Nhanganyaya kuCVD TaC Coating:

CVD TaC Coating i tekinoroji inoshandisa kemikari vapor deposition kuisa tantalum carbide (TaC) yekuputira pamusoro pe substrate. Tantalum carbide ndeyepamusoro-inoshanda ceramic zvinhu ine yakanakisa mechaniki uye makemikari zvimiro. Iyo CVD maitiro inogadzira yunifomu yeTaC firimu pamusoro peiyo substrate kuburikidza negasi maitiro.

Main features:

Excellent kuoma uye kupfeka kuramba: Tantalum carbide ine kuomarara kwakanyanya, uye CVD TaC Coating inogona kuvandudza zvakanyanya kupfeka kuramba kweiyo substrate. Izvi zvinoita kuti iyo yekupfekedza ive yakanaka kune maapplication munzvimbo dzepamusoro-soro, senge maturusi ekucheka uye mold.

High Temperature Kugadzikana: TaC coatings inodzivirira yakakosha choto uye reactor zvikamu pakupisa kusvika ku2200 ° C, zvichiratidza kugadzikana kwakanaka. Inochengetedza kugadzikana kwemakemikari uye mechanical pasi pemamiriro ekushisa kwakanyanya, zvichiita kuti ive yakakodzera kune-high-temperature yekugadzirisa uye kushandiswa munzvimbo dzepamusoro-soro.

Yakanakisa kugadzikana kwemakemikari: Tantalum carbide ine yakasimba corrosion resistance kune akawanda acids uye alkalis, uye CVD TaC Coating inogona kudzivirira zvinobudirira kukanganisa kune substrate munzvimbo dzinoparadza.

High melting point: Tantalum carbide ine nzvimbo yakakwirira yekunyunguduka (inenge 3880 ° C), ichibvumira CVD TaC Coating kuti ishandiswe mumamiriro ekupisa kwepamusoro pasina kunyunguduka kana kukanganisa.

Excellent thermal conductivity: TaC coating ine high thermal conductivity, iyo inobatsira kunyatsobvisa kupisa muhutano hwepamusoro uye kudzivirira kupisa kwenzvimbo.

Zvingango shandiswa:

• Gallium Nitride (GaN) uye Silicon Carbide epitaxial CVD reactor components zvinosanganisira wafer carriers, satellite dish, showerheads, sirin'i, uye susceptors.

• Silicon carbide, gallium nitride uye aluminum nitride (AlN) crystal growth components zvinosanganisira crucibles, vabati vembeu, gidhi ringi nemasefa.

• Zvikamu zveindasitiri zvinosanganisira kuramba kudziyisa zvinhu, jekiseni nozzles, masking mhete uye brazing jigs

Zvishandiso zvekushandisa:

• Tembiricha yakagadzikana pamusoro pe2000 ° C, ichibvumira kushanda pakupisa kwakanyanya

•Inopikisa hydrogen (Hz), ammonia (NH3), monosilane (SiH4) nesilicon (Si), ichidzivirira munzvimbo dzakaoma dzemakemikari.

• Thermal shock resistance inogonesa kukurumidza kushanda kutenderera

• Graphite ine kunamatira kwakasimba, kuve nechokwadi chehupenyu hurefu hwebasa uye pasina coating delamination.

• Ultra-yakakwirira kuchena kubvisa kusvibiswa kusingakoshi kana kusvibiswa

• Conformal coating coverage to tight dimensional tolerances

Zvido zvehunyanzvi:

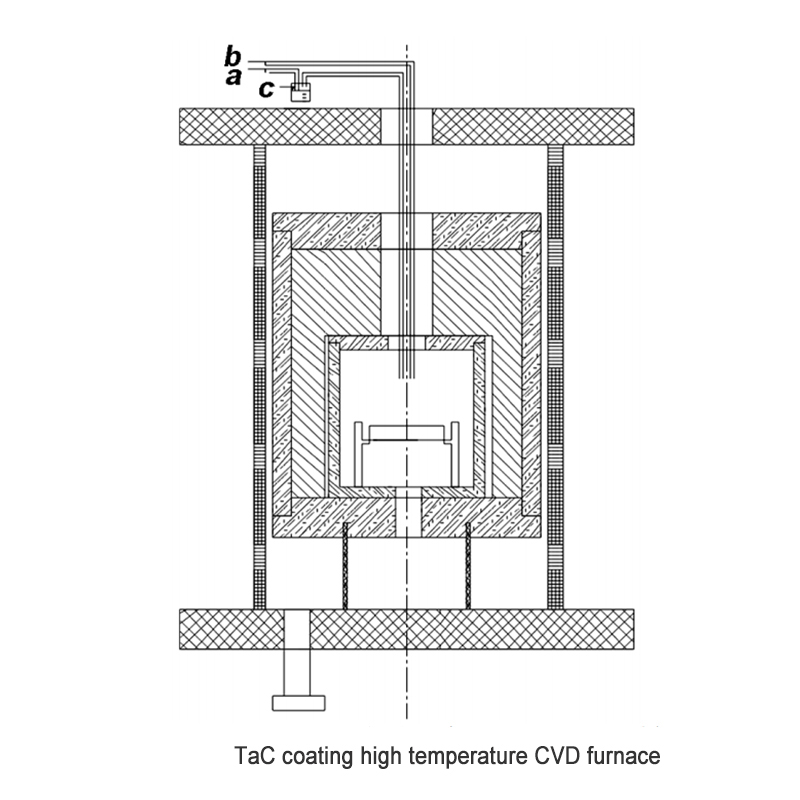

Kugadzirira kwe dense tantalum carbide coatings neCVD:

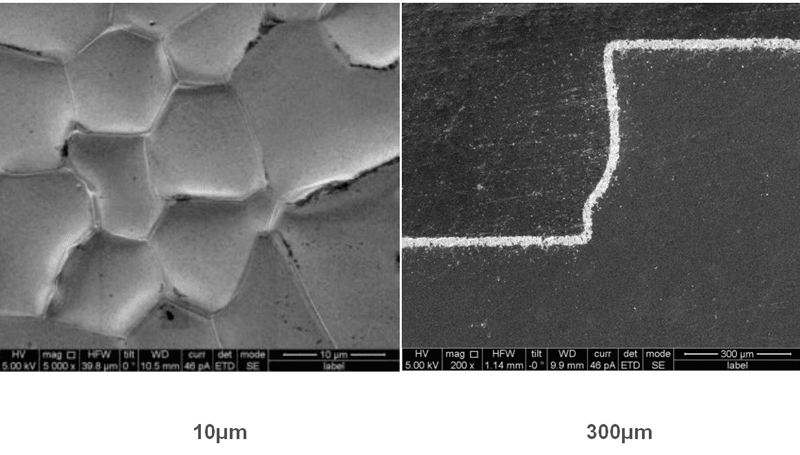

TAC yekupfekedza ine yakakwira crystallinity uye yakanakisa kufanana:

CVD TAC COATING Technical Parameters_Semicera:

| Zvenyama zvimiro zveTaC coating | |

| Density | 14.3 (g/cm³) |

| Bulk Concentration | 8 x 1015/cm |

| Specific emssivity | 0.3 |

| Thermal kuwedzera coefficient | 6.3 10-6/K |

| Kuoma (HK) | 2000 HK |

| Bulk Resistivity | 4.5 ohm-cm |

| Resistance | 1x10-5Om*cm |

| Thermal kugadzikana | <2500℃ |

| Mobility | 237 cm2/Vs |

| Graphite saizi inoshanduka | -10 ~ -20um |

| Coating ukobvu | ≥20um yakajairika kukosha (35um+10um) |

Zviri pamusoro apa ndiwo maitiro akajairika.