Pamatanho ese anobatanidzwa mukugadzira chip, iyo yekupedzisira kuguma kwewaferinofanira kuchekwa kuita madhiri ega oiswa mumabhokisi madiki, akavharirwa ane mapini mashoma ari pachena. Iyo chip ichaongororwa zvichienderana nechikumbaridzo chayo, kuramba, ikozvino, uye voltage kukosha, asi hapana anozofunga nezve kutaridzika kwayo. Munguva yekugadzira, isu tinodzokorora kupuruzira wafer kuti tiwane inodiwa planarization, kunyanya kune yega yega photolithography nhanho. Thewaferkumusoro kunofanirwa kunge kwakati sandarara nekuti, sezvo chip yekugadzira nzira inodzikira, lenzi yemuchina wephotolithography inoda kuwana nanometer-scale resolution nekuwedzera manhamba aperture (NA) yelens. Nekudaro, izvi panguva imwe chete zvinoderedza kudzika kwekutarisa (DoF). Kudzika kwekutarisa kunoreva kudzika mukati umo iyo optical system inogona kuchengetedza kutarisa. Kuve nechokwadi chekuti mufananidzo wefotolithography unoramba wakajeka uye wakatarisana, iwo epamusoro akasiyana ewaferinofanira kuwira mukati mekudzika kwekutarisa.

Mumashoko akapfava, muchina wephotolithography unopira kutarisisa kugona kuvandudza imaging chaiyo. Semuyenzaniso, chizvarwa chitsva cheEUV photolithography michina ine nhamba yekuvhura ye0.55, asi kudzika kwekutarisa kunongori 45 nanometers, iine kunyange diki diki yekufungidzira renji panguva yephotolithography. Kana iyowaferhaina kupfava, ine ukobvu husina kuenzana, kana kubvongodzwa kwepamusoro, zvinokonzeresa nyaya panguva yephotolithography panzvimbo dzepamusoro uye dzakaderera.

Photolithography haisi iyo yega nzira inoda yakatsetsekawaferpamusoro. Mamwe akawanda mamwe maitiro ekugadzira chip anodawo wafer polishing. Semuyenzaniso, mushure mekunyorova etching, kukwenenzverwa kunodiwa kutsvedzerera nzvimbo yakakasharara kuitira kunotevera kukoira uye kuisa. Mushure mekusadzika kwegoronga (STI), kupukuta kunodiwa kutsvedzerera yakawandisa silicon dioxide uye kupedzisa mugero kuzadza. Mushure mekuisa simbi, kukwenenzverwa kunodiwa kuti ubvise simbi yakawandisa uye kudzivirira mudziyo mapfupi maseketi.

Naizvozvo, kuberekwa kwechipisi kunosanganisira matanho akawanda ekukwenenzvesa kudzikisa kushata kwewafer uye kusiyana kwepamusoro uye kubvisa zvinhu zvakawandisa kubva pamusoro. Pamusoro pezvo, kuremara kwepamusoro kunokonzerwa neakasiyana maitiro nyaya pawafer kazhinji inongoonekwa mushure mega ega nhanho yekupukuta. Saka, mainjiniya ane basa rekupolisha ane basa rakakura. Ndivo nhamba dzepakati mukugadzira chip uye vanowanzo takura mhosva mumisangano yekugadzira. Ivo vanofanirwa kuve nehunyanzvi mune zvese zvakanyorova etching uye kuburitsa kwemuviri, senzira huru dzekupukuta mukugadzira chip.

Ndedzipi nzira dzewafer polishing?

