Tantalum carbide (TaC)ndeyepamusoro-yepamusoro tembiricha inodzivirira ceramic zvinhu zvine zvakanakira zvekunyunguduka kwakakwira, kuomarara kwepamusoro, kugadzikana kwakanaka kwemakemikari, magetsi akasimba uye ekupisa kwemafuta, nezvimwewo.TaC coatinginogona kushandiswa seablation-resistant coating, oxidation-resistant coating, uye kupfeka-resistant coating, uye inoshandiswa zvakanyanya mumhepo inodzivirira kupisa kwemhepo, chizvarwa chechitatu semiconductor single crystal kukura, magetsi emagetsi uye mamwe minda.

Maitiro:

Tantalum carbide (TaC)imhando yemhando yepamusoro-yepamusoro inodzivirira tembiricha ye ceramic zvinhu zvine zvakanakira zvekunyunguduka kwepamusoro, kuomarara kwepamusoro, kugadzikana kwakanaka kwemakemikari, simba remagetsi uye rinopisa conductivity. Naizvozvo,TaC coatinginogona kushandiswa seablation-resistant coating, oxidation-resistant coating, uye kupfeka-resistant coating, uye inoshandiswa zvakanyanya mumhepo inodzivirira kupisa kwemhepo, chizvarwa chechitatu semiconductor single crystal kukura, magetsi emagetsi uye mamwe minda.

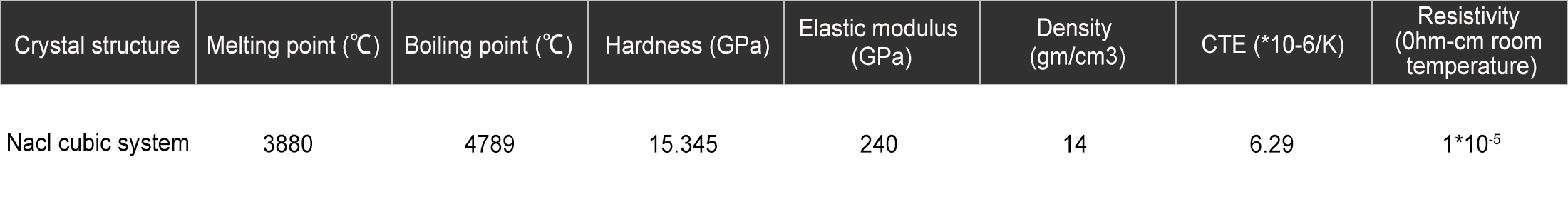

Intrinsic characterization yecoatings:

