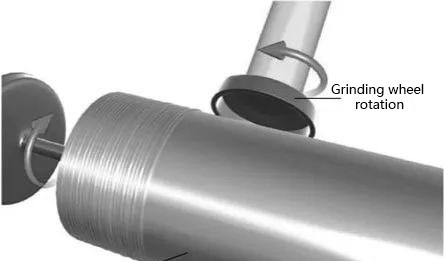

Rolling inoreva maitiro ekukuya dhayamita rekunze resilicon imwe kristaro tsvimbo kuita imwe kristaro tsvimbo yedhayamita inodiwa uchishandisa dhaimondi rinokuya vhiri, uye kukuya kunze kweyakadzika mupendero wereferensi kana nzvimbo yekumisikidza yeimwe crystal tsvimbo.

Iyo yekunze dhayamita pamusoro peiyo imwechete yekristaro tsvimbo yakagadziridzwa neiyo imwe chete yekristaro choto haina kutsetseka uye yakapfava, uye dhayamita yaro yakakura kudarika dhayamita yesilicon wafer inoshandiswa mukushandisa kwekupedzisira. Iyo dhayamita yetsvimbo inodiwa inogona kuwanikwa nekutenderedza dhayamita rekunze.

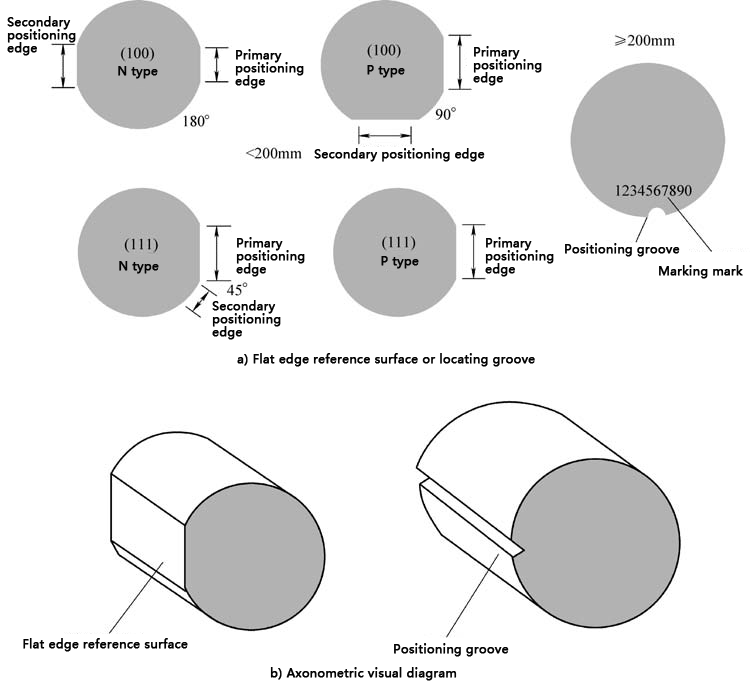

Chigayo chinokunguruka chine basa rekukuya furati yakatsetseka referensi kana kuti positioning groove yesilicon single crystal rod, kureva kuti, kuita ongororo yekunanga pane imwe crystal tsvimbo ine dhayamita inodiwa. Pachigayo chimwechete chinotenderedza, iyo flat edge referensi repamusoro kana nzvimbo yekumisikidza yeimwe crystal tsvimbo inovhurika. Kazhinji, tsvimbo imwe chete yekristaro ine dhayamita isingasviki 200mm inoshandisa nzvimbo yakatsetseka yereferensi, uye tsvimbo imwe chete yekristaro ine dhayamita ye200mm uye pamusoro inoshandisa migero yekumisikidza. Single crystal rods ine dhayamita ye200mm inogonawo kugadzirwa neflat edge referensi nzvimbo sezvinodiwa. Chinangwa cheiyo imwechete crystal rod orientation reference surface ndeyekusangana nezvinodiwa zveotomatiki yekumisikidza mashandiro ezvishandiso mukugadzira dunhu rakasanganiswa; kuratidza kutaridzika kwekristaro uye conductivity mhando yesilicon wafer, nezvimwewo, kufambisa manejimendi ekugadzira; iyo main positioning edge kana positioning groove is perpendicular to the <110> direction. Munguva ye chip kurongedza maitiro, iyo dicing process inogona kukonzera yakasikwa cleavage yewafer, uye chinzvimbo chinogona kudzivirirawo chizvarwa chezvimedu.

Zvinangwa zvikuru zvekutenderedza zvinosanganisira: Kuvandudza kunaka kwepamusoro: Kutenderedza kunogona kubvisa mabhura uye kusaenzana pamusoro peiyo silicon wafers uye kunatsiridza kutsetseka kwepamusoro kwesilicon wafers, iyo yakakosha kune inotevera photolithography uye etching maitiro. Kuderedza kushushikana: Kushushikana kunogona kugadzirwa panguva yekucheka uye kugadzirisa kwesilicon wafers. Kutenderedza kunogona kubatsira kuburitsa izvi zvinonetsa uye kudzivirira iyo silicon wafers kubva pakupwanya mune dzinotevera maitiro. Kuvandudza simba remagetsi esilicon wafers: Munguva yekutenderedza, mipendero yesilicon wafers inove yakapfava, iyo inobatsira kuvandudza simba remuchina wesilicon wafers uye kuderedza kukuvadzwa panguva yekufambisa uye kushandiswa. Kuve nechokwadi chechokwadi chedimensional: Nekutenderedza, iyo dimensional yechokwadi yesilicon wafers inogona kuve nechokwadi, izvo zvakakosha pakugadzirwa kwesemiconductor zvishandiso. Kuvandudza zvimiro zvemagetsi zvesilicon wafers: Iko kumucheto kugadzirisa kwesilicon wafers kune yakakosha pesvedzero pamagetsi avo. Kutenderedza kunogona kuvandudza zvimiro zvemagetsi zvesilicon wafers, senge kuderedza kuvuza ikozvino. Aesthetics: Mheto dzesilicon wafers dzakapfava uye dzinowedzera kunaka mushure mekutenderedzwa, izvo zvinodiwawo kune mamwe mamiriro ekushandisa.

Nguva yekutumira: Jul-30-2024