MEMS Kugadzirisa - Kusunga: Kunyorera uye Kuita muSemiconductor Indasitiri, Semicera Yakagadzirirwa Sevhisi.

Mumaindasitiri emicroelectronics uye semiconductor, tekinoroji yeMEMS (micro-electromechanical systems) yave imwe yetekinoroji yakakosha inotyaira hunyanzvi uye hunyanzvi hwekuita. Nekufambira mberi kwesainzi uye tekinoroji, tekinoroji yeMEMS yakashandiswa zvakanyanya mumasensa, majekiseni, michina yemaziso, michina yekurapa, zvemagetsi zvemotokari uye mamwe minda, uye zvishoma nezvishoma yave chikamu chakakosha chehunyanzvi hwazvino. Muminda iyi, nzira yekubatanidza (Bonding), senhanho yakakosha mukugadzirisa kweMEMS, inoita basa rakakosha mukuita uye kuvimbika kwechigadzirwa.

Bonding inyanzvi inobatanidza zvakasimba zvinhu zviviri kana kupfuura nenzira yepanyama kana yemakemikari. Kazhinji, zvidimbu zvakasiyana zvezvinhu zvinoda kubatanidzwa nekubatana muMEMS zvishandiso kuti uwane kutendeseka kwechimiro uye kushanda kwekuita. Muchigadzirwa chekugadzira michina yeMEMS, kusungirirwa hakusi nzira yekubatanidza chete, asiwo inobata zvakananga kugadzikana kwekupisa, simba remagetsi, kushanda kwemagetsi nezvimwe zvinhu zvechigadzirwa.

Mune yakakwirira-chaiyo MEMS kugadzirisa, bonding tekinoroji inoda kuve nechokwadi chekubatana kwepedyo pakati pezvinhu uku uchidzivirira chero hurema hunokanganisa kushanda kwechishandiso. Naizvozvo, kunyatso kudzora maitiro ekubatanidza uye emhando yepamusoro yekubatanidza zvinhu zvinhu zvakakosha kuti uve nechokwadi chekuti chigadzirwa chekupedzisira chinosangana nezviyero zveindasitiri.

MEMS bonding applications mune semiconductor indasitiri

Muindasitiri yesemiconductor, tekinoroji yeMEMS inoshandiswa zvakanyanya mukugadzirwa kwemidziyo midiki senge ma sensors, accelerometers, pressure sensors, uye gyroscopes. Nekuwedzera kuri kuita kudiwa kwezvinhu zvidiki, zvakabatanidzwa, uye zvine hungwaru, iko kurongeka uye kuita zvinodiwa zveMEMS zvishandiso zviri kuwedzerawo. Mumashandisirwo aya, tekinoroji yekubatanidza inoshandiswa kubatanidza zvinhu zvakasiyana senge silicon wafers, girazi, simbi, uye mapolymers kuita mabasa anoshanda uye akagadzikana.

1. Pressure sensors uye accelerometers

Muminda yemotokari, aerospace, zvemagetsi zvevatengi, nezvimwewo, MEMS pressure sensors uye accelerometers anoshandiswa zvakanyanya mukuyera uye kutonga masisitimu. Iyo yekubatanidza maitiro inoshandiswa kubatanidza silicon machipisi uye sensor zvinhu kuti ive nechokwadi chepamusoro senitivity uye kunyatsoita. Aya masensa anofanirwa kukwanisa kumira zvakanyanya kwezvakatipoteredza, uye emhando yepamusoro-bonding maitiro anogona kudzivirira zvinobudirira zvinhu kubva pakubvisa kana kusashanda nekuda kwekushanduka kwekushisa.

2. Micro-optical devices uye MEMS optical switches

Mumunda we optical communications uye laser madivayiri, MEMS optical zvishandiso uye optical switches inoita basa rakakosha. Bonding tekinoroji inoshandiswa kuwana chaiyo kubatana pakati pesilicon-based MEMS zvishandiso uye zvinhu zvakaita seoptical fibers uye magirazi kuve nechokwadi chekushanda uye kugadzikana kweiyo optical chiratidzo chekufambisa. Kunyanya mumashandisirwo ane yakakwirira frequency, yakafara bandwidth uye kureba-kufambiswa kutapurirana, yakakwirira-inoshanda bonding tekinoroji yakakosha.

3. MEMS gyroscopes uye inertial sensors

MEMS gyroscopes uye inertial sensors anoshandiswa zvakanyanya kunyatso kufambisa uye chinzvimbo mumaindasitiri ekupedzisira akadai sekutyaira akazvimirira, marobhoti, uye aerospace. High-chaiyo bonding maitiro anogona kuvimbisa kuvimbika kwemidziyo uye kudzivirira kuderedzwa kwekuita kana kutadza panguva yekushanda kwenguva refu kana kushanda kwepamusoro-frequency.