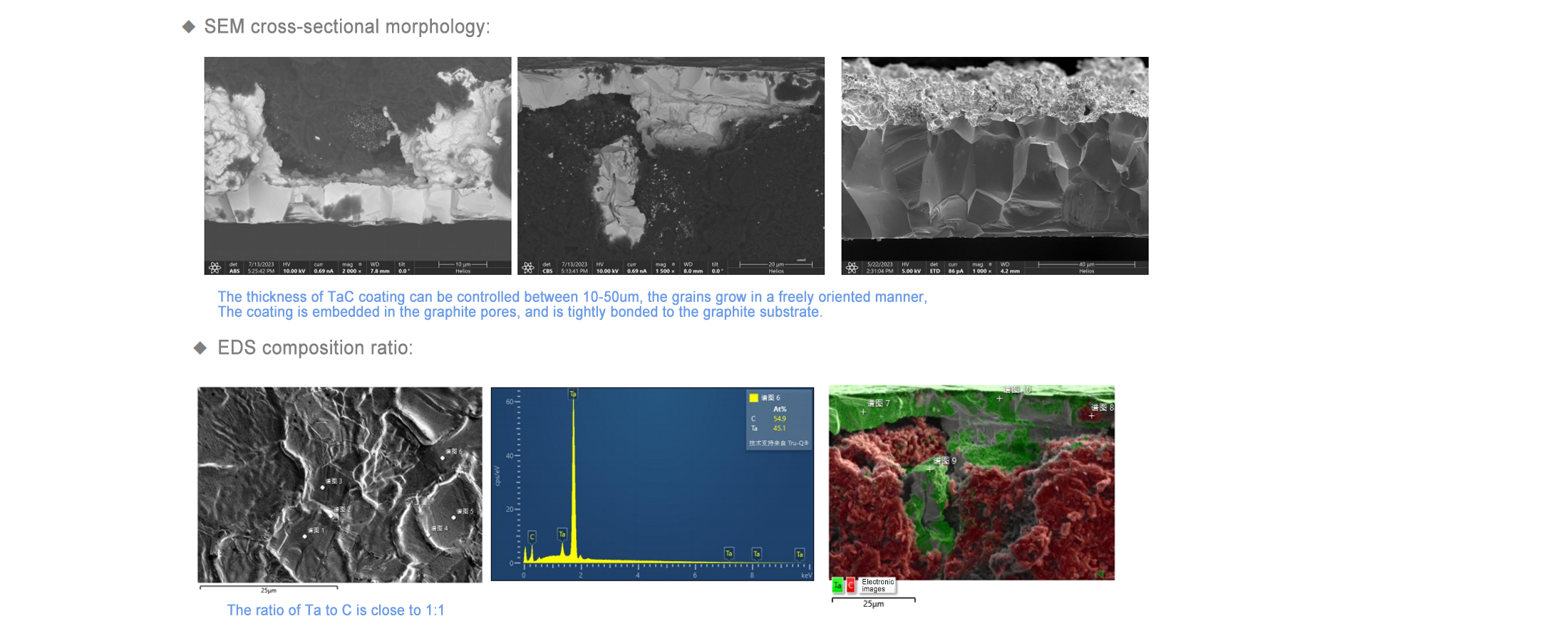

Isu tinoshandisa slurry-sintering nzira yekugadziriraTaC coatingsyehukobvu hwakasiyana pane magraphite substrates ehukuru hwakasiyana. Kutanga, yakakwirira-yakachena poda ine Ta source uye C sosi inogadziriswa ne dispersant uye binder kuti iite yunifomu uye yakagadzikana precursor slurry. Panguva imwecheteyo, maererano nehukuru hwezvikamu zvegraphite uye nehupamhi hunodiwaTaC coating, iyo pre-coating inogadzirirwa nekupfapfaidza, kudurura, kupinza uye mamwe mafomu. Pakupedzisira, inopisa kusvika pamusoro pe2200 ℃ munzvimbo yevacuum kugadzirira yunifomu, yakakora, imwe-chikamu, uye zvakanaka-crystalline.TaC coating.

Intrinsic characterization yecoatings:

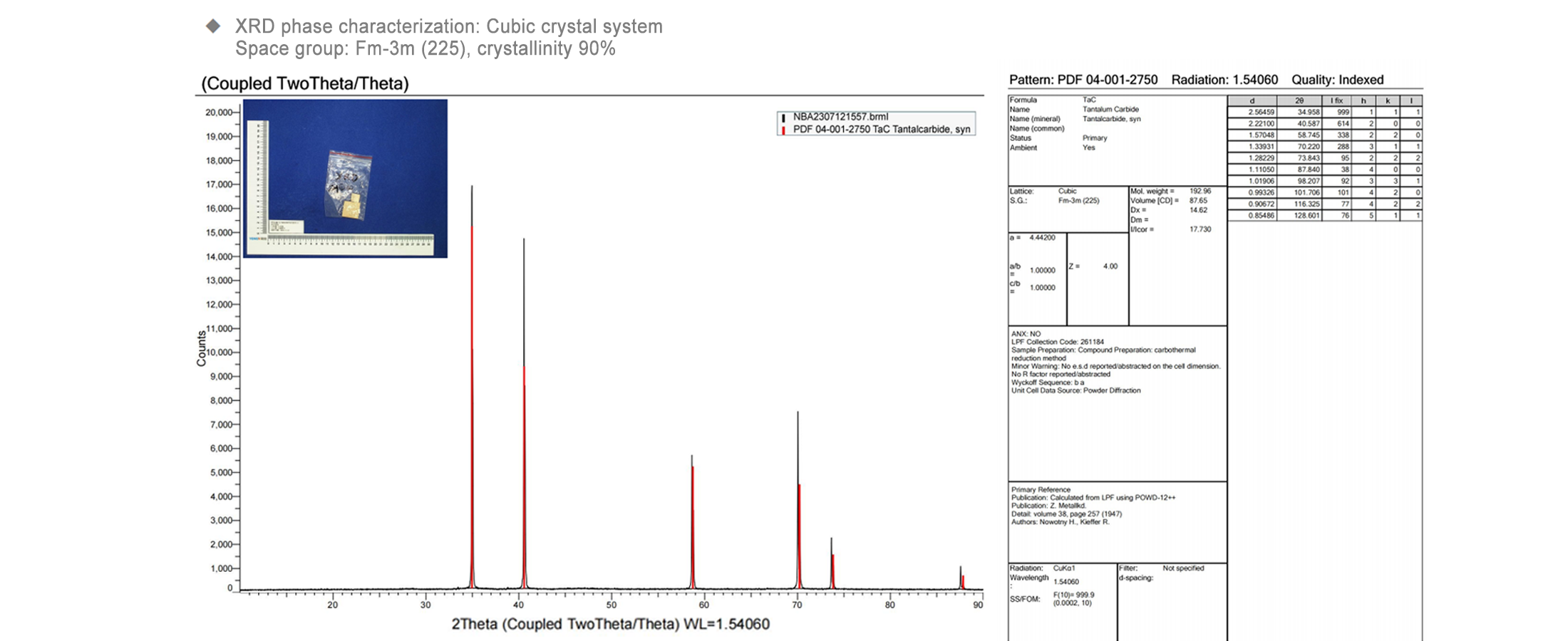

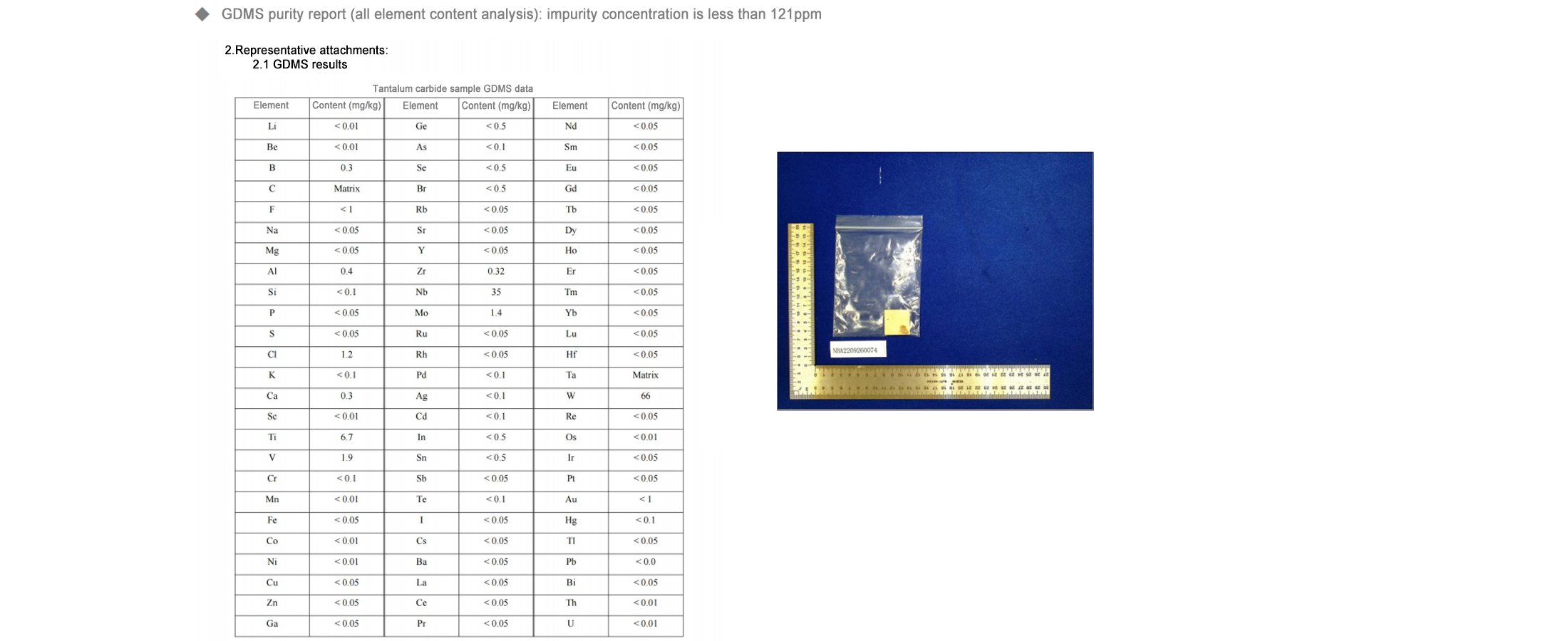

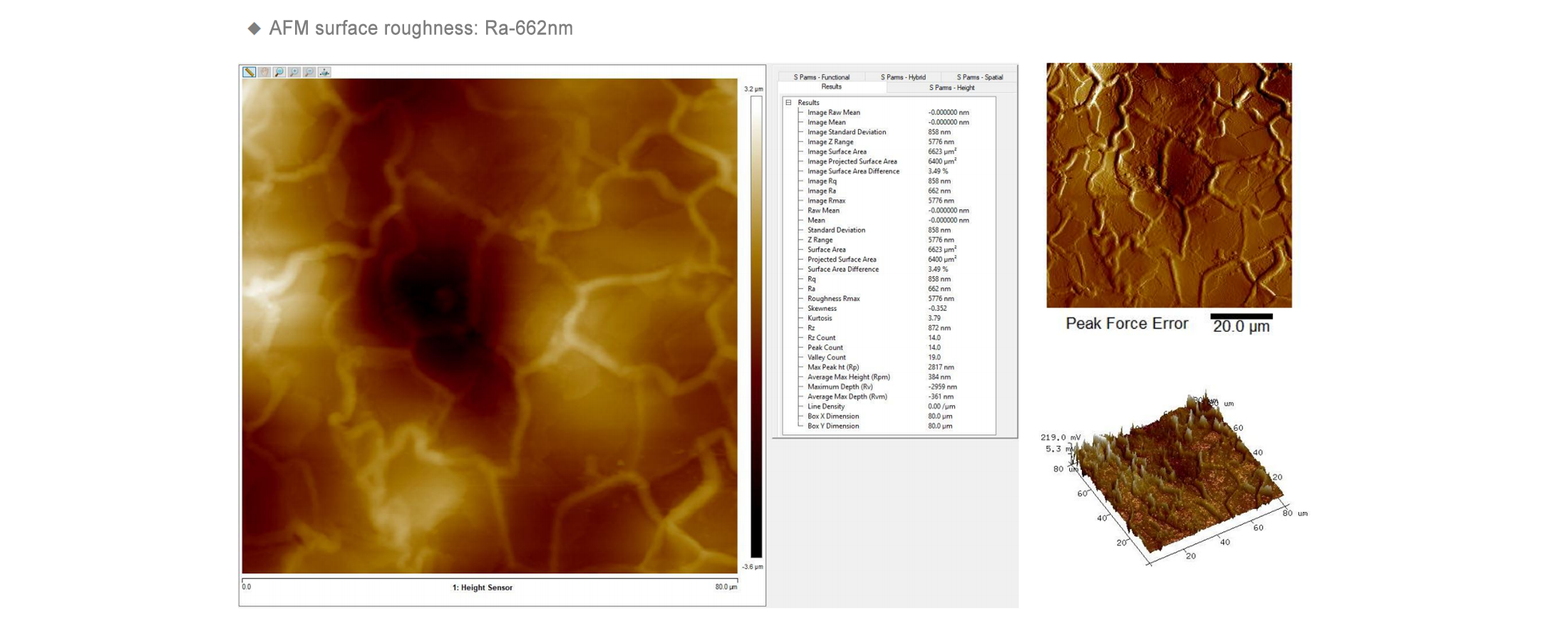

Ukobvu hweTaC coatinginenge 10-50 μm, zviyo zvinokura muhutano hwekusununguka, uye inoumbwa neTaC ine imwe-phase face-centered cubic structure, isina mamwe tsvina; iyo yekuputira yakaoma, chimiro chakakwana, uye crystallinity yakakwirira.TaC coatinginogona kuzadza pores pamusoro pe graphite, uye inosungirirwa nekemikari kune graphite matrix nesimba guru rekubatanidza. Chiyero cheTa kusvika kuC mukuputira chiri pedyo ne1: 1. Iyo GDMS kuchena yekuona referensi chiyero ASTM F1593, iyo yekusachena kusungwa iri pasi pe121ppm. Iyo arithmetic inoreva kutsauka (Ra) yeprofile yekubikira ndeye 662nm.

