Semiconductor magetsi emagetsi anotora nzvimbo yakakosha mumagetsi emagetsi masisitimu, kunyanya mumamiriro ekukurumidza kuvandudza matekinoroji akadai sehungwaru hwekugadzira, kutaurirana kwe5G uye mota nyowani dzemagetsi, zvinodiwa zvekushanda kwavari zvakagadziridzwa.

Silicon carbide(4H-SiC) yave chinhu chakanakira kugadzira yakakwirira-inoshanda semiconductor magetsi maturusi nekuda kweyakanakira yayo seyakafara bandgap, yakakwira yekupisa conductivity, yakakwira kuparara kwemunda simba, yakakwirira saturation drift rate, kugadzikana kwekemikari uye neradiation kuramba. Nekudaro, 4H-SiC ine kuomarara kwakanyanya, brittleness yakakwira, inertness yakasimba yemakemikari, uye kuoma kwekugadzirisa kwakanyanya. Hunhu hwepamusoro hweiyo substrate wafer hwakakosha kune hombe-chikuru mashandisirwo emidziyo.

Naizvozvo, kuvandudza kunaka kwe4H-SiC substrate wafers, kunyanya kubvisa yakakanganisika layer pane wafer processing surface, ndiyo kiyi yekubudirira, yakaderera-kurasikirwa uye yepamusoro 4H-SiC substrate wafer processing.

Kuedza

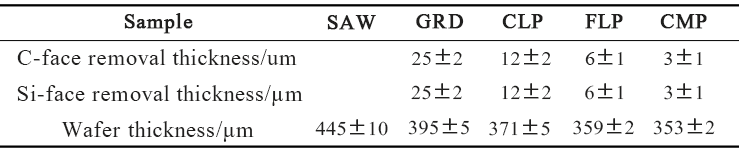

Chiyedzo chinoshandisa 4-inch N-mhando 4H-SiC ingot inokura nenzira yekufambisa mhute, iyo inogadziriswa kuburikidza nekucheka waya, kugaya, kugaya, kugaya zvakanaka uye kupukuta, uye inorekodha kubviswa ukobvu kweiyo C pamusoro uye Si pamusoro. uye yekupedzisira wafer ukobvu mune yega yega maitiro.

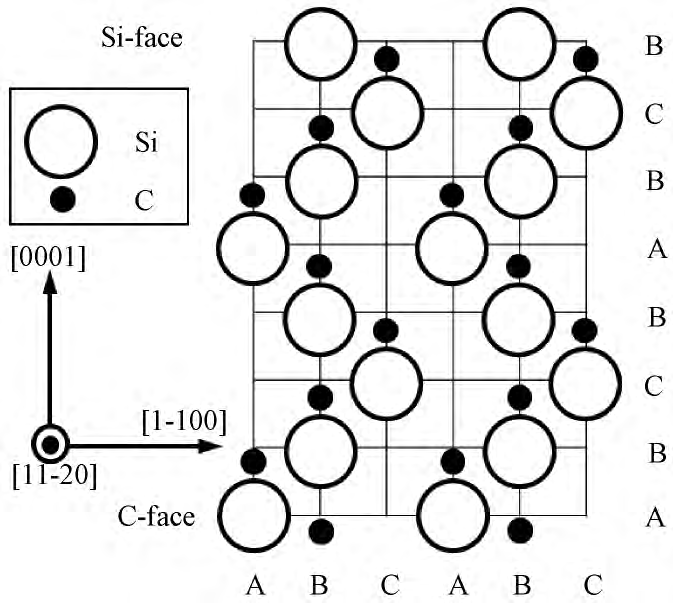

Mufananidzo 1 Schematic diagram ye4H-SiC crystal structure

Mufananidzo 2 Hukobvu hwakabviswa kubva kuC-side uye Si-divi re4H-SiC wafermushure mematanho akasiyana ekugadzirisa uye ukobvu hwewafer mushure mekugadzirisa

The gobvu, pamusoro morphology, roughness uye mechanical zvimiro zvewafer zvainyatsoratidzwa newafer geometry parameter tester, differential interference microscope, atomic force microscope, pamusoro roughness yekuyeresa chiridzwa uye nanoindenter. Pamusoro pezvo, yakakwirira-resolution X-ray diffractometer yakashandiswa kuongorora mhando yekristaro yewafer.

Aya nhanho dzekuedza uye nzira dzekuyedza dzinopa yakadzama tekinoroji rutsigiro rwekudzidza chiyero chekubvisa zvinhu uye mhando yepamusoro panguva yekugadziriswa kwe4H-SiC wafers.

