy nzira

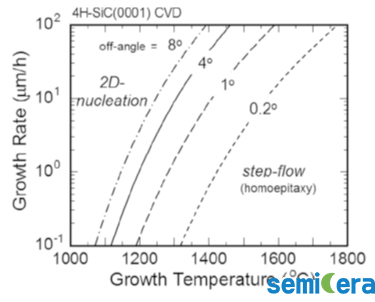

FIG. 4. Mamiriro akakosha ekukura kweCVD ne4H-SiC nhanho-inodzorwa epitaxy nzira

FIG. 5. Kuenzanisa kwekukura kwemazinga pasi pezvinyorwa zvakasiyana-siyana zvesilicon mu 4H-SiC epitaxy

Parizvino, silicon carbide epitaxy tekinoroji yakakura mune yakaderera uye yepakati voltage application (senge 1200 volt zvishandiso). Ukobvu hwakafanana, doping concentration yakaenzana uye kuremara kugoverwa kweiyo epitaxial layer inogona kusvika padanho rakanaka, iro rinogona kuzadzisa zvinodiwa zvepakati nepasi voltage SBD (Schottky diode), MOS (metal oxide semiconductor field effect transistor), JBS ( junction diode) nemimwe michina.

Nekudaro, mumunda wekumanikidza kwakanyanya, epitaxial wafers achiri kuda kukunda matambudziko mazhinji. Semuenzaniso, kune zvishandiso zvinoda kumira 10,000 volts, ukobvu hweiyo epitaxial layer inoda kuita 100μm. Kuenzaniswa nemidziyo yakaderera-voltage, ukobvu hweepitaxial layer uye kufanana kweiyo doping concentration kwakasiyana zvakanyanya, kunyanya kufanana kweiyo doping concentration. Panguva imwecheteyo, iyo katatu kukanganisa mu epitaxial layer ichaparadzawo kushanda kwese kwechigadzirwa. Mumashandisirwo epamusoro-voltage, mhando dzemidziyo dzinowanzoshandisa zvigadziriso zvebipolar, izvo zvinoda hupenyu hwepamusoro vashoma mu epitaxial layer, saka maitiro anoda kuvandudzwa kuti avandudze hupenyu hwevashoma.

Parizvino, epitaxy yemumba inonyanya kuita 4 inches uye 6 inches, uye chikamu chehukuru hwesilicon carbide epitaxy chiri kuwedzera gore negore. Saizi yesilicon carbide epitaxial sheet inonyanya kudzikiswa nehukuru hwesilicon carbide substrate. Parizvino, iyo 6-inch silicon carbide substrate yakatengeswa, saka iyo silicon carbide epitaxial iri kufamba zvishoma nezvishoma kubva pa4 inches kuenda pa6 inches. Nekuenderera mberi kwekuvandudzwa kwesilicon carbide substrate kugadzirira tekinoroji uye kuwedzera huwandu, mutengo wesilicon carbide substrate uri kuderera zvishoma nezvishoma. Mukuumbwa kweiyo epitaxial sheet mutengo, iyo substrate inotora inopfuura 50% yemutengo, saka nekuderera kweiyo substrate mutengo, mutengo wesilicon carbide epitaxial sheet unotarisirwawo kudzikira.

Nguva yekutumira: Jun-03-2024