Tsanangudzo

MOCVD Substrate Heater, Heating Elements yeMOCVD

Graphite hita:

Ma graphite heater components anoshandiswa muchoto chekushisa chepamusoro uye tembiricha inosvika 2200 degree pavacuum nharaunda uye 3000 degree munzvimbo ine deoxidized uye yakaiswa gasi.

Zvinhu zvikuru zve graphite heater

1. kufanana kwekupisa chimiro.

2. yakanaka conductivity yemagetsi uye mutoro mukuru wemagetsi.

3. corrosion resistance.

4. inoxidizability.

5. kuchena kwemakemikari yakakwirira.

6. high mechanical simba.

Iyo inobatsira isimba rinoshanda, kukosha kwepamusoro uye kuderera kwekugadzirisa.

Tinogona kuburitsa anti-oxidation uye hupenyu hurefu hurefu graphite crucible, graphite mold uye zvese zvikamu zve graphite heater.

Chemical Graphite

Advantage: High tembiricha kuramba

Kushandisa:MOCVD/Vacuum furnace/Hot Zone

Hukuru Density:1.68-1.91g/cm3

Flexural simba: 30-46Mpa

Kuramba:7-12μΩm

Main parameters ye graphite heater

| Kutsanangurwa Kwehunyanzvi | VET-M3 |

| Hukuru Density (g/cm3) | ≥1.85 |

| Zvemukati zveMadota (PPM) | ≤500 |

| Shore Hardness | ≥45 |

| Chaicho Kuramba (μ.Ω.m) | ≤12 |

| Flexural Strength (Mpa) | ≥40 |

| Compressive Strength (Mpa) | ≥70 |

| Max. Saizi yezviyo (μm) | ≤43 |

| Coefficient of Thermal Expansion Mm/°C | ≤4.4*10-6 |

Graphite heater yevira remagetsi ine zvimiro zvekudzivirira kupisa, oxidation kuramba, yakanaka conductivity yemagetsi uye nani mechanic intensity. Isu tinokwanisa muchina akasiyana marudzi egraphite heater zvinoenderana nemagadzirirwo evatengi.

Profile yekambani

WeiTai Energy Technology Co., Ltd. inotungamira mutengesi wemhando yepamusoro semiconductor ceramics uye chete mugadziri muChina anogona panguva imwe chete kupa yakakwirira-kuchena silicon carbide ceramic (kunyanya iyo Recrystallized SiC) uye CVD SiC coating. Pamusoro pezvo, kambani yedu yakazvipirawo kuminda yeceramic yakadai sealuminium, aluminium nitride, zirconia, uye silicon nitride, nezvimwe.

Zvigadzirwa zvedu zvikuru zvinosanganisira: silicon carbide etching disc, silicon carbide boat tow, silicon carbide wafer boat (Photovoltaic & Semiconductor), silicon carbide furnace chubhu, silicon carbide cantilever paddle, silicon carbide chucks, silicon carbide beam, pamwe neCVD SiC coating uye TaC. coating. Zvigadzirwa zvinonyanya kushandiswa mu semiconductor uye photovoltaic maindasitiri, senge midziyo yekukura kwekristaro, epitaxy, etching, kurongedza, kupfekedza uye diffusion furnaces, nezvimwe.

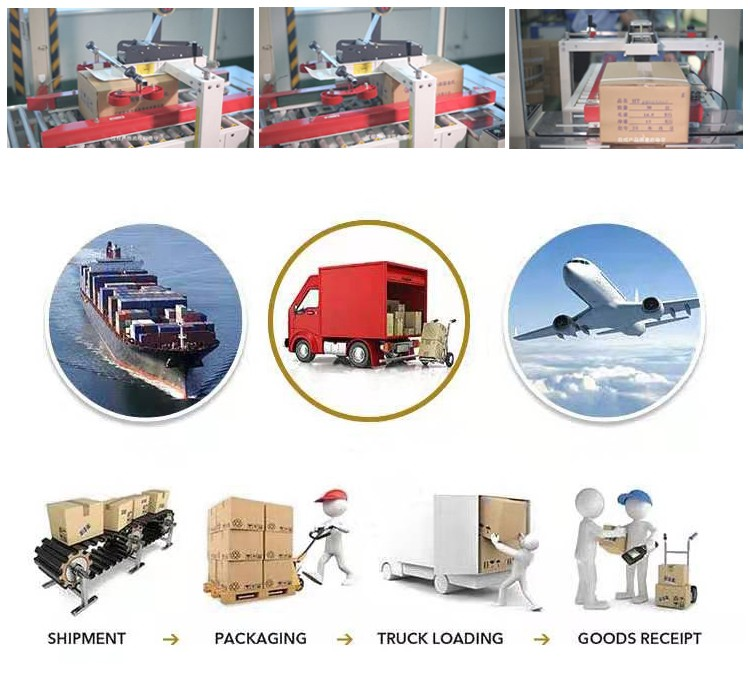

Kambani yedu ine yakakwana yekugadzira michina senge kuumba, sintering, kugadzirisa, coating midziyo, nezvimwewo, iyo inogona kupedzisa ese anodiwa malink ekugadzirwa kwechigadzirwa uye kuve nepamusoro kutonga kwemhando yechigadzirwa; Iyo yakakwana chirongwa chekugadzira chinogona kusarudzwa zvinoenderana nezvinodiwa zvechigadzirwa, zvichikonzera kuderera kwemutengo uye kupa vatengi zvigadzirwa zvinokwikwidza; Isu tinokwanisa kuchinjika uye zvine hungwaru kuronga kugadzirwa kwakavakirwa pane odha yekutumira zvinodiwa uye takabatana neyepamhepo odha manejimendi masisitimu, ichipa vatengi nekukurumidza uye yakavimbiswa nguva yekutumira.