Kuburikidza nemiedzo, vaongorori vakaongorora shanduko muyero yekubvisa zvinhu (MRR), morphology yepasi uye kushata, pamwe nemagetsi zvivakwa uye kristaro mhando ye4H-.SiC wafersmumatanho akasiyana-siyana ekugadzirisa (waya kutema, kukuya, kukuya, kukuya, kupukuta).

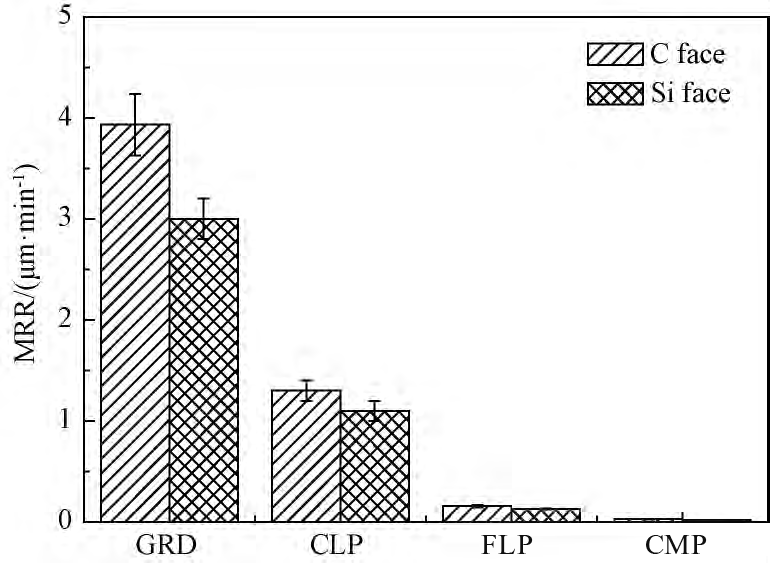

Mufananidzo 3 Material kubviswa mwero weC-chiso uye Si-chiso che4H-SiC wafermumatanho akasiyana ekugadzirisa

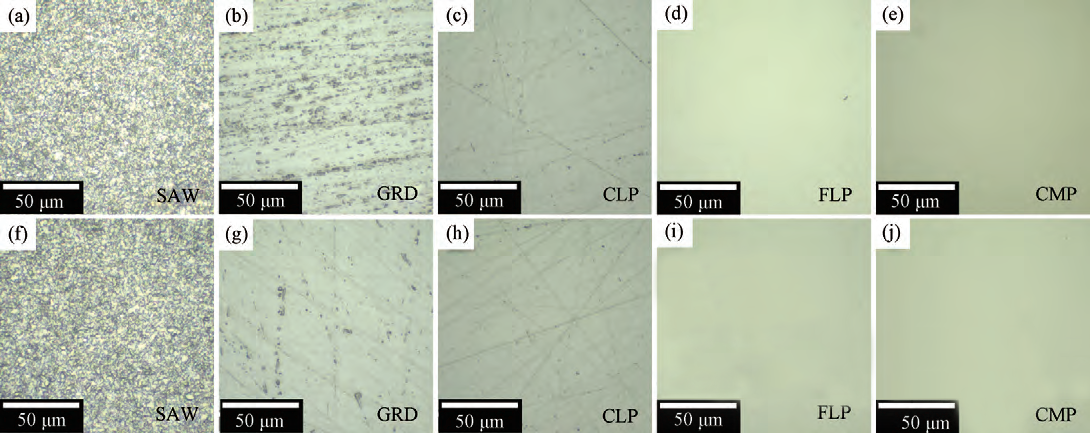

Chidzidzo chacho chakawana kuti nekuda kwe anisotropy ye mechanical properties yezviso zvakasiyana-siyana zvekristal zve 4H-SiC, pane kusiyana kweMRR pakati peC-face neSi-face pasi pemaitiro akafanana, uye MRR yeC-chiso yakakwirira zvikuru kupfuura iyo yaSi-face. Nekufambira mberi kwematanho ekugadzirisa, iyo yepamusoro morphology uye kushata kwe4H-SiC wafers inogadziridzwa zvishoma nezvishoma. Mushure mekupenya, Ra yeC-chiso ndeye 0.24nm, uye Ra yeSi-face inosvika 0.14nm, iyo inogona kusangana nezvinodiwa zve epitaxial kukura.

Mufananidzo 4 Optical microscope mifananidzo yeC pamusoro (a~e) uye Si pamusoro (f~j) ye4H-SiC wafer mushure mekugadzirisa matanho akasiyana.

