Iyo Solid Silicon Carbide(SiC) Etching Rings inopihwa neSemicera inogadzirwa neChemical Vapor Deposition (CVD) nzira uye mhedzisiro yakasarudzika mumunda weiyo chaiyo etching process application. Aya maSolid Silicon Carbide (SiC) Etching Rings anozivikanwa nekuomarara kwawo, kugadzikana kwemafuta uye kuramba kwecorrosion, uye emhando yepamusoro yezvinhu inovimbiswa neCVD synthesis.

Yakagadzirirwa chaizvo etching maitiro, iyo Solid Silicon Carbide (SiC) Etching Rings 'rugged chimiro uye yakasarudzika zvinhu zvimiro zvinoita basa rakakosha mukuita chaiko uye kuvimbika. Kusiyana nemidziyo yechinyakare, iyo yakasimba SiC chikamu chine kusimba kusingaenzaniswi uye kupfeka kuramba, zvichiita kuti ive chinhu chakakosha mumaindasitiri anoda kunyatsojeka uye hupenyu hurefu.

Yedu Solid Silicon Carbide (SiC) Etching Rings ndeyechokwadi inogadzirwa uye mhando inodzorwa kuti ive nechokwadi chekuita kwavo kwepamusoro uye kuvimbika. Ingave mukugadzira semiconductor kana mamwe mativi ane hukama, aya Solid Silicon Carbide (SiC) Etching Rings anogona kupa yakagadzikana etching kuita uye yakanakisa etching mhedzisiro.

Kana iwe uchifarira yedu Solid Silicon Carbide (SiC) Etching Mhete, ndapota taura nesu. Chikwata chedu chinokupa ruzivo rwakadzama rwechigadzirwa uye nehunyanzvi tekinoroji rutsigiro kuzadzisa zvaunoda. Isu tinotarisira kumisikidza kudyidzana kwenguva refu newe uye pamwe nekusimudzira kusimudzira indasitiri.

✓Yepamusoro-mhando mumusika weChina

✓Sevhisi yakanaka nguva dzose kwauri, 7*24 maawa

✓Nguva pfupi yekutumira

✓Idiki MOQ inogamuchirwa uye inogamuchirwa

✓Masevhisi echivanhu

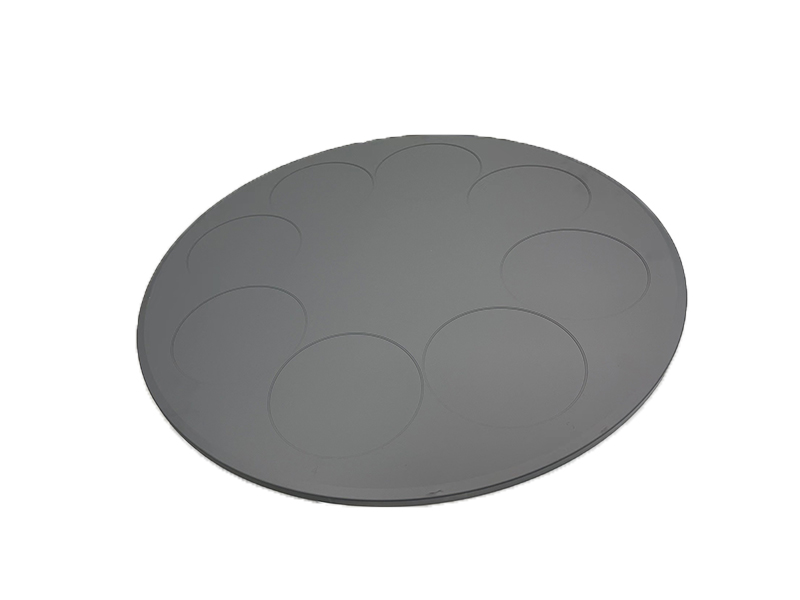

Epitaxy Kukura Susceptor

Silicon / silicon carbide wafers inoda kupfuura nematanho akawanda kuti ashandiswe mumidziyo yemagetsi. Nzira yakakosha ndeyesilicon/sic epitaxy, umo silicon/sic wafers inotakurwa pachigadziko chegraphite. Yakakosha mabhenefiti eSemicera's silicon carbide-yakavharwa graphite base inosanganisira yakanyanya kuchena kuchena, yunifomu yekupfeka, uye yakanyanyisa hupenyu hwesevhisi. Vanewo kukwirira kwemakemikari uye kugadzikana kwekupisa.

