Kukuya dhisiki chinhu chakakosha chekugadzira michina yekugadzirwa kwesilicon wafers kune Ultra-hombe chiyero chakabatanidzwa maseketi mu semiconductor indasitiri. Inowanzo shandiswa simbi yakakandwa kana kabhoni simbi yekukuya disc ine yakaderera sevhisi hupenyu uye yakakura yekupisa yekuwedzera coefficient. Muchigadziro chekugadzira silicon wafers, kunyanya mukuita kwepamusoro-kumhanya kugaya kana kupuruzira, flatness uye parallelism yesilicon wafers zvakaoma kuve nechokwadi nekuda kwekupfeka uye kupisa kwekupisa kweiyo grinding disc.

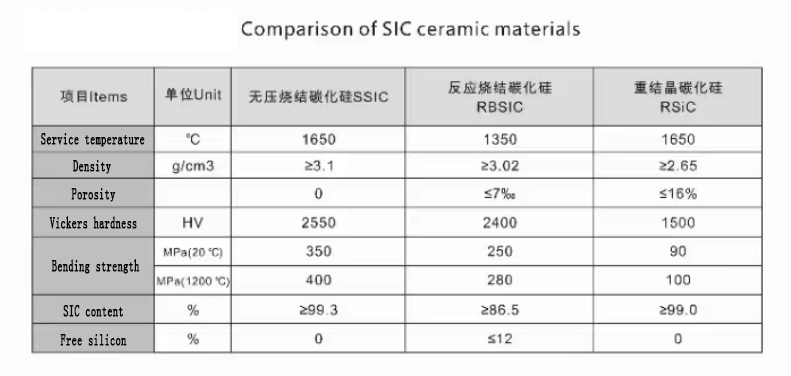

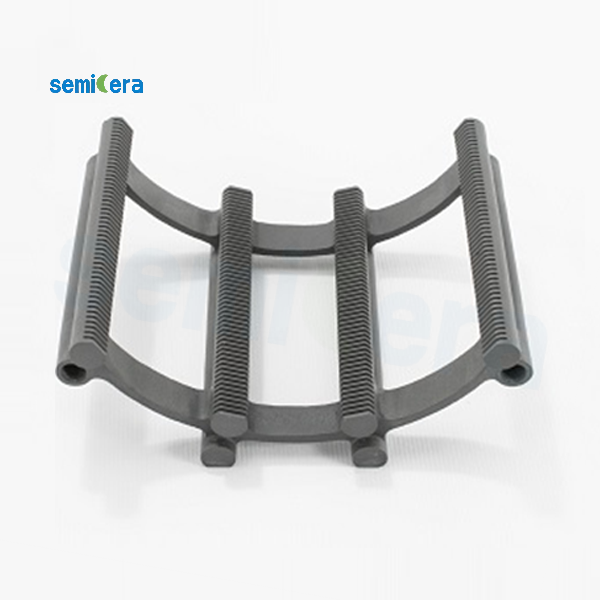

Iyo yekukuya dhisiki yesilicon carbide ceramic inogona kukuyiwa uye kukwenenzverwa nekumhanya kwakanyanya nekuda kwekuoma kwakanyanya uye kudiki kupfeka kwedhisiki rekukuya, uye iyo yekudziya yekuwedzera coefficient yakangofanana neiyo yesilicon wafer. Kunyanya mumakore achangopfuura, saizi yesilicon wafer iri kuwedzera kukura uye kukura, izvo zvinoisa kumberi kwepamusoro zvinodiwa zvemhando uye kugona kwesilicon wafer kugaya.