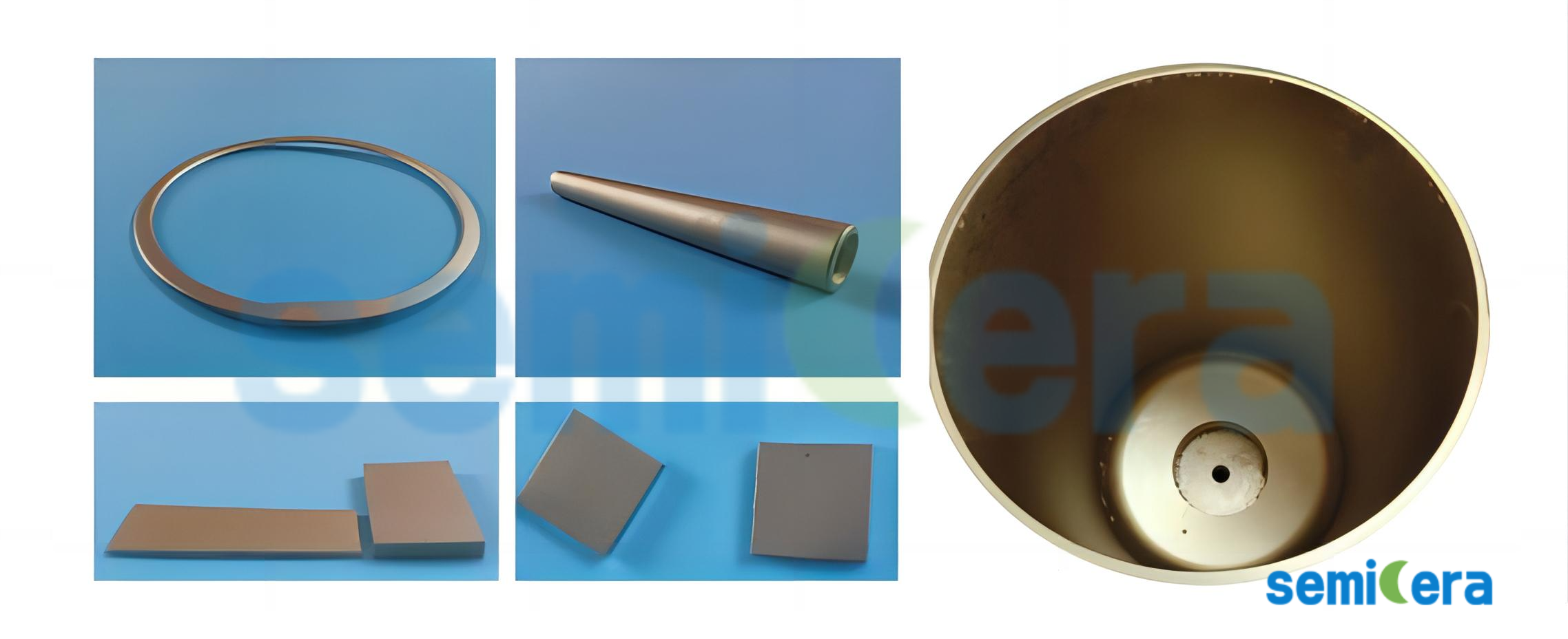

General Applications:

Gan uyeSiC epitaxialCVD reactor components, zvinosanganisira wafer carriers, satellite dish, showerheads, top covers uye susceptors.

SiC, GaN uye AlN makristasi ekukura zvikamu, zvinosanganisira crucibles, mbeu dzekristaro dzinobata, kuyerera madhairekitori uye mafirita.

Zvikamu zveindasitiri, zvinosanganisira resistive kudziyisa zvinhu, nozzles, mhete dzekudzivirira uye zvigadziriso zvebrazing.

Zvinhu zvakakosha:

High tembiricha kugadzikana pa2600 ℃

Inopa kuchengetedzwa kwakadzikama munzvimbo dzakaomarara dzemakemikari eH2, NH3, SiH4uye Si vapor

Inokodzera kugadzirwa kwemazhinji nemapfupi ekugadzira ma cycles.