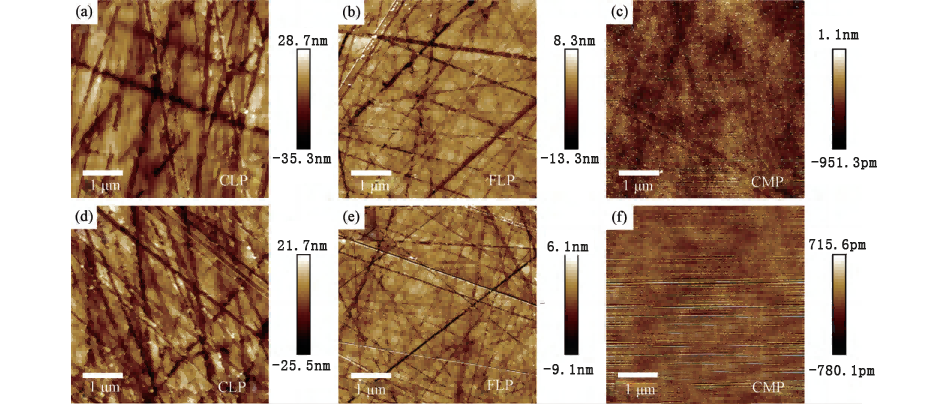

Mufananidzo 5 Atomic simba microscope mifananidzo yeC pamusoro (a~c) uye Si pamusoro (d~f) ye4H-SiC wafer mushure meCLP, FLP uye CMP kugadzirisa matanho.

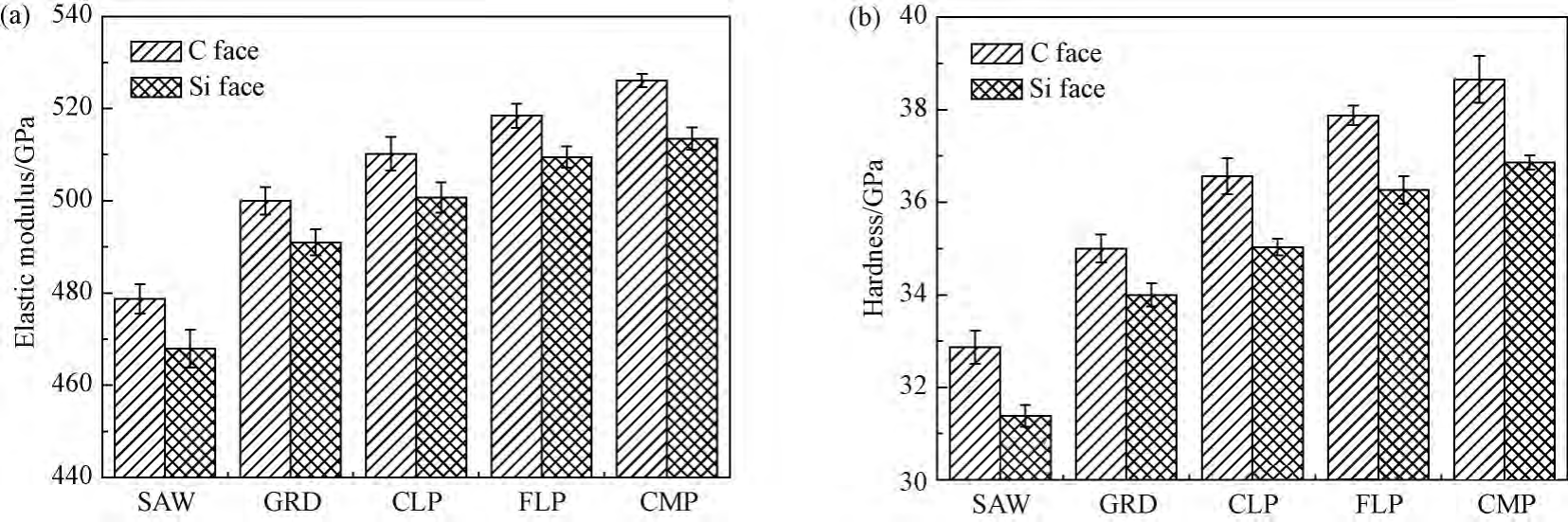

Mufananidzo 6 (a) elastic modulus uye (b) kuoma kweiyo C pamusoro uye Si pamusoro pe4H-SiC wafer mushure mematanho ekugadzirisa akasiyana.