LED Chip Kugadzirwa

Munguva yekuputira kwakakura kweMOCVD reactor, chigadziko chepuraneti kana mutakuri anofambisa substrate wafer. Kuitwa kwechigadziko chinhu chine simba guru pahutano hwekuputira, izvo zvinokanganisa chiyero chezvimedu zvechip. Semicera's silicon carbide-coated base inowedzera kugona kwekugadzira kwemhando yepamusoro LED wafers uye inoderedza wavelength kutsauka. Isu tinopawo mamwe magirafu zvikamu kune ese MOCVD reactor ari kushandiswa parizvino. Tinogona kupfeka chero chinhu chine silicon carbide coating, kunyangwe iyo chikamu dhayamita inosvika 1.5M, isu tinogona kuramba takapfeka nesilicon carbide.

Semiconductor Munda, Oxidation Diffusion process, Etc.

Mukuita semiconductor, iyo oxidation yekuwedzera maitiro inoda yakakwira chigadzirwa kuchena, uye paSemicera tinopa tsika uye CVD yekupfekedza masevhisi kune mazhinji esilicon carbide zvikamu.

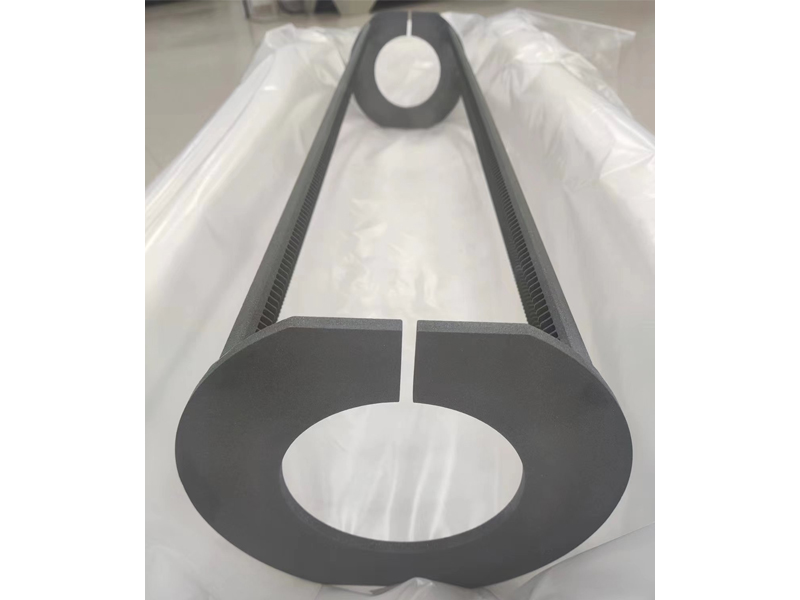

Mufananidzo unotevera unoratidza rough-yakagadziriswa silicon carbide slurry yeSemicea uye iyo silicon carbide furnace chubhu inocheneswa mu100.0-levelisina guruvaroom. Vashandi vedu vari kushanda vasati vapfeka. Kuchena kwesilicon carbide yedu kunogona kusvika 99.99%, uye kuchena kwe sic coating yakakura kupfuura 99.99995%.

Raw Silicon Carbide Paddle uye SiC Process Tube muKuchenesa

Silicon Carbide Wafer Boat CVD SiC Coated