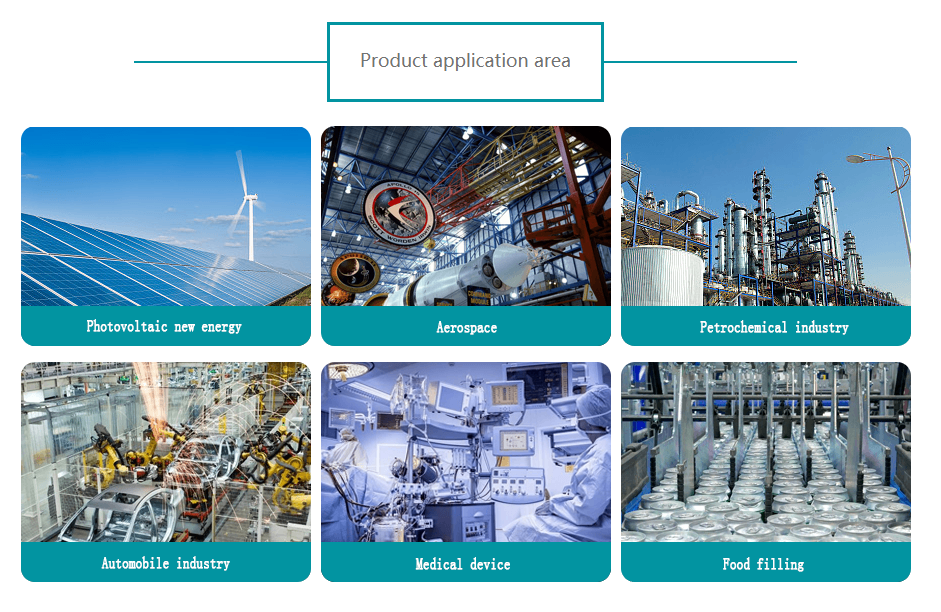

Iko kushandiswa kwesilicon carbide ceramic grinding disc kuchavandudza zvakanyanya kunaka uye kugona kwesilicon wafer kugaya. Panguva imwecheteyo, iyo silicon carbide ceramic grinding disk inogona zvakare kushandiswa kukuya nekupukuta ndege yezvimwe zvinhu zvakaita seflake kana block zvinhu. Nekuvandudzwa kwemaindasitiri, kunyanya kuitwa kweiyo ISO14000 chiyero chepasi rose, zvinodiwa zvepamusoro zvakaiswa pamberi pekutakura zvinwiwa zvisingakodzeri kuchengetedza kwezvakatipoteredza.

Imwe yeakakosha maitiro esilicon carbide ceramics isimba rayo rekushisa kwepamusoro, ndiko kuti, simba racho harina kuderedzwa pa1600 madhigirii, uye kupikisa oxidation yakanaka kwazvo, saka inogona kushandiswa munzvimbo dzakakwirira dzekudziya. Zvakadai sendiro yepamusoro yevira rekushisa, tsigiro, uye tembiricha yekuyedza zvigadziriso.

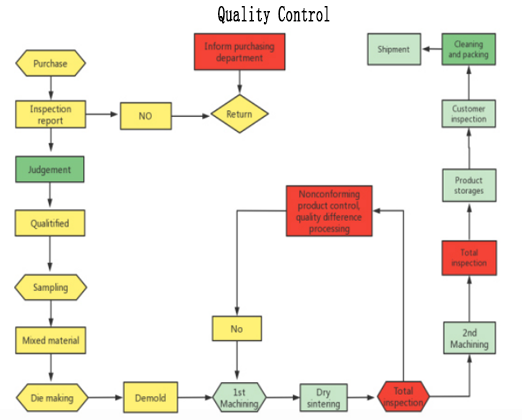

SemiceraEnergy Technology Co., Ltd inyanzvi yekutsvagisa, kusimudzira, kugadzira uye kutengesa kwesilicon carbide ceramic zvigadzirwa.Kubva pakavambwa muna 2016,SemiceraSimba rave nehunyanzvi isostatic yekutsikirira kuumba maitiro, churu chinotsikirira kuumba maitiro, grouting molding process uye vacuum extrusion molding process. Kambani yedu inoshandisa 6 silicon carbide ceramic sintering mitsara yekugadzira, ine 8 CNC, 6 chaiyo yekukuya michina, inogona zvakare kukupa iwe silicon carbide ceramic sintered zvigadzirwa, asiwo inogona kupa silicon carbide ceramics, alumina ceramics, aluminium nitride ceramics, zirconia ceramics processing services. .

-

Kugadzira Makambani eGraphite Soft Felt ...

-

Big discounting Polyacrylonitrile Thermal Insul...

-

2019 Yemhando yepamusoro Silicon Carbide Liner Sisic T...

-

Ordinary Discount Electric Double Spiral Cerami...

-

Nyanzvi China Silicon Carbide Graphite Cru...

-

Sample Yemahara YeSpecial Type Sic Products Doubl...