Kukosha kwekuita zvinodiwa zve bonding tekinoroji muMEMS kugadzirisa

Mukugadzirisa kweMEMS, kunaka kwehutano hwekubatanidza kunogadzirisa zvakananga kushanda, hupenyu uye kugadzikana kwechigadzirwa. Kuti uve nechokwadi chekuti zvishandiso zveMEMS zvinogona kushanda zvakavimbika kwenguva yakareba mumamiriro akasiyana ekushandisa, tekinoroji yekubatanidza inofanirwa kuve neinotevera yakakosha kuita:

1. Kugadzikana kwepamusoro kwekushisa

Nzvimbo zhinji dzekushandisa muindasitiri yesemiconductor dzine tembiricha yakakwira, kunyanya muminda yemotokari, aerospace, etc. Kugadzikana kwekupisa kwechinhu chinosungirirwa kwakakosha uye kunogona kutsungirira shanduko yekushisa pasina kuderedzwa kana kutadza.

2. High kupfeka resistance

Zvishandiso zveMEMS zvinowanzo sanganisira zvimiro zvemichini, uye kupokana kwenguva refu uye kufamba kunogona kukonzera kupera kwezvikamu zvekubatanidza. Iyo yekubatanidza zvinhu inoda kuve yakanakisa kupfeka kuramba kuve nechokwadi kugadzikana uye kugona kwechigadzirwa mukushandisa kwenguva refu.

3. Kuchena kwepamusoro

Iyo semiconductor indasitiri ine zvakaomesesa zvinodiwa pakuchena kwezvinhu. Chero chidiki chinosvibisa chinogona kukonzera kutadza kwechishandiso kana kuderedzwa kwekuita. Naizvozvo, zvinhu zvinoshandiswa mukugadzirisa kwekubatanidza zvinofanirwa kuve nekuchena kwakanyanya kuti ive nechokwadi chekuti mudziyo haukanganiswe nekusvibiswa kwekunze panguva yekushanda.

4. Kunyatsobatana kwechokwadi

MEMS zvishandiso zvinowanzoda micron-level kana kunyange nanometer-level kugadzirisa kurongeka. Iyo yekubatanidza maitiro inofanirwa kuve nechokwadi cheiyo chaiyo docking yega rega rezvinhu kuti ive nechokwadi chekuti kushanda uye kuita kwechishandiso hakukanganiswe.

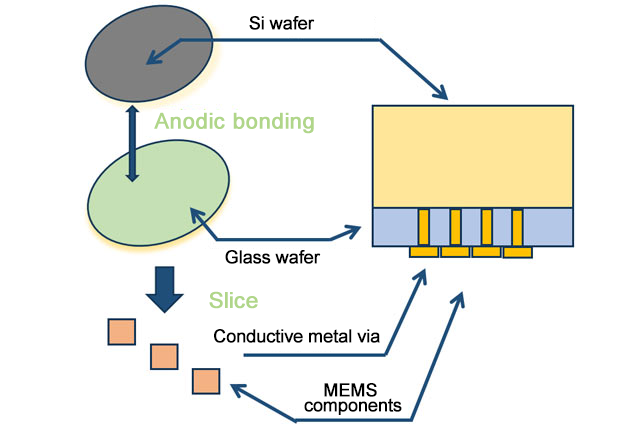

Anodic bonding

Anodic bonding:

● Inoshanda pakubatana pakati pesilicon wafers negirazi, simbi negirazi, semiconductor uye alloy, uye semiconductor negirazi.

Eutectoid bonding:

● Inoshandiswa kune zvinhu zvakadai sePbSn, AuSn, CuSn, uye AuSi

Glue bonding:

● Shandisa glue yakakosha yekubatanidza, yakakodzera kune zvakakosha kubatanidza glues seAZ4620 uye SU8

● Inoshanda kune 4-inch uye 6-inch

Semicera Tsika Bonding Service

Semupi anotungamira muindasitiri weMEMS kugadzirisa mhinduro, Semicera yakazvipira kupa vatengi nepamusoro-chaiyo, yakakwirira-yakagadzikana customized bonding masevhisi. Tekinoroji yedu yekubatanidza inogona kushandiswa zvakanyanya mukubatana kwezvinhu zvakasiyana, zvinosanganisira silicon, girazi, simbi, ceramics, nezvimwe, zvichipa mhinduro nyowani dzepamusoro-magumo maapplication muminda semiconductor neMEMS.

Semicera ine michina yekugadzira yepamusoro uye zvikwata zvehunyanzvi, uye inogona kupa yakagadziridzwa zvisungo zvisungo zvinoenderana nezvinodiwa chaizvo nevatengi. Kunyangwe iri yakavimbika yekubatanidza pasi petembiricha yepamusoro uye yakanyanya kudzvanywa nharaunda, kana chaiyo micro-chishandiso bonding, Semicera inogona kusangana neyakaomesesa dhizaini zvinodiwa kuti ive nechokwadi chekuti chigadzirwa chega chega chinogona kusangana nemhando yepamusoro zviyero.

Tsika yedu yekubatanidza sevhisi haina kuganhurirwa kune yakajairwa bonding maitiro, asi zvakare inosanganisira simbi yekubatanidza, thermal compression bonding, adhesive bonding uye mamwe maitiro, ayo anogona kupa nyanzvi yehunyanzvi rutsigiro rwezvinhu zvakasiyana, zvimiro uye zvinodiwa zvekushandisa. Uye zvakare, Semicera inogona zvakare kupa vatengi-yakazara-sevhisi kubva kuprototype kusimudzira kusvika pakugadzirwa kwakawanda kuti ive nechokwadi chekuti zvese zvinodikanwa zvetekinoroji zvevatengi zvinogona kuzadziswa nemazvo.