Tantalum carbide (TaC)ibhinari musanganiswa wetantalum uye kabhoni ine kemikari fomula TaC x, apo x inowanzosiyana pakati pe0.4 ne 1. Yakaomarara zvakanyanya, brittle, refractory ceramic zvinhu zvine metallic conductivity. Iwo mashava-grey hupfu uye anowanzo gadziriswa nekupisa.

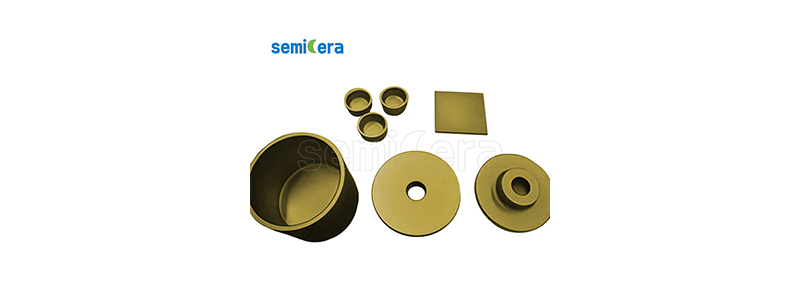

Tantalum carbidechinhu chakakosha chesimbi ceramic material. Imwe yakakosha kushandiswa kwetantalum carbide ndeye tantalum carbide coating.

Chigadzirwa maitiro e tantalum carbide coating

High melting point: Nzvimbo yekunyungudika kwetantalum carbideyakakwirira se3880°C, iyo inoita kuti igadzikane munzvimbo dzakakwirira dzekushisa uye kwete nyore kunyunguduka kana kuderedza.

Mamiriro ekushanda:Kazhinji, yakajairika Kushanda mamiriro eTantalum carbide (TaC) i2200°C. Tichifunga nezvenzvimbo yayo yakanyanya kunyungudika, TaC yakagadzirirwa kushingirira tembiricha yakadai pasina kurasikirwa nehunhu hwayo.

Kuoma uye kupfeka kuramba: Iine kuomarara kwakanyanya (Mohs kuomarara inenge 9-10) uye inogona kunyatso ramba kupfeka uye kukwenya.

Kugadzikana kwemakemikari: Iine kugadzikana kwakanaka kwemakemikari kune akawanda acids uye alkalis uye inogona kuramba corrosion uye maitiro emakemikari.

Thermal conductivity: Good thermal conductivity inoita kuti inyatso kupararira uye kuitisa kupisa, kuderedza kukanganiswa kwekupisa kuunganidza pane zvinhu.

Mamiriro ekushandisa uye zvakanakira mune semiconductor indasitiri

MOCVD midziyo: MuMOCVD (makemikari vapor deposition) midziyo,tantalum carbide coatingsanoshandiswa kuchengetedza kamuri yekupindura uye zvimwe zvakakwirira-tembiricha zvikamu, kuderedza kukukurwa kwemidziyo nemadhipoziti, uye kuwedzera hupenyu hwebasa remidziyo.

Zvakanakira: Kuvandudza kukwirisa-kupisa kwemidziyo, kuderedza kuwanda kwekugadzirisa uye mutengo, uye kunatsiridza kugadzirwa kwakanaka.

Wafer processing: Inoshandiswa mukugadzira wafer uye kutapurirana masisitimu, tantalum carbide coatings inogona kukwidziridza kusakara uye kusakara kwemidziyo.

Zvakanakira: Deredza matambudziko emhando yechigadzirwa anokonzerwa nekupfeka kana ngura, uye ive nechokwadi chekugadzikana uye kuenderana kwekugadziriswa kwewafer.

Semiconductor process zvishandiso: Mune semiconductor process maturusi, senge ion implanters uye etchers, tantalum carbide coatings inogona kuvandudza kusimba kwezvishandiso.

Zvakanakira: Wedzera hupenyu hwesevhisi yezvishandiso, kuderedza nguva yekudzikisa uye kutsiva mutengo, uye kunatsiridza kugadzirwa kwakanaka.

Nzvimbo dzekushisa kwepamusoro: Muzvikamu zvemagetsi uye zvishandiso munzvimbo dzekushisa kwepamusoro, tantalum carbide coatings inoshandiswa kuchengetedza zvinhu kubva pakupisa kwakanyanya.

Advantages: Iva nechokwadi chekugadzikana uye kuvimbika kwezvikamu zvemagetsi pasi pemamiriro ekupisa kwakanyanya.

Future Development Trends

Kuvandudza Zvinhu: Nekuvandudzwa kwesainzi yezvinhu, kugadzirwa uye deposition tekinoroji yetantalum carbide coatingsicharamba ichivandudza kuvandudza kushanda kwayo uye kuderedza mari. Semuenzaniso, zvakanyanya kusimba uye zvisingadhuri zvekupfeka zvinhu zvinogona kugadzirwa.

Deposition Technology: Zvichave zvichigoneka kuve nehunyanzvi uye hwakanyatso dhizaini matekinoroji, akadai seyakagadziridzwa PVD uye CVD tekinoroji, kukwidziridza kunaka uye kuita kwetantalum carbide coatings.

Nzvimbo Itsva Yekushandisa: Nzvimbo dzekushandisa dzetantalum carbide coatingsichawedzera kune mamwe epamusoro-tekinoroji uye maindasitiri minda, senge aerospace, simba uye maindasitiri emotokari, kuzadzisa kudiwa kwepamusoro-kuita zvinhu.

Nguva yekutumira: Aug-08-2024