Iyo thermal oxide layer yesilicon wafer ndeye oxide layer kana silica layer yakaumbwa pamusoro penzvimbo isina chinhu yesilicon wafer pasi pekushisa kwepamusoro mamiriro ane oxidizing agent.Iyo thermal oxide layer yesilicon wafer inowanzokura muhorizontal chubhu choto, uye tembiricha yekukura inowanzosvika 900 ° C ~ 1200 ° C, uye kune nzira mbiri dzekukura dze "wet oxidation" uye "dry oxidation". Thermal oxide layer "yakakura" oxide layer ine yakakwirira homogeneity uye yakakwirira dielectric simba pane iyo CVD yakaiswa oxide layer. Iyo thermal oxide layer ndeye yakanakisa dielectric layer se insulator. Mune akawanda silicon-yakavakirwa zvishandiso, iyo thermal oxide layer inoita basa rakakosha sedoping inovharira layer uye pamusoro dielectric.

Mazano: Oxidation mhando

1. Dry oxidation

Iyo silicon inopindirana neokisijeni, uye iyo oxide layer inofamba ichienda kune basal layer. Dry oxidation inoda kuitwa patembiricha ye850 kusvika 1200 ° C, uye chiyero chekukura chakaderera, chinogona kushandiswa kuMOS insulation gedhi kukura. Kana yemhando yepamusoro, yekupedzisira-yakaonda silicon oxide layer ichidikanwa, yakaoma oxidation inosarudzwa pane kunyorova oxidation.

Dry oxidation simba: 15nm ~ 300nm (150A ~ 3000A)

2. Wet oxidation

Iyi nzira inoshandisa musanganiswa wehydrogen uye high-purity oxygen kupisa pa ~ 1000 ° C, zvichiita kuti ibudise mhute yemvura kuumba oxide layer. Kunyangwe kunyorova oxidation haigone kuburitsa seyemhando yepamusoro oxidation layer seyakaoma oxidation, asi yakakwana kuti ishandiswe seyandoga zone, zvichienzaniswa nekuoma oxidation ine mukana wakajeka ndeyekuti ine yakakura kukura mwero.

Wet oxidation kugona: 50nm~ 15µm (500A ~15µm)

3. Dry method - wet method - yakaoma nzira

Nenzira iyi, yakachena yakaoma okisijeni inoburitswa muchoto cheoxidation padanho rekutanga, hydrogen inowedzerwa pakati peiyo oxidation, uye hydrogen inochengetwa mumagumo kuti ienderere mberi neiyo oxidation neiyo yakachena yakaoma okisijeni kuti iite denser oxidation chimiro kupfuura. iyo yakajairika wet oxidation process muchimiro chemvura chiutsi.

4. TEOS oxidation

| Oxidation Technique | Kunyorova oxidation kana Dry oxidation |

| Diameter | 2″ / 3″ / 4″ / 6″ / 8″ / 12″ |

| Oxide Ukobvu | 100 Å ~ 15µm |

| Kushivirira | +/- 5% |

| Surface | Single Side Oxidation (SSO) / Kaviri Sides Oxidation (DSO) |

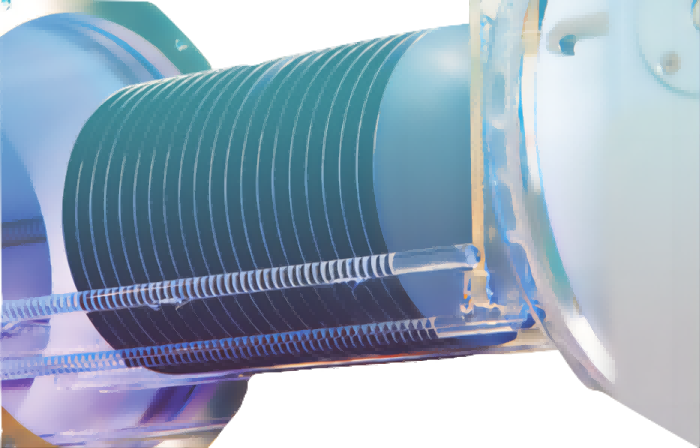

| Furnace | Horizontal chubhu choto |

| Gasi | Hydrogen uye Oxygen gasi |

| Tembiricha | 900 ℃ ~ 1200 ℃ |

| Refractive index | 1.456 |