Silicon nitride (Si₃N₄) ceramics, seyakagadziridzwa zviumbwa zveceramics, ine zvivakwa zvakanakisa senge tembiricha yakakwira, kusimba kwepamusoro, kuomarara kwepamusoro, kuomarara kwepamusoro, kuramba kukwira, oxidation kuramba, uye kupfeka kuramba. Pamusoro pezvo, ivo vanopa yakanaka yekupisa kuvhundutsa kuramba, dielectric zvivakwa, yakakwirira yekupisa conductivity, uye yakanakisa yepamusoro-frequency electromagnetic wave transmission performance. Aya akatanhamara akazara zvivakwa anoita kuti ashandiswe zvakanyanya muzvakaoma zvimiro zvikamu, kunyanya mune aerospace uye mamwe epamusoro-tech minda.

Nekudaro, Si₃N₄, iri komboni ine yakasimba covalent zvisungo, ine yakagadzika dhizaini inoita kuti sintering kune yakakwira density iome kuburikidza neiyo solid-state diffusion chete. Kukurudzira sintering, sintering aids, senge simbi oxides (MgO, CaO, Al₂O₃) uye isingawanzo pasi oxides (Yb₂O₃, Y₂O₃, Lu₂O₃, CeO₂), inowedzerwa kufambisa densification kuburikidza nemvura-chikamu sintering mechanism.

Parizvino, tekinoroji yepasi rose semiconductor mudziyo iri kufambira mberi ichienda kumagetsi akakwira, mafungu mahombe, uye kuwanda kwemagetsi. Tsvagiridzo munzira dzekugadzira Si₃N₄ ceramics yakakura. Ichi chinyorwa chinozivisa sintering maitiro anonyatso kuvandudza density uye yakazara ma mechanical zvivakwa zvesilicon nitride ceramics.

Yakajairwa Sintering Nzira dzeSi₃N₄ Ceramics

Kuenzanisa Kwekuita kweSi₃N₄ Ceramics Yakagadzirirwa Neakasiyana Sintering Nzira.

1. Reactive Sintering (RS):Reactive sintering yaive nzira yekutanga yakashandiswa kugadzira maindasitiri kugadzirira Si₃N₄ ceramics. Zviri nyore, zvinodhura, uye zvinokwanisa kugadzira zvimiro zvakaoma. Nekudaro, ine nguva yakareba yekugadzira kutenderera, iyo isingakodzeri kugadzirwa kwemaindasitiri-chiyero.

2. Pressureless Sintering (PLS):Iyi ndiyo inonyanya kukosha uye yakapusa sintering maitiro. Nekudaro, zvinoda zvemhando yepamusoro Si₃N₄ zvigadziriso uye zvinowanzokonzera maceramics ane density yakaderera, shrinkage yakakosha, uye tsika yekutsemuka kana kukanganisa.

3. Hot-Press Sintering (HP):Iko kushandiswa kwe uniaxial mechanical pressure kunowedzera simba rekufambisa rekunyungura, zvichiita kuti zvidhinha zvakasvibirira zvigadzirwe patembiricha 100-200 ° C yakaderera pane iyo inoshandiswa mukupisa kusina kumanikidzika. Iyi nzira inowanzo shandiswa kugadzira akareruka-akaumbwa-akaumbwa maceramics asi yakaoma kuzadzisa ukobvu uye maumbirwo anodiwa zve substrate zvinhu.

4. Spark Plasma Sintering (SPS):SPS inoratidzirwa nekukurumidza sintering, kunatswa zviyo, uye kuderedzwa tembiricha yekupisa. Nekudaro, SPS inoda kudyara kwakakosha mumidziyo, uye kugadzirira kwekupisa kwekupisa Si₃N₄ ceramics kuburikidza neSPS ichiri mudanho rekuyedza uye haisati yave maindasitiri.

5. Gasi-Pressure Sintering (GPS):Nekushandisa gasi kudzvanywa, nzira iyi inodzivirira kuparara kweceramic uye kurasikirwa nehuremu pakupisa kwakanyanya. Zviri nyore kugadzira yakakwirira-density ceramics uye inogonesa kugadzirwa kwebatch. Nekudaro, imwe-nhanho gasi-kumanikidza sintering process inotamburira kuburitsa zvimiro zvemukati zvine yunifomu yemukati nekunze ruvara uye chimiro. Kushandisa maviri-nhanho kana akawanda-nhanho sintering maitiro anogona zvakanyanya kuderedza intergranular okisijeni yemukati, kunatsiridza kupisa conductivity, uye kuwedzera huwandu hwese.