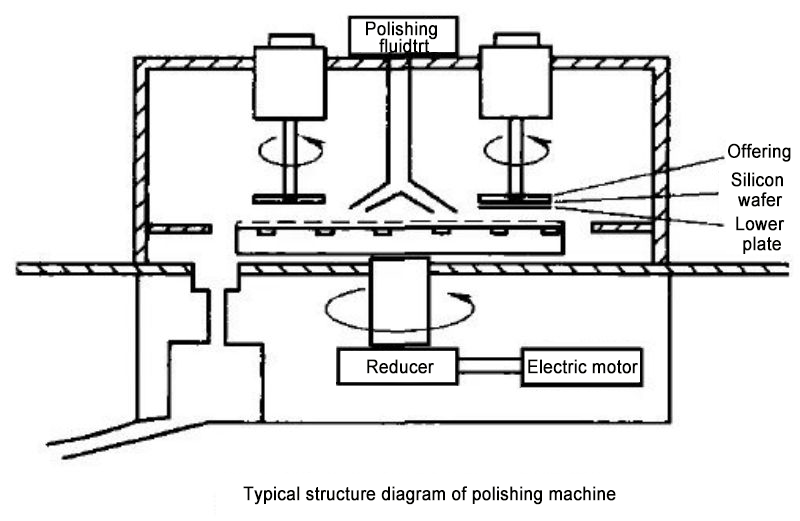

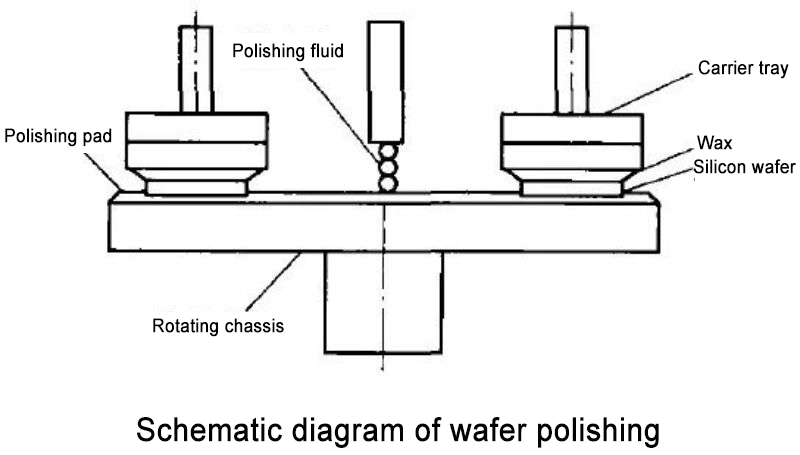

Maitiro ekupukuta anogona kuiswa muzvikamu zvitatu zvakakura zvichienderana nemisimboti yekudyidzana pakati pemvura yekupukuta uye iyo silicon wafer pamusoro:

1. Mechanical Polishing Method:

Mechanical polishing inobvisa iyo yakakwenenzverwa maburi epasi kuburikidza nekucheka uye deformation yepurasitiki kuti iwane nzvimbo yakatsetseka. Zvishandiso zvakajairika zvinosanganisira matombo emafuta, mavhiri emvere dzemakwai, uye sandpaper, inonyanya kushandiswa nemaoko. Zvikamu zvakakosha, senge nzvimbo dzemiviri inotenderera, zvinogona kushandisa maturntable uye mamwe maturusi ekubatsira. Kune nzvimbo dzine zvemhando yepamusoro zvinodiwa, super-yakanyanya kukwenenzverwa nzira dzinogona kushandiswa. Super-fine polishing inoshandisa abrasive maturusi akanyatsogadzirwa, ayo, mune abrasive-ine-ine polishing fluid, inotsikirirwa zvine simba pamusoro peiyo workpiece uye inotenderedzwa nekumhanya kwakanyanya. Iyi tekinoroji inogona kuwana hutsinye hwepamusoro hweRa0.008μm, iyo yepamusoro-soro pakati penzira dzese dzekupolisha. Iyi nzira inowanzoshandiswa kune optical lens molds.

2. Kemikari Kupenya Nzira:

Kemikari polishing inosanganisira kunyungudika kwakasarudzika kweiyo micro-protrusions pane yepasi pechinhu muchemikari yepakati, zvichikonzera nzvimbo yakatsetseka. Mabhenefiti makuru eiyi nzira kushaikwa kwekudiwa kwemidziyo yakaoma, kugona kupururudza yakaoma-yakaumbwa maworkpieces, uye kugona kupururudza akawanda maworkpiece panguva imwe chete nehunyanzvi hwepamusoro. Iyo yakakosha nyaya yekupenya kwemakemikari ndiko kuumbwa kwemvura inopenya. Iko kushata kwepamusoro kunowanikwa nekemikari polishing kazhinji makumi akati wandei emamicrometer.

