Parizvino, chizvarwa chechitatu chesemiconductors chinotongwa nesilicon carbide. Mumutengo wekugadzirwa kwemidziyo yayo, iyo substrate inoverengera 47%, uye epitaxy account ye23%. Izvo zviviri pamwe chete zvinoverengera nezve 70%, inova ndiyo inonyanya kukosha chikamu chesilicon carbidemudziyo kugadzira indasitiri cheni.

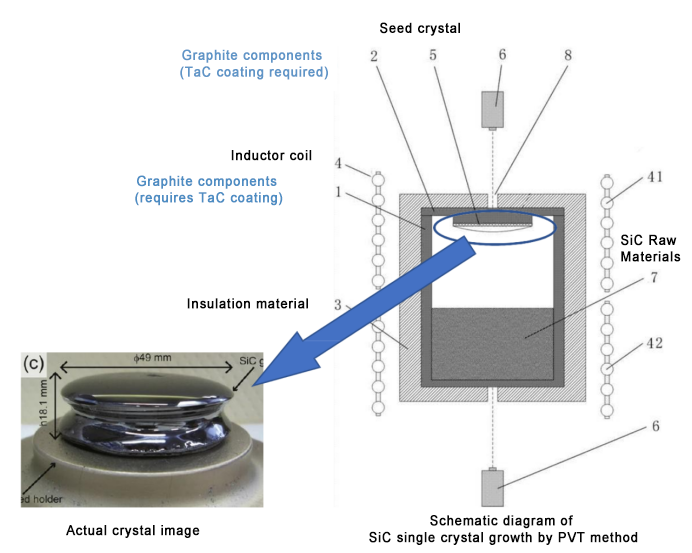

Iyo inowanzoshandiswa nzira yekugadzirirasilicon carbidesingle crystals ndiyo PVT (physical vapor transport) nzira. Nheyo yacho ndeyekugadzira zvigadzirwa munzvimbo yakakwirira yekupisa uye mhodzi yekristaro munzvimbo yakaderera tembiricha. Iyo mbishi pa tembiricha yepamusoro inoora uye yakananga kugadzira gasi chikamu zvinhu pasina mvura chikamu. Izvi zvinhu zvegasi zvechikamu zvinotakurwa kuenda kukristaro yembeu pasi pekutyaira kweaxial tembiricha gradient, uye nucleate uye inokura pakristaro yembeu kuumba silicon carbide imwe kristaro. Parizvino, makambani ekunze akadai seCree, II-VI, SiCrystal, Dow nemakambani epamba akadai seTianyue Advanced, Tianke Heda, uye Century Golden Core ese anoshandisa nzira iyi.

Kune anopfuura mazana maviri emakristaro mafomu esilicon carbide, uye kunyatso kudzora kunodiwa kugadzira iyo inodiwa imwechete yekristaro fomu (iyo huru ndeye 4H crystal fomu). Sekureva kweTianyue Advanced's prospectus, goho rekambani yekristaro mu2018-2020 uye H1 2021 yaive 41%, 38.57%, 50.73% uye 49.90% zvakateerana, uye substrate goho yaive 72.61%, 5, 75% uye 75%. zvichiteerana. Parizvino goho rinokwana 37.7%. Tichitora nzira yePVT semuenzaniso, goho rakaderera rinonyanya kukonzerwa nematambudziko anotevera muSiC substrate kugadzirira:

1. Kuomerwa mukudzora tembiricha yemunda: SiC crystal tsvimbo dzinoda kugadzirwa patembiricha yakakwira ye2500 ℃, nepo makristasi esilicon achingoda 1500 ℃, saka mavira ekristaro akasarudzika anodiwa, uye tembiricha yekukura inoda kudzorwa panguva yekugadzira. , iyo yakaoma zvikuru kudzora.