Nekudaro, iyo yakanyanya sintering tembiricha yematanho maviri gasi-kudzvanywa sintering yakatungamira tsvakiridzo yapfuura kuti itarise zvakanyanya pakugadzirira Si₃N₄ ceramic substrates ine yakakwira yekupisa conductivity uye kamuri-tembiricha yekukotama simba. Tsvagiridzo paSi₃N₄ ceramics ine yakazara mamechani zvivakwa uye yakakwirira-tembiricha michina zvimiro zvine mashoma.

Gasi-Pressure Two-Step Sintering Method yeSi₃N₄

Yang Zhou nevamwe vaaishanda navo vekuChongqing University of Technology vakashandisa sintering aid system ye5 wt.% Yb₂O₃ + 5 wt.% Al₂O₃ kugadzirira Si₃N₄ ceramics vachishandisa nhanho imwe uye nhanho mbiri gasi-kumanikidza sintering maitiro pa1800 ° C. Iyo Si₃N₄ ceramics inogadzirwa neaviri-nhanho sintering maitiro aive nepamusoro density uye zvirinani akazara mekinika zvivakwa. Izvi zvinotevera muchidimbu mhedzisiro yeimwe-nhanho uye maviri-nhanho gasi-kumanikidza sintering maitiro pane iyo microstructure uye mechanical zvimiro zveSi₃N₄ ceramic components.

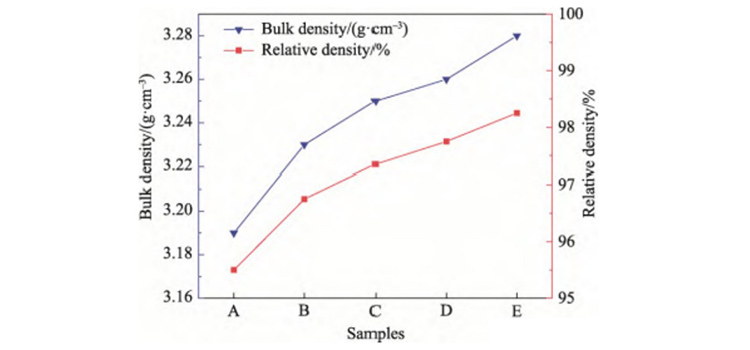

Density Iyo densification process yeSi₃N₄ inowanzo sanganisira matanho matatu, nekupindirana pakati pematanho. Danho rekutanga, kupatsanurwa patsva, uye nhanho yechipiri, kunyura-kunaya, ndiwo matanho akanyanya kuomesesa e densification. Yakakwana yekuita nguva mumatanho aya inovandudza zvakanyanya sampuli density. Kana iyo pre-sintering tembiricha ye-matanho maviri sintering process yakaiswa ku 1600 ° C, β-Si₃N₄ tsanga dzinogadzira chimiro uye kugadzira yakavharwa pores. Mushure mekutanga-kupisa, kuwedzera kupisa pasi pekushisa kwakanyanya uye nitrogen pressure inosimudzira mvura-chikamu kuyerera uye kuzadza, iyo inobatsira kubvisa yakavharwa pores, ichiwedzera kuvandudza density yeSi₃N₄ ceramics. Naizvozvo, iwo masampula anogadzirwa neaviri-nhanho sintering maitiro anoratidza yakakwirira density uye hukama density pane iyo inogadzirwa ne-imwe-nhanho sintering.

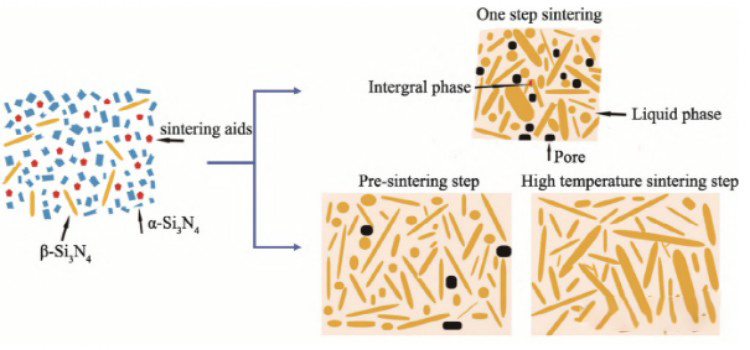

Phase uye Microstructure Panguva imwe-nhanho sintering, nguva iripo kuti particle rearrangement uye zviyo muganhu diffusion ishoma. Mune nhanho mbiri-sintering process, danho rekutanga rinoitwa pakadzika tembiricha uye yakaderera gasi kudzvanywa, iyo inowedzera iyo particle rearrangement nguva uye inoguma mune yakakura zviyo. Tembiricha inobva yawedzerwa kusvika padanho repamusoro-soro, apo zviyo zvinoramba zvichikura kuburikidza neOstwald kuibva, zvichibereka high-density Si₃N₄ ceramics.

