Semicera's Silicon On Insulator (SOI) Wafer iri kumberi kweiyo semiconductor innovation, ichipa yakagadziridzwa magetsi yekuzviparadzanisa nevamwe uye yepamusoro yekupisa kuita. Iyo SOI chimiro, ine yakaonda silicon layer pane inodzivirira substrate, inopa zvakakosha mabhenefiti epamusoro-inoshanda zvemagetsi zvigadzirwa.

Yedu SOI wafers akagadzirirwa kuderedza parasitic capacitance uye leakage currents, izvo zvakakosha pakugadzira yakakwirira-kumhanya uye yakaderera-simba akabatanidzwa maseketi. Iyi tekinoroji yepamberi inovimbisa kuti zvishandiso zvinoshanda zvakanyanya, nekumhanyisa kumhanya uye kuderedzwa kwesimba rekushandisa, yakakosha kumagetsi emazuva ano.

Iwo epamberi ekugadzira maitiro anoshandiswa neSemicera anovimbisa kugadzirwa kweSOI wafers ane yakanakisa kufanana uye kuenderana. Hunhu uhwu hwakakosha pakushandisa munharembozha, mota, uye zvemagetsi zvevatengi, uko kunodiwa zvinhu zvinovimbika uye zvinoshanda zvakanyanya.

Pamusoro pemabhenefiti avo emagetsi, Semicera's SOI wafers inopa yakanyanya kupisa kupisa, inosimudzira kupisa kupisa uye kugadzikana mune yakakwirira-density uye yakakwirira-simba zvishandiso. Iyi ficha inonyanya kukosha mumashandisirwo anosanganisira akakosha kugadzirwa kwekupisa uye inoda kunoshanda kunodzora kupisa.

Nekusarudza Semicera's Silicon PaInsulator Wafer, iwe unodyara mune chigadzirwa chinotsigira kufambira mberi kwekucheka-kumucheto matekinoroji. Kuzvipira kwedu kune mhando uye innovation kunovimbisa kuti yedu SOI wafers inosangana nezvinodiwa zvemazuva ano semiconductor indasitiri, ichipa hwaro hwechinotevera-chizvarwa zvigadzirwa zvemagetsi.

| Items | Kugadzirwa | Tsvakurudzo | Dummy |

| Crystal Parameters | |||

| Polytype | 4H | ||

| Kutadza kwekutarisa pamusoro | <11-20 >4±0.15° | ||

| Electrical Parameters | |||

| Dopant | n-mhando Nitrogen | ||

| Resistivity | 0.015-0.025ohm·cm | ||

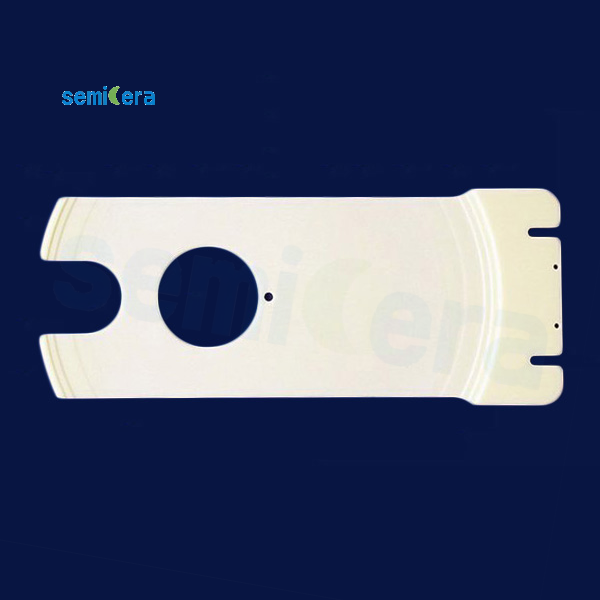

| Mechanical Parameters | |||

| Diameter | 150.0±0.2mm | ||

| Ukobvu | 350±25 μm | ||

| Primary flat orientation | [1-100]±5° | ||

| Primary flat urefu | 47.5±1.5mm | ||

| Secondary flat | Hapana | ||

| TTV | ≤5 μm | ≤10 μm | ≤15 μm |

| LTV | ≤3 μm(5mm*5mm) | ≤5 μm(5mm*5mm) | ≤10 μm(5mm*5mm) |

| Bow | -15μm ~ 15μm | -35μm ~ 35μm | -45μm ~ 45μm |

| Warp | ≤35 μm | ≤45 μm | ≤55 μm |

| Mberi(Si-face) roughness(AFM) | Ra≤0.2nm (5μm*5μm) | ||

| Chimiro | |||

| Micropipe density | <1 pa/cm2 | <10 ea/cm2 | <15 ea/cm2 |

| Metal tsvina | ≤5E10atomu/cm2 | NA | |

| BPD | ≤1500 ea/cm2 | ≤3000 ea/cm2 | NA |

| TSD | ≤500 ea/cm2 | ≤1000 ea/cm2 | NA |

| Mberi Hunhu | |||

| Mberi | Si | ||

| Surface finish | Si-face CMP | ||

| Zvimedu | ≤60ea/wafer (saizi≥0.3μm) | NA | |

| Makwara | ≤5ea/mm. Kureba kwekuwedzera ≤Diameter | Cumulative kureba≤2*Diameter | NA |

| Orenji svuura/makomba/mavara/mitsetse/pakatsemuka/kusvibiswa | Hapana | NA | |

| Edge chips/indents/fracture/hex plates | Hapana | ||

| Polytype nzvimbo | Hapana | Cumulative area≤20% | Cumulative area≤30% |

| Front laser marking | Hapana | ||

| Back Quality | |||

| Back finish | C-chiso CMP | ||

| Makwara | ≤5ea/mm,Cumulative kureba≤2*Diameter | NA | |

| Kuremara kumashure (kumucheto machipisi / indents) | Hapana | ||

| Back roughness | Ra≤0.2nm (5μm*5μm) | ||

| Back laser marking | 1 mm (kubva kumusoro kumucheto) | ||

| Edge | |||

| Edge | Chamfer | ||

| Packaging | |||

| Packaging | Epi-yakagadzirira ine vacuum packaging Multi-wafer kaseti kurongedza | ||

| * Notes: "NA" zvinoreva kuti hapana chikumbiro Zvinhu zvisina kutaurwa zvinogona kureva SEMI-STD. | |||