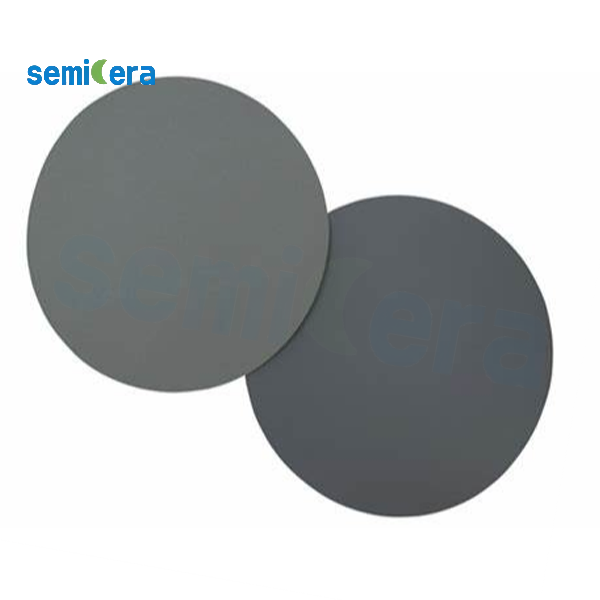

Silicon carbide imhando yekugadzira carbide ine SiC molecule. Kana yapihwa simba, silica nekabhoni zvinowanzoumbwa pakupisa kwepamusoro kwe2000°C. Silicon carbide ine theoretical density ye3.18g/cm3, kuomarara kweMohs kunotevera diamond, uye kuomarara kwe3300kg/mm3 pakati pe9.2 ne9.8. Nekuda kwekuoma kwayo kwepamusoro uye kushomeka kwepamusoro, ine hunhu hwekupisa tembiricha inopikisa uye inoshandiswa kune dzakasiyana siyana dzekusapfeka, corrosion-resistant uye yakakwirira-tembiricha michina zvikamu. Irwo rudzi rutsva rwekupfeka-resistant ceramic tekinoroji.

1, Chemical properties.

(1) Oxidation kuramba: Kana iyo silicon carbide zvinhu ichidziya kusvika 1300 ° C mumhepo, iyo silicon dioxide inodzivirira layer inotanga kugadzirwa pamusoro pesilicon carbide crystal. Nekukora kwechikamu chekudzivirira, iyo yemukati silicon carbide inoramba ichiwedzera oxidize, kuitira kuti iyo silicon carbide ive yakanaka oxidation kuramba. Kana tembiricha yasvika kupfuura 1900K(1627 ° C), iyo silicon dioxide inodzivirira firimu inotanga kukuvadzwa, uye oxidation yesilicon carbide inowedzerwa, saka 1900K ndiyo tembiricha yekushanda yesilicon carbide mumhepo ine oxidizing.

(2) Acid uye alkali kuramba: nekuda kwebasa resilicon dioxide inodzivirira firimu, silicon carbide ine zvimiro mubasa resilicon dioxide inodzivirira firimu.

2, Zvenyama uye zvemagetsi zvivakwa.

(1) Density: Iyo particle density yeakasiyana silicon carbide makristasi ari padyo, anowanzo onekwa se3.20g/mm3, uye echisikigo packing density yesilicon carbide abrasives iri pakati pe1.2-1.6g/mm3, zvichienderana nekukura kwechikamu. particle size shape and particle size shape.

(2) Kuomarara: Iyo Mohs kuomarara kwesilicon carbide ndeye 9.2, iyo micro-density yeWessler i3000-3300kg/mm2, kuomarara kweKnopp i2670-2815kg/mm, iyo abrasive yakakwirira kupfuura corundum, padyo nedhaimondi, cubic. boron nitride uye boron carbide.

(3) Thermal conductivity: zvigadzirwa zvesilicon carbide zvine high thermal conductivity, diki yekupisa yekuwedzera coefficient, yakakwirira yekupisa kuvhunduka, uye ndeyemhando yepamusoro refractory zvinhu.

3, Magetsi zvinhu.

| Item | Unit | Data | Data | Data | Data | Data |

| RBsic(sic) | NBSiC | SSiC | RSiC | OSiC | ||

| SiC content | % | 85 | 76 | 99 | ≥99 | ≥90 |

| Yemahara silicon yemukati | % | 15 | 0 | 0 | 0 | 0 |

| Max sevhisi tembiricha | ℃ | 1380 | 1450 | 1650 | 1620 | 1400 |

| Density | g/cm^3 | 3.02 | 2.75-2.85 | 3.08-3.16 | 2.65-2.75 | 2.75-2.85 |

| Open porosity | % | 0 | 13-15 | 0 | 15-18 | 7-8 |

| Kupeta simba 20 ℃ | Mpa | 250 | 160 | 380 | 100 | / |

| Kupeta simba 1200 ℃ | Mpa | 280 | 180 | 400 | 120 | / |

| Modulus ye elasticity 20 ℃ | Gpa | 330 | 580 | 420 | 240 | / |

| Modulus ye elasticity 1200 ℃ | Gpa | 300 | / | / | 200 | / |

| Thermal conductivity 1200 ℃ | W/mk | 45 | 19.6 | 100-120 | 36.6 | / |

| Coefficient of thermalexpansion | K^-lx10^-8 | 4.5 | 4.7 | 4.1 | 4.69 | / |

| HV | kg/m^m2 | 2115 | / | 2800 | / | / |