2. Slow production speed: Kukura kwechinyakare silicon zvinhu 300 mm paawa, asi silicon carbide single crystals inogona chete kukura 400 microns paawa, inova kanenge ka800 mutsauko.

3. Zvido zvepamusoro zvezvigadzirwa zvakanaka zvezvigadzirwa, uye dema bhokisi goho rakaoma kudzora munguva: Izvo zvakakosha zvigadziriso zveSiC wafers zvinosanganisira microtube density, dislocation density, resistivity, warpage, roughness, etc. Munguva yekukura kwekristaro, ndiyo. inodiwa kunyatso kudzora ma paramita akadai sesilicon-kabhoni ratio, kukura tembiricha gradient, kristaro kukura mwero, uye kuyerera kwemhepo. Zvikasadaro, polymorphic inclusions inogona kuitika, zvichikonzera makristasi asina kukodzera. Mubhokisi dema re graphite crucible, hazvibviri kuona chimiro chekukura kwekristaro munguva chaiyo, uye yakanyatso kudziya yekudzora munda, kuenzanisa zvinhu, uye ruzivo kuunganidza kunodiwa.

4. Kuoma mukuwedzera kwekristaro: Pasi pegasi chikamu chekufambisa nzira, teknolojia yekuwedzera yeSiC crystal kukura yakaoma zvikuru. Sezvo saizi yekristaro inowedzera, kuoma kwayo kukura kunowedzera zvakanyanya.

5. Kazhinji goho rakaderera: Goho rakaderera rinonyanya kuumbwa nezvisungo zviviri: (1) Crystal rod goho = semiconductor-grade crystal rod output / (semiconductor-grade crystal rod output + non-semiconductor-grade crystal rod output) × 100%; (2) Substrate goho = inokwanisa substrate kubuda / (yakakodzera substrate kubuda + isina kukwana substrate kubuda) × 100%.

Mukugadzirira kwepamusoro-soro uye kukohwa kwepamusorosilicon carbide substrates, musimboti unoda zvirinani zvinhu zvemunda zvinopisa kuti zvinyatso kudzora tembiricha yekugadzira. Iwo anopisa munda crucible kits anoshandiswa parizvino anonyanya kuchena-kuchena graphite zvimiro zvikamu, izvo zvinoshandiswa kupisa nekunyungudutsa kabhoni poda uye silicon poda uye kuramba ichidziya. Zvigadzirwa zvegraphite zvine hunhu hwesimba rakananga uye chaiyo modulus, yakanaka yekupisa kuvhunduka uye kusaora, asi ine zvakaipira kuve nyore oxidized munzvimbo dzekupisa kweokisijeni, isingamirire ammonia, uye kushomeka kwekudzivirira. Mukuita kwesilicon carbide single crystal kukura uyesilicon carbide epitaxial waferkugadzirwa, zvakaoma kuzadzisa zvinodiwa nevanhu zvinowedzera kuomesera pakushandiswa kwezvinhu zvegraphite, izvo zvinokanganisa zvakanyanya kukura kwayo uye kushanda kwayo. Naizvozvo, machira ekupisa akadai se tantalum carbide atanga kubuda.

2. Hunhu hweTantalum Carbide Coating

TaC ceramic ine nzvimbo yekunyunguduka inosvika 3880 ℃, kuomarara kwepamusoro (Mohs kuomarara 9-10), hombe yekupisa yekupisa (22W · m-1 · K-1), simba rakakura rekukotama (340-400MPa), uye kuwedzera kudiki kwemafuta. coefficient (6.6 × 10−6K-1), uye inoratidza yakanakisa thermochemical kugadzikana uye zvakanakisa zvemuviri zvimiro. Iyo ine yakanaka kuenderana kwemakemikari uye mechanical kuenderana negraphite uye C / C inoumbwa zvinhu. Naizvozvo, TaC coating inoshandiswa zvakanyanya muaerospace yekudzivirira kupisa, kukura kwekristaro imwe chete, magetsi emagetsi, uye michina yekurapa.

TaC-yakavharwagraphite ine makemikari ari nani ekudzivisa kuparara pane isina graphite kana SiC-yakavharwa graphite, inogona kushandiswa zvakadzikama pakupisa kwepamusoro kwe2600 °, uye haibatike nezvinhu zvakawanda zvesimbi. Ndiyo yakanakisa kupfekwa mune yechitatu-chizvarwa semiconductor single crystal kukura uye wafer etching mamiriro. Inogona kuvandudza zvakanyanya kutonga kwekushisa uye kusvibiswa mukugadzirisa uye kugadziriraemhando yepamusoro silicon carbide wafersuye zvinoenderanaepitaxial wafers. Inonyanya kukodzera kukura GaN kana AlN makristasi ega ane MOCVD midziyo uye kukura SiC imwe chete makristasi ane PVT midziyo, uye kunaka kwemakristasi akakura anovandudzwa zvakanyanya.

III. Zvakanakira zveTantalum Carbide Coated Devices

Iko kushandiswa kweTantalum Carbide TaC coating kunogona kugadzirisa dambudziko rekristaro kumucheto kukanganisa uye kunatsiridza mhando yekukura kwekristaro. Ndiyo imwe yeakakosha tekinoroji nzira ye "kukura nekukurumidza, kukura gobvu, uye kukura kureba". Tsvagiridzo yeindasitiri yakaratidzawo kuti Tantalum Carbide Coated Graphite Crucible inogona kuwana yakawedzera kupisa kupisa, nekudaro ichipa yakanakisa maitiro ekutonga kweSiC single crystal kukura, nekudaro ichidzikisa zvakanyanya mukana wekuumbwa kwepolycrystalline kumucheto kweSiC makristasi. Uye zvakare, Tantalum Carbide Graphite Coating ine maviri makuru mabhenefiti:

(I) Kuderedza SiC Defects

Panyaya yekudzora SiC single crystal defects, pane kazhinji nzira nhatu dzakakosha. Pamusoro pekugadzirisa maparamendi ekukura uye emhando yepamusoro sosi zvinhu (senge SiC sosi poda), uchishandisa Tantalum Carbide Coated Graphite Crucible inogonawo kuwana yakanaka crystal mhando.

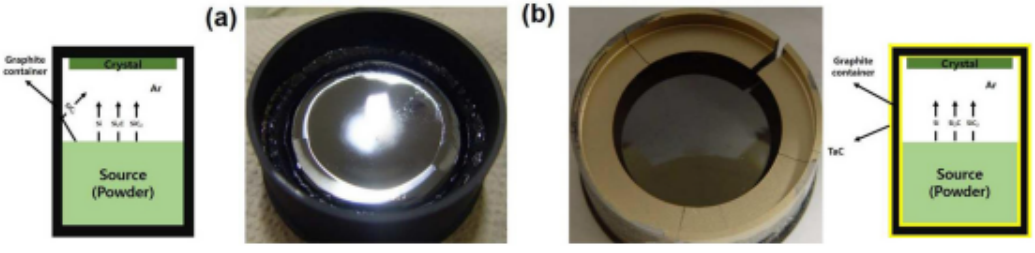

Schematic dhizaini yeyakajairwa graphite crucible (a) uye TAC yakavharwa crucible (b)

Zvinoenderana nekutsvagisa kwakaitwa neYunivhesiti yeEastern Europe muKorea, kusachena kukuru muSiC crystal kukura initrogen, uye tantalum carbide coated graphite crucibles inogona kunyatso kudzikamisa nitrogen kubatanidzwa kweSiC makristasi, nekudaro kuderedza chizvarwa chekuremara senge micropipes nekuvandudza kristaro. quality. Zvidzidzo zvakaratidza kuti pasi pemamiriro akafanana, iyo inotakura mitsetse yeSiC wafers yakakura mune yakajairwa graphite crucibles uye TAC coated crucibles ingangoita 4.5 × 1017 / cm uye 7.6 × 1015 / cm, zvichiteerana.

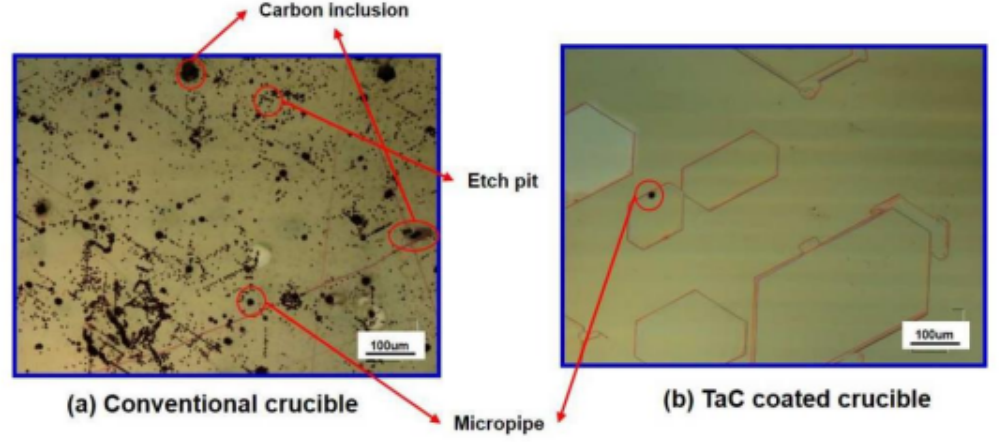

Kuenzanisa kwekuremara muSiC imwe makristasi akakura mune akajairwa graphite crucibles (a) uye TAC coated crucibles (b)

(II) Kuvandudza hupenyu hwema graphite crucibles

Parizvino, mari yeSiC crystals yakaramba yakakwirira, iyo iyo mari ye graphite consumables inotora inenge 30%. Chinokosha pakudzikisa mutengo we graphite consumables ndeyekuwedzera hupenyu hwayo hwebasa. Zvinoenderana nedata kubva kuBritish timu yekutsvagisa, tantalum carbide coatings inogona kuwedzera hupenyu hwebasa rezvikamu zvegraphite ne30-50%. Maererano nekuverenga uku, kungotsiva tantalum carbide coated graphite kunogona kuderedza mutengo weSiC makristasi ne9% -15%.

4. Tantalum carbide coating gadziriro yekugadzirira

TaC yekuputira nzira dzekugadzirira dzinogona kukamurwa muzvikamu zvitatu: yakasimba chikamu nzira, yemvura chikamu nzira uye gasi chikamu nzira. Iyo yakasimba chikamu nzira inonyanya kusanganisira yekudzikisa nzira uye nzira yemakemikari; iyo yemvura chikamu nzira inosanganisira yakanyungudutswa munyu nzira, sol-gel nzira (Sol-Gel), slurry-sintering nzira, plasma spraying nzira; iyo gasi chikamu nzira inosanganisira kemikari vapor deposition (CVD), kemikari vapor infiltration (CVI) uye yemuviri vapor deposition (PVD). Nzira dzakasiyana dzine zvadzo zvakanakira nekuipira. Pakati pavo, CVD inzira yakakura uye yakashandiswa zvakanyanya kugadzirira TaC machira. Nekuenderera mberi nekuvandudzika kwemaitiro, maitiro matsva akadai sewaya inopisa kemikari vapor deposition uye ion beam inobatsira kemikari vapor deposition yakagadziridzwa.

TaC coating yakagadziridzwa kabhoni-yakavakirwa zvinhu zvinonyanya zvinosanganisira graphite, kabhoni faibha, uye kabhoni/carbon inoumbwa zvinhu. Nzira dzekugadzira machira eTaC pagraphite anosanganisira kumwaya plasma, CVD, slurry sintering, nezvimwe.

Zvakanakira nzira yeCVD: Iyo CVD nzira yekugadzira maTaC coatings yakavakirwa patantalum halide (TaX5) setantalum sosi uye hydrocarbon (CnHm) senge kabhoni sosi. Mukati memamwe mamiriro, iwo akaodzwa kuita Ta uye C zvakateerana, uye obva aita mumwe nemumwe kuti awane TaC coatings. Iyo CVD nzira inogona kuitiswa pane yakaderera tembiricha, iyo inogona kudzivirira kukanganisa uye kuderedzwa kwemakanika zvinhu zvinokonzerwa nepamusoro-tembiricha kugadzirira kana kurapwa kwekupfeka kune imwe nhanho. Kuumbwa uye chimiro chekuputira zvinodzoreka, uye zvine zvakanakira kuchena kwepamusoro, kusimba kwepamusoro, uye ukobvu hwakafanana. Zvinotonyanya kukosha, kuumbwa uye chimiro cheTaC coatings yakagadzirwa neCVD inogona kugadzirwa uye kudzorwa zviri nyore. Iyo inzira yakakura uye inoshandiswa zvakanyanya kugadzirira emhando yepamusoro TaC coatings.

Izvo zvakakosha zvinopesvedzera zvinhu zve process zvinosanganisira:

A. Gas flow rate (tantalum source, hydrocarbon gas as carbon source, carrier gas, dilution gas Ar2, kuderedza gasi H2): Shanduko yegasi inoyerera ine simba guru pane tembiricha, nzvimbo yekumanikidza, uye gasi kuyerera munzvimbo. iyo reaction chamber, zvichikonzera shanduko mukuumbwa, chimiro, uye kuita kwejasi. Kuwedzera chiyero chekuyerera kweAr kunodzikisa chiyero chekukura kwejasi uye kuderedza saizi yezviyo, nepo molar mass ratio yeTaCl5, H2, uye C3H6 inokanganisa kuumbwa kwekuputira. Iyo molar ratio yeH2 kusvika kuTaCl5 ndeye (15-20): 1, iyo inonyanya kukodzera. Huyero yemolar yeTaCl5 kusvika kuC3H6 inofungirwa pedyo ne3:1. Yakawandisa TaCl5 kana C3H6 inokonzeresa kuumbwa kweTa2C kana yemahara kabhoni, zvichikanganisa kunaka kwewafer.

B. Deposition tembiricha: Kukwirira tembiricha yekuisa, ndiko kukurumidza kweyero yekuisa, kukura saizi yezviyo, uye kushatisa kwacho. Pamusoro pezvo, tembiricha nekumhanya kwekuora kwehydrocarbon kuita C uye TaCl5 kuora kuita Ta kwakasiyana, uye Ta neC zvinowanzoita Ta2C. Tembiricha ine simba guru paTaC coating yakagadziridzwa kabhoni zvinhu. Sezvo tembiricha yekuisa ichiwedzera, mwero wekuisa unowedzera, saizi yechikamu inowedzera, uye chimiro chechidimbu chinoshanduka kubva kudenderedzwa kuenda ku polyhedral. Uye zvakare, iyo yakakwira tembiricha yekuisa, iyo inokurumidza kuparara kweTaCl5, iyo shoma yemahara C ichave, iyo yakanyanya kushushikana mujasi, uye kuputika kuchagadzirwa nyore. Nekudaro, yakaderera deposition tembiricha inotungamira kune yakaderera coating deposition kunyatsoita, kurebesa nguva yekuisa, uye yakakwira mari yezvinhu.

C. Deposition pressure: Deposition pressure yakanyatsoenderana nekusununguka kwesimba remvura uye ichakanganisa nguva yekugara gasi muimba yekupindura, zvichiita kuti iite nucleation speed uye particle size yekuvhara. Sezvo kumanikidza kwekuisa kunowedzera, nguva yekugara gasi inova yakareba, mareactants ane nguva yakawanda yekupinda nucleation reactions, iyo reaction rate inowedzera, zvimedu zvinova zvakakura, uye kupfeka kunowedzera kukora; Ukuwo, sezvo deposition pressure inodzikira, kuita gasi rekugara nguva ipfupi, chiyero chekuita chinodzikira, zvimedu zvinova zvidiki, uye kupfeka kuri kutetepa, asi deposition pressure haina mhedzisiro pachimiro chekristaro uye kuumbwa kwejasi.

V. Kuvandudza maitiro e tantalum carbide coating

Thermal yekuwedzera coefficient yeTaC (6.6 × 10−6K-1) yakati siyanei neiyo ye carbon-based materials senge graphite, carbon fiber, uye C/C composite zvinhu, izvo zvinoita kuti single-phase TaC coatings ive nyore kuputika uye. kudonha. Kuti uwedzere kuvandudza iyo ablation uye oxidation kuramba, yakakwirira-tembiricha kugadzikana, uye yakakwirira-tembiricha kemikari corrosion resistance yeTaC coatings, vaongorori vakaita tsvakiridzo pamasisitimu ekupfekedza akadai seanosanganisa coating system, yakasimba mhinduro-inosimudzira coating masisitimu, uye gradient. Coating systems.

Iyo composite coating system ndeyekuvhara kutsemuka kwejira rimwe chete. Kazhinji, mamwe machira anounzwa mukati kana mukati mechikamu cheTaC kuti iite composite coating system; iyo yakasimba mhinduro inosimbisa coating system HfC, ZrC, nezvimwewo vane yakafanana face-centered cubic structure seTaC, uye macarbides maviri anogona kunyungudika zvisingaite mukati memumwe nemumwe kuita chigadziko chakasimba chekugadzirisa. Iyo Hf (Ta) C yekupotera haina kuputika uye ine yakanaka kunamatira kune C / C inoumbwa zvinhu. Iyo yekupfeka ine yakanakisa anti-ablation performance; iyo gradient coating system gradient coating inoreva iyo coating component inotevedza ukobvu hwayo. Chimiro chinogona kuderedza kushushikana kwemukati, kuvandudza kusawirirana kwemafuta ekuwedzera coefficients, uye kudzivirira kutsemuka.

(II) Tantalum carbide coating mudziyo zvigadzirwa

Zvinoenderana nehuwandu uye kufungidzira kweQYR (Hengzhou Bozhi), iyo yepasirese tantalum carbide coating musika kutengesa muna 2021 yakasvika US $ 1.5986 miriyoni (kunze kwekuzvigadzira kweCree kuzvigadzira uye kuzvipa tantalum carbide coating mudziyo zvigadzirwa), uye ichiri kutanga. matanho ekusimudzira maindasitiri.

1. Mhete dzekuwedzera dzekristaro uye macrucibles anodiwa pakukura kwekristaro: Kubva pa200 crystal growth furnaces per bhizinesi, chikamu chemusika cheTaC coated devices chinodiwa nemakambani makumi matatu ekukura kwekristaro inenge mabhiriyoni 4.7 yuan.

2. Matireyi eTaC: Tray imwe neimwe inogona kutakura mawafer matatu, tireyi imwe neimwe inogona kushandiswa kwemwedzi mumwe, uye tireyi imwe inopedzwa pamapfumbu zana ega ega. 3 miriyoni mawafer anoda 30,000 matireyi eTaC, tireyi yega yega ingangoita 20,000 zvidimbu, uye anoda kusvika 600 miriyoni gore rega rega.

3. Zvimwe zviitiko zvekuderedza kabhoni. Zvakadai seyepamusoro-tembiricha yevira, CVD nozzle, mapaipi echoto, nezvimwe, angangoita zana remamiriyoni.

Nguva yekutumira: Jul-02-2024