3. Chemical Mechanical Polishing (CMP) Nzira:

Imwe neimwe yenzira mbiri dzekutanga dzekupukuta ine zvayakasiyana zvakanakira. Kubatanidza nzira mbiri idzi kunogona kuzadzisa mhedzisiro mukuita. Kemikari mechanical polishing inosanganisa mechanical friction uye makemikari ekuora maitiro. Munguva yeCMP, makemikari reagents ari mumvura yekupolisha oxidize iyo yakakwenenzverwa substrate zvinhu, ichigadzira yakapfava oxide layer. Iyi oxide layer inozobviswa kuburikidza ne mechanical friction. Kudzokorora iyi oxidation uye mechanical kubvisa maitiro anobudirira kupukuta.

Matambudziko Azvino uye Matambudziko muChemical Mechanical Polishing (CMP):

CMP inotarisana nematambudziko akati wandei uye nyaya munzvimbo dzetekinoroji, hupfumi, uye kuchengetedzwa kwezvakatipoteredza:

1) Maitiro Kuenderana: Kuwana kuenderana kwakanyanya muCMP maitiro kunoramba kwakaoma. Kunyangwe mukati memutsetse mumwechete wekugadzira, misiyano midiki mumatanho ekuita pakati pemabhechi akasiyana kana michina inogona kukanganisa kuenderana kwechigadzirwa chekupedzisira.

2) Kuchinjika kune Zvishandiso Zvitsva: Sezvo zvinhu zvitsva zvichiramba zvichibuda, tekinoroji yeCMP inofanirwa kuenderana nehunhu hwayo. Zvimwe zvemhando yepamusoro zvinogona kunge zvisingaenderane nemaitiro echinyakare eCMP, zvinoda kuvandudzwa kwezvinwiwa zvinokwenenzverwa zvekupelisha uye mabrasives.

3) Saizi Mhedzisiro: Sezvo semiconductor mudziyo zviyero zvichiramba zvichidzikira, nyaya dzinokonzerwa nehukuru mhedzisiro dzinowedzera kukosha. Zviyero zvidiki zvinoda kureba kwepamusoro, izvo zvinoda kunyatsoita CMP maitiro.

4) Material Removal Rate Control: Mune mamwe maapplication, kunyatso kudzora kweyero yekubvisa zvinhu zvezvinhu zvakasiyana kwakakosha. Kuve nechokwadi chekubvisa mareti akachinjika pamatanho akasiyana panguva yeCMP kwakakosha pakugadzira michina inoshanda zvakanyanya.

5) Hushamwari Hwezvakatipoteredza: Zvinwiwa zvekupukuta uye mabrasives anoshandiswa muCMP anogona kunge aine zvinokuvadza zvakatipoteredza. Tsvagiridzo uye kusimudzira kwezvakatipoteredza zvine hushamwari uye zvakagadzikana CMP maitiro uye zvinhu zvakakosha matambudziko.

6) Hungwaru uye otomatiki: Nepo hungwaru uye otomatiki mwero weCMP masisitimu ari kuvandudza zvishoma nezvishoma, anofanirwa kuramba achitarisana nenzvimbo dzakaoma uye dzakasiyana dzekugadzira. Kuwana mazinga epamusoro e otomatiki uye nehungwaru yekutarisa kuti uvandudze kugadzirwa kwakanaka idambudziko rinoda kugadziriswa.

7) Kudzora Mutengo: CMP inosanganisira yakakwirira midziyo uye mari yezvinhu. Vagadziri vanofanirwa kuvandudza maitiro ekuita uku vachiyedza kudzikisa mitengo yekugadzira kuchengetedza kukwikwidza kwemusika.

Nguva yekutumira: Jun-05-2024