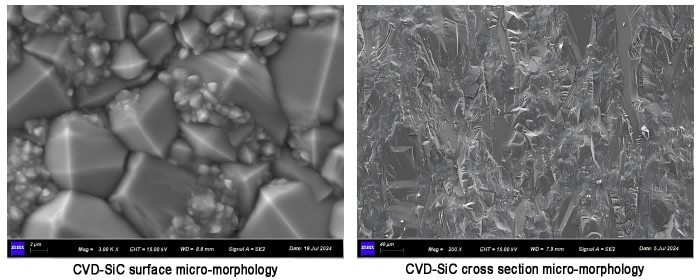

CVD Bulk Silicon Carbide (SiC)

MuchidimbuCVDyakawanda silicon carbide (SiC)chinhu chinonyanya kutsvakwa mumidziyo yeplasma etching, nekukurumidza thermal process (RTP) application, uye mamwe maitiro ekugadzira semiconductor. Yayo yakasarudzika mechaniki, kemikari, uye yekupisa zvimiro inoita kuti ive yakanakira zvinhu zvepamberi tekinoroji maapplication ayo anoda kunyatsojeka uye kusimba.

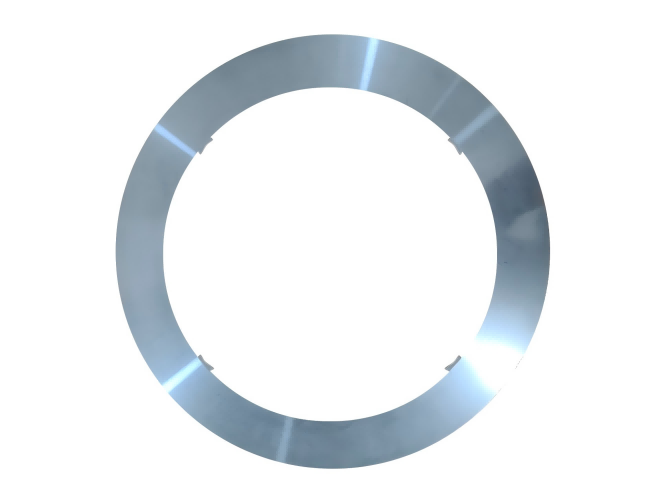

Zvishandiso zveCVD Bulk SiC:Bulk SiC yakakosha muindasitiri yesemiconductor, kunyanya muplasma etching masisitimu, uko zvinhu zvakaita semhete dzekutarisa, magasi eshawa, mhete dzemupendero, uye maplatens anobatsirwa kubva kuSiC's corrosion resistance and thermal conductivity. Kushandiswa kwayo kunowedzera kusvikaRTPmasisitimu nekuda kwekugona kweSiC kutsungirira kukurumidza kushanduka kwekushisa pasina kuderera kwakanyanya.

Kuwedzera kune etching michina, CVDyakawanda SiCinofarirwa mumavira ekuparadzira uye maitiro ekukura kwekristaro, uko kugadzikana kwakanyanya kwekupisa uye kuramba kune hutsinye hwemakemikari nharaunda zvinodiwa. Hunhu uhu hunoita kuti SiC ive chinhu chesarudzo chekushandisa zvakanyanya-kudiwa zvinosanganisira tembiricha yakakwira uye magasi anoparadza, seaya ane chlorine uye fluorine.

Zvakanakira zveCVD Bulk SiC Zvikamu:

•High Density:Nehuremu hwe3.2 g/cm³,CVD yakawanda SiCzvikamu zvinopokana zvakanyanya nekupfeka uye mechanical kukanganisa.

•Superior Thermal Conductivity:Inopa thermal conductivity ye300 W/m·K, yakawanda SiC inodzora kupisa zvakanaka, ichiita kuti ive yakanaka kune zvikamu zvinoratidzwa kune zvakanyanya kupisa kutenderera.

•Exceptional Chemical Resistance:Iyo yakaderera reactivity yeSiC ine etching magasi, anosanganisira chlorine uye fluorine-based makemikari, inovimbisa hupenyu hurefu hwechikamu.

•Adjustable Resistivity: CVD yakawanda SiC'sresistivity inogona kugadziriswa mukati mehuwandu hwe10⁻²–10⁴ Ω-cm, ichiita kuti ienderane kune chaiyo etching uye semiconductor yekugadzira zvinodiwa.

•Thermal Expansion Coefficient:Iine thermal expansion coefficient ye4.8 x 10⁻⁶/°C (25–1000°C), CVD bulk SiC inoramba kuvhunduka kwekushisa, kuchengetedza dimensional kugadzikana kunyangwe panguva yekudziya nekukurumidza uye kutonhora kutenderera.

•Kugara muPlasma:Kuratidzira kune plasma uye reactive magasi hazvidzivisiki mune semiconductor maitiro, asiCVD yakawanda SiCinopa kukwirira kwekupokana nekuora uye kudzikisira, kuderedza kutsiva frequency uye mutengo wekugadzirisa.

Zvido zvehunyanzvi:

•Diameter:Yakakura kupfuura 305 mm

•Resistivity:Inochinjika mukati me10⁻²–10⁴ Ω-cm

•Density:3.2 g/cm³

•Thermal Conductivity:300 W/m·K

•Thermal Expansion Coefficient:4.8 x 10⁻⁶/°C (25–1000°C)

Customization uye Flexibility:AtSemicera Semiconductor, isu tinonzwisisa kuti ese semiconductor application ingangoda zvakasiyana zvirevo. Ndosaka yedu CVD yakawanda SiC zvikamu zvakazara customizable, ine inogadziriswa resistivity uye akarongedzerwa zviyero kuti zvienderane nezvido zvako zvemidziyo. Kunyangwe iwe uri kukwenenzvera yako plasma etching masisitimu kana kutsvaga anogara kwenguva refu muRTP kana diffusion maitiro, yedu CVD yakawanda SiC inopa isingaenzaniswi kuita.