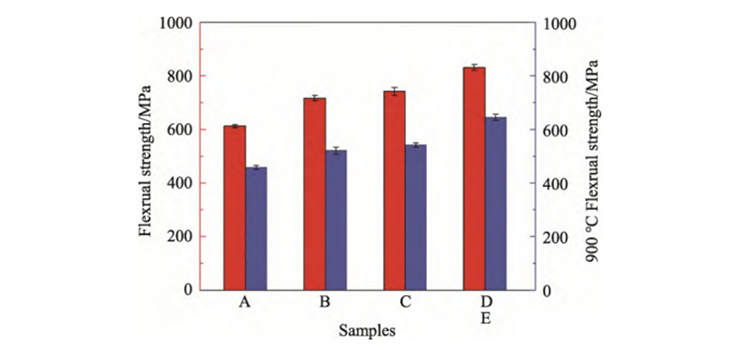

Mechanical Properties Kupfava kwechikamu che intergranular pakupisa kwakanyanya ndicho chikonzero chikuru chekudzikisa simba. Mune imwe-nhanho sintering, kusajairika kukura kwezviyo kunogadzira mapores madiki pakati pezviyo, izvo zvinodzivirira zvakakosha kuvandudzwa kwesimba rekupisa. Nekudaro, mune maviri-nhanho sintering process, chikamu chegirazi, chakagovaniswa mumiganhu yezviyo, uye tsanga dzakafanana dzakakura dzinowedzera simba remukati, zvichikonzera yakakwirira-tembiricha yekukotama simba.

Mukupedzisa, kubata kwenguva refu panguva imwe-nhanho sintering kunogona kunyatso dzikisa porosity yemukati uye kuwana yunifomu yemukati ruvara uye chimiro asi zvinogona kutungamirira kukusakura kwezviyo kukura, izvo zvinoshatisa mamwe ma mechanic properties. Nekushandisa nhanho mbiri sintering process-kushandisa yakaderera-tembiricha pre-sintering kuwedzera particle rearrangement nguva uye yakakwirira-tembiricha inobata kukurudzira kukura kwezviyo zvakafanana-Si₃N₄ ceramic ine hukama hukuru hwe98.25%, yunifomu microstructure, uye yakanakisa yakazara mamejini zvivakwa. inogona kugadzirwa zvinobudirira.

| Zita | Substrate | Epitaxial layer composition | Epitaxial process | Epitaxial medium |

| Silicon homoepitaxial | Si | Si | Vapor Phase Epitaxy (VPE) | SiCl4+H2 |

| Silicon heteroepitaxial | Safire kana spinel | Si | Vapor Phase Epitaxy (VPE) | SiH₄+H₂ |

| GaAs homoepitaxial | GaAs | GaAs GaAs | Vapor Phase Epitaxy (VPE) | AsCl₃+Ga+H₂ (Ar) |

| GaAs | GaAs GaAs | Molecular Beam Epitaxy (MBE) | Ga+As | |

| GaAs heteroepitaxial | GaAs GaAs | GaAlAs/GaAs/GaAlAs | Liquid Phase Epitaxy (LPE) Vapor Phase (VPE) | Ga+Al+CaAs+ H2 Ga+AsH3+PH3+CHl+H2 |

| GaP homoepitaxial | GaP | GaP(GaP;N) | Liquid Phase Epitaxy (LPE) Liquid Phase Epitaxy (LPE) | Ga+GaP+H2+(NH3) Ga+Gas+GaP+NH3 |

| Superlattice | GaAs | GaAlAs/GaAs (kutenderera) | Molecular Beam Epitaxy (MBE) MOCVD | Ca, As, Al GaR₃+AlR3+AsH3+H2 |

| InP homoepitaxial | InP | InP | Vapor Phase Epitaxy (VPE) Liquid Phase Epitaxy (LPE) | PCl3+Mu+H2 Mu+InAs+GaAs+InP+H₂ |

| Si/GaAs Epitaxy | Si | GaAs | Molecular Beam Epitaxy (MBE) MOGVD | Ga, As GaR₃+AsH₃+H₂ |

Nguva yekutumira: Zvita-24-2024