Silicon nitride yakasanganiswa nesilicon carbide kiln ine hunhu hwehutembiricha hwepamusoro, yakanaka yekupisa kuvhundutsa kuramba, deformation nyore, oxidation kuramba, corrosion resistance, yakanaka thermal conductivity zvichingodaro.

Main performance zviratidzo

| Item | Firebrick index | Kiln specification | Index yechigadzirwa chakaumbwa |

| Inooneka porosity(%) | <16 | <16 | <14 |

| Bulk density(g/cm3) | 2 2.65 | 2 2.65 | 2 2.68 |

| Kudzvinyirira simba pakupisa kwekamuri(MPa) | 2 160 | 2 170 | 2 180 |

| Kupeta simba pakudziya kwekamuri(1400X:) MPa | 2 40 | 2 45 | 2 45 |

| High tembiricha yekukotama simba(1400r) MPa | 2 50 | 2 50 | 2 50 |

| Coefficient yekuwedzera kwekushisa(110CTC)xioVC | <4.18 | <4.18 | <4.18 |

| Thermal conductivity(1100C) | 216 | 2 16 | 216 |

| Refractories(°C ) | 1800 | 1800 | 1800 |

| 0.2 MPa Kupfava tembiricha pasi pemutoro(X:) | 1600 | 1600 | > 1700 |

| Maximum yekushanda tembiricha(°C) | 1550 | 1550 | 1550 |

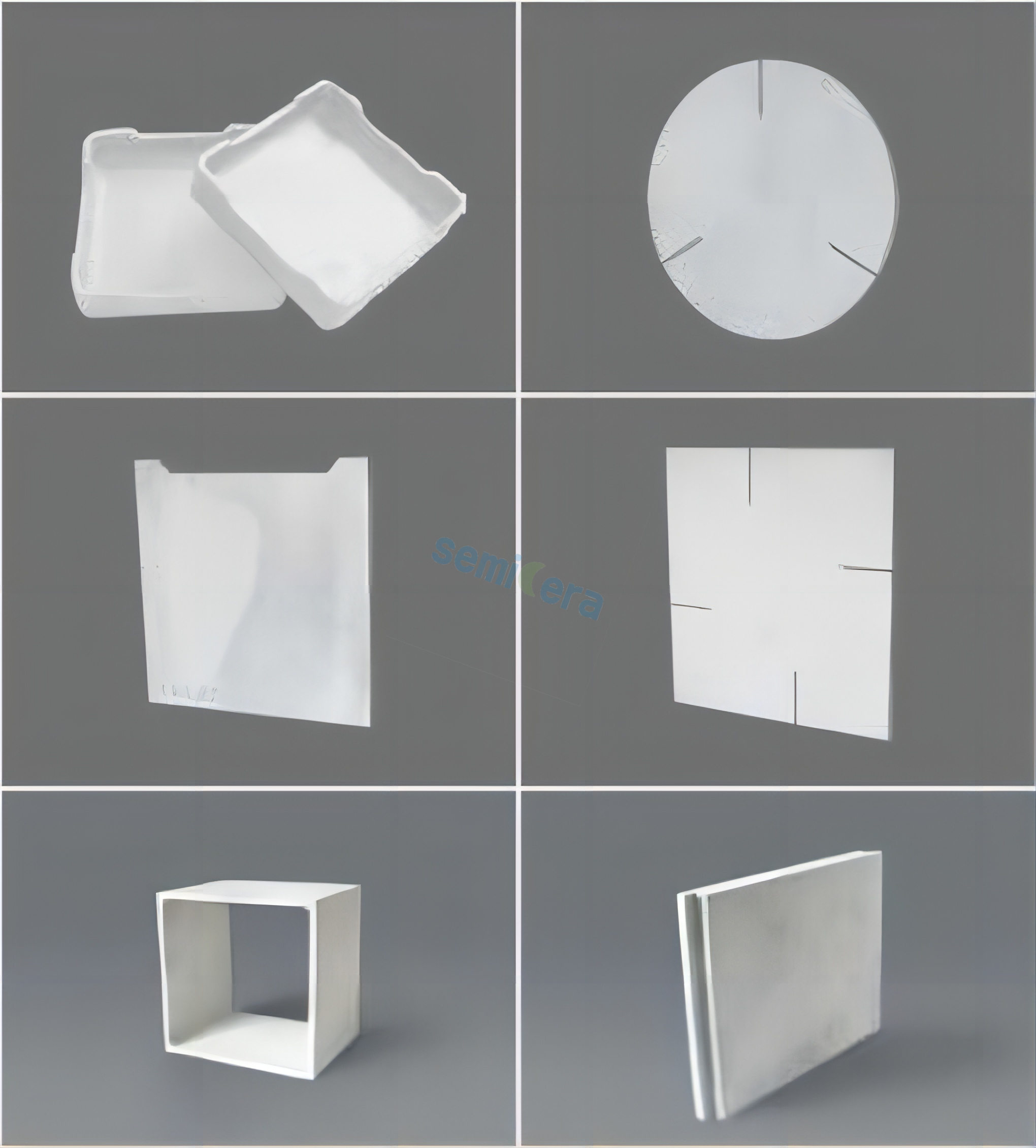

Zvigadzirwa izvi zvinoshandiswa zvakanyanya muceramic kugaya vhiri, yakakwira aluminium zvigadzirwa, aluminium porcelain bhora, honi yeindasitiri, yemagetsi ceramic, yakakwira voltage yemagetsi porcelain, sanitary ware, zuva nezuva porcelain, nitride alloy uye furo ceramics uye mamwe maindasitiri.

Kupfeka kupikisa kweSi3N4-SiC zvinhu ndeye 3.13 nguva yesimbi isingagadzirike (Crl5Mo3), uye huremu hunongova 1/3 chete yesimbi isingapfekeki (Crl5Mo3).

Iyo corrosion resistance yemhando yekudzikisa kunaka kweSi3N4-SiC uye calcium carbide uye alumina mune akasiyana mhinduro ndeaya anotevera:

| Test mhinduro | Tembiricha ("C) | Si3N4-SiC | Kazhinji ceramics | Aluminium carbide | Aluminium oxide |

| 98 %Sulfuric acid | 100 | 1.8 | 55.0 | > 1000 | 65,0 |

| 50 %Sodium hydroxide | 100 | 2,5 | > 1000 | 5.0 | 75.0 |

| 53 %Hydrofluoric asidhi | 25 | <0.2 | 7.9 | 8.0 | 20,0 |

| 85 %Phosphoric acid | 100 | <0.2 | 8.8 | 55.0 | > 1000 |

| 70 %Nitric acid | 100 | <0.2 | 0.5 | > 1000 | 7,0 |

| 45 %Potassium hydroxide | 100 | <0.2 | > 1000 | 3.0 | 60,0 |

| 25 %Hydrochloric acid | 70 | <0.2 | 0.9 | 85.0 | 72,0 |

| 10% Hydrofluoric acid +57% Nitric acid

| 25 | <0.2 | > 1000 | > 1000 | 16,0 |