Zvakanakira

High tembiricha oxidation kuramba

Yakanakisa Corrosion resistance

Zvakanaka Abrasion kuramba

High coefficient yekupisa conductivity

Self-lubricity, low density

High kuoma

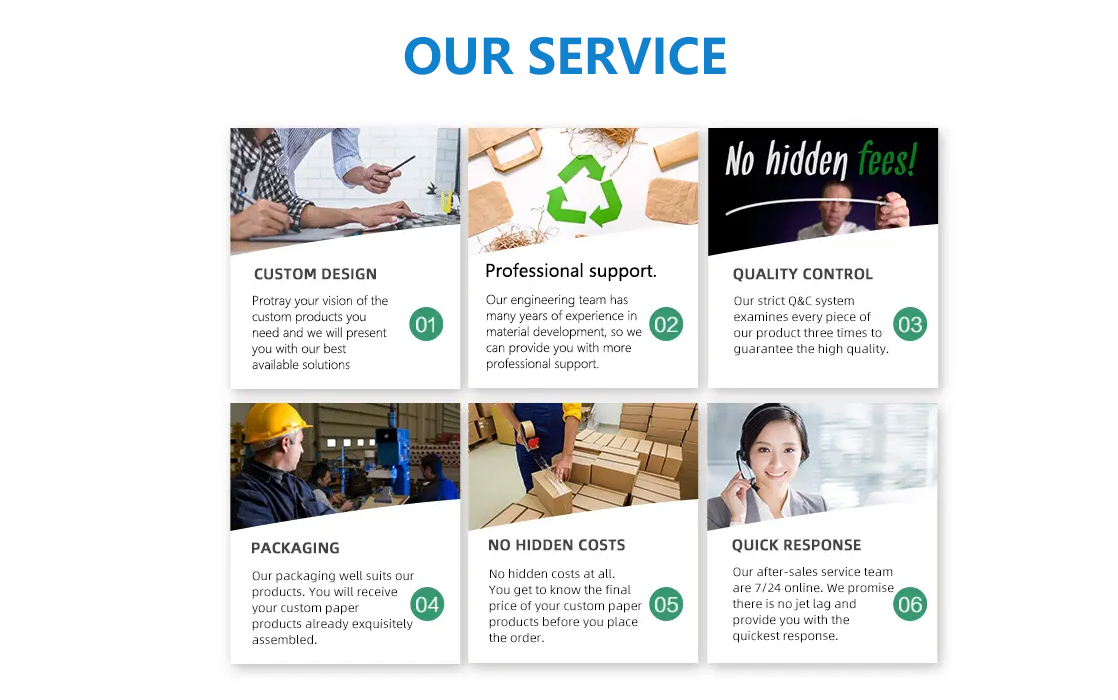

Customized dhizaini.

Applications

-Kupfeka-inodzivirira Munda: gwenzi, ndiro, jecha rinoputika nozzle, dutu remhepo, dhiramu rekukuya, nezvimwe ...

-Yakakwira Temperature Munda: siC Slab, Kudzima Tube Furnace, Radiant Tube, crucible, Heating Element, Roller, Beam, Heat Exchanger, Cold Air Pipe, Burner Nozzle, Thermocouple Dziviriro Tube, SiC chikepe, Kiln Car Structure, Setter, zvichingodaro.

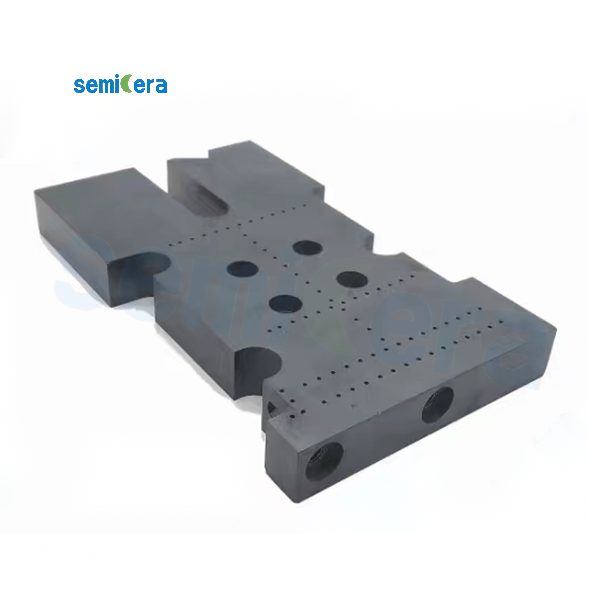

-Silicon Carbide Semiconductor: SiC wafer chikepe, sic chuck, sic paddle, sic kaseti, sic diffusion chubhu, wafer fork, suction ndiro, gwara, zvichingodaro.

-Silicon Carbide Seal Munda: marudzi ese ekuisa chisimbiso mhete, kutakura, bushing, nezvimwe.

-Photovoltaic Munda: Cantilever Paddle, Grinding Barrel, Silicon Carbide Roller, nezvimwewo.

-Lithium Battery Field

Zvenyama Zvimiro zveSiC

| Property | Value | Nzira |

| Density | 3.21 g/cc | Sink-float uye dimension |

| Kupisa chaiko | 0.66 J/g °K | Pulsed laser flash |

| Flexural simba | 450 MPa560 MPa | 4 point bend, RT4 point bend, 1300° |

| Kutsemuka kuomarara | 2.94 MPa m1/2 | Microindentation |

| Kuoma | 2800 | Vicker's, 500g mutoro |

| Elastic ModulusYoung's Modulus | 450 GPA430 GPA | 4 pt bend, RT4 pt bend, 1300 °C |

| Saizi yezviyo | 2 – 10 µm | SEM |

Thermal Properties yeSiC

| Thermal Conductivity | 250 W/m °K | Laser flash nzira, RT |

| Kuwedzera kweThermal (CTE) | 4.5 x 10-6 °K | Tembiricha yemumba kusvika 950 °C, silica dilatometer |

Technical Parameters

| Item | Unit | Data | ||||

| RBSiC(SiSiC) | NBSiC | SSiC | RSiC | OSiC | ||

| SiC content | % | 85 | 75 | 99 | 99.9 | ≥99 |

| Yemahara silicon yemukati | % | 15 | 0 | 0 | 0 | 0 |

| Max sevhisi tembiricha | ℃ | 1380 | 1450 | 1650 | 1620 | 1400 |

| Density | g/cm3 | 3.02 | 2.75-2.85 | 3.08-3.16 | 2.65-2.75 | 2.75-2.85 |

| Open porosity | % | 0 | 13-15 | 0 | 15-18 | 7-8 |

| Kupeta simba 20 ℃ | Мpa | 250 | 160 | 380 | 100 | / |

| Kupeta simba 1200 ℃ | Мpa | 280 | 180 | 400 | 120 | / |

| Modulus ye elasticity 20 ℃ | Gpa | 330 | 580 | 420 | 240 | / |

| Modulus ye elasticity 1200 ℃ | Gpa | 300 | / | / | 200 | / |

| Thermal conductivity 1200 ℃ | W/mK | 45 | 19.6 | 100-120 | 36.6 | / |

| Coefficient yekuwedzera kwekushisa | K-1X10-6 | 4.5 | 4.7 | 4.1 | 4.69 | / |

| HV | Kg/mm2 | 2115 | / | 2800 | / | / |

Iyo CVD silicon carbide coating pamusoro pekunze kweiyo recrystallized silicon carbide ceramic zvigadzirwa zvinogona kusvika pakuchena kweinopfuura 99.9999% kusangana nezvinodiwa nevatengi muindasitiri yesemiconductor.