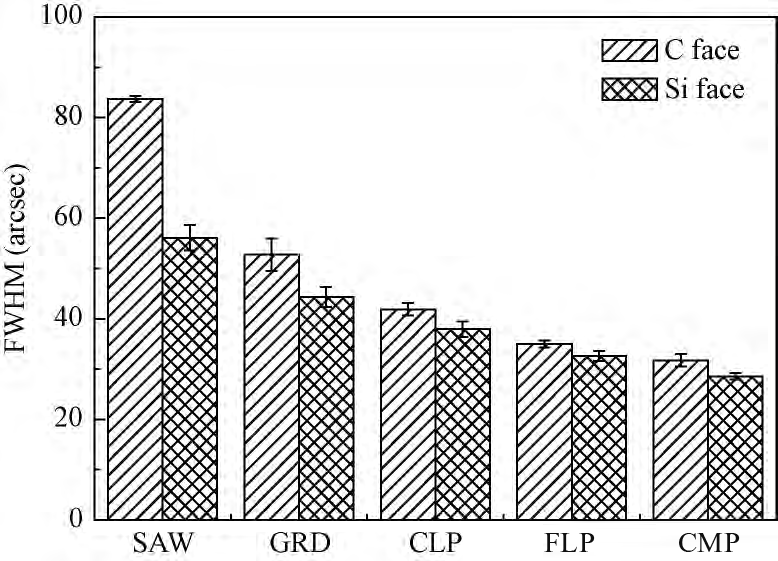

Muyedzo wemidziyo wemuchina unoratidza kuti iyo C pamusoro peiyo wafer ine hurombo hwakaoma kupfuura iyo Si pamusoro zvinhu, yakakura brittle fracture panguva yekugadziriswa, nekukurumidza kubviswa kwezvinhu, uye kushomeka kwepasi morphology uye hutsinye. Kubvisa iyo yakakanganisika layer pane yakagadziriswa nzvimbo ndiyo kiyi yekuvandudza pamusoro pemhando yewafer. Iyo hafu-urefu hupamhi hweiyo 4H-SiC (0004) inozunguza curve inogona kushandiswa intuitively uye nemazvo kuratidza uye kuongorora iyo yekukuvadzwa kwepamusoro denga rewafer.

Mufananidzo 7 (0004) inozunguza curve hafu-yakafara yeC-chiso uye Si-chiso che4H-SiC wafer mushure mekugadzirisa matanho akasiyana.

Mhedzisiro yetsvagiridzo inoratidza kuti iyo yekukuvadzwa kwepamusoro yewafer inogona kubviswa zvishoma nezvishoma mushure me4H-SiC wafer processing, iyo inovandudza kunaka kwepamusoro peiyo wafer uye inopa tekinoroji yehunyanzvi hwepamusoro, kurasikirwa-kurasikirwa uye kwemhando yepamusoro kugadzirisa. ye4H-SiC substrate wafers.

Vatsvakurudzi vakagadzira 4H-SiC wafers kuburikidza nematanho akasiyana ekugadzirisa akadai sekucheka waya, kugaya, kugaya, kukuya uye kupukuta, uye vakadzidza migumisiro yemaitiro aya pamusoro pemhando yewafer.

Mhedzisiro yacho inoratidza kuti nekufambira mberi kwematanho ekugadzirisa, iyo yepamusoro morphology uye roughness yewafer inogadziridzwa zvishoma nezvishoma. Mushure mekupenya, kushata kweC-face uye Si-face kunosvika 0.24nm uye 0.14nm zvichiteerana, izvo zvinosangana nezvinodiwa zveepitaxial kukura. Iyo C-chiso chewafer ine hurombo hwakaoma kupfuura iyo Si-face zvinhu, uye inowanzoita brittle kutyoka panguva yekugadziriswa, zvichikonzera kushomeka kwepamusoro morphology uye roughness. Kubvisa iyo yekukuvadzwa kwepamusoro peiyo yakagadziriswa nzvimbo ndiyo kiyi yekuvandudza kunaka kweiyo wafer. Iyo hafu-yakafara ye4H-SiC (0004) inozunguza curve inogona intuitively uye nemazvo kuratidzira pamusoro pekukuvadzwa kwepamusoro kwewafer.

Tsvagiridzo inoratidza kuti iyo yakakanganisika layer iri pamusoro pe4H-SiC wafers inogona kubviswa zvishoma nezvishoma kuburikidza ne4H-SiC wafer processing, zvinobudirira kuvandudza pamusoro pemhando yewafer, ichipa tekinoroji yehunyanzvi hwepamusoro-kushanda, kuderera-kurasikirwa, uye yakakwirira-. kugadzirisa kwemhando ye4H-SiC substrate wafers.

Nguva yekutumira: Jul-08-2024