2. Kuedza Maitiro

2.1 Kurapa kweAdhesive Firimu

Zvakaonekwa kuti zvakananga kugadzira kabhoni firimu kana kusungirirana negraphite bepa paSiC wafersyakavharwa neadhesive inotungamira kune akati wandei nyaya:

1. Pasi pemamiriro ekutsvaira, iyo inonamatira firimu paSiC wafersyakagadzira chitarisiko chakafanana nekuda kwekuburitswa kwemhepo kwakakosha, zvichikonzera porosity yepasi. Izvi zvakadzivirira mitsara yekunamatira kubva pakubatana zvakanaka mushure mecarbonization.

2. Panguva yekubatana, iyowaferinofanira kuiswa papepa regraphite munguva imwe chete. Kana repositioning ikaitika, kusaenzana kudzvanywa kunogona kuderedza kunamira kwakafanana, zvichikanganisa kunaka kwekubatana.

3. Mukushanda kwevacuum, kusunungurwa kwemhepo kubva kune yakanamatira yakakonzera peeling uye kuumbwa kwevakawanda voids mukati memufirimu wekunamatira, zvichiita kuti pave nekukanganisa kwekubatanidza. Kuti ugadzirise nyaya idzi, pre-kuomesa adhesive panewafer'sbonding pamusoro uchishandisa ndiro inopisa mushure mekutenderera-kupfeka kunokurudzirwa.

2.2 Carbonization Maitiro

Maitiro ekugadzira kabhoni firimu paneSiC seed waferuye kuisunga kune graphite bepa kunoda carbonization yeadhesive layer pane chaiyo tembiricha kuti ive nechokwadi chekubatana kwakasimba. Isina kukwana carbonization yeadhesive layer inogona kutungamirira mukuora kwayo panguva yekukura, kusunungura tsvina inobata crystal kukura kwehutano. Naizvozvo, kuve nechokwadi kuti yakazara carbonization yeadhesive layer kwakakosha kune yakakwirira-density bonding. Ichi chidzidzo chinoongorora maitiro ekushisa pane adhesive carbonization. A yunifomu layer ye photoresist yakaiswa kune iyowaferpamusoro uye kuiswa muchoto chechubhu pasi pevacuum (<10 Pa). Tembiricha yakasimudzwa kusvika kumatanho ekutanga (400 ℃, 500 ℃, uye 600 ℃) uye yakachengetwa kwemaawa matatu-5 kuti iwane carbonization.

Miedzo yakaratidzwa:

Pa400 ℃, mushure memaawa matatu, firimu rekunamatira harina carbonize uye rakaonekwa rima rakatsvuka; hapana shanduko yakakosha yakaonekwa mushure memaawa mana.

Pa500 ℃, mushure memaawa matatu, firimu rakashanduka dema asi richiramba richiendesa chiedza; hapana shanduko yakakosha mushure memaawa mana.

Pa 600 ℃, mushure memaawa matatu, firimu rakaita dema risina kufambisa mwenje, zvichiratidza kuzara kwecarbonization.

Saka, tembiricha yakakodzera yekubatanidza inoda kuve ≥600℃.

2.3 Adhesive Application process

Kufanana kwefirimu rekunamatira chiratidzo chakakosha chekuongorora maitiro ekunamatira uye kuve nechokwadi cheyunifomu yekubatanidza. Ichi chikamu chinoongorora iyo yakakwana yekumhanyisa kumhanya uye yekuputira nguva yeakasiyana anonamira firimu ukobvu. Kufanana

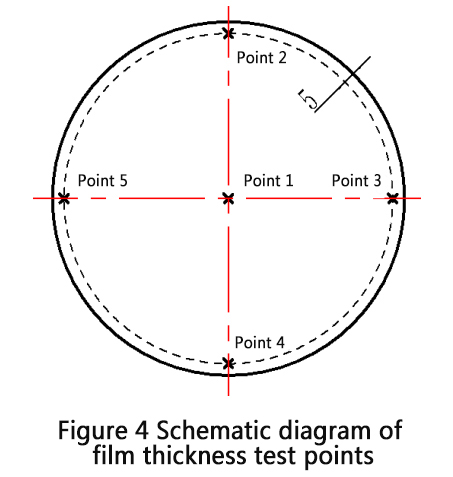

u yefirimu ukobvu inotsanangurwa sereshiyo yehushoma hwemufirimu ukobvu Lmin kusvika kuhupamhi hwefirimu ukobvu Lmax pamusoro penzvimbo inobatsira. Mapoinzi mashanu pachifukidzo akasarudzwa kuyera ukobvu hwefirimu, uye kufanana kwakaverengerwa. Mufananidzo 4 unoratidza zviyero zvekuyera.

Kune yakakwirira-density chisungo pakati peSiC wafer uye graphite zvikamu, yakasarudzika inonamira firimu ukobvu ndeye 1-5 µm. Firimu gobvu re2 µm rakasarudzwa, rinoshanda kune ese ari maviri kabhoni firimu kugadzirira uye wafer / graphite mapepa ekubatanidza maitiro. Iyo yakakwana spin-coating parameters ye carbonizing adhesive ndeye 15 s pa 2500 r/min, uye yekubatanidza inonamira, 15 s pa 2000 r/min.

2.4 Bonding Maitiro

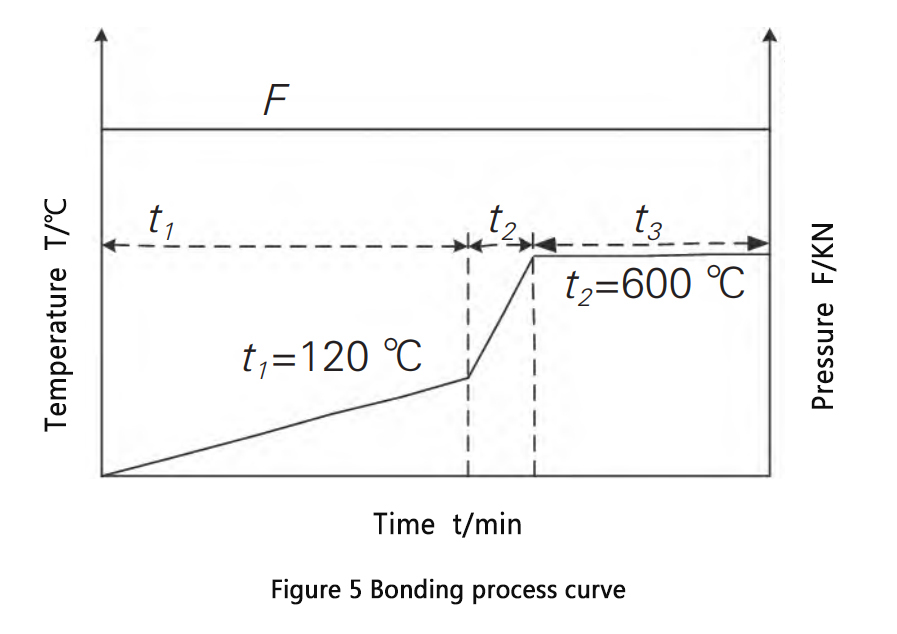

Munguva yekubatanidzwa kweSiC wafer kune graphite / graphite bepa, zvakakosha kubvisa zvachose mweya uye organic magasi anogadzirwa panguva yecarbonization kubva kune bonding layer. Kubviswa kwegasi kusina kukwana kunoguma nemavoids, zvichitungamira kune isina-dense bonding layer. Mhepo nemagasi egasi anogona kubviswa uchishandisa mechanical pombi yemafuta. Pakutanga, kuenderera mberi kwekushanda kwepombi yemagetsi inoita kuti kamuri yevacuum isvike painogumira, ichibvumira kubviswa kwemhepo yakakwana kubva pakusungirirwa. Kukurumidza kukwira kwekushisa kunogona kudzivirira kubviswa kwegasi panguva yekupisa-kupisa carbonization, kuumba voids muchikamu chekubatanidza. Adhesive zvimiro zvinoratidza kubuda kwakakosha pa ≤120 ℃, kudzikamisa pamusoro peiyi tembiricha.

Kudzvinyirirwa kwekunze kunoshandiswa panguva yekubatana kuti kuwedzere kuwanda kwefirimu yekunamatira, zvichiita kuti kudzingwa kwemhepo uye organic gasi, zvichiita kuti pave nepamusoro-density bonding layer.

Mukupfupisa, iyo yekubatanidza nzira curve inoratidzwa muFigure 5 yakagadzirwa. Pasi pekumanikidzwa kwakananga, tembiricha inosimudzwa kune yekubuda kunze tembiricha (~ 120 ℃) uye inobatwa kusvika kubuda kunze kwapera. Zvadaro, tembiricha inowedzerwa kune tembiricha yecarbonization, inochengeterwa kwenguva inodiwa, inoteverwa nekutonhora kwechisikigo kusvika kune tembiricha yekamuri, kusunungurwa kwekumanikidza, uye kubviswa kwechifukidzo chakasungwa.

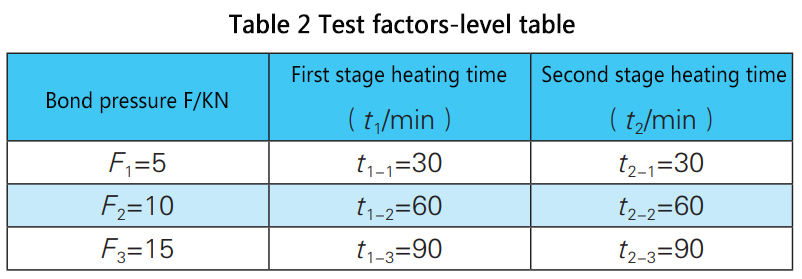

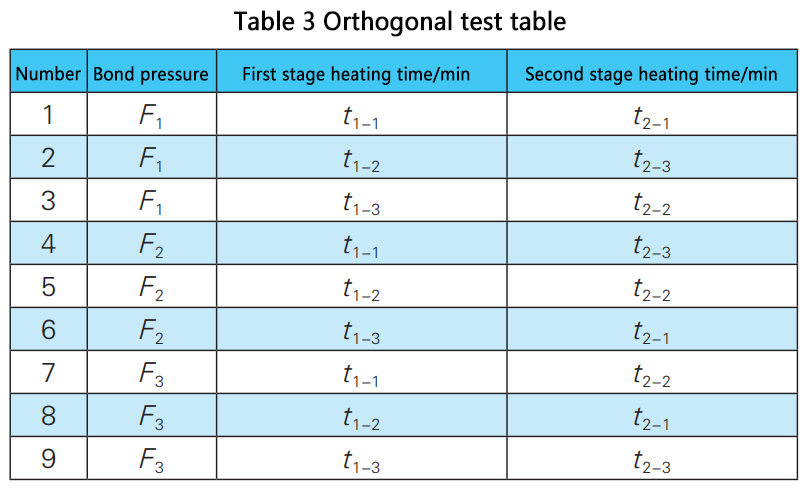

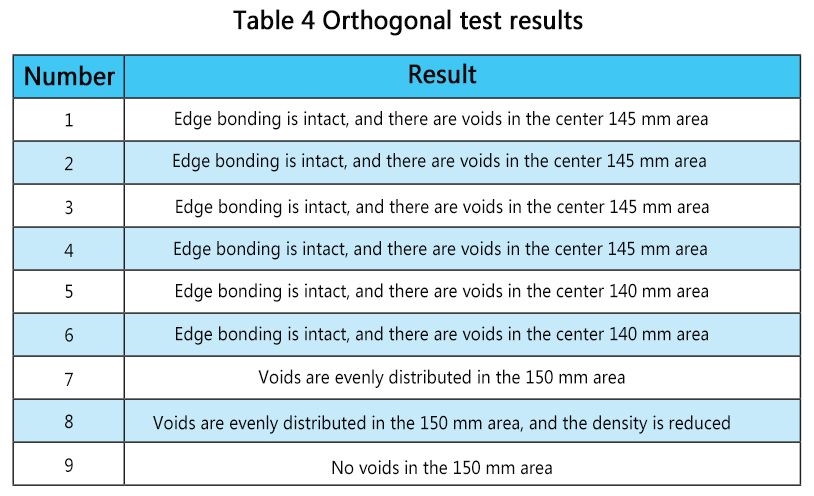

Zvinoenderana nechikamu 2.2, iyo inonamira firimu inoda kuvezwa kabhoni pa600 ℃ kweanopfuura maawa matatu. Naizvozvo, mukubatanidza curve, T2 yakaiswa ku600 ℃ uye t2 kusvika kumaawa matatu. Izvo zvakakosha zvakakosha zvehutano hwekubatanidza curve, yakatemwa kuburikidza ne orthogonal miedzo yekudzidza migumisiro yehutano hwekubatanidza, nhanho yekutanga yekupisa nguva t1, uye yechipiri-chikamu chekupisa nguva t2 pamigumisiro yekubatanidza, inoratidzwa muTables 2-4.

Mibairo yakaratidzwa:

Pakumanikidza kwekubatanidza kwe5 kN, nguva yekudziya yaive nemhedzisiro shoma pakubatana.

Pa10 kN, nzvimbo isina chinhu muchikamu chekubatanidza yakadzikira nekudziya kwekutanga kwekutanga.

Pa15 kN, kuwedzera kupisa-danho rekutanga zvakanyanya kuderedzwa voids, pakupedzisira kuvabvisa.

Yechipiri-nhanho yekudziya yenguva yekupisa pakubata haina kuoneka mune orthogonal bvunzo. Kugadzirisa kudzvanywa kwechisungo pa15 kN uye yekutanga-nhanho yekudziya nguva pa90 min, yechipiri-nhanho yekudziya nguva dze30, 60, uye 90 min zvese zvakakonzera isina-isina-yemahara dense bonding layer, zvichiratidza yechipiri-danho rekupisa nguva yaive. kukanganiswa kudiki pakubatana.

Hunhu hwakanyanya hweiyo bonding process curve ndeiyi: bonding pressure 15 kN, nhanho yekutanga kupisa nguva 90 min, yekutanga-nhanho tembiricha 120 ℃, yechipiri-nhanho yekupisa nguva 30 min, yechipiri-danho tembiricha 600 ℃, uye yechipiri-danho rekubata nguva. 3 maawa.

Nguva yekutumira: